You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2<br />

Squirrel-cage motors<br />

Technical information<br />

Modular technology<br />

■ Brakes (continued)<br />

The brake can also be supplied<br />

for other <strong>voltage</strong>s.<br />

Brake connection <strong>voltage</strong>:<br />

24 V DC Order Code C00<br />

2x 400 V AC Order Code C01<br />

Order Codes C00 and C01 must<br />

only be used in conjunction with<br />

Order Code G26.<br />

Rating plate<br />

The motors have a second rating<br />

plate with the brake data on<br />

the opposite side of the motor.<br />

Connection<br />

The motors are fitted with an additional<br />

terminal box next to the<br />

main terminal box which is used<br />

for the brake connection.<br />

KFB brakes are equipped with a<br />

standard rectifier bridge or halfway<br />

rectifier. Special connections<br />

are not required. Optimal<br />

operating times are achieved<br />

without special circuitry.<br />

Mechanical manual release<br />

The brakes can be released<br />

manually with screws as standard.<br />

The brakes can be supplied<br />

with a mechanical manual<br />

release using an actuator lever.<br />

Order Code K82.<br />

2/54<br />

Siemens M 11 · 2003/2004<br />

Other characteristics of the KFB<br />

brake<br />

High IP65 degree of<br />

protection.<br />

Corrosion-resistant in seawater<br />

and in the tropics.<br />

This brake is a dynamic brake,<br />

not simply a holding brake.<br />

For this reason, there is less<br />

wear, especially in the case of<br />

emergency stops (commissioning).<br />

High wear reserves; repeated<br />

stepless air gap readjustment<br />

possible. This results in very<br />

long downtimes and <strong>low</strong> service<br />

and operating costs.<br />

The function and wear can be<br />

monitored with a microswitch<br />

and proximity switch. Microswitch<br />

on/off is standard<br />

for LG motors. Optionally an<br />

anti-condensation heating.<br />

Fully functional brake for enclosure<br />

acceptance test. Visual<br />

inspection of brake possible<br />

during operation.<br />

The brake (air gap) can be adjusted<br />

in the workshop, for example,<br />

and mounted to the<br />

motor without further adjustments.<br />

The working parts can be replaced<br />

without great outlay.<br />

After the housing has been<br />

opened (three screws), it is<br />

easy to replace the friction lining<br />

carrier. It is not necessary<br />

to disassemble the entire<br />

brake.<br />

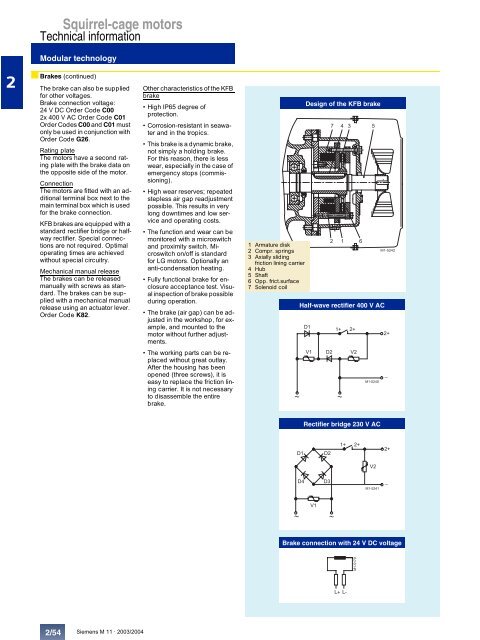

1 Armature disk<br />

2 Compr. springs<br />

3 Axially sliding<br />

friction lining carrier<br />

4 Hub<br />

5 Shaft<br />

6 Opp. frict.surface<br />

7 Solenoid coil<br />

Design of the KFB brake<br />

%<br />

" ! #<br />

Half-wave rectifier 400 V AC<br />

,<br />

8 , 8<br />

<br />

$<br />

# "<br />

Rectifier bridge 230 V AC<br />

, ,<br />

, "<br />

8<br />

, !<br />

<br />

<br />

# "<br />

# "<br />

Brake connection with 24 V DC <strong>voltage</strong><br />

L+ L-<br />

M1-5179<br />

8