2012 — Number 1 - ExxonMobil

2012 — Number 1 - ExxonMobil

2012 — Number 1 - ExxonMobil

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Testing<br />

for the best<br />

<strong>ExxonMobil</strong> lab ensures tubular-goods<br />

quality while reaching major safety milestone.<br />

It’s Saturday morning, and<br />

your “to-do” list includes a<br />

simple plumbing repair under the<br />

kitchen sink. Job completed, you<br />

reconnect two pipes. You turn<br />

on the faucet to check for leaks,<br />

and, to your dismay, water is<br />

dripping from the connection.<br />

Imagine a more serious situation.<br />

The pipe is a half-foot in<br />

diameter, thousands of feet in<br />

length and extends well below<br />

the ocean floor from an offshore<br />

production platform exposed to<br />

severe conditions while producing<br />

oil or gas. In this instance,<br />

failure of the connection is simply<br />

not an option.<br />

For the past 25 years,<br />

<strong>ExxonMobil</strong>’s Tubular Goods Test<br />

Facility (TGTF) in Houston has<br />

conducted thorough, comprehensive<br />

evaluations to make sure<br />

that doesn’t happen. It puts casing<br />

and tubing (steel pipe, also<br />

called “tubulars”) and pipe connections<br />

used in oil and gas wells<br />

through punishing tests to ensure<br />

that they perform safely in any<br />

environment, on land or sea.<br />

TGTF is a full-scale lab –<br />

the only one of its kind among<br />

major oil companies – with the<br />

unique testing ability to assess<br />

the performance of pipe and<br />

pipe connectors.<br />

“The facility’s primary mission,”<br />

says David Baker, tubular technology<br />

team lead, “is to ensure the<br />

mechanical integrity and reliability<br />

of the tubular equipment installed<br />

25 Story by Bill Corporon Photography by Robert Seale<br />

in <strong>ExxonMobil</strong>’s wells. We place a<br />

special emphasis on connections<br />

because they’re such a critical<br />

link in the tubular system.”<br />

The facility, managed by the<br />

Drilling and Subsurface group<br />

within <strong>ExxonMobil</strong> Upstream<br />

Research Company, also develops<br />

proprietary and patented<br />

technology and helps the company<br />

select high-quality tubular<br />

goods at cost-effective prices.<br />

In the quarter-century that<br />

TGTF employees have carried<br />

out the facility’s mission, they’ve<br />

also achieved a stellar safety<br />

record – no lost-time incidents.<br />

How testing is done<br />

The TGTF is in a 20,000-squarefoot<br />

building about 20 miles<br />

southeast of downtown Houston.<br />

It contains three key testing<br />

components:<br />

An assembly area where pipe<br />

can be screwed together and<br />

taken apart multiple times to<br />

evaluate its durability. The area<br />

is also used to assess “galling”<br />

in the pipe’s connection<br />

threads. Galling describes damage<br />

to the pipe threads that<br />

prevents two pieces from fitting<br />

together correctly.<br />

A “burst pit” to test how a<br />

connection behaves when<br />

pressure inside the pipe is<br />

high enough to cause the pipe<br />

to tear. A heavy metal slab<br />

that locks securely into posi-<br />

tion covers the pit to safely<br />

confine the failed pipe.<br />

A pressure containment building<br />

housing a frame that can<br />

apply a load of more than<br />

2 million pounds. It’s used to<br />

evaluate the performance of<br />

pipes under very-high-pressure<br />

fluid loads. The frame is<br />

essentially a massive hydraulic<br />

press that can push and<br />

pull on the pipe. The pushing<br />

and pulling create tension<br />

and compression that simulate<br />

what happens in operating<br />

wells.<br />

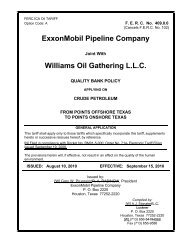

Keegan Johnson (above),<br />

daily operations coordinator<br />

at the Tubular Goods<br />

Test Facility in Houston,<br />

monitors the assembly of<br />

a pipe connection.