technology, energy efficiency and environmental externalities in the ...

technology, energy efficiency and environmental externalities in the ...

technology, energy efficiency and environmental externalities in the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TECHNOLOGY, ENERGY EFFICIENCY<br />

AND ENVIRONMENTAL EXTERNALITIES<br />

IN THE CEMENT INDUSTRY<br />

School of Environment, Resources <strong>and</strong> Development<br />

Asian Institute of Technology<br />

Bangkok - Thail<strong>and</strong><br />

ASIAN INSTITUTE<br />

OF TEC HN OLOGY<br />

19 5 9

TECHNOLOGY, ENERGY<br />

EFFICIENCY AND<br />

ENVIRONMENTAL EXTERNALITIES<br />

IN THE CEMENT INDUSTRY<br />

Raw Materials<br />

Preparation<br />

Cl<strong>in</strong>ker Production<br />

- Dry Process √<br />

- Wet Process<br />

- Semi-wet Process<br />

- Semi-dry Process<br />

F<strong>in</strong>ish<strong>in</strong>g<br />

Stack<br />

(650°C)<br />

Flue<br />

gases<br />

Flue<br />

gases<br />

To<br />

Stack<br />

Stack<br />

(350°C)<br />

Heated Air<br />

(250°C)<br />

Exhaust<br />

(250°C)<br />

Energy Flow<br />

Raw Materials<br />

(Limestone, Alum<strong>in</strong>a, Iron oxide,<br />

o<strong>the</strong>r m<strong>in</strong>or constituents, etc.<br />

Limestone usually m<strong>in</strong>ed on site)<br />

Crush<strong>in</strong>g & Preblend<strong>in</strong>g<br />

Screen<strong>in</strong>g & Mill<strong>in</strong>g<br />

Proportion<strong>in</strong>g &<br />

Blend<strong>in</strong>g<br />

Dry<strong>in</strong>g<br />

Screen<strong>in</strong>g & Mill<strong>in</strong>g<br />

Burn<strong>in</strong>g <strong>in</strong> <strong>the</strong> Kiln<br />

Cl<strong>in</strong>ker Cool<strong>in</strong>g<br />

70°C<br />

Mix<strong>in</strong>g with gypsum <strong>and</strong><br />

F<strong>in</strong>ish gr<strong>in</strong>d<strong>in</strong>g<br />

Packag<strong>in</strong>g <strong>and</strong> Shipp<strong>in</strong>g<br />

F<strong>in</strong>ished Packaged<br />

Cement<br />

Cement Industry<br />

(Dry Process)<br />

Electricity<br />

Electricity<br />

Electricity<br />

Electricity &<br />

Energy (Fuel)<br />

Electricity<br />

Electricity<br />

Energy (Fuel)<br />

(3-4MJ/kg)<br />

Dust (1150°C)<br />

Electricity<br />

(Blower)<br />

Electricity<br />

(30 kWh/ton)<br />

Electricity<br />

(1.5 kWh/ton)<br />

23.5-34.5<br />

kWh/ton<br />

23-30 kWh/ton<br />

3-4MJ/kg<br />

To<br />

Stack<br />

Brahman<strong>and</strong> Mohanty<br />

Flue<br />

gases<br />

To<br />

Stack<br />

Flue<br />

gases<br />

To<br />

Stack<br />

Dust<br />

Dust<br />

Dust<br />

Dust<br />

Exhaust<br />

Waste<br />

Heated<br />

Air<br />

Effluent Flow &<br />

Emissions<br />

Raw Materials<br />

(Limestone, Alum<strong>in</strong>a, Iron oxide,<br />

o<strong>the</strong>r m<strong>in</strong>or constituents, etc.<br />

Limestone usually m<strong>in</strong>ed on site)<br />

Crush<strong>in</strong>g & Preblend<strong>in</strong>g<br />

Screen<strong>in</strong>g & Mill<strong>in</strong>g<br />

Proportion<strong>in</strong>g &<br />

Blend<strong>in</strong>g<br />

Dry<strong>in</strong>g<br />

Screen<strong>in</strong>g & Mill<strong>in</strong>g<br />

Burn<strong>in</strong>g <strong>in</strong> <strong>the</strong> Kiln<br />

Cl<strong>in</strong>ker Cool<strong>in</strong>g<br />

Mix<strong>in</strong>g with gypsum <strong>and</strong><br />

F<strong>in</strong>ish gr<strong>in</strong>d<strong>in</strong>g<br />

Packag<strong>in</strong>g <strong>and</strong> Shipp<strong>in</strong>g<br />

F<strong>in</strong>ished Packaged<br />

Cement<br />

School of Environment, Resources <strong>and</strong> Development<br />

Asian Institute of Technology<br />

Bangkok - Thail<strong>and</strong><br />

Dust (to disposal system)<br />

* The dotted l<strong>in</strong>e represents Wet Process only

Technology, Energy Efficiency <strong>and</strong> Environmental Externalities<br />

<strong>in</strong> <strong>the</strong> Pulp <strong>and</strong> Paper Industry<br />

© Asian Institute of Technology, 1997<br />

Edited by Brahman<strong>and</strong> Mohanty<br />

Published by School of Environment, Resources <strong>and</strong> Development<br />

Asian Institute of Technology<br />

P.O. Box 4, Pathumthani 12120<br />

Thail<strong>and</strong><br />

e-mail: visu@ait.ac.th<br />

NOTICE<br />

Nei<strong>the</strong>r <strong>the</strong> Swedish International Development Cooperation Agency (Sida) nor <strong>the</strong> Asian<br />

Institute of Technology (AIT) makes any warranty, expressed or implied, or assume any legal<br />

liability for <strong>the</strong> accuracy, completeness, or usefulness of any <strong>in</strong>formation, appratus, product,<br />

or represents that its use would not <strong>in</strong>fr<strong>in</strong>ge privately owned rights. Reference here<strong>in</strong> to any<br />

trademark, or manufacturer, or o<strong>the</strong>rwise does not constitute or imply its endorsement,<br />

recommendation, or favor<strong>in</strong>g by Sida or AIT.<br />

ISBN 974 - 8256 – 70--7<br />

Pr<strong>in</strong>ted <strong>in</strong> India by All India Press, Pondicherry.

FOREWORD<br />

The use of fossil fuels leads to <strong>the</strong> emission of so-called "Green House Gases (GHG)", a<br />

concept which comprises carbon dioxide, nitrous oxides, sulfur oxides, etc. In recent years, a<br />

good deal of research has provided enough material to put forward <strong>the</strong> claim that a big<br />

<strong>in</strong>crease <strong>in</strong> <strong>the</strong> concentration of carbon dioxide <strong>in</strong> <strong>the</strong> atmosphere would lead to a rise <strong>in</strong> <strong>the</strong><br />

average global temperature, with negative consequences for <strong>the</strong> global climate. This claim<br />

has been confirmed by <strong>the</strong> United Nations Intergovernmental Panel on Climate Change<br />

(IPCC) <strong>in</strong> its second scientific assessment published <strong>in</strong> 1996.<br />

Global warm<strong>in</strong>g can have catastrophic impact on human <strong>and</strong> global security: isl<strong>and</strong> nations<br />

<strong>and</strong> low ly<strong>in</strong>g coastal regions would be permanently drowned by <strong>the</strong> rise <strong>in</strong> <strong>the</strong> level of <strong>the</strong><br />

oceans brought on by <strong>the</strong> melt<strong>in</strong>g of polar ice; drought would become widespread; <strong>and</strong><br />

desertification would exp<strong>and</strong> <strong>and</strong> accelerate. Persistent fam<strong>in</strong>es, mass migrations <strong>and</strong> largescale<br />

conflict would be <strong>the</strong> result. Agriculture, food <strong>and</strong> water security, <strong>and</strong> <strong>in</strong>ternational<br />

trade would come under severe stra<strong>in</strong>.<br />

Until recently, <strong>in</strong>dustrialized countries have accounted for most of <strong>the</strong> emission of <strong>the</strong><br />

GHG, <strong>in</strong> particular carbon dioxide, because <strong>the</strong>ir economic development has been very<br />

strongly based on <strong>the</strong> use of fossil fuels. However, <strong>the</strong> same dynamic has also led to a<br />

situation where <strong>the</strong> newly <strong>in</strong>dustrializ<strong>in</strong>g countries of Asia <strong>and</strong> Lat<strong>in</strong> America (<strong>the</strong> strong<br />

South) are today contribut<strong>in</strong>g significantly to <strong>the</strong> emission of carbon dioxide. This tendency<br />

will spread to <strong>and</strong> encompass an <strong>in</strong>creas<strong>in</strong>g number of develop<strong>in</strong>g countries unless both <strong>the</strong><br />

<strong>in</strong>dustrialized <strong>and</strong> <strong>the</strong> develop<strong>in</strong>g countries jo<strong>in</strong>tly agree on implement<strong>in</strong>g <strong>the</strong> measures to<br />

halt <strong>and</strong> <strong>the</strong>n reverse <strong>the</strong> global trend towards a rapid rise <strong>in</strong> <strong>the</strong> emission of carbon dioxide.<br />

