You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

■ Insulation, winding, motor protection, and anti-condensation heating<br />

.<br />

DURIGNIT ® Insulation IR 2000<br />

■The DURIGNIT IR 2000 insulation<br />

system comprises highgrade<br />

enameled wires and insulating<br />

sheet materials combined<br />

with solvent-free impregnating<br />

resin.<br />

The system ensures a high level<br />

of mechanical and electrical<br />

strength as well as good serviceability<br />

and a long motor life.<br />

The insulation offers general<br />

protection for the windings<br />

against corrosive gases, vapors,<br />

dust, oil and increased humidity,<br />

and resists the normal<br />

stresses of vibration.<br />

The insulation is suitable for an<br />

absolute humidity of up to 30 g<br />

water per m3 . The windings<br />

must not become moist. Higher<br />

values on request!<br />

■The windings of the 1LA8 motors<br />

are impregnated using<br />

the UV or VPI techniques.<br />

Please inquire about extreme<br />

applications.<br />

All motors are designed for<br />

class F.<br />

Utilization of motors for rated<br />

output and mains-fed operation<br />

for class B.<br />

All 1LA and 1LG motors can be<br />

stamped with the ratings in accordance<br />

with the selection tables<br />

and rated <strong>voltage</strong> range as<br />

well as with a service factor (SF)<br />

of 1.1 (for 1LA9 and 1LG6 SF =<br />

1.15) and 1.05 for frame sizes<br />

400 and 450. Order Code C11.<br />

The service factor is already<br />

stamped on the rating plate of<br />

standard ex-stock motors and<br />

1LA8 motors.<br />

If the motor is used for class F,<br />

the rated output specified in the<br />

selection and ordering data can<br />

be increased by 10% (by 15%<br />

for 1LA9 and 1LG6 and by 5%<br />

for frame sizes 400 and 450).<br />

Order Code C12.<br />

If the catalogue ratings are<br />

used, it is permissible to increase<br />

the temperature of the<br />

coolant to 55 °C (or to 50 °C for<br />

frame sizes 400 and 450). Order<br />

Code C13.<br />

The service factor (SF) is not<br />

stamped on the rating plate for<br />

Order Codes C12 and C13.<br />

Restarting against residual<br />

field and opposite phase<br />

All motors can be reclosed<br />

against 100% residual field after<br />

a system <strong>voltage</strong> failure.<br />

Motor protection with PTC<br />

thermistor<br />

The motors are usually protected<br />

by delayed terminal overload<br />

protection devices (either circuit-breakers<br />

for motor protection<br />

or overload relays).<br />

This type of protection is current-sensitive<br />

and is particularly<br />

effective under locked-rotor<br />

conditions.<br />

The motors can also be protected<br />

by means of semiconductor<br />

temperature sensors (thermistors)<br />

embedded in the winding<br />

and operating in conjunction<br />

with a tripping unit (thermistor<br />

motor protection) (Order Code<br />

A11 or A12).<br />

This type of protection is temperature-sensitive<br />

and prevents<br />

the motor windings from overheating,<br />

e.g. due to sharply fluctuating<br />

loads or frequent switching.<br />

■All 1LA8 motors with the standard<br />

design are fitted with 6<br />

PTC thermistors for alarm and<br />

tripping.<br />

■The response temperature of<br />

the PTC thermistors for the<br />

1LA, 1MJ and 1LG motors corresponds<br />

to class F.<br />

In order to achieve full thermal<br />

protection it is necessary to<br />

combine a thermally delayed<br />

overcurrent release and a PTC<br />

thermistor. Full motor protection<br />

implemented only with PTC<br />

thermistors on request.<br />

For type 1MJ motors:<br />

Always use PTC thermistors if<br />

the duty is anything other than<br />

S1.<br />

