Last updates on HEMA, Products, Partners, and Exhibitions

Last updates on HEMA, Products, Partners, and Exhibitions

Last updates on HEMA, Products, Partners, and Exhibitions

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

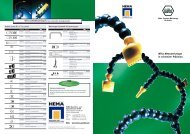

+++ <strong>HEMA</strong> at EMO Milan HALL 3, St<strong>and</strong> G05 +++ <strong>HEMA</strong> at EMO Milan HALL 3, St<strong>and</strong> G05 +++<br />

<str<strong>on</strong>g>Last</str<strong>on</strong>g> <str<strong>on</strong>g>updates</str<strong>on</strong>g> <strong>on</strong> <strong>HEMA</strong>, <strong>Products</strong>, <strong>Partners</strong>, <strong>and</strong> Exhibiti<strong>on</strong>s<br />

The <strong>HEMA</strong> catalogue for protective<br />

<strong>and</strong> inspecti<strong>on</strong> systems presents a<br />

modern layout for our new products<br />

In time for EMO - The World of Machine<br />

Tools <strong>HEMA</strong> presents its specialised<br />

catalogue for protective <strong>and</strong> inspecti<strong>on</strong><br />

systems.<br />

Catalogue 2009<br />

Besides its refreshingly modern layout<br />

<strong>and</strong> further improvements to user c<strong>on</strong>venience<br />

the catalogue presents a new<br />

extensive programme of chip c<strong>on</strong>veyors<br />

<strong>and</strong> power roller shutter systems. Also<br />

our comprehensive range of bellows has<br />

been exp<strong>and</strong>ed yet again with smart<br />

extensi<strong>on</strong>s.<br />

Roller with electric drive<br />

Editi<strong>on</strong> 2009<br />

SAMURAI Vector C², ready to install soluti<strong>on</strong><br />

Chip c<strong>on</strong>veyor<br />

In our PC glass range we present a new<br />

projectile proof screw-<strong>on</strong> soluti<strong>on</strong> for<br />

VISIPORT. The current catalogue is now<br />

ready for download from our website<br />

www.hema-schutz.de.<br />

You can also request this free of charge:<br />

either email us at info@hema-schutz.de,<br />

or collect your pers<strong>on</strong>al copy from our<br />

EMO st<strong>and</strong> G05 in Hall 3 at EMO in<br />

Milan. We look forward to some interesting<br />

talks with you over an espresso.<br />

<strong>HEMA</strong> Global - The Group is exp<strong>and</strong>ing<br />

its producti<strong>on</strong> <strong>and</strong> sales rooms<br />

at the Qingdao locati<strong>on</strong> in the<br />

People's Republic of China<br />

Following successful growth in recent<br />

years our Qingdao locati<strong>on</strong> had to<br />

exp<strong>and</strong> its producti<strong>on</strong> capacities <strong>and</strong><br />

services rooms.<br />

German Industry Park, Qingdao<br />

Within just twelve m<strong>on</strong>ths the <strong>HEMA</strong><br />

partner in China, Dr Zhengkang Zhao,<br />

had new buildings erected that need<br />

not shy away from internati<strong>on</strong>al<br />

comparis<strong>on</strong>.<br />

Steffen Walter, Dr. Zengkang Zhao<br />

Affiliated with the German Industry<br />

Park the company now presents its<br />

producti<strong>on</strong> <strong>and</strong> customer advice divisi<strong>on</strong>s<br />

distributed over a surface of<br />

15,000 square metres <strong>on</strong> four floors.<br />

Here <strong>HEMA</strong> Zhao is a key pillar <strong>and</strong><br />

utilises over 30% of the new area for<br />

catering to the Asian market with even<br />

greater efficiency.<br />

Today many of our customers see the<br />

ideal complement in the coordinated<br />

collaborati<strong>on</strong> between the <strong>on</strong>site <strong>HEMA</strong><br />

partner <strong>and</strong> their Asian subsidiaries.<br />

We shall be pleased to support your<br />

efforts in this growth regi<strong>on</strong>, which will<br />

be gaining even greater significance in<br />

future.<br />

Electric brake - presentati<strong>on</strong> at EMO<br />

in Milan<br />

<strong>HEMA</strong> clamping <strong>and</strong> braking systems<br />

are designed for precisi<strong>on</strong> applicati<strong>on</strong>s<br />

with strokes c<strong>on</strong>siderably less than <strong>on</strong>e<br />

millimetre.<br />

However there are many fields that<br />

cannot reliably fulfil these precisi<strong>on</strong><br />

requirements for the guides <strong>and</strong> c<strong>on</strong>tact<br />

surfaces.<br />

Our latest offer has been designed for<br />

just these fields, <strong>and</strong> we would like to

+++ <strong>HEMA</strong> at EMO Milan Hall 3, St<strong>and</strong> G05 +++ <strong>HEMA</strong> at EMO Milan Hall 3, St<strong>and</strong> G05 +++ <strong>HEMA</strong> at<br />

