You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

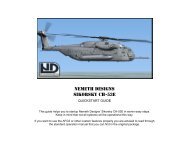

Let’s have a look at the progress. Looking<br />

nice. Next time we’ll work on the end bents.<br />

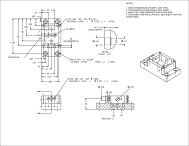

Next get the bent posts and bottom beam cut<br />

and drilled for 3/16” dowels. Measure the<br />

lengths of the bents from the actual project,<br />

not the plan. By now errors have crept in and<br />

the plan is only guidance. That’s about it for<br />

fabrication of the bents. The rest of the bents<br />

go together during final assembly.<br />

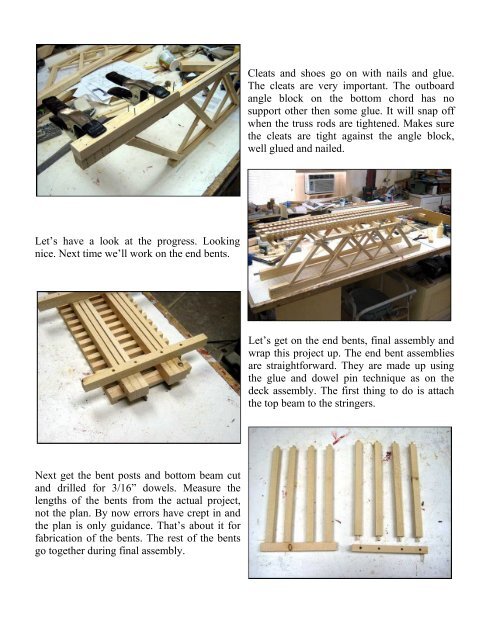

Cleats and shoes go on with nails and glue.<br />

The cleats are very important. The outboard<br />

angle block on the bottom chord has no<br />

support other then some glue. It will snap off<br />

when the truss rods are tightened. Makes sure<br />

the cleats are tight against the angle block,<br />

well glued and nailed.<br />

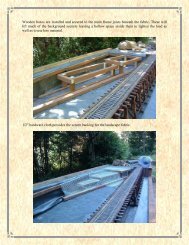

Let’s get on the end bents, final assembly and<br />

wrap this project up. The end bent assemblies<br />

are straightforward. They are made up using<br />

the glue and dowel pin technique as on the<br />

deck assembly. The first thing to do is attach<br />

the top beam to the stringers.