■PTC thermistors are absolutely<br />

necessary if these motors are<br />

used for converter-fed operation.<br />

In this case, an additional<br />

thermistor is fitted in the terminal<br />

box for 1MJ6. Order Code<br />

A15 or A16.<br />

No additional anti-condensation<br />

heater can be integrated in designs<br />

with temperature sensors<br />

and frame sizes up to 200 L.<br />

Thermistor protection takes the<br />

form of three PTC thermistors<br />

connected in series and embedded<br />

in the stator winding of<br />

the motor. The 3RN1 tripping<br />

unit which completes the system<br />

must be ordered separately<br />

– it is PTB certified. Further details<br />

about its mode of operation,<br />

circuitry, and price can be<br />

found in Catalogue LV 10,<br />

Order No.:<br />

E86060-K1002-A101-A4-7600.<br />

Pole-changing motors with two<br />

separate windings need twice<br />

the number of temperature sensors.<br />

If an alarm signal is to be output<br />

prior to the motor being shut<br />

down, two groups of three temperature<br />

sensors will be needed.<br />

The alarm signal is usually<br />

output at 10 K be<strong>low</strong> shutdown<br />

temperature.<br />

Motor temperature detection<br />

with temperature sensor<br />

KTY84<br />

See "Converter-fed operation"<br />

Page 2/44.<br />

Squirrel-cage motors<br />

Technical information<br />

Electrical features<br />

Anti-condensation heating<br />

Supply <strong>voltage</strong> 230 V<br />

Order Code K45<br />

Supply <strong>voltage</strong> 115 V<br />

Order Code K46<br />

Anti-condensation heaters can<br />

be fitted to motors whose windings<br />

are exposed to a risk of<br />

condensation due to the ambient<br />

climate, e.g. stationary motors<br />

in a damp environment or<br />

motors subjected to considerable<br />

fluctuations in temperature.<br />

An additional M16 x 1.5 or<br />

M20 x 1.5 cable entry fitting is<br />

provided in the terminal box for<br />

the power supply cable.<br />

The anti-condensation heater<br />

must not be switched on while<br />

the motor is running.<br />

An alternative to anti-condensation<br />

heaters (involving no extra<br />

cost) is to connect a <strong>voltage</strong> of<br />

around 4 to 10% of the motor<br />

rated <strong>voltage</strong> to stator terminals<br />

U1 and V1; 20 to 30% of the motor<br />

rated current provide an adequate<br />

heating effect (does not<br />

apply to 1MA6 motors, frame<br />

sizes 225 M to 315 L, 1LA8).<br />

For 1MJ6 motors:<br />

No built-in anti-condensation<br />

heater is available for 1MJ6 motors<br />

up to frame size 160 L when<br />

equipped with PTC thermistors.<br />

For 1MA . and 1LA . motors in<br />

Zone 21:<br />

No built-in anti-condensation<br />

heater is available up to frame<br />

size 200L.<br />

For 1LA . motors in Zones 2 and<br />

22:<br />

Built-in anti-condensation heating<br />

on request.<br />

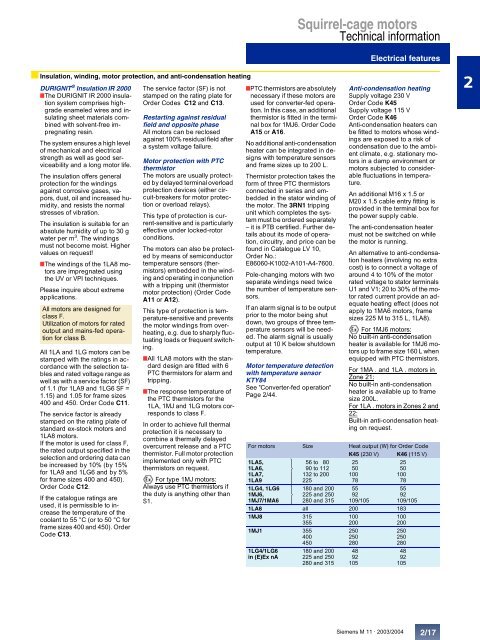

For motors Size Heat output (W) for Order Code<br />

K45 (230 V) K46 (115 V)<br />

1LA5,<br />

1LA6,<br />

1LA7,<br />

á<br />

â<br />

ß<br />

56 to 80<br />

90 to 112<br />

132 to 200<br />

25<br />

50<br />

100<br />

25<br />

50<br />

100<br />

1LA9 ã 225<br />

78<br />

78<br />

1LG4, 1LG6<br />

1MJ6,<br />

1MJ7/1MA6<br />

á<br />

â<br />

ã<br />

180 and 200<br />

225 and 250<br />

280 and 315<br />

55<br />

92<br />

109/105<br />

55<br />

92<br />

109/105<br />

1LA8 all 200 183<br />

1MJ8 315<br />

100<br />

100<br />

355<br />

200<br />

200<br />

1MJ1 355<br />

250<br />

250<br />

400<br />

250<br />

250<br />

450<br />

280<br />

280<br />

1LG4/1LG6 180 and 200 48<br />

48<br />

in (E)Ex nA 225 and 250 92<br />

92<br />

280 and 315 105<br />

105<br />

Siemens M 11 · 2003/2004 2/17<br />

2