That is <strong>the</strong> central purpose of <strong>the</strong> IPCC, which has succeeded <strong>in</strong> obta<strong>in</strong><strong>in</strong>g commitments<br />

from most of <strong>the</strong> <strong>in</strong>dustrialized countries to reduce <strong>the</strong>ir emissions of carbon dioxide.<br />

At <strong>the</strong> 1995 meet<strong>in</strong>g <strong>in</strong> Berl<strong>in</strong> of <strong>the</strong> Conference of <strong>the</strong> Parties (CoP) to <strong>the</strong> United Nations<br />

Climate Convention, it was decided to <strong>in</strong>itiate negotiations to streng<strong>the</strong>n <strong>the</strong> emissionreduction<br />

measures by <strong>the</strong> <strong>in</strong>dustrialized countries, as well as countries of Eastern Europe<br />

<strong>and</strong> <strong>the</strong> Former Soviet Union. The f<strong>in</strong>al negotiations are planned to take place at <strong>the</strong><br />

December 1997 meet<strong>in</strong>g <strong>in</strong> Kyoto of <strong>the</strong> CoP, which ought to result <strong>in</strong> legal <strong>in</strong>struments to<br />

ensure that <strong>the</strong> agreed measures are be<strong>in</strong>g fulfilled.<br />

The fossil fuel generated climate problem is very complex, with strong vested <strong>in</strong>terests <strong>and</strong><br />

special alliances. There is still considerable skepticism <strong>in</strong> <strong>the</strong> develop<strong>in</strong>g world about <strong>the</strong><br />

need for measures to counter global warm<strong>in</strong>g, <strong>in</strong> particular <strong>in</strong> <strong>the</strong> strong South, which <strong>in</strong> no<br />

way wants to jeopardize its own rapid economic development. It is <strong>the</strong>refore imperative to<br />

f<strong>in</strong>d <strong>in</strong>novative solutions, both technical <strong>and</strong> <strong>in</strong>stitutional, to <strong>the</strong> climate problem, which are

acceptable to both <strong>the</strong> North <strong>and</strong> <strong>the</strong> South. Meet<strong>in</strong>g this challenge calls for <strong>in</strong>ter alia<br />

research programs that tackle <strong>the</strong> technological, techno-economic <strong>and</strong> policy problems <strong>in</strong><br />

promot<strong>in</strong>g <strong>the</strong> transition to decreas<strong>in</strong>g use of fossil fuels, <strong>in</strong>creas<strong>in</strong>g <strong>energy</strong> <strong>efficiency</strong> <strong>and</strong><br />

fuel substitution, <strong>and</strong> carbon recycl<strong>in</strong>g systems of <strong>energy</strong> production <strong>and</strong> use.<br />

The Asian Regional Research Programme on Energy, Environment <strong>and</strong> Climate<br />

(ARRPEEC) is part of this global effort, which Sida is very pleased to have <strong>in</strong>itiated <strong>and</strong> is<br />

fully support<strong>in</strong>g. The ARRPEEC comprises technological, techno-economic <strong>and</strong> policy<br />

research on <strong>energy</strong> <strong>efficiency</strong>, fuel substitution <strong>and</strong> carbon recycl<strong>in</strong>g <strong>in</strong> <strong>the</strong> pr<strong>in</strong>cipal<br />

economic sectors of East, Sou<strong>the</strong>ast <strong>and</strong> South Asian countries.<br />

M R Bhagavan<br />

Senior Research Adviser, Department for Research Cooperation<br />

Swedish International Development Cooperation Agency, Sida

PREFACE<br />

Industries have always played a crucial role <strong>in</strong> <strong>the</strong> socio-economic development of a country.<br />

They have contributed primarily to <strong>in</strong>creased prosperity, greater employment <strong>and</strong> livelihood<br />

opportunities. On <strong>the</strong> o<strong>the</strong>r h<strong>and</strong>, <strong>in</strong>dustries are accused of accelerat<strong>in</strong>g <strong>the</strong> consumption of<br />

scarce fossil fuels <strong>and</strong> of pollut<strong>in</strong>g <strong>the</strong> local, regional, <strong>and</strong> global environment by releas<strong>in</strong>g<br />

solid, liquid <strong>and</strong> gaseous pollutants to <strong>the</strong>ir surround<strong>in</strong>gs.<br />

Experiences ga<strong>in</strong>ed worldwide have shown that <strong>the</strong>se impacts of <strong>in</strong>dustries on resource use<br />

<strong>and</strong> <strong>the</strong> environment can be conta<strong>in</strong>ed through more efficient production processes <strong>and</strong><br />

adoption of cleaner technologies <strong>and</strong> procedures. Thus, fossil fuel consumption can be cut<br />

down drastically <strong>and</strong> waste generation can be avoided or m<strong>in</strong>imized to <strong>the</strong> lowest possible<br />

level. Regulatory regimes <strong>in</strong>troduced <strong>in</strong> several countries have led <strong>the</strong> <strong>in</strong>dustries to adopt<br />

appropriate measures. Some countries have adopted economic <strong>in</strong>struments to reflect <strong>the</strong> true<br />

cost of goods <strong>and</strong> services by <strong>in</strong>ternaliz<strong>in</strong>g <strong>the</strong> <strong>environmental</strong> costs of <strong>the</strong>ir <strong>in</strong>put,<br />

production, use, recycl<strong>in</strong>g <strong>and</strong> disposal.<br />

The improvement of production system through <strong>the</strong> use of technologies <strong>and</strong> processes that<br />

utilize resources more efficiently <strong>and</strong> achieve “more with less” is an important pathway<br />

towards <strong>the</strong> long-term sustenance of <strong>in</strong>dustries. It is <strong>in</strong> this context that a research project<br />

was undertaken by <strong>the</strong> Asian Institute of Technology (AIT), with <strong>the</strong> support of <strong>the</strong> Swedish<br />

International Development Cooperation Agency (Sida). The project entitled “Development<br />

of Energy Efficient <strong>and</strong> Environmentally Sound Industrial Technologies <strong>in</strong> Asia” was<br />

launched with <strong>the</strong> specific objective to enhance <strong>the</strong> synergy among selected Asian<br />

develop<strong>in</strong>g countries <strong>in</strong> <strong>the</strong>ir efforts to grasp <strong>the</strong> mechanism <strong>and</strong> various aspects related to<br />

<strong>the</strong> adoption <strong>and</strong> propagation of <strong>energy</strong> efficient <strong>and</strong> <strong>environmental</strong>ly sound technologies.<br />

Three <strong>energy</strong> <strong>in</strong>tensive <strong>and</strong> <strong>environmental</strong>ly pollut<strong>in</strong>g <strong>in</strong>dustrial sub-sectors (cement, iron &<br />

steel, <strong>and</strong> pulp & paper) <strong>and</strong> four Asian countries of vary<strong>in</strong>g sizes, political systems <strong>and</strong><br />

stages of development (Ch<strong>in</strong>a, India, Philipp<strong>in</strong>es, Sri Lanka) were selected <strong>in</strong> <strong>the</strong> framework<br />

of this study. To enhance <strong>in</strong>-country capacity build<strong>in</strong>g <strong>in</strong> <strong>the</strong> subject matter, collaboration<br />

was sought from reputed national <strong>in</strong>stitutes who nom<strong>in</strong>ated experts to actively participate <strong>in</strong><br />

<strong>the</strong> execution of <strong>the</strong> project.<br />

The activities undertaken <strong>in</strong> <strong>the</strong> first phase of <strong>the</strong> project were <strong>the</strong> follow<strong>in</strong>g:<br />

- Evaluation of <strong>the</strong> status of technologies <strong>in</strong> selected <strong>energy</strong> <strong>in</strong>tensive <strong>and</strong><br />

<strong>environmental</strong>ly pollut<strong>in</strong>g <strong>in</strong>dustries;<br />

- Identification of potential areas for <strong>energy</strong> conservation <strong>and</strong> pollution abatement <strong>in</strong><br />

<strong>the</strong>se <strong>in</strong>dustries;<br />

- Analysis of <strong>the</strong> technological development of <strong>energy</strong> <strong>in</strong>tensive <strong>and</strong> pollut<strong>in</strong>g<br />

<strong>in</strong>dustries <strong>in</strong> relation with <strong>the</strong> national regulatory measures;<br />

- Identification of major barriers to <strong>efficiency</strong> improvements <strong>and</strong> pollution<br />

abatement <strong>in</strong> <strong>the</strong> <strong>in</strong>dustrial sector.<br />

Based on <strong>the</strong> <strong>in</strong>itial guidel<strong>in</strong>es prepared at AIT under <strong>the</strong> leadership of Dr. X. Chen,<br />

discussions were held with <strong>the</strong> experts from <strong>the</strong> national research <strong>in</strong>stitutes (NRIs) of <strong>the</strong><br />

four participat<strong>in</strong>g countries. The outcomes of <strong>the</strong>se meet<strong>in</strong>gs were used as a basis for <strong>the</strong><br />

preparation of country reports which were presented at two project workshops held at

Manila <strong>in</strong> May 1995 <strong>and</strong> at Bangkok <strong>in</strong> November 1995. On <strong>the</strong> basis of <strong>the</strong> reports<br />

submitted, cross-country comparison reports were prepared at AIT <strong>and</strong> additional relevant<br />

