You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8<br />

Squirrel-cage motors<br />

Accessories<br />

Modular technology, slide rails, foundation blocks,<br />

taper pins, couplings, encoder mounting<br />

Squirrel-cage motors<br />

Modular technology<br />

The components of the modular<br />

installation concept can be ordered<br />

as accessories. The<br />

brake is not permitted to be retrofitted<br />

due to its relevance for<br />

safety.<br />

Cables for rotary pulse encoders<br />

can be ordered according<br />

to Catalogue DA 65.11.<br />

Slide rails with fixing bolts<br />

and tensioning screws to<br />

DIN 42 923<br />

Slide rails are an easy and convenient<br />

means of adjusting the<br />

belt tension of a machine in the<br />

absence of an idler pulley. They<br />

are secured to the foundation<br />

with rag bolts or foundation<br />

blocks.<br />

The assignment of slide rails to<br />

motor frame sizes is stated in<br />

DIN 42 923.<br />

No standard slide rails are available<br />

for motors of frame sizes<br />

355 to 450 (please inquire).<br />

Sources:<br />

Lütgert & Co. GmbH<br />

PO Box 42 51<br />

D-33276 Güthersloh<br />

Tel. +49 52 41-74 07-0<br />

Fax +49 52 41-74 07-90<br />

http://www.luetgert-antriebe.de<br />

e-mail:<br />

luetgert-antriebe@t-online.de<br />

1) The separately driven fan<br />

2CW2 . . . includes a fan unit with<br />

fan impeller, the separately driven<br />

8/2<br />

Siemens M 11 · 2003/2004<br />

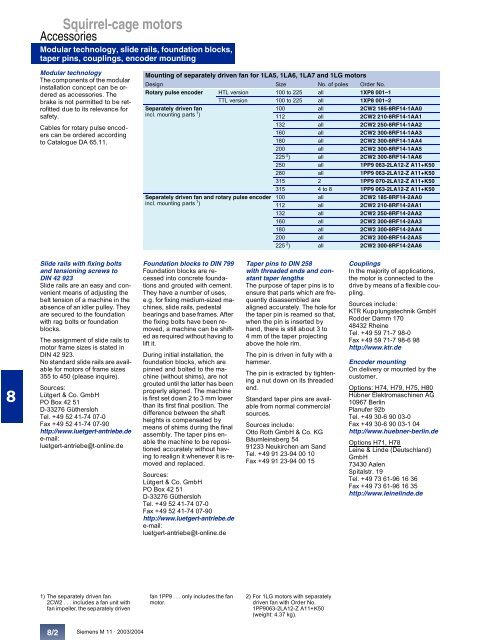

Mounting of separately driven fan for 1LA5, 1LA6, 1LA7 and 1LG motors<br />

Design Size No. of poles Order No.<br />

Rotary pulse encoder HTL version 100 to 225 all 1XP8 001–1<br />

TTL version 100 to 225 all 1XP8 001–2<br />

Separately driven fan<br />

incl. mounting parts 1 )<br />

Separately driven fan and rotary pulse encoder<br />

incl. mounting parts 1 )<br />

Foundation blocks to DIN 799<br />

Foundation blocks are recessed<br />

into concrete foundations<br />

and grouted with cement.<br />

They have a number of uses,<br />

e.g. for fixing medium-sized machines,<br />

slide rails, pedestal<br />

bearings and base frames. After<br />

the fixing bolts have been removed,<br />

a machine can be shifted<br />

as required without having to<br />

lift it.<br />

During initial installation, the<br />

foundation blocks, which are<br />

pinned and bolted to the machine<br />

(without shims), are not<br />

grouted until the latter has been<br />

properly aligned. The machine<br />

is first set down 2 to 3 mm <strong>low</strong>er<br />

than its first final position. The<br />

difference between the shaft<br />

heights is compensated by<br />

means of shims during the final<br />

assembly. The taper pins enable<br />

the machine to be repositioned<br />

accurately without having<br />

to realign it whenever it is removed<br />

and replaced.<br />

Sources:<br />

Lütgert & Co. GmbH<br />

PO Box 42 51<br />

D-33276 Güthersloh<br />

Tel. +49 52 41-74 07-0<br />

Fax +49 52 41-74 07-90<br />

http://www.luetgert-antriebe.de<br />

e-mail:<br />

luetgert-antriebe@t-online.de<br />

fan 1PP9 . . . only includes the fan<br />

motor.<br />

100 all 2CW2 185-8RF14-1AA0<br />

112 all 2CW2 210-8RF14-1AA1<br />

132 all 2CW2 250-8RF14-1AA2<br />

160 all 2CW2 300-8RF14-1AA3<br />

180 all 2CW2 300-8RF14-1AA4<br />

200 all 2CW2 300-8RF14-1AA5<br />

225 2 ) all 2CW2 300-8RF14-1AA6<br />

250 all 1PP9 063-2LA12-Z A11+K50<br />

280 all 1PP9 063-2LA12-Z A11+K50<br />

315 2 1PP9 070-2LA12-Z A11+K50<br />

315 4 to 8 1PP9 063-2LA12-Z A11+K50<br />

100 all 2CW2 185-8RF14-2AA0<br />

112 all 2CW2 210-8RF14-2AA1<br />

132 all 2CW2 250-8RF14-2AA2<br />

160 all 2CW2 300-8RF14-2AA3<br />

180 all 2CW2 300-8RF14-2AA4<br />

200 all 2CW2 300-8RF14-2AA5<br />

225 2 ) all 2CW2 300-8RF14-2AA6<br />

Taper pins to DIN 258<br />

with threaded ends and constant<br />

taper lengths<br />

The purpose of taper pins is to<br />

ensure that parts which are frequently<br />

disassembled are<br />

aligned accurately. The hole for<br />

the taper pin is reamed so that,<br />

when the pin is inserted by<br />

hand, there is still about 3 to<br />

4 mm of the taper projecting<br />

above the hole rim.<br />

The pin is driven in fully with a<br />

hammer.<br />

The pin is extracted by tightening<br />

a nut down on its threaded<br />

end.<br />

Standard taper pins are available<br />

from normal commercial<br />

sources.<br />

Sources include:<br />

Otto Roth GmbH & Co. KG<br />

Bäumleinsberg 54<br />

91233 Neukirchen am Sand<br />

Tel. +49 91 23-94 00 10<br />

Fax +49 91 23-94 00 15<br />

2) For 1LG motors with separately<br />

driven fan with Order No.<br />

1PP9063-2LA12-Z A11+K50<br />

(weight: 4.37 kg).<br />

Couplings<br />

In the majority of applications,<br />

the motor is connected to the<br />

drive by means of a flexible coupling.<br />

Sources include:<br />

KTR Kupplungstechnik GmbH<br />

Rodder Damm 170<br />

48432 Rheine<br />

Tel. +49 59 71-7 98-0<br />

Fax +49 59 71-7 98-6 98<br />

http://www.ktr.de<br />

Encoder mounting<br />

On delivery or mounted by the<br />

customer.<br />

Options: H74, H79, H75, H80<br />

Hübner Elektromaschinen AG<br />

10967 Berlin<br />

Planufer 92b<br />

Tel. +49 30-6 90 03-0<br />

Fax +49 30-6 90 03-1 04<br />

http://www.huebner-berlin.de<br />

Options H71, H78<br />

Leine & Linde (Deutschland)<br />

GmbH<br />

73430 Aalen<br />

Spitalstr. 19<br />

Tel. +49 73 61-96 16 36<br />

Fax +49 73 61-96 16 35<br />

http://www.leinelinde.de