Power Electronics Technology

Power Electronics Technology

Power Electronics Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THERMALmanagement<br />

els the temperature increase<br />

becomes a factor in determining<br />

ampacity because the<br />

resistivity of the conductor<br />

changes with temperature.<br />

The relationship is linear, i.e.,<br />

resistivity increases proportional to the change in temperature<br />

at a rate determined by the temperature coefficient of<br />

the conductor:<br />

R T = R T0 × [(1 + (T - T 0 )] (1)<br />

Where:<br />

T = Temperature at which resistivity is measured<br />

T 0 = Reference temperature (ambient)<br />

= Linear temperature coefficient (copper = 0.004)<br />

R T = Resistivity at measurement temperature<br />

R T0 = Resistivity at reference temperature<br />

For a copper conductor, every 25°C increase in temperature<br />

means a drop of about 5% in maximum ampacity<br />

due to an increase in conductor resistivity, RT . Since<br />

this presents the probability of further power dissipation<br />

and temperature rise, MiB design practice must consider<br />

effective methods not only to control and reduce conductor<br />

resistivity, but also to provide low thermal resistance<br />

pathways for heat dissipation.<br />

In a printed circuit board, ampacity depends on a number<br />

of different factors:<br />

• Conductive + convective capability provided by spreading<br />

layers, ground layers, stack-up<br />

• Ratio of track width to thickness<br />

• Ambient temperature<br />

• Adjacent high current tracks<br />

• AC or DC current<br />

• Presence and frequency of partial crosssection<br />

shrinkage<br />

• Presence, number, and conductive<br />

cross-section of plated through holes in<br />

series with the conductor.<br />

Therefore effective design needs to<br />

consider more variables than are normally<br />

addressed by the IPC-2152 current vs.<br />

temperature charts.<br />

MIB<br />

“Metal in the Board” or “MiB” includes<br />

a number of approaches where MiB<br />

building blocks are combined to provide<br />

effective high-current solutions.<br />

The “DWPCB” (discrete wire PCB) type<br />

Fig. 1. Gullwing heat sink on TO-252<br />

power device.<br />

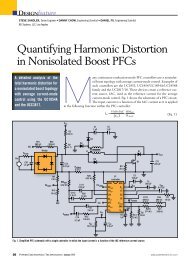

External Only<br />

Low heat spreading<br />

Low heat spreading<br />

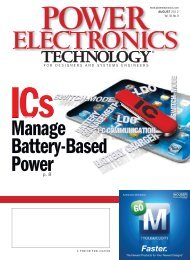

Wire Bonder<br />

Bonded Elements<br />

Etched Conductor<br />

Pattern<br />

Substrate Cross-Section<br />

Fig. 2. “Discrete Wire” process- bonding high current elements to inner layer.<br />

is one of the most versatile. One of the commercially<br />

available versions of DWPCB is HSMtec, developed by<br />

the Austrian PCB manufacturer Häusermann GmbH.<br />

HSMtec uses 0.5 mm diameter copper wire and rectangular<br />

sectioned 0.5 mm thick copper strips (“profiles”)<br />

to provide discrete low resistance electrical and thermal<br />

pathways in the board as shown in Fig. 2.<br />

There are a number of advantages to this solution compared<br />

to conventional thick copper or metal core boards:<br />

• Conventional PCB processes ensure consistently high<br />

reliability<br />

• Enhanced thermal and current pathways only where<br />

needed<br />

• Cost of MiB limited to those nets needing MiB<br />

• Wiring densities up to and including HDI enable logic<br />

and power integration<br />

• FR-4 materials reduce CTE mismatch common to aluminum<br />

based substrates<br />

• Board may be folded during assembly, providing photometric<br />

solutions for LED luminaires and eliminating<br />

daughter boards/connectors<br />

The profiles and wires that make up the MiB compo-<br />

Internal + External<br />

Heat spreading<br />

Heat spreading<br />

Fig. 3. Effect on heat spreading of thermal dissipation plane (source: Häusermann GmbH).<br />

8 <strong>Power</strong> <strong>Electronics</strong> <strong>Technology</strong> | June 2013 www.powerelectronics.com