Electromagnetic disk brake SSB-1000<br />

present to you our SSB-1000 type in a<br />

little more detail as a universal operating/retaining/emergency<br />

brake for<br />

general machine building.<br />

The SSB-1000 is an extremely compact<br />

operating/retaining/emergency brake<br />

with very low energy c<strong>on</strong>sumpti<strong>on</strong>. Its<br />

floating bearing compensates for minor<br />

axial asymmetries in the brake disc.<br />

Electromagnetic disk brake SSB-1000<br />

The floating bearing for the whole brake<br />

compensates for minor runout errors in<br />

the brake disc <strong>and</strong> presents a full<br />

c<strong>on</strong>tact surface in c<strong>on</strong>juncti<strong>on</strong> with the<br />

parallel transfer of forces to the brake<br />

blocks. The linings therefore do not<br />

need to be ground in.<br />

The brake is available for three disc<br />

thicknesses (20, 25, 30 mm), in two<br />

flange designs, <strong>and</strong> for two braking<br />

torque ranges.<br />

Potential applicati<strong>on</strong>s are e.g. in producti<strong>on</strong><br />

lines with FTS interlinking to multiple<br />

machining centres.<br />

Here the comp<strong>on</strong>ents are c<strong>on</strong>veyed over<br />

rails from machine to machine with a<br />

mean tolerance of 1 to 5 mm. Our brake<br />

engages at the transfer stati<strong>on</strong> <strong>and</strong> is<br />

disengaged everywhere else.<br />

A new, innovative type of magnetic<br />

system reliably prevents overheating<br />

<strong>and</strong> minimises current c<strong>on</strong>sumpti<strong>on</strong><br />

(rated power 2 kVA in the breakaway<br />

phase; <strong>on</strong>ly 10 VA in the retaining<br />

phase).<br />

The system is designed for IP 65 classificati<strong>on</strong><br />

<strong>and</strong> can be operated with 230 V<br />

or 400 V.<br />

It applies a nominal retaining force of<br />

10 kN or braking torques up to 6.5 kNm,<br />

depending <strong>on</strong> the brake disc diameter.<br />

At <strong>on</strong>ly 25 kg the comp<strong>on</strong>ent presents<br />

an excellent power to mass ratio. We<br />

can also provide an opti<strong>on</strong>al c<strong>on</strong>diti<strong>on</strong><br />

m<strong>on</strong>itor with up to two sensors, an electric<br />

wear limit indicator, <strong>and</strong> special<br />

designs with sintered linings.<br />

The product can also be used in cranes,<br />

as a chassis brake e.g. in c<strong>on</strong>veyor<br />

systems <strong>and</strong> mining plant, <strong>and</strong> in<br />

envir<strong>on</strong>ments with high temperatures.<br />

NEW - LinClamp can now clamp <strong>and</strong><br />

brake in bends as well<br />

In a number of machines traverses take<br />

place not <strong>on</strong>ly al<strong>on</strong>g straight lines, but<br />

also over gently curving rails.<br />

LinClamp for linear curved guides<br />

Roof cover<br />

LinClamp S, size 100 (new)<br />

Accordingly the market offers roller<br />

guides <strong>and</strong> linear curved guides.<br />

These elements facilitate high precisi<strong>on</strong><br />

guiding that cannot be obtained with<br />

the c<strong>on</strong>venti<strong>on</strong>al combinati<strong>on</strong>s of rotary<br />

<strong>and</strong> linear traverses.<br />

The LinClamp S Series provides the<br />

ideal clamping or braking element for<br />

these applicati<strong>on</strong>s. Its adaptable clamping<br />

jaw geometry provides a reliable,<br />

fully functi<strong>on</strong>al soluti<strong>on</strong> for practical<br />

applicati<strong>on</strong>s.<br />

The <strong>HEMA</strong> complete roof cover<br />

system allows degrees of freedom <strong>on</strong><br />

oversized portal machining centre<br />

Portal milling machines are masters of<br />

versatility. Owing to the gantry design<br />

the moved masses are very small, so<br />

above all large workpieces can be<br />

machined efficiently.<br />

Five side, five axis machining can generate<br />

even complex shapes out of the<br />

material in a short time.

