technology, energy efficiency and environmental externalities in the ...

technology, energy efficiency and environmental externalities in the ...

technology, energy efficiency and environmental externalities in the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

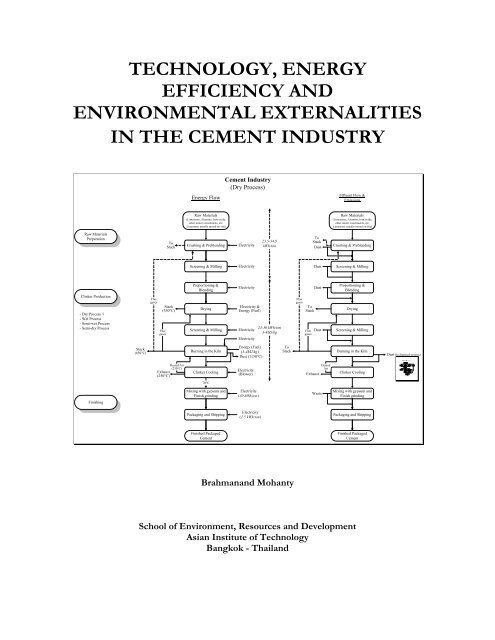

TECHNOLOGY, ENERGY<br />

EFFICIENCY AND<br />

ENVIRONMENTAL EXTERNALITIES<br />

IN THE CEMENT INDUSTRY<br />

Raw Materials<br />

Preparation<br />

Cl<strong>in</strong>ker Production<br />

- Dry Process √<br />

- Wet Process<br />

- Semi-wet Process<br />

- Semi-dry Process<br />

F<strong>in</strong>ish<strong>in</strong>g<br />

Stack<br />

(650°C)<br />

Flue<br />

gases<br />

Flue<br />

gases<br />

To<br />

Stack<br />

Stack<br />

(350°C)<br />

Heated Air<br />

(250°C)<br />

Exhaust<br />

(250°C)<br />

Energy Flow<br />

Raw Materials<br />

(Limestone, Alum<strong>in</strong>a, Iron oxide,<br />

o<strong>the</strong>r m<strong>in</strong>or constituents, etc.<br />

Limestone usually m<strong>in</strong>ed on site)<br />

Crush<strong>in</strong>g & Preblend<strong>in</strong>g<br />

Screen<strong>in</strong>g & Mill<strong>in</strong>g<br />

Proportion<strong>in</strong>g &<br />

Blend<strong>in</strong>g<br />

Dry<strong>in</strong>g<br />

Screen<strong>in</strong>g & Mill<strong>in</strong>g<br />

Burn<strong>in</strong>g <strong>in</strong> <strong>the</strong> Kiln<br />

Cl<strong>in</strong>ker Cool<strong>in</strong>g<br />

70°C<br />

Mix<strong>in</strong>g with gypsum <strong>and</strong><br />

F<strong>in</strong>ish gr<strong>in</strong>d<strong>in</strong>g<br />

Packag<strong>in</strong>g <strong>and</strong> Shipp<strong>in</strong>g<br />

F<strong>in</strong>ished Packaged<br />

Cement<br />

Cement Industry<br />

(Dry Process)<br />

Electricity<br />

Electricity<br />

Electricity<br />

Electricity &<br />

Energy (Fuel)<br />

Electricity<br />

Electricity<br />

Energy (Fuel)<br />

(3-4MJ/kg)<br />

Dust (1150°C)<br />

Electricity<br />

(Blower)<br />

Electricity<br />

(30 kWh/ton)<br />

Electricity<br />

(1.5 kWh/ton)<br />

23.5-34.5<br />

kWh/ton<br />

23-30 kWh/ton<br />

3-4MJ/kg<br />

To<br />

Stack<br />

Brahman<strong>and</strong> Mohanty<br />

Flue<br />

gases<br />

To<br />

Stack<br />

Flue<br />

gases<br />

To<br />

Stack<br />

Dust<br />

Dust<br />

Dust<br />

Dust<br />

Exhaust<br />

Waste<br />

Heated<br />

Air<br />

Effluent Flow &<br />

Emissions<br />

Raw Materials<br />

(Limestone, Alum<strong>in</strong>a, Iron oxide,<br />

o<strong>the</strong>r m<strong>in</strong>or constituents, etc.<br />

Limestone usually m<strong>in</strong>ed on site)<br />

Crush<strong>in</strong>g & Preblend<strong>in</strong>g<br />

Screen<strong>in</strong>g & Mill<strong>in</strong>g<br />

Proportion<strong>in</strong>g &<br />

Blend<strong>in</strong>g<br />

Dry<strong>in</strong>g<br />

Screen<strong>in</strong>g & Mill<strong>in</strong>g<br />

Burn<strong>in</strong>g <strong>in</strong> <strong>the</strong> Kiln<br />

Cl<strong>in</strong>ker Cool<strong>in</strong>g<br />

Mix<strong>in</strong>g with gypsum <strong>and</strong><br />

F<strong>in</strong>ish gr<strong>in</strong>d<strong>in</strong>g<br />

Packag<strong>in</strong>g <strong>and</strong> Shipp<strong>in</strong>g<br />

F<strong>in</strong>ished Packaged<br />

Cement<br />

School of Environment, Resources <strong>and</strong> Development<br />

Asian Institute of Technology<br />

Bangkok - Thail<strong>and</strong><br />

Dust (to disposal system)<br />

* The dotted l<strong>in</strong>e represents Wet Process only