<strong>in</strong>formation was sought from <strong>the</strong> NRIs to bridge some of <strong>the</strong> gaps found <strong>in</strong> <strong>the</strong>ir respective<br />

reports. This is <strong>the</strong> third of <strong>the</strong> four volumes of documents which have resulted from this<br />

<strong>in</strong>teractive research work between AIT <strong>and</strong> <strong>the</strong> NRIs.<br />

This volume on “Technology, <strong>energy</strong> <strong>efficiency</strong> <strong>and</strong> <strong>environmental</strong> <strong>externalities</strong> <strong>in</strong> <strong>the</strong> pulp<br />

<strong>and</strong> paper <strong>in</strong>dustry” covers a description of <strong>the</strong> paper manufactur<strong>in</strong>g process, <strong>and</strong> <strong>the</strong> <strong>energy</strong><br />

<strong>and</strong> <strong>environmental</strong> aspects associated with it. Then <strong>the</strong>re is a cross-country comparison of<br />

<strong>the</strong> pulp <strong>and</strong> paper sector <strong>in</strong> <strong>the</strong> four countries, followed by <strong>in</strong>dividual country reports<br />

prepared by <strong>the</strong> four NRIs. The first five chapters were prepared by Dr. B. Mohanty <strong>and</strong> Dr.<br />

Uwe Stoll with <strong>the</strong> assistance of research associates figur<strong>in</strong>g <strong>in</strong> <strong>the</strong> Project Team.<br />

S<strong>in</strong>cere thanks are extended to all <strong>the</strong> members of <strong>the</strong> Project Team <strong>in</strong>clud<strong>in</strong>g <strong>the</strong> support<strong>in</strong>g<br />

staff, past <strong>and</strong> present, for <strong>the</strong>ir active participation <strong>and</strong> contribution to <strong>the</strong> project. The<br />

enthusiasm <strong>and</strong> dynamism of Dr. X. Chen dur<strong>in</strong>g <strong>the</strong> execution of <strong>the</strong> first phase <strong>and</strong> <strong>the</strong><br />

underst<strong>and</strong><strong>in</strong>g <strong>and</strong> leadership provided by Dr. C. Visvanathan <strong>in</strong> <strong>the</strong> crucial completion<br />

period of <strong>the</strong> project are acknowledged here. The project would have never seen <strong>the</strong> light of<br />

<strong>the</strong> day without <strong>the</strong> support of Sida. F<strong>in</strong>ally, appreciations are due to two <strong>in</strong>dividuals who<br />

have actually conceived <strong>the</strong> Asian Regional Research Programme on Energy, Environment<br />

<strong>and</strong> Climate (ARRPEEC) <strong>and</strong> provided constant support <strong>and</strong> encouragement to this specific<br />

project under <strong>the</strong> overall program: Dr. M.R. Bhagawan, Senior Research Adviser at Sida, <strong>and</strong><br />

Dr. S.C. Bhattacharya, Professor at AIT.<br />

Brahman<strong>and</strong> Mohanty<br />

Asian Institute of Technology<br />

June, 1997

PROJECT TEAM<br />

Faculty Members (Asian Institute of Technology - School of Environment,<br />

Resources <strong>and</strong> Development)<br />

- Dr. Xavier Chen, Energy Program (Until February 1996)<br />

- Dr. Brahman<strong>and</strong> Mohanty, Energy Program<br />

- Dr. Uwe Stoll, Environmental Eng<strong>in</strong>eer<strong>in</strong>g Program (Until January 1996)<br />

- Dr. C. Visvanathan, Environmental Eng<strong>in</strong>eer<strong>in</strong>g Program (From January 1996)<br />

Research Associates (Asian Institute of Technology - School of Environment,<br />

Resources <strong>and</strong> Development)<br />

- Ms. Nahid Am<strong>in</strong><br />

- Ms. Lilita B. Bacareza<br />

- Mr. Z. Kh<strong>and</strong>kar<br />

- Mr. Aung Na<strong>in</strong>g Oo<br />

- Mr. K. Parameshwaran<br />

National Research Institutes<br />

- Institute for Techno-Economics <strong>and</strong> Energy System Analysis, Ts<strong>in</strong>ghua<br />

University, Beij<strong>in</strong>g, Ch<strong>in</strong>a (Prof. Qiu Daxiong)<br />

- Energy Management Centre, M<strong>in</strong>istry of Power, New Delhi, India (Mr. S.<br />

Ramaswamy)<br />

- Department of Energy, Manila, Philipp<strong>in</strong>es (Mr. C.T. Tupas)<br />

- Energy Conservation Fund, M<strong>in</strong>istry of Irrigation, Power <strong>and</strong> Energy, Colombo,<br />

Sri Lanka (Mr. U. Daranagama)<br />

Research Fellows<br />

- Dr. Wu Xiaobo, School of Management, Zhejiang University, Ch<strong>in</strong>a (January-<br />

June 1996)<br />

- Ms. Wang Yanjia, Ts<strong>in</strong>ghua University, Ch<strong>in</strong>a (May-November 1996)<br />

- Mr. Anil Kumar Aneja, Thapar Corporate R&D Centre, India (May-November<br />

1996)<br />

- Ms. Marisol Portal, National Power Corporation, Philipp<strong>in</strong>es (May-November<br />

1996)<br />

- Mr. Gam<strong>in</strong>i Senanayake, Industrial Services Bureau of North Western Prov<strong>in</strong>ce,<br />

Sri Lanka (May-November 1996)

Table of Contents<br />

1. GENERAL.................................................................................................................................. 1<br />

2. PROCESS DESCRIPTION ...................................................................................................... 2<br />

2.1 CEMENT KILN ....................................................................................................................... 4<br />

2.2 CEMENT KILN PROCESSES .................................................................................................... 5<br />

2.2.1 Wet Process................................................................................................................. 5<br />

2.2.2 Semi-wet Processes ..................................................................................................... 7<br />

2.2.3 Semi-dry Process......................................................................................................... 7<br />

2.2.4 Dry Process................................................................................................................. 8<br />

3. ENERGY ISSSUES IN THE CEMENT INDUSTRY .......................................................... 10<br />

3.1 TYPICAL ENERGY CONSUMPTION PATTERNS ..................................................................... 10<br />

3.2 ENERGY EFFICIENCY MEASURES........................................................................................ 13<br />

3.2.1 Short Term Measures ................................................................................................ 13<br />

3.2.2 Medium Term Measures............................................................................................ 14<br />

3.2.2.1 Measures on Processed Materials <strong>and</strong> Products ....................................................... 14<br />

3.2.2.2 Changes <strong>and</strong> Modifications <strong>in</strong> Sub-Processes .......................................................... 14<br />

3.2.2.3 Recovery of Waste Heat........................................................................................... 16<br />

3.2.3 Long Term Measures................................................................................................. 17<br />

3.2.3.1 Conversion from Wet to Dry Process....................................................................... 17<br />

3.2.3.2 Cogeneration ............................................................................................................ 18<br />

3.2.3.3 Computer-Controlled System ................................................................................... 18<br />

3.3 NEW ENERGY EFFICIENT TECHNOLOGIES FOR CEMENT MANUFACTURING ...................... 18<br />

3.3.1 Suspension Preheat<strong>in</strong>g Technology .......................................................................... 20<br />

3.3.2 Suspension Preheat<strong>in</strong>g/Precalc<strong>in</strong>ation Technology.................................................. 20<br />

3.4 CONCLUDING REMARKS ..................................................................................................... 21<br />

4. ENVIRONMENTAL POLLUTION AND MANAGEMENT.............................................. 22<br />

4.1 SOURCES AND CHARACTERISTICS OF POLLUTANTS ........................................................... 22<br />

4.1.1 Water Pollution ......................................................................................................... 22<br />

4.1.2 Air Pollution.............................................................................................................. 22<br />

4.1.2.1 Particulates ............................................................................................................... 23<br />

4.1.2.2 Gaseous Substances.................................................................................................. 26<br />

4.1.3 Solid Waste................................................................................................................ 26<br />

4.2 CURRENT POLLUTION ABATEMENT STRATEGY AND TECHNOLOGIES ............................... 26<br />

4.2.1 Air Pollution Control ................................................................................................ 26<br />

4.2.1.1 Dust Collect<strong>in</strong>g Devices ........................................................................................... 26<br />

4.2.1.2 Gaseous Emission Control........................................................................................ 29<br />

4.2.2 Water Pollution Control............................................................................................ 29<br />

4.2.3 Solid Waste Disposal................................................................................................. 30<br />

4.2.3.1 L<strong>and</strong>fill ..................................................................................................................... 30<br />

4.3 OTHER ENVIRONMENTAL CONSIDERATIONS IN CEMENT INDUSTRY ................................. 30<br />

4.3.1 Noise Pollution.......................................................................................................... 31<br />

4.3.2 Reduction of Ground Vibrations ............................................................................... 32<br />

4.3.3 Raw Materials Resources <strong>and</strong> Site Restoration ........................................................ 32<br />

4.3.4 Utilization of Waste Materials as Raw Material <strong>and</strong> Fuel <strong>in</strong> Cement Industry........ 32<br />

4.4 CONCLUDING REMARKS ..................................................................................................... 35<br />

