Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2<br />

Squirrel-cage motors<br />

Technical information<br />

Mechanical design<br />

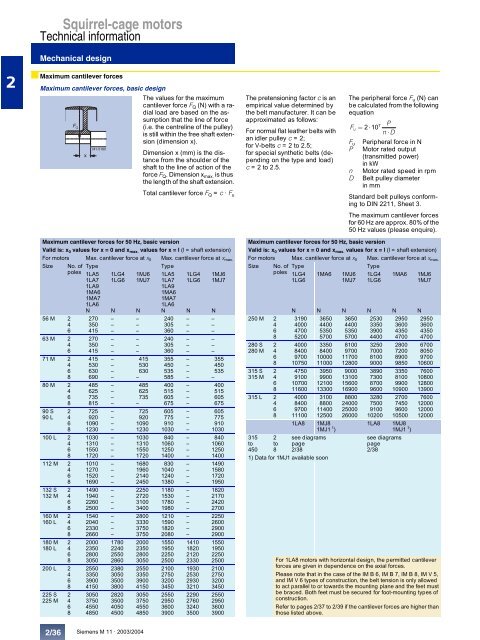

■ Maximum cantilever forces<br />

Maximum cantilever forces, basic design<br />

The values for the maximum<br />

cantilever force FQ (N) with a radial<br />

load are based on the assumption<br />

that the line of force<br />

FQ (i.e. the centreline of the pulley)<br />

is still within the free shaft extension<br />

(dimension x).<br />

x<br />

M1-5180<br />

Dimension x (mm) is the distance<br />

from the shoulder of the<br />

shaft to the line of action of the<br />

force FQ. Dimension xmax. is thus<br />

the length of the shaft extension.<br />

Total cantilever force FQ = c · Fu 2/36<br />

Siemens M 11 · 2003/2004<br />

The pretensioning factor c is an<br />

empirical value determined by<br />

the belt manufacturer. It can be<br />

approximated as fol<strong>low</strong>s:<br />

For normal flat leather belts with<br />

an idler pulley c = 2;<br />

for V-belts c = 2 to 2.5;<br />

for special synthetic belts (depending<br />

on the type and load)<br />

c = 2 to 2.5.<br />

The peripheral force Fu (N) can<br />

be calculated from the fol<strong>low</strong>ing<br />

equation<br />

7 P<br />

Fu<br />

2¸10 n¸D F u<br />

Peripheral force in N<br />

P Motor rated output<br />

(transmitted power)<br />

in kW<br />

n Motor rated speed in rpm<br />

D Belt pulley diameter<br />

in mm<br />

Standard belt pulleys conforming<br />

to DIN 2211, Sheet 3.<br />

The maximum cantilever forces<br />

for 60 Hz are approx. 80% of the<br />

50 Hz values (please enquire).<br />

Maximum cantilever forces for 50 Hz, basic version<br />

Maximum cantilever forces for 50 Hz, basic version<br />

Valid is: x0 values for x = 0 and xmax. values for x = l (l = shaft extension) Valid is: x0 values for x = 0 and xmax. values for x = l (l = shaft extension)<br />

For motors Max. cantilever force at x0 Max. cantilever force at xmax. For motors Max. cantilever force at x0 Max. cantilever force at xmax. Size No. of Type Type<br />