EMO Milan Hall 3, St<strong>and</strong> G05 +++ <strong>HEMA</strong> at EMO Milan Hall 3, St<strong>and</strong> G05 +++<br />

The structure minimises vibrati<strong>on</strong>s for<br />

high dimensi<strong>on</strong>al accuracy, surface<br />

quality, <strong>and</strong> maximised cutting efficiency.<br />

When designing <strong>and</strong> adapting each<br />

working chamber in the portal milling<br />

machine there are virtually no limits to<br />

the imaginati<strong>on</strong>.<br />

<strong>HEMA</strong> cover systems installed at<br />

various positi<strong>on</strong>s al<strong>on</strong>g the x, y, or z axis<br />

or as a complete roof cover allow<br />

various c<strong>on</strong>cepts for the clamping table,<br />

integrated partiti<strong>on</strong>s, a t<strong>and</strong>em or duo<br />

design, <strong>and</strong> various pallet changers.<br />

CoverShutter<br />

Our soluti<strong>on</strong>s with integrated rail guides<br />

<strong>and</strong> pneumatic closing elements enhance<br />

the workpiece loading flexibility<br />

<strong>and</strong> at the same time provide reliable<br />

machining protecti<strong>on</strong> for the work<br />

chamber <strong>and</strong> the operator's work room.<br />

VISIPORT - projectile proof screw<br />

uni<strong>on</strong>s - IWF tested soluti<strong>on</strong> now<br />

available<br />

Modern machining centres should be<br />

allrounders. However with this combinati<strong>on</strong><br />

of milling <strong>and</strong> turning also<br />

manufacturers assigned traditi<strong>on</strong>ally to<br />

the pure milling sectors have to adapt<br />

their safety c<strong>on</strong>cepts to the turning<br />

machine st<strong>and</strong>ard DIN EN 12415.<br />

These machining centres must therefore<br />

be inevitably fitted with glass / polycarb<strong>on</strong>ate<br />

safety windows with verified<br />

retenti<strong>on</strong> properties in the corresp<strong>on</strong>ding<br />

safety classes, in most cases<br />

B2/B3 or C2/C3.<br />

An additi<strong>on</strong>al problem here affects how<br />

the inspecti<strong>on</strong> windows are integrated.<br />

HLVB <strong>HEMA</strong> Linear vertical brake<br />

VISIPORT can be attached with an<br />

adhesive <strong>and</strong> so presents a possible<br />

soluti<strong>on</strong>.<br />

Nevertheless some customers still want<br />

to use their spanners. When the<br />

VISIPORT is screwed through the<br />

glass/PC composite a projectile impacting<br />

the window will loosen the<br />

screws, <strong>and</strong> there is an incalculable risk<br />

for the operator.<br />

VISIPORT - integrated mounting plate<br />

On the strength of projectile tests<br />

c<strong>on</strong>ducted at the Berlin IWF Institute for<br />

all safety classes from A1 to C3 for<br />

inspecti<strong>on</strong> windows <strong>HEMA</strong> has verified<br />

the safety of the <strong>HEMA</strong> VISIPORT screw<br />

uni<strong>on</strong> system.<br />

Customers can now utilise this soluti<strong>on</strong><br />

with an untroubled c<strong>on</strong>science.<br />

Editi<strong>on</strong> 2009<br />

HLVB <strong>HEMA</strong> linear vertical brake<br />

for the purely mechanical retenti<strong>on</strong><br />

of loads<br />

<strong>HEMA</strong> sees itself as a partner for<br />

customised soluti<strong>on</strong>s.<br />

A major German machine tool builder<br />

approached us with the assignment to<br />

fit an additi<strong>on</strong>al locking system to the<br />

machine housing's sliding door that<br />

opened upwards.<br />

HLVB layout drawing<br />

The vertical, h<strong>and</strong> operated sliding door<br />

needs a counterbalance.<br />

As a result it can be opened <strong>and</strong> closed<br />

with the minimum of effort <strong>and</strong> remains<br />

at any positi<strong>on</strong> without falling closed.

+++ <strong>HEMA</strong> at EMO Milan Hall 3, St<strong>and</strong> G05 +++ <strong>HEMA</strong> at EMO Milan Hall 3 +++<br />

