Number 4 - ExxonMobil in the UK

Number 4 - ExxonMobil in the UK

Number 4 - ExxonMobil in the UK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

17<br />

The automotive<br />

<strong>in</strong>dustry represents<br />

a major market for<br />

products manufactured<br />

by <strong>ExxonMobil</strong><br />

Chemical Company.<br />

Dur<strong>in</strong>g <strong>the</strong> past<br />

year, <strong>the</strong> company<br />

expanded its role <strong>in</strong> that<br />

<strong>in</strong>dustry by <strong>in</strong>troduc<strong>in</strong>g<br />

new product applications<br />

and add<strong>in</strong>g capacity<br />

at company plants <strong>in</strong><br />

Florida and Louisiana as<br />

well as through a thirdparty<br />

facility <strong>in</strong> S<strong>in</strong>gapore.<br />

The effort has opened new<br />

markets and also has won<br />

<strong>the</strong> company recognition for its<br />

technical leadership.<br />

Better battery efficiency<br />

<strong>ExxonMobil</strong> Chemical was honored<br />

<strong>in</strong> October when it received<br />

a lead<strong>in</strong>g <strong>in</strong>dustry <strong>in</strong>novation<br />

award for its battery separator<br />

film technology. Pioneered by a<br />

team of company scientists led<br />

by Dr. Pat Brant, this technology<br />

can significantly improve<br />

<strong>the</strong> power, capacity, stability and<br />

safety of lithium-ion batteries.<br />

Such enhanced performance<br />

can enable <strong>the</strong> use of smaller,<br />

more powerful batteries <strong>in</strong> <strong>the</strong><br />

next generation of lower-emission<br />

vehicles.<br />

One such automobile is <strong>the</strong><br />

new Maya-300, manufactured<br />

by Canada-based Electrovaya,<br />

which produces lithium-ion<br />

battery systems. Last January,<br />

<strong>ExxonMobil</strong> announced that its<br />

battery separator film technology<br />

will be a key component of<br />

Electrovaya’s battery systems.<br />

Story by Thomas L. Torget<br />

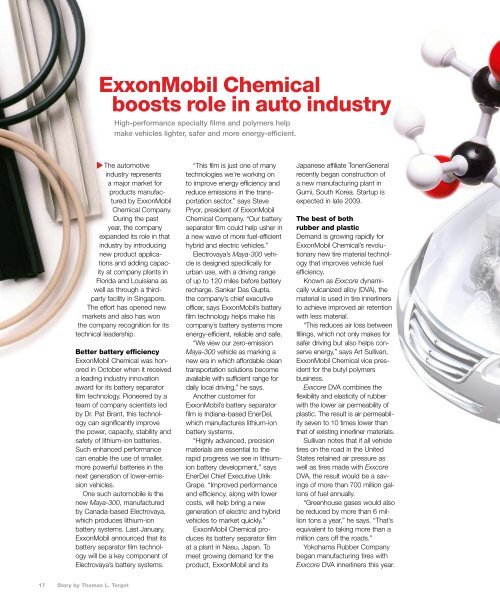

<strong>ExxonMobil</strong> Chemical<br />

boosts role <strong>in</strong> auto <strong>in</strong>dustry<br />

High-performance specialty films and polymers help<br />

make vehicles lighter, safer and more energy-efficient.<br />

“This film is just one of many<br />

technologies we’re work<strong>in</strong>g on<br />

to improve energy efficiency and<br />

reduce emissions <strong>in</strong> <strong>the</strong> transportation<br />

sector,” says Steve<br />

Pryor, president of <strong>ExxonMobil</strong><br />

Chemical Company. “Our battery<br />

separator film could help usher <strong>in</strong><br />

a new wave of more fuel-efficient<br />

hybrid and electric vehicles.”<br />

Electrovaya’s Maya-300 vehicle<br />

is designed specifically for<br />

urban use, with a driv<strong>in</strong>g range<br />

of up to 120 miles before battery<br />

recharge. Sankar Das Gupta,<br />

<strong>the</strong> company’s chief executive<br />

officer, says <strong>ExxonMobil</strong>’s battery<br />

film technology helps make his<br />

company’s battery systems more<br />

energy-efficient, reliable and safe.<br />

“We view our zero-emission<br />

Maya-300 vehicle as mark<strong>in</strong>g a<br />

new era <strong>in</strong> which affordable clean<br />

transportation solutions become<br />

available with sufficient range for<br />

daily local driv<strong>in</strong>g,” he says.<br />

Ano<strong>the</strong>r customer for<br />

<strong>ExxonMobil</strong>’s battery separator<br />

film is Indiana-based EnerDel,<br />

which manufactures lithium-ion<br />

battery systems.<br />

“Highly advanced, precision<br />

materials are essential to <strong>the</strong><br />

rapid progress we see <strong>in</strong> lithiumion<br />

battery development,” says<br />

EnerDel Chief Executive Ulrik<br />

Grape. “Improved performance<br />

and efficiency, along with lower<br />

costs, will help br<strong>in</strong>g a new<br />

generation of electric and hybrid<br />

vehicles to market quickly.”<br />

<strong>ExxonMobil</strong> Chemical produces<br />

its battery separator film<br />

at a plant <strong>in</strong> Nasu, Japan. To<br />

meet grow<strong>in</strong>g demand for <strong>the</strong><br />

product, <strong>ExxonMobil</strong> and its<br />

Japanese affiliate TonenGeneral<br />

recently began construction of<br />

a new manufactur<strong>in</strong>g plant <strong>in</strong><br />

Gumi, South Korea. Startup is<br />

expected <strong>in</strong> late 2009.<br />

The best of both<br />

rubber and plastic<br />

Demand is grow<strong>in</strong>g rapidly for<br />

<strong>ExxonMobil</strong> Chemical’s revolutionary<br />

new tire material technology<br />

that improves vehicle fuel<br />

efficiency.<br />

Known as Exxcore dynamically<br />

vulcanized alloy (DVA), <strong>the</strong><br />

material is used <strong>in</strong> tire <strong>in</strong>nerl<strong>in</strong>ers<br />

to achieve improved air retention<br />

with less material.<br />

“This reduces air loss between<br />

fill<strong>in</strong>gs, which not only makes for<br />

safer driv<strong>in</strong>g but also helps conserve<br />

energy,” says Art Sullivan,<br />

<strong>ExxonMobil</strong> Chemical vice president<br />

for <strong>the</strong> butyl polymers<br />

bus<strong>in</strong>ess.<br />

Exxcore DVA comb<strong>in</strong>es <strong>the</strong><br />

flexibility and elasticity of rubber<br />

with <strong>the</strong> lower air permeability of<br />

plastic. The result is air permeability<br />

seven to 10 times lower than<br />

that of exist<strong>in</strong>g <strong>in</strong>nerl<strong>in</strong>er materials.<br />

Sullivan notes that if all vehicle<br />

tires on <strong>the</strong> road <strong>in</strong> <strong>the</strong> United<br />

States reta<strong>in</strong>ed air pressure as<br />

well as tires made with Exxcore<br />

DVA, <strong>the</strong> result would be a sav<strong>in</strong>gs<br />

of more than 700 million gallons<br />

of fuel annually.<br />

“Greenhouse gases would also<br />

be reduced by more than 6 million<br />

tons a year,” he says. “That’s<br />

equivalent to tak<strong>in</strong>g more than a<br />

million cars off <strong>the</strong> roads.”<br />

Yokohama Rubber Company<br />

began manufactur<strong>in</strong>g tires with<br />

Exxcore DVA <strong>in</strong>nerl<strong>in</strong>ers this year.