5. CROSS-COUNTRY COMPARISON OF THE CEMENT SECTOR ................................ 36<br />

5.1 INTRODUCTION ................................................................................................................... 36<br />

5.2 OVERVIEW OF THE INDUSTRY............................................................................................. 36<br />

5.2.1 Role <strong>in</strong> National Economy ........................................................................................ 36<br />

5.2.2 Share <strong>in</strong> Total Energy Consumption ......................................................................... 36<br />

5.2.3 Trends of Production................................................................................................. 37<br />

5.2.4 Mills <strong>and</strong> Capacities ................................................................................................. 38<br />

i

5.3 CHARACTERISTICS OF THE PARAMETERS AFFECTING ENERGY EFFICIENCY...................... 40<br />

5.3.1 Process Mix............................................................................................................... 42<br />

5.3.2 Average Kiln Size ...................................................................................................... 42<br />

5.3.3 Energy Consumption by Type ................................................................................... 43<br />

5.3.4 Awareness on Energy Conservation ......................................................................... 43<br />

5.4 CHARACTERISTICS OF THE PARAMETERS AFFECTING POLLUTION ABATEMENT MEASURES44<br />

5.4.1 Causes for <strong>the</strong> Pollution Problems ........................................................................... 45<br />

5.4.2 Current Pollution Control Strategies........................................................................ 45<br />

5.4.2.1 Pollution Control Strategies <strong>in</strong> Ch<strong>in</strong>a....................................................................... 45<br />

5.4.2.2 Pollution Control Strategies <strong>in</strong> India ........................................................................ 45<br />

5.4.2.3 Pollution Control Strategies <strong>in</strong> Philipp<strong>in</strong>es............................................................... 46<br />

5.4.2.4 Pollution Control Strategies <strong>in</strong> Sri Lanka................................................................. 46<br />

5.4.3 Comparison of Effluent <strong>and</strong> Emission Characteristics ............................................. 46<br />

5.5 POTENTIAL FOR ENERGY EFFICIENCY IMPROVEMENTS...................................................... 48<br />

5.5.1 Measures on Structure of <strong>the</strong> Industry ...................................................................... 48<br />

5.5.2 Potential of Energy Conservation Measures ............................................................ 48<br />

5.6 POTENTIAL FOR POLLUTION ABATEMENT.......................................................................... 49<br />

5.7 CONCLUSION....................................................................................................................... 50<br />

6. PROFILE OF IRON AND STEEL INDUSTRY IN ASIAN INDUSTRIALIZING<br />

COUNTRIES........................................................................................................................... 52<br />

6.1 COUNTRY REPORT: CHINA.................................................................................................. 52<br />

6.1.1 Introduction............................................................................................................... 52<br />

6.1.2 Technological Trajectory of Ch<strong>in</strong>a’s Cement Industry............................................. 52<br />

6.1.2.1 Higher Growth Rate of Production........................................................................... 54<br />

6.1.2.2 Rapid Increase of Small Size Cement Plants............................................................ 54<br />

6.1.2.3 Production Satisfies <strong>the</strong> Internal Dem<strong>and</strong> ................................................................ 54<br />

6.1.2.4 Better Production Quality <strong>and</strong> Low Energy Intensity .............................................. 54<br />

6.1.2.5 Coal as <strong>the</strong> Ma<strong>in</strong> Fuel............................................................................................... 56<br />

6.1.3 Evolution of Energy Efficiency <strong>in</strong> <strong>the</strong> Cement Industry ............................................ 58<br />

6.1.4 Environmental Externalities of Technological Development <strong>in</strong> <strong>the</strong> Cement Industry60<br />

6.1.5 Potential for Energy Efficiency Improvement <strong>and</strong> Pollution Abatement through<br />

Technological Change............................................................................................. 66<br />

6.1.6 Status of Application of New Technologies for Energy Efficiency Improvement <strong>and</strong><br />

Pollution Abatement ................................................................................................ 69<br />

6.1.7 Conclusions............................................................................................................... 71<br />

6.2 COUNTRY REPORT: INDIA................................................................................................... 73<br />

6.2.1 Introduction............................................................................................................... 73<br />

6.2.2 Technological Trajectory of India’s Cement Industry .............................................. 73<br />

6.2.2.1 Current Scenario....................................................................................................... 73<br />

6.2.2.2 Structure of <strong>the</strong> Cement Industry.............................................................................. 75<br />

6.2.3 Evolution of Energy Efficiency <strong>in</strong> <strong>the</strong> Cement Industry of India............................... 75<br />

6.2.3.1 Process Technology Profile...................................................................................... 77<br />

6.2.3.2 Plant Size.................................................................................................................. 77<br />

6.2.3.3 Thermal Energy Consumption.................................................................................. 78<br />

6.2.3.4 Electrical Energy Consumption................................................................................ 78<br />

6.2.3.5 Domestic Manufacture of Cement Mach<strong>in</strong>ery & Equipment ................................... 79<br />

6.2.4 Environmental Externalities...................................................................................... 84<br />

6.2.5 Status of Application of New Technologies............................................................... 85<br />

6.2.5.1 Status of <strong>the</strong> Development of Technology <strong>in</strong> India.................................................. 85<br />

6.2.5.2 Particulate Pollution <strong>and</strong> Abatement ........................................................................ 88<br />

6.2.5.3 Status of Research <strong>and</strong> Development ....................................................................... 93<br />

6.3 COUNTRY REPORT: PHILIPPINES......................................................................................... 94<br />

6.3.1 Introduction............................................................................................................... 94<br />

6.3.2 Technological Trajectory of <strong>the</strong> Philipp<strong>in</strong>e Cement Industry................................... 94<br />

6.3.2.1 Production Capacity ................................................................................................. 94<br />

ii

6.3.2.2 Plant Development ................................................................................................... 95<br />

6.3.3 Evolution of Energy Efficiency <strong>in</strong> <strong>the</strong> Philipp<strong>in</strong>e Cement Industry........................... 96<br />

6.3.4 Environmental Externalities of <strong>the</strong> Cement Industry <strong>in</strong> <strong>the</strong> Philipp<strong>in</strong>es ................... 98<br />

6.3.4.1 Environmental St<strong>and</strong>ards for Pollution Control <strong>and</strong> Abatement.............................. 98<br />

6.3.4.2 Pollution Control Equipment.................................................................................... 99<br />

6.3.5 Potential for Energy Efficiency Improvement <strong>and</strong> Pollution Abatement through<br />

Technological Change............................................................................................. 99<br />

6.3.6 Status of Application of New Technologies............................................................. 101<br />

6.3.7 Conclud<strong>in</strong>g Remarks ............................................................................................... 101<br />

BIBLIOGRAPHY ...................................................................................................................... 102<br />

iii

General 1<br />

1. GENERAL<br />

Rapid <strong>in</strong>dustrialization <strong>and</strong> <strong>in</strong>frastructure development <strong>in</strong> Asian develop<strong>in</strong>g countries has<br />

led to higher cement consumption, <strong>and</strong> eventually <strong>in</strong>creased production requirement.<br />

Though <strong>the</strong> production <strong>in</strong>creased ma<strong>in</strong>ly due to extended plant capacities <strong>and</strong> <strong>in</strong>troduction<br />

of new factories, little attention was paid to efficient <strong>energy</strong> utilization <strong>and</strong> <strong>environmental</strong><br />

pollution control <strong>in</strong> <strong>the</strong> cement <strong>in</strong>dustry of Asian countries.<br />

Cement is a highly <strong>energy</strong> <strong>in</strong>tensive product. In a cement factory, <strong>the</strong> <strong>energy</strong> bill normally<br />

accounts for 20-25% of <strong>the</strong> total production cost. The major <strong>energy</strong> consum<strong>in</strong>g areas <strong>in</strong><br />

cement <strong>in</strong>dustry are <strong>the</strong> high-temperature processes; almost 55-85% of <strong>the</strong> <strong>energy</strong> <strong>in</strong>put of<br />

<strong>the</strong> f<strong>in</strong>al product is consumed <strong>in</strong> <strong>the</strong> high-temperature kiln. Advanced technologies for<br />

waste heat recovery <strong>and</strong> rationalization of <strong>energy</strong> use could offer significant <strong>energy</strong> sav<strong>in</strong>g<br />

opportunities <strong>in</strong> cement <strong>in</strong>dustry which is ever explod<strong>in</strong>g due to <strong>the</strong> rapid global<br />

<strong>in</strong>frastructure development, especially <strong>in</strong> develop<strong>in</strong>g countries.<br />

This document addresses <strong>the</strong> cement production technologies <strong>in</strong> use, various measures for<br />

efficient utilization of <strong>energy</strong>, major sources of pollution, <strong>and</strong> <strong>the</strong> techniques <strong>and</strong> practices<br />

<strong>in</strong> vogue to abate pollution <strong>in</strong> <strong>the</strong> cement <strong>in</strong>dustry to <strong>the</strong> best possible extent. It fur<strong>the</strong>r<br />

discusses about o<strong>the</strong>r <strong>environmental</strong> problems such as noise pollution, ground vibration<br />

etc., which are serious concerns for <strong>the</strong> <strong>environmental</strong>ists <strong>in</strong> developed countries, as well as<br />

<strong>the</strong> possibilities of utilization of waste from o<strong>the</strong>r <strong>in</strong>dustries by <strong>the</strong> cement <strong>in</strong>dustry. F<strong>in</strong>ally,<br />

country reports on <strong>the</strong> cement <strong>in</strong>dustry for four Asian develop<strong>in</strong>g countries, namely, P.R.<br />

Ch<strong>in</strong>a, India, <strong>the</strong> Philipp<strong>in</strong>es <strong>and</strong> Sri Lanka, which are preceded by a cross-country<br />

comparison of <strong>the</strong> <strong>in</strong>dustry.

