You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

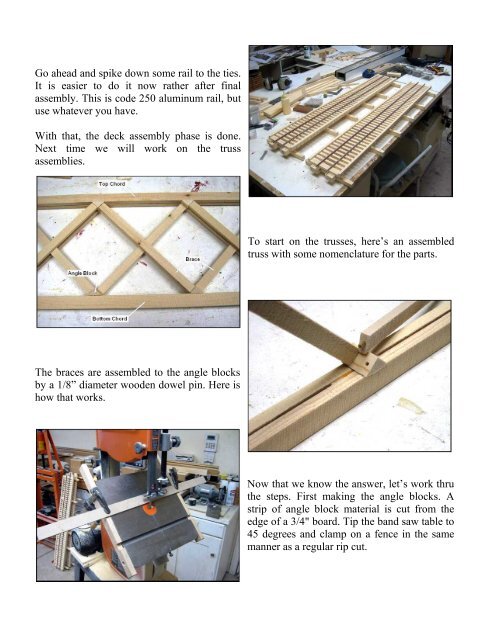

Go ahead and spike down some rail to the ties.<br />

It is easier to do it now rather after final<br />

assembly. This is code 250 aluminum rail, but<br />

use whatever you have.<br />

With that, the deck assembly phase is done.<br />

Next time we will work on the truss<br />

assemblies.<br />

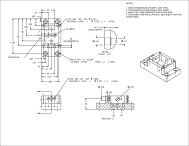

The braces are assembled to the angle blocks<br />

by a 1/8” diameter wooden dowel pin. Here is<br />

how that works.<br />

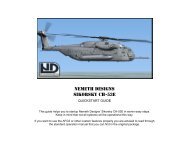

To start on the trusses, here’s an assembled<br />

truss with some nomenclature for the parts.<br />

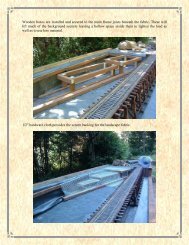

Now that we know the answer, let’s work thru<br />

the steps. First making the angle blocks. A<br />

strip of angle block material is cut from the<br />

edge of a 3/4" board. Tip the band saw table to<br />

45 degrees and clamp on a fence in the same<br />

manner as a regular rip cut.