What happens when the c<strong>on</strong>necti<strong>on</strong> to<br />

the counterbalance fails?<br />

The sliding door must then be retained<br />

with an additi<strong>on</strong>al system if there is to<br />

be no danger to the operator. However<br />

the clamping force should take effect<br />

<strong>on</strong>ly when the counterbalance fails, i.e.<br />

in »normal mode« this force must be<br />

balanced out with some kind of system.<br />

This balancing out is ideally the force<br />

exerted by the counterbalance itself,<br />

which is made possible with a suitable<br />

release mechanism.<br />

The <strong>HEMA</strong> HLVB design provides<br />

particular advantages. The release<br />

mechanism is activated by the counterbalance.<br />

In other words the clamping<br />

element is integrated directly in the flux<br />

of forces, <strong>and</strong> as so<strong>on</strong> as this is disrupted<br />

at any point the element is activated<br />

immediately. Owing to the element's<br />

optimal installed positi<strong>on</strong> the braked<br />

mass provides an additi<strong>on</strong>al boost to the<br />

retaining force.<br />

In this project the braking distance was<br />

verified to be less than 5 mm <strong>on</strong> the test<br />

rig. There has been some thought about<br />

an expansi<strong>on</strong> with a pneumatic or<br />

electromagnetic release.<br />

DiskClamp for hydraulic braking in<br />

excess of 12,000 Nm<br />

Our new <strong>and</strong> most powerful DiskClamp<br />

to date does not of course represent the<br />

series st<strong>and</strong>ard. However the team of<br />

developers headed by Edmund Likus<br />

has delivered yet another milest<strong>on</strong>e in<br />

the form of the DSC 670.<br />

DiskClamp DSC 670, inner diameter 670 mm<br />

At a swivel table manufactured by an<br />

Italian series machine producer the<br />

DSC 670 operates at 50 bar to exert a<br />

braking torque of 12,000 Nm over thirty<br />

six pist<strong>on</strong>s <strong>on</strong> its disc.<br />

DiskClamp DSC 670<br />

The internal diameter is 670 mm. In<br />

collaborati<strong>on</strong> with the customer the<br />

system was developed ready for use in<br />

the record time of three m<strong>on</strong>ths. Our<br />

next DiskClamp project will deal with<br />

the subject of emergency braking <strong>on</strong><br />

high speed spindles.<br />

We shall be pleased to support you in<br />

your requests <strong>and</strong> actual project ideas.<br />

PClamp E now at an even lower<br />

price<br />

This entry level product for low cost bar<br />

<strong>and</strong> cylinder clamping is now available<br />

at an even lower price! Thanks to optimised<br />

comp<strong>on</strong>ents we can now offer a<br />

15% or 25% discount <strong>on</strong> this product.<br />

The compact E model can do almost<br />

everything the N types can.<br />

PClamp E<br />

The compact versi<strong>on</strong> for lower retaining<br />

forces, the PClamp E is characterised by<br />

a smaller installati<strong>on</strong> height <strong>and</strong> is<br />

therefore ideal for applicati<strong>on</strong>s in<br />

c<strong>on</strong>stricted spaces or operating areas<br />

requiring low retaining forces.<br />

Initiators cannot be used here. Although<br />

the clamping unit's exterior differs from<br />

the N, X, <strong>and</strong> ISO versi<strong>on</strong>s, the operating<br />

principle is identical.<br />

Imprint:<br />

<strong>HEMA</strong> Maschinen- und<br />

Apparateschutz GmbH<br />

Seligenstädter Straße 82<br />

63500 Seligenstadt, Germany<br />

Ph<strong>on</strong>e: +49 (0) 6182/773-0<br />

Fax: +49 (0) 6182/773-35<br />

E-Mail: info@hema-schutz.de<br />

Web: www.hema-schutz.de<br />

Editi<strong>on</strong> 2009<br />

VECTOR C² OUTSIDE - optimally<br />

closing lamellas, also in corners<br />

EMO news - Japan's number <strong>on</strong>e<br />

machine tool maker puts its trust in its<br />

latest HSC machining centre after<br />

exhaustive endurance tests <strong>on</strong> the<br />

<strong>HEMA</strong> cover variant VECTOR C²<br />

Outside.<br />

The VECTOR C² features as a chip protector<br />

two overlapping edged plates<br />

secured to each fold.<br />

This corner lamella soluti<strong>on</strong> <strong>on</strong> three<br />

sides is highly aesthetic <strong>and</strong> reliable.<br />

The stable design, also travelling at<br />

speeds in excess of 100 m/min, shows in<br />

this example the structural flexibility at<br />

the inside angles, outside angles, <strong>and</strong> in<br />

combinati<strong>on</strong> with several coupled<br />

angles.<br />

Detail of SAMURAI Vector<br />

The special <strong>HEMA</strong> design of the two<br />

lamellas in the corner provides excellent<br />

sealing <strong>and</strong> stripping properties.<br />

One feature that particularly c<strong>on</strong>vinced<br />

<strong>HEMA</strong> customers was the lamellas'<br />

c<strong>on</strong>tact pressure.<br />

Endurance tests verified the reliability<br />

of the VECTOR C² under the most<br />

gruelling c<strong>on</strong>diti<strong>on</strong>s, <strong>and</strong> new projects<br />

can be tested under field c<strong>on</strong>diti<strong>on</strong>s<br />

before kickoff.