2 Technology, Energy Efficiency <strong>and</strong> Environmental Externalities of <strong>the</strong> Cement Industry<br />

2. PROCESS DESCRIPTION<br />

The pr<strong>in</strong>cipal raw materials for cement manufactur<strong>in</strong>g are:<br />

- limestone (quarried from <strong>the</strong> m<strong>in</strong>e, near which <strong>the</strong> plant is usually located),<br />

- silica <strong>and</strong> alum<strong>in</strong>a from clay, shale or s<strong>and</strong>, <strong>and</strong><br />

- iron from iron ore or steel mill scale.<br />

The major processes <strong>in</strong>volved <strong>in</strong> production are:<br />

- excavation of limestone (quarry<strong>in</strong>g)<br />

- crush<strong>in</strong>g of limestone<br />

- preparation of o<strong>the</strong>r raw materials<br />

- gr<strong>in</strong>d<strong>in</strong>g of raw materials <strong>in</strong> <strong>the</strong> raw mill<br />

- storage of raw meal <strong>in</strong> a raw meal silo<br />

- blend<strong>in</strong>g of limestone powder to control CaCO3 percentage<br />

- burn<strong>in</strong>g of raw meal to form cl<strong>in</strong>ker<br />

- gr<strong>in</strong>d<strong>in</strong>g <strong>the</strong> cl<strong>in</strong>ker with gypsum <strong>in</strong> cement mill<br />

- storage of cement <strong>in</strong> silo<br />

- pack<strong>in</strong>g <strong>and</strong> distribution of cement<br />

The kiln feed is prepared by proportion<strong>in</strong>g, gr<strong>in</strong>d<strong>in</strong>g <strong>and</strong> blend<strong>in</strong>g <strong>the</strong> raw materials <strong>in</strong>to a<br />

consistent <strong>and</strong> homogeneous composition so that, after mild heat<strong>in</strong>g to drive off any water<br />

<strong>and</strong> CO2 available <strong>in</strong> <strong>the</strong> limestone (CaCO3), one obta<strong>in</strong>s typically 64% calcium oxide<br />

(CaO), 22% silicon dioxide (SiO2), 3.5% alum<strong>in</strong>um oxide (Al2O3), <strong>and</strong> 3.0% iron ore (as<br />

Fe2O3) (Sell, 1992). These raw materials are processed at very high temperatures so <strong>the</strong>y<br />

react by solid-solid reactions to form cl<strong>in</strong>ker which consists of four major compounds as<br />

shown <strong>in</strong> Table 2.1. The exact proportions of <strong>the</strong>se f<strong>in</strong>al products determ<strong>in</strong>e <strong>the</strong> cement<br />

characteristics; for example, <strong>the</strong> harden<strong>in</strong>g time, <strong>the</strong> early strength <strong>and</strong> <strong>the</strong> f<strong>in</strong>al strength.<br />

Table 2.1. Portl<strong>and</strong> cement cl<strong>in</strong>ker compounds<br />

Chemical name M<strong>in</strong>eral<br />

phase<br />

name<br />

Chemical formula Cement<br />

chemists<br />

designation<br />

Percentage <strong>in</strong><br />

ord<strong>in</strong>ary<br />

cement<br />

Tricalcium Silicate Alite 3CaO.SiO2 C3S 45<br />

Diacalcium Silicate Belite 2CaO.SiO2 C2S 25<br />

Tricalcium Alum<strong>in</strong>ate Celite 3CaO.Al2O3 C3A 11<br />

Tetracalcium Alum<strong>in</strong>o-ferrite Iron 4CaO.Al2O3.Fe2O3 C4AF 8<br />

(Source: Dodson, 1990)<br />

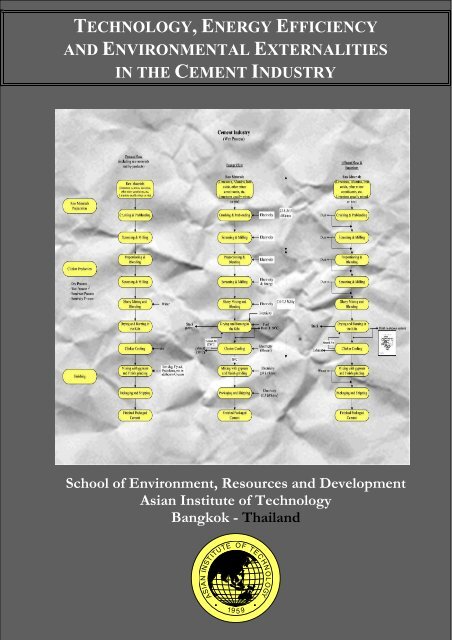

The ma<strong>in</strong> steps of <strong>the</strong> cement manufactur<strong>in</strong>g process are shown schematically <strong>in</strong> Figure<br />

2.1.

Process Description 3<br />

Fig. 2.1. Steps <strong>in</strong> <strong>the</strong> manufacture of Portl<strong>and</strong> cement

4 Technology, Energy Efficiency <strong>and</strong> Environmental Externalities of <strong>the</strong> Cement Industry<br />

The largest volume of raw material is CaCO3 or comparable materials (such as oyster shells<br />

<strong>in</strong> locations where appropriate). The CaCO3 as m<strong>in</strong>ed is often <strong>in</strong> chunks up to 750 mm <strong>in</strong><br />

diameter. These must be crushed to about 10 mm, <strong>and</strong> <strong>the</strong>n mixed with <strong>the</strong> s<strong>and</strong>, shale,<br />

<strong>and</strong> o<strong>the</strong>r <strong>in</strong>gredients for fur<strong>the</strong>r gr<strong>in</strong>d<strong>in</strong>g to about 60µm <strong>in</strong> diameter. Frequently, <strong>the</strong> <strong>in</strong>itial<br />

crush<strong>in</strong>g is done at <strong>the</strong> quarry, prior to transport to <strong>the</strong> cement plant. After gr<strong>in</strong>d<strong>in</strong>g,<br />

depend<strong>in</strong>g upon <strong>the</strong> exact process, water may be added. The mixture is <strong>the</strong>n taken to some<br />

high-temperature process<strong>in</strong>g unit known as rotary kiln for conversion to cement cl<strong>in</strong>ker.<br />

The cl<strong>in</strong>ker must be cooled before fur<strong>the</strong>r process<strong>in</strong>g. Then it is ei<strong>the</strong>r stored, sold or<br />

transported (to <strong>in</strong>dividual gr<strong>in</strong>d<strong>in</strong>g mills), or is ground at <strong>the</strong> plant with gypsum <strong>and</strong> o<strong>the</strong>r<br />

possible additives to a f<strong>in</strong>e powder of f<strong>in</strong>ished cement. The cement is ei<strong>the</strong>r packaged or<br />

sold <strong>in</strong> bulk to <strong>the</strong> distributors.<br />

2.1 Cement Kiln<br />

The Cement kilns are large; up to 230 m <strong>in</strong> length <strong>and</strong> 8 m <strong>in</strong> diameter; <strong>in</strong>cl<strong>in</strong>ed at an angle<br />

of three to six degrees, <strong>and</strong> l<strong>in</strong>ed with temperature-resistant refractory brick. They rotate at<br />

about 50 to 70 revolutions per hour <strong>in</strong> <strong>the</strong> older generation plants, <strong>and</strong> 170 to 180 <strong>in</strong> <strong>the</strong><br />

more modern ones. The feed material is <strong>in</strong>troduced at <strong>the</strong> elevated end <strong>and</strong> is moved<br />

slowly by <strong>the</strong> rotation of <strong>the</strong> kiln down towards <strong>the</strong> fir<strong>in</strong>g end, where heat is applied by a<br />

flame of coal, gas, oil or a comb<strong>in</strong>ation of <strong>the</strong>se fuels. Coal is most widely used as <strong>the</strong> kiln<br />

fuel nowadays.<br />

Several dist<strong>in</strong>ct <strong>the</strong>rmal zones exist <strong>in</strong> <strong>the</strong> kiln. At <strong>the</strong> elevated end where <strong>the</strong> feed is<br />

<strong>in</strong>troduced, is a dry<strong>in</strong>g <strong>and</strong> preheat<strong>in</strong>g zone <strong>in</strong> which <strong>the</strong> material reaches a temperature of<br />

about 800 o C. This is followed by <strong>the</strong> calc<strong>in</strong><strong>in</strong>g zone where carbon dioxide is driven off <strong>the</strong><br />

limestone, convert<strong>in</strong>g it to free lime at a material temperature close to 1000 o C. The<br />

chemical reaction tak<strong>in</strong>g place <strong>in</strong> this zone is as follows:<br />

