operation - Victor Technologies

operation - Victor Technologies

operation - Victor Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

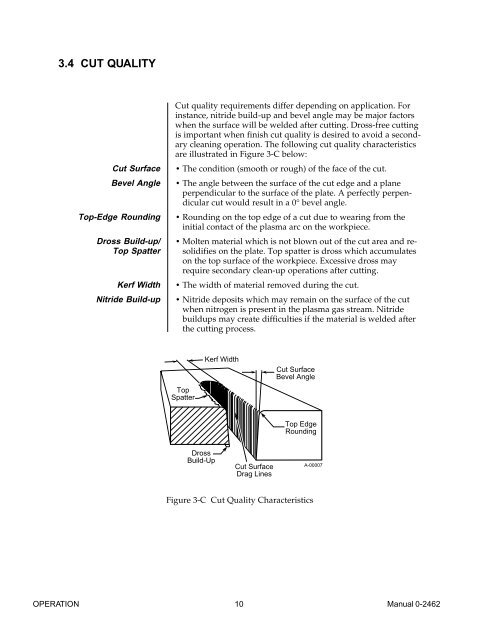

3.4 CUT QUALITY<br />

Cut Surface<br />

Bevel Angle<br />

Top-Edge Rounding<br />

Dross Build-up/<br />

Top Spatter<br />

Kerf Width<br />

Nitride Build-up<br />

Cut quality requirements differ depending on application. For<br />

instance, nitride build-up and bevel angle may be major factors<br />

when the surface will be welded after cutting. Dross-free cutting<br />

is important when finish cut quality is desired to avoid a secondary<br />

cleaning <strong>operation</strong>. The following cut quality characteristics<br />

are illustrated in Figure 3-C below:<br />

The condition (smooth or rough) of the face of the cut.<br />

The angle between the surface of the cut edge and a plane<br />

perpendicular to the surface of the plate. A perfectly perpendicular<br />

cut would result in a 0° bevel angle.<br />

Rounding on the top edge of a cut due to wearing from the<br />

initial contact of the plasma arc on the workpiece.<br />

Molten material which is not blown out of the cut area and resolidifies<br />

on the plate. Top spatter is dross which accumulates<br />

on the top surface of the workpiece. Excessive dross may<br />

require secondary clean-up <strong>operation</strong>s after cutting.<br />

The width of material removed during the cut.<br />

Nitride deposits which may remain on the surface of the cut<br />

when nitrogen is present in the plasma gas stream. Nitride<br />

buildups may create difficulties if the material is welded after<br />

the cutting process.<br />

Top<br />

Spatter<br />

Dross<br />

Build-Up<br />

Kerf Width<br />

Cut Surface<br />

Drag Lines<br />

Cut Surface<br />

Bevel Angle<br />

Top Edge<br />

Rounding<br />

Figure 3-C Cut Quality Characteristics<br />

A-00007<br />

OPERATION 10 Manual 0-2462