A comparative discrete-dislocation/nonlocal crystal-plasticity

A comparative discrete-dislocation/nonlocal crystal-plasticity

A comparative discrete-dislocation/nonlocal crystal-plasticity

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

typeset2:/sco3/jobs1/ELSEVIER/msa/week.17/Pmsa15088y.001 Wed May 16 07:53:37 2001 Page Wed<br />

12<br />

D. Columbus, M. Grujicic / Materials Science and Engineering A000 (2001) 000–000<br />

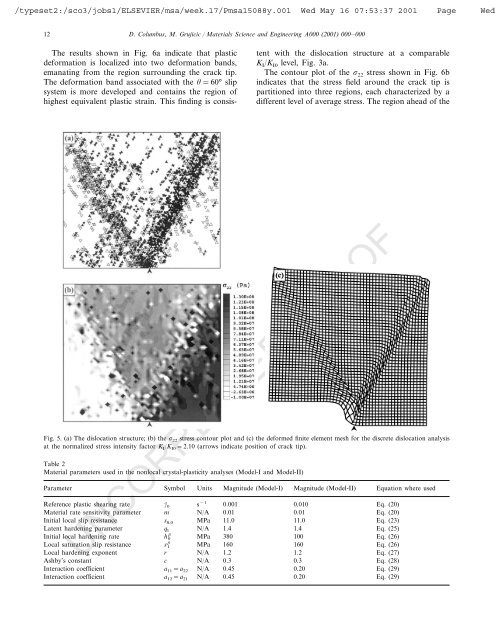

The results shown in Fig. 6a indicate that plastic<br />

deformation is localized into two deformation bands,<br />

emanating from the region surrounding the crack tip.<br />

The deformation band associated with the =60° slip<br />

system is more developed and contains the region of<br />

highest equivalent plastic strain. This finding is consis-<br />

tent with the <strong>dislocation</strong> structure at a comparable<br />

K I/K I0 level, Fig. 3a.<br />

The contour plot of the 22 stress shown in Fig. 6b<br />

indicates that the stress field around the crack tip is<br />

partitioned into three regions, each characterized by a<br />

different level of average stress. The region ahead of the<br />

Fig. 5. (a) The <strong>dislocation</strong> structure; (b) the 22 stress contour plot and (c) the deformed finite element mesh for the <strong>discrete</strong> <strong>dislocation</strong> analysis<br />

at the normalized stress intensity factor K I/K I0=2.10 (arrows indicate position of crack tip).<br />

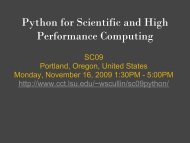

Table 2<br />

Material parameters used in the <strong>nonlocal</strong> <strong>crystal</strong>-<strong>plasticity</strong> analyses (Model-I and Model-II)<br />

Parameter<br />

Symbol Units Magnitude (Model-I) Magnitude (Model-II) Equation where used<br />

s 0.001<br />

0.010<br />

−1 Reference plastic shearing rate<br />

0<br />

Eq. (20)<br />

Material rate sensitivity parameter m N/A 0.01 0.01 Eq. (20)<br />

Initial local slip resistance sS,0 MPa 11.0<br />

11.0<br />

Eq. (23)<br />

Latent hardening parameter<br />

ql N/A 1.4 1.4<br />

Eq. (25)<br />

Initial local hardening rate h MPa 380<br />

100<br />

0<br />

Eq. (26)<br />

Local saturation slip resistance s MPa<br />

1 160 160 Eq. (26)<br />

Local hardening exponent r N/A 1.2<br />

1.2<br />

Eq. (27)<br />

Ashby’s constant c N/A 0.3 0.3 Eq. (28)<br />

Interaction coefficient a11=a 22 N/A 0.45<br />

0.20<br />

Eq. (29)<br />

Interaction coefficient<br />

a12=a 21 N/A 0.45 0.20 Eq. (29)<br />

UNCORRECTED PROOF