CaCO3 ⇑ CaO + CO2<br />

By <strong>the</strong> time <strong>the</strong> calc<strong>in</strong>ation is complete, <strong>the</strong> free lime enters <strong>the</strong> <strong>in</strong>termediate zone where<br />

temperature prevails <strong>in</strong> <strong>the</strong> range of 1000 - 1200 o C <strong>and</strong> <strong>the</strong> basic oxide (CaO) reacts with<br />

silica (SiO2) <strong>and</strong> alum<strong>in</strong>a (Al2O3) as shown:<br />

Al2O3 + CaO ⇑ CaO.Al2O3 (mono-calcium alum<strong>in</strong>ate)<br />

2CaO + CaO.Al2O3 ⇑ 3CaO.Al2O3 (tri-calcium alum<strong>in</strong>ate)<br />

SiO2 + 2CaO ⇑ 2CaO.SiO2 (di-calicium silicate)<br />

2CaO + Fe2O3 ⇑ 2CaO.Fe2O3<br />

2CaO.Fe2O3 + 2CaO + Al2O3 ⇑ 4CaO.Al2O3.Fe2O3

Process Description 5<br />

Next is <strong>the</strong> s<strong>in</strong>ter<strong>in</strong>g zone where, at a temperature of about 1300 o C, s<strong>in</strong>ter<strong>in</strong>g of <strong>the</strong><br />

materials beg<strong>in</strong>s. While s<strong>in</strong>ter<strong>in</strong>g, di-calcium silicate gets saturated with <strong>the</strong> rema<strong>in</strong><strong>in</strong>g free<br />

lime <strong>and</strong> forms tri-calcium silicate.<br />

2CaO.SiO2 + CaO ⇑ 3CaO.SiO2 (tri-calcium silicate)<br />

By <strong>the</strong> time <strong>the</strong> materials reach <strong>the</strong> flame area, <strong>the</strong>y are white hot (1425 -1550 o C). In a<br />

semi-liquid state at this stage, <strong>the</strong>y acquire a greenish black color <strong>and</strong> form nodules about<br />

25 mm <strong>in</strong> diameter which, on cool<strong>in</strong>g, is referred to as cl<strong>in</strong>ker. After this extremely hot<br />

area, <strong>the</strong> temperature drops, <strong>and</strong> <strong>the</strong> cl<strong>in</strong>ker starts to cool. The materials <strong>the</strong>n f<strong>in</strong>ally drop<br />

out of <strong>the</strong> kiln onto a cooler, through which large volume of relatively cool air is passed.<br />

The air from <strong>the</strong> cooler, ra<strong>the</strong>r than be<strong>in</strong>g wasted, is channeled <strong>in</strong>to <strong>the</strong> kiln as combustion<br />

air for <strong>the</strong> flame. This air, <strong>in</strong> travers<strong>in</strong>g <strong>the</strong> kiln, becomes turbulent, <strong>and</strong> often picks up<br />

some of <strong>the</strong> f<strong>in</strong>er raw material particles which become entra<strong>in</strong>ed <strong>in</strong> <strong>the</strong> air stream. The air<br />

simultaneously transfers heat to <strong>the</strong> back end of <strong>the</strong> kiln. Before <strong>the</strong> air can exit <strong>the</strong> kiln, it<br />

is passed through a dense curta<strong>in</strong> of cha<strong>in</strong>s that serves two purposes:<br />

- removes some of <strong>the</strong> entra<strong>in</strong>ed dust, <strong>and</strong><br />

- acts as a mechanism for heat transfer <strong>in</strong> order to reta<strong>in</strong> heat as much as possible<br />

with<strong>in</strong> <strong>the</strong> kiln.<br />

The air, after leav<strong>in</strong>g <strong>the</strong> kiln, is ducted to an electrostatic precipitator for particulate<br />

removal, <strong>and</strong> <strong>the</strong>n to <strong>the</strong> stack. The cl<strong>in</strong>ker is <strong>the</strong>n conveyed to <strong>the</strong> f<strong>in</strong>ish-gr<strong>in</strong>d<strong>in</strong>g section<br />

where about five percent of gypsum is added to it. The mixture is f<strong>in</strong>ely ground <strong>in</strong> ball or<br />

tube mills, close-circuited with air separators, to give f<strong>in</strong>ished cement. The cement is<br />

conveyed to <strong>the</strong> storage silos, usually by pneumatic conveyors.<br />

2.2 Cement Kiln Processes<br />

There are four basic types of cement kilns currently <strong>in</strong> use: wet process, semi-wet process,<br />

semi-dry process, <strong>and</strong> dry process. Of <strong>the</strong>se, <strong>the</strong> dry process is <strong>the</strong> most <strong>energy</strong> efficient<br />

<strong>and</strong> most commonly used <strong>technology</strong> nowadays.<br />

2.2.1 Wet process<br />

Worldwide, a considerable proportion of cement cl<strong>in</strong>ker is still produced by <strong>the</strong> wet<br />

process where<strong>in</strong> <strong>the</strong> raw materials are prepared <strong>and</strong> mixed with <strong>the</strong> aid of water (30-40%)<br />

<strong>and</strong> fed <strong>in</strong>to <strong>the</strong> upper end of <strong>the</strong> kiln as a slurry. Wet process is particularly useful when<br />

<strong>the</strong> raw materials conta<strong>in</strong> a significant amount of moisture as quarried. This process has <strong>the</strong><br />

advantage of uniform feed blend<strong>in</strong>g, but requires more <strong>energy</strong> than <strong>the</strong> o<strong>the</strong>r types of kilns,<br />

s<strong>in</strong>ce <strong>the</strong> water must be evaporated dur<strong>in</strong>g <strong>the</strong> process. Similar process reactions as

6 Technology, Energy Efficiency <strong>and</strong> Environmental Externalities of <strong>the</strong> Cement Industry<br />

described <strong>in</strong> section 2.1 lead to <strong>the</strong> formation of cl<strong>in</strong>ker. A typical wet-process rotary kiln is<br />

shown <strong>in</strong> Figure 2.2.<br />

Fig. 2.2. Diagram of a typical wet procvess rotary kiln<br />

Fig. 2.3. Diagram of a typical preheater system

Process Description 7<br />

2.2.2 Semi-wet processes<br />

Semi-wet cement process<strong>in</strong>g employs grate-kiln methods (Figure 2.3). In <strong>the</strong> semi-wet<br />

cement manufactur<strong>in</strong>g process <strong>the</strong> raw materials prepared by wet process<strong>in</strong>g are first<br />

mechanically dewatered - preferably with filter presses - <strong>and</strong> <strong>the</strong>n fed <strong>in</strong> <strong>the</strong> form of<br />

nodules to a dry<strong>in</strong>g unit. This dry<strong>in</strong>g unit may be <strong>the</strong> third compartment of a travel<strong>in</strong>g grate<br />

preheater. Nowadays, a dispersion dryer or impact dryer is preferably <strong>in</strong>stalled ahead of <strong>the</strong><br />

preheater or precalc<strong>in</strong>er kiln. In cases where former wet kilns have been converted <strong>in</strong>to<br />

one-stage or two-stage preheater kilns on this pr<strong>in</strong>ciple, impact dryers have hi<strong>the</strong>rto been<br />

employed. Advantages of grate-kiln systems <strong>in</strong>clude:<br />

- a controlled feed rate<br />

- no flush<strong>in</strong>g of materials <strong>in</strong>to <strong>the</strong> kiln<br />

- no segregation of raw materials due to differential shapes <strong>and</strong> densities<br />

- avoidance of fluidization of <strong>the</strong> materials<br />

- m<strong>in</strong>imal dust<strong>in</strong>g<br />

- production of uniform cl<strong>in</strong>ker<br />

- low <strong>energy</strong> requirement (70% of that required for modern long wet kiln), <strong>and</strong><br />

- ability to use higher-alkali feeds than many o<strong>the</strong>r process<strong>in</strong>g techniques.<br />

2.2.3 Semi-dry process<br />

In <strong>the</strong> semi-dry process, nodules or pellets (approximately 12% water) formed from raw<br />

meal with <strong>the</strong> aid of water are used. The travel<strong>in</strong>g grate preheater kiln cont<strong>in</strong>ues to be<br />

available as a technically well developed pyro-process<strong>in</strong>g unit. Kilns of this type, however,<br />

suffer from some disadvantages <strong>in</strong>herent <strong>in</strong> <strong>the</strong> system, such as:<br />

- relatively high <strong>in</strong>itial cost <strong>and</strong> operat<strong>in</strong>g expenses associated with kiln outputs,<br />

- specific quality requirements of <strong>the</strong> raw materials (grate process requires nodules to<br />

be consistent <strong>in</strong> size <strong>and</strong> composition which is often very difficult to achieve),<br />

- relatively high overall heat consumption (only <strong>the</strong> exhaust air from <strong>the</strong> cooler is<br />

available for dry<strong>in</strong>g <strong>the</strong> materials dur<strong>in</strong>g gr<strong>in</strong>d<strong>in</strong>g),<br />

- restrictions as to <strong>the</strong> use of low-grade fuels, <strong>and</strong><br />

- <strong>in</strong>ability to apply precalc<strong>in</strong>ation.<br />

Because of <strong>the</strong>se drawbacks, this system has lost <strong>the</strong> weight it once possessed. However it<br />

is reported that several of <strong>the</strong> newer <strong>in</strong>stallations <strong>in</strong> <strong>the</strong> United States do employ grate-kiln<br />

methods (Sell, 1992). Depend<strong>in</strong>g upon <strong>the</strong> local conditions, <strong>in</strong> certa<strong>in</strong> situations, <strong>the</strong>y are<br />

deemed preferable to preheater systems.