Size No. of Type Type<br />

poles 1LA5 1LG4 1MJ6 1LA5 1LG4 1MJ6<br />

poles 1LG4 1MA6 1MJ6 1LG4 1MA6 1MJ6<br />

1LA7 1LG6 1MJ7 1LA7 1LG6 1MJ7<br />

1LG6<br />

1MJ7 1LG6<br />

1MJ7<br />

1LA9<br />

1LA9<br />

1MA6<br />

1MA6<br />

1MA7<br />

1MA7<br />

1LA6<br />

1LA6<br />

N N N N N N<br />

N N N N N N<br />

56 M 2 270 – – 240 – –<br />

250 M 2 3190 3650 3650 2530 2950 2950<br />

4 350 – – 305 – –<br />

4 4000 4400 4400 3350 3600 3600<br />

6 415 – – 360 – –<br />

6 4700 5350 5350 3900 4350 4350<br />

63 M 2 270 – – 240 – –<br />

8 5200 5700 5700 4400 4700 4700<br />

4 350 – – 305 – –<br />

280 S 2 4000 3350 8100 3250 2800 6700<br />

6 415 – – 360 – –<br />

280 M 4 8400 8400 9700 7000 7200 8050<br />

71 M 2<br />

4<br />

415<br />

530<br />

–<br />

–<br />

415<br />

530<br />

355<br />

450<br />

–<br />

–<br />

355<br />

450<br />

6<br />

8<br />

9700<br />

10750<br />

10000<br />

11000<br />

11700<br />

12800<br />

8100<br />

9000<br />

8900<br />

9850<br />

9700<br />

10600<br />

6 630 – 630 535 – 535 315 S 2 4750 3950 9000 3890 3350 7600<br />

8 690 – – 585 – –<br />

315 M 4 9100 9900 13100 7300 8100 10800<br />

80 M 2<br />

4<br />

485<br />

625<br />

–<br />

–<br />

485<br />

625<br />

400<br />

515<br />

–<br />

–<br />

400<br />

515<br />

6<br />

8<br />

10700<br />

11600<br />

12100<br />

13300<br />

15600<br />

16900<br />

8700<br />

9600<br />

9900<br />

10900<br />

12800<br />

13900<br />

6 735 – 735 605 – 605 315 L 2 4000 3100 8800 3280 2700 7600<br />

8 815 – – 675 – 675<br />

4 8400 8800 24000 7500 7450 12000<br />

90 S<br />

90 L<br />

2<br />

4<br />

725<br />

920<br />

–<br />

–<br />

725<br />

920<br />

605<br />

775<br />

–<br />

–<br />

605<br />

775<br />

6<br />

8<br />

9700<br />

11100<br />

11400<br />

12500<br />

25000<br />

26000<br />

9100<br />

10200<br />

9600<br />

10500<br />

12000<br />

12000<br />

6<br />

8<br />

1090<br />

1230<br />

–<br />

–<br />

1090<br />

1230<br />

910<br />

1030<br />

–<br />

–<br />

910<br />

1030<br />

1LA8 1MJ8<br />

1MJ1<br />

100 L 2 1030 – 1030 840 – 840<br />

4 1310 – 1310 1060 – 1060<br />

6 1550 – 1550 1250 – 1250<br />

8 1720 – 1720 1400 – 1400<br />

112 M 2 1010 – 1680 830 – 1490<br />

4 1270 – 1960 1040 – 1580<br />

6 1520 – 2140 1240 – 1720<br />

8 1690 – 2450 1380 – 1950<br />

132 S 2 1490 – 2250 1180 – 1820<br />

132 M 4 1940 – 2720 1530 – 2170<br />

6 2260 – 3100 1780 – 2420<br />

8 2500 – 3400 1980 – 2700<br />

160 M 2 1540 – 2800 1210 – 2250<br />

160 L 4 2040 – 3330 1590 – 2600<br />

6 2330 – 3750 1820 – 2900<br />

8 2660 – 3750 2080 – 2900<br />

180 M 2 2000 1780 2000 1550 1410 1550<br />

180 L 4 2350 2240 2350 1950 1820 1950<br />

200 L<br />

6<br />

8<br />

2<br />

2800<br />

3050<br />

2550<br />

2550<br />

2860<br />

2380<br />

2800<br />

3050<br />

2550<br />

2250<br />

2500<br />

2100<br />

2120<br />

2330<br />

1930<br />

2250<br />

2500<br />

2100<br />

4 3350 3050 3350 2750 2530 2750<br />

6 3900 3500 3900 3200 2930 3200<br />

8 4150 3800 4150 3450 3210 3450<br />

225 S<br />

225 M<br />

2<br />

4<br />

3050<br />

3750<br />

2820<br />

3500<br />

3050<br />

3750<br />

2550<br />

2950<br />

2290<br />

2760<br />

2550<br />

2950<br />

6 4550 4050 4550 3600 3240 3600<br />

8 4850 4500 4850 3900 3500 3900<br />

1 )<br />

1LA8 1MJ8<br />

1MJ1 1 )<br />

315 2 see diagrams<br />

see diagrams<br />

to to page<br />

page<br />

450 8 2/38<br />

2/38<br />

1) Data for 1MJ1 available soon<br />

For 1LA8 motors with horizontal design, the permitted cantilever<br />

forces are given in dependence on the axial forces.<br />

Please note that in the case of the IM B 6, IM B 7, IM B 8, IM V 5,<br />

and IM V 6 types of construction, the belt tension is only al<strong>low</strong>ed<br />

to act parallel to or towards the mounting plane and the feet must<br />

be braced. Both feet must be secured for foot-mounting types of<br />

construction.<br />

Refer to pages 2/37 to 2/39 if the cantilever forces are higher than<br />

those listed above.