8 Technology, Energy Efficiency <strong>and</strong> Environmental Externalities of <strong>the</strong> Cement Industry<br />

2.2.4 Dry process<br />

A long kiln similar to that used <strong>in</strong> <strong>the</strong> wet process can also be used for a dry process. Dry<br />

process consumes significantly less <strong>energy</strong> <strong>and</strong> can often h<strong>and</strong>le particulate emission<br />

problems more easily. Moreover, <strong>the</strong>re are dry process<strong>in</strong>g techniques far superior to <strong>the</strong> dry<br />

kiln which already consumes less <strong>energy</strong> than <strong>the</strong> wet process.<br />

Newer cement plants use <strong>the</strong> dry process <strong>in</strong> which <strong>the</strong> raw material is fed to <strong>the</strong> kiln as dry<br />

powder. In <strong>the</strong> most recently erected plants, preheater <strong>and</strong> precalc<strong>in</strong>er units have been<br />

added to improve <strong>the</strong> <strong>the</strong>rmal <strong>efficiency</strong> of <strong>the</strong> process by us<strong>in</strong>g hot kiln gases to pre-heat<br />

<strong>and</strong> pre-calc<strong>in</strong>e <strong>the</strong> feed before it enters <strong>the</strong> kiln. The preferable dry process<strong>in</strong>g method is<br />

by a suspension preheater system as shown <strong>in</strong> Figure 2.4. The f<strong>in</strong>ely ground dry raw<br />

materials are fed <strong>in</strong>to <strong>the</strong> preheater at <strong>the</strong> top, counter-current to <strong>the</strong> air flow. This air flow<br />

orig<strong>in</strong>ates <strong>in</strong> <strong>the</strong> cooler <strong>and</strong> thus has been heated by travers<strong>in</strong>g through <strong>the</strong> cooler <strong>and</strong> also<br />

a short rotary kiln section before be<strong>in</strong>g ducted to <strong>the</strong> preheater. Hence, it is sufficiently hot<br />

to not only preheat, but also partially calc<strong>in</strong>e <strong>the</strong> <strong>in</strong>com<strong>in</strong>g materials. The physical<br />

arrangement of a series of cyclones on <strong>the</strong> preheater is such that <strong>the</strong> hot air <strong>and</strong> <strong>the</strong> feed<br />

can have <strong>in</strong>timate contact <strong>in</strong> a series of stages for maximum heat transfer <strong>and</strong> optimum<br />

<strong>efficiency</strong>. The addition of a flash calc<strong>in</strong>er, a stationary furnace <strong>in</strong>terposed between <strong>the</strong> rotary<br />

kiln <strong>and</strong> <strong>the</strong> suspension preheater, <strong>in</strong>creases <strong>the</strong> amount of calc<strong>in</strong>ation that occurs with<strong>in</strong><br />

<strong>the</strong> preheater, thus <strong>in</strong>creas<strong>in</strong>g <strong>the</strong> potential capacity of <strong>the</strong> rotary kiln. When <strong>the</strong> raw mill<br />

has passed all <strong>the</strong> stages, it is heated up to 800°C <strong>and</strong> is extensively calc<strong>in</strong>ed before enter<strong>in</strong>g<br />

<strong>the</strong> kiln. The temperature of <strong>the</strong> hot gas drops to 300°C from 1000°C.<br />

The hot particulate feed, after pass<strong>in</strong>g through <strong>the</strong> preheater <strong>and</strong> <strong>the</strong> flash calc<strong>in</strong>er, enters a<br />

short rotary kiln where it undergoes cl<strong>in</strong>kerization. The rational beh<strong>in</strong>d accomplish<strong>in</strong>g only<br />

this last stage of <strong>the</strong> process<strong>in</strong>g with<strong>in</strong> <strong>the</strong> kiln is better economy, particularly <strong>in</strong> terms of<br />

<strong>energy</strong> conservation. In addition, most of <strong>the</strong> dust generated can be reta<strong>in</strong>ed with<strong>in</strong> <strong>the</strong><br />

preheater, cutt<strong>in</strong>g back <strong>the</strong> dust problems to a great extent.<br />

Shaft kilns (Figure 2.5) constitute ano<strong>the</strong>r dry process<strong>in</strong>g technique, used to some extent <strong>in</strong><br />

Europe. Shaft kilns have lower <strong>the</strong>rmal <strong>and</strong> power requirements per ton of cl<strong>in</strong>ker<br />

produced than those of rotary kilns <strong>and</strong> are comparable to <strong>the</strong> preheater systems. Their<br />

major disadvantages are <strong>the</strong> small capacity <strong>and</strong> a less uniform product, primarily as a result<br />

of tunnel<strong>in</strong>g of <strong>the</strong> gases through <strong>the</strong> load.

Process Description 9<br />

Fig. 2.4 Diagram of a shaft kiln<br />

Fig. 2.5 Diagram of grate-kiln process

10 Technology, Energy Efficiency <strong>and</strong> Environmental Externalities of <strong>the</strong> Cement Industry<br />

3. ENERGY ISSSUES IN THE CEMENT INDUSTRY<br />

3.1 Typical Energy Consumption Patterns<br />

The cement manufactur<strong>in</strong>g processes consume two types of primary <strong>energy</strong>: <strong>the</strong>rmal<br />

<strong>energy</strong> provided by coal, natural gas or oil, <strong>and</strong> mechanical <strong>energy</strong> converted from<br />

electricity. The <strong>the</strong>rmal <strong>energy</strong> accounts for about 87% of <strong>the</strong> total primary <strong>energy</strong> <strong>and</strong> is<br />

ma<strong>in</strong>ly used <strong>in</strong> cl<strong>in</strong>ker production. Typical <strong>the</strong>rmal <strong>energy</strong> <strong>and</strong> electricity consumptions of<br />

cement manufactur<strong>in</strong>g processes are given <strong>in</strong> Table 3.1.<br />

Table 3.1. Specific <strong>the</strong>rmal <strong>energy</strong> <strong>and</strong> electricity consumption for cement<br />

Process Thermal Energy (GJ/ton) Electricity (kWh/ton)<br />

Wet Process 5.02-5.43 70-125<br />

Semi-wet Process 3.15-3.86 70-125<br />

Dry Process 2.88-3.40 110-125<br />

Semi-dry Process 3.10-3.50 110-125<br />

The secondary <strong>energy</strong> sources used <strong>in</strong> cement production are kiln exhaust gas <strong>and</strong> hot air<br />

from cl<strong>in</strong>ker cooler. A process flow diagram show<strong>in</strong>g <strong>the</strong> various sources of <strong>energy</strong> used <strong>in</strong><br />

<strong>the</strong> cement manufactur<strong>in</strong>g process is given <strong>in</strong> Figures 3.1a & 3.1b.<br />

Secondary heat conta<strong>in</strong>ed <strong>in</strong> <strong>the</strong> hot kiln exhaust gas is utilized primarily <strong>in</strong> pre-dry<strong>in</strong>g <strong>and</strong><br />

preheat<strong>in</strong>g <strong>the</strong> raw materials before <strong>the</strong>ir <strong>in</strong>troduction <strong>in</strong>to <strong>the</strong> kiln <strong>and</strong> raw mill. The waste<br />

heat conta<strong>in</strong>ed <strong>in</strong> <strong>the</strong> exhaust air from <strong>the</strong> cl<strong>in</strong>ker cooler too serves to preheat combustion<br />

air <strong>and</strong> also to dry <strong>and</strong> preheat <strong>the</strong> raw materials before <strong>the</strong>y enter <strong>the</strong> raw mill <strong>and</strong> kiln.<br />

The two most <strong>energy</strong>-<strong>in</strong>tensive phases <strong>in</strong> cement manufactur<strong>in</strong>g are cl<strong>in</strong>ker production <strong>and</strong><br />

gr<strong>in</strong>d<strong>in</strong>g. The cl<strong>in</strong>ker production process consumes ma<strong>in</strong>ly <strong>the</strong>rmal <strong>energy</strong> <strong>in</strong> <strong>the</strong> form of<br />

coal, oil or gas, while gr<strong>in</strong>d<strong>in</strong>g consumes ma<strong>in</strong>ly electrical <strong>energy</strong>.<br />

Typical specific <strong>energy</strong> consumption values for different cement manufactur<strong>in</strong>g processes<br />

are shown <strong>in</strong> Figure 3.2.<br />

For <strong>the</strong> best available <strong>technology</strong> of dry process production with cyclone preheater <strong>and</strong><br />

precalc<strong>in</strong>er, <strong>the</strong> specific <strong>energy</strong> consumption is 3.05 MJ/kg of cl<strong>in</strong>ker. However, some<br />

cement mills <strong>in</strong> develop<strong>in</strong>g countries are still utiliz<strong>in</strong>g <strong>the</strong> wet process with obsolete<br />

technologies <strong>and</strong> consum<strong>in</strong>g up to 8 MJ/kg of cl<strong>in</strong>ker.

Energy Issues <strong>in</strong> <strong>the</strong> Cement Industry 11<br />

Fig. 3.1a. Flow diagram s of a typical dry process cement plant<br />

* T he dotte d l<strong>in</strong> e re pres ents We t Pro ces s on ly

12 Technology, Energy Efficiency <strong>and</strong> Environmental Externalities of <strong>the</strong> Cement Industry<br />

Fig 3.1b.Flow diagram of a typical wet process cement plant<br />

* Th e dot ted l <strong>in</strong>e re pres ents Wet Proc ess only

Energy Issues <strong>in</strong> <strong>the</strong> Cement Industry 13<br />

MJ/kg of Cement<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

7.5%<br />

6.5%<br />

82%<br />

4%<br />

10.1%<br />

8.9%<br />

75.5%<br />

5.5%<br />

11%<br />

11%<br />

55%<br />

23%<br />

Wet process Semi-wet process Dry process Semi-dry process<br />

Raw materials preparation Cl<strong>in</strong>ker production F<strong>in</strong>ish<strong>in</strong>g O<strong>the</strong>rs<br />

10.5%<br />

9.3%<br />

60%<br />

20.2%<br />

Figure 3.2. Typical specific <strong>energy</strong> consumption for cement manufactur<strong>in</strong>g<br />

3.2 Energy Efficiency Measures<br />

The utilization of as much secondary <strong>energy</strong> sources as possible <strong>and</strong> <strong>the</strong> reduction of <strong>the</strong><br />

primary purchased <strong>energy</strong> are <strong>the</strong> objectives of <strong>energy</strong> conservation measures <strong>in</strong> <strong>the</strong> cement<br />

<strong>in</strong>dustry. These measures can be classified accord<strong>in</strong>g to <strong>the</strong> level of <strong>energy</strong> sav<strong>in</strong>gs <strong>and</strong><br />

types of <strong>in</strong>vestments <strong>in</strong>volved as follows.<br />

3.2.1 Short term measures<br />

Some of <strong>the</strong> basic <strong>energy</strong> sav<strong>in</strong>g measures that can be readily implemented <strong>in</strong> <strong>the</strong> short<br />

term without major <strong>in</strong>vestments are:<br />

- <strong>in</strong>spection to encourage conservation activity<br />

- tra<strong>in</strong><strong>in</strong>g program for operat<strong>in</strong>g <strong>energy</strong> <strong>in</strong>tensive equipment such as crusher,<br />

gr<strong>in</strong>d<strong>in</strong>g mill, pneumatic separator, vibrat<strong>in</strong>g screen, etc.<br />

- replacement of worn-out parts of crusher <strong>and</strong> gr<strong>in</strong>d<strong>in</strong>g mach<strong>in</strong>es<br />

- controll<strong>in</strong>g <strong>the</strong> slurry water at optimum level (for wet process)<br />

( reduction of moisture content by 5% can save 338 MJ/ton of cl<strong>in</strong>ker)<br />

- controll<strong>in</strong>g <strong>the</strong> combustion air<br />

(10% reduction <strong>in</strong> excess air can save 34-85 MJ/ton of cl<strong>in</strong>ker)<br />

- controll<strong>in</strong>g <strong>the</strong> composition of raw materials<br />

(<strong>the</strong> fluctuation encountered <strong>in</strong> <strong>the</strong> composition of <strong>the</strong> raw materials fed to a<br />

cement kiln is generally compensated by an over-bak<strong>in</strong>g which leads to <strong>energy</strong><br />

losses)<br />

- plugg<strong>in</strong>g of all air leakage

14 Technology, Energy Efficiency <strong>and</strong> Environmental Externalities of <strong>the</strong> Cement Industry<br />

- ensur<strong>in</strong>g <strong>the</strong> un<strong>in</strong>terrupted operation of <strong>the</strong> kiln<br />

- power factor improvement of electric motors<br />

- turn<strong>in</strong>g off motors <strong>and</strong> heaters when<br />

not <strong>in</strong> use.<br />

- <strong>in</strong>sulation enhancement of kiln<br />

Energy sav<strong>in</strong>gs of <strong>the</strong> order of 10-15%<br />

can be achieved by adopt<strong>in</strong>g <strong>the</strong>se short term<br />

measures<br />

<strong>in</strong> develop<strong>in</strong>g countries.<br />

3.2.2 Medium term measures<br />

These <strong>in</strong>clude switch<strong>in</strong>g to new <strong>and</strong> more efficient technologies<br />

as well as recovery of<br />

materials<br />

<strong>and</strong> waste heat with moderate capital expenditures.<br />

3.2.2.1 Measures on processed materials <strong>and</strong> products<br />

(i) Installation of dust collection system<br />

The high velocity gases pass<strong>in</strong>g through <strong>the</strong> kiln carry along a large portion of dust, thus<br />

los<strong>in</strong>g materials as well as <strong>energy</strong> due to <strong>the</strong> extra raw material that has to be processed for<br />

<strong>the</strong> same amount of output. Each percentage of material loss will consume additional<br />

<strong>energy</strong> of about 42 MJ/ton of cl<strong>in</strong>ker. Larger size dust particles can be removed by<br />

cyclones <strong>and</strong> smaller<br />

size dust can be removed by electrostatic precipitators, bag filters or<br />

wet<br />

scrubbers.<br />

(ii) Diversification of cement products<br />

The blend<strong>in</strong>g of certa<strong>in</strong> materials like granulated slag, fly ash <strong>and</strong> pozzolans with <strong>the</strong><br />

cement makes it possible to produce more cement from <strong>the</strong> same amount of cl<strong>in</strong>ker, <strong>and</strong> as<br />

a result, <strong>the</strong> fuel consumption per ton of cement can be reduced. About 20% of cl<strong>in</strong>ker can<br />

be replaced by fly ash <strong>and</strong> up to 25% by blast furnace slag without<br />

chang<strong>in</strong>g <strong>the</strong> character<br />

of<br />

<strong>the</strong> ord<strong>in</strong>ary Portl<strong>and</strong> cement as a general purpose cement.<br />

3.2.2.2 Changes <strong>and</strong> modifications <strong>in</strong> sub-processes<br />

(i) Reduction of water content of slurry<br />

The water content of slurry can be reduced by any <strong>the</strong> follow<strong>in</strong>g means:<br />

- addition of chemicals of slurry th<strong>in</strong>ners<br />

- us<strong>in</strong>g proper filters so that slurry is dewatered mechanically<br />

- preheat<strong>in</strong>g <strong>the</strong> slurry by utiliz<strong>in</strong>g <strong>the</strong> secondary <strong>energy</strong> sources<br />

(each percentage of water reduction <strong>in</strong> <strong>the</strong> slurry will <strong>in</strong>crease <strong>the</strong> kiln capacity<br />

by<br />

about 1.5% <strong>and</strong> reduce <strong>the</strong> <strong>energy</strong> consumption by 68 MJ/ton of cl<strong>in</strong>ker)

Energy Issues <strong>in</strong> <strong>the</strong> Cement Industry 15<br />

(ii) Installation of dual fir<strong>in</strong>g system<br />

The reaction at <strong>the</strong> kiln takes place at two stages, firstly at a lower temperature range of<br />

800-900°C (which is called calc<strong>in</strong>ation) <strong>and</strong> <strong>the</strong>n at a higher temperature range of 1300-<br />

1500°C (termed as burn<strong>in</strong>g). Low grade fuels can be used <strong>in</strong> <strong>the</strong> lower temperature range<br />

combustion so that fuels with higher calorific values can be replaced. Depend<strong>in</strong>g on <strong>the</strong><br />

system,<br />

20-25% of <strong>the</strong> total fuel can be replaced by low grade fuel be<strong>in</strong>g utilized for <strong>the</strong><br />

calc<strong>in</strong>ation phase.<br />

(iii) Change<br />

<strong>in</strong> cl<strong>in</strong>ker gr<strong>in</strong>d<strong>in</strong>g system: vertical roller mills to replace tube <strong>and</strong> ball<br />

mills<br />

Upgradation of equipment such as jaw-crusher to gyratory crusher, ball mill to vertical<br />

roller<br />

mill (VRM), worm gears to helical <strong>and</strong> spiral gears, etc., can <strong>in</strong>crease<br />

<strong>the</strong> <strong>efficiency</strong> of<br />

power transmission system <strong>and</strong> reduce specific power consumption.<br />

In roller mills, raw materials are dried dur<strong>in</strong>g pulverization us<strong>in</strong>g waste heat from <strong>the</strong> kiln<br />

<strong>and</strong> size reduction is effected by roller or comparable gr<strong>in</strong>d<strong>in</strong>g elements travel<strong>in</strong>g over <strong>the</strong><br />

circular bed of material which is <strong>the</strong>n subjected to a prelim<strong>in</strong>ary classify<strong>in</strong>g action by a<br />

stream of air sweep<strong>in</strong>g through <strong>the</strong> mill. The gr<strong>in</strong>d<strong>in</strong>g <strong>efficiency</strong> of VRM is more than<br />