Membrane Based Triethylene Glycol Separation and Recovery from ...

Membrane Based Triethylene Glycol Separation and Recovery from ...

Membrane Based Triethylene Glycol Separation and Recovery from ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2.4.7.4 Variables that affect the performance of pervaporation.<br />

Feed concentration<br />

Due to the concentration of the preferentially permeating (usually minor) solution<br />

component, being depleted in the process. There are two aspects to be considered the<br />

activity of the target component in the feed <strong>and</strong> the solubility of the target component in<br />

the membrane.<br />

<strong>Membrane</strong> thickness<br />

Refers to dry thickness because flux is inversely proportional to membrane thickness, thin<br />

a membrane favors the overall flux but decrease selectivity. Moreover, thin membranes are<br />

used for low swelling glassy membranes <strong>and</strong> thick membranes are used for high swelling<br />

elastomeric membranes to maintain the selectivity.<br />

Permeate pressure<br />

Permeate pressure provides the driving force in pervaporation which the permeation rate of<br />

any feed component increases as its partial permeate pressure is lowered. The highest<br />

conceivable permeate pressure is the vapor pressure of the penetrant in the liquid feed.<br />

Moreover, the effect of this parameter on pervaporation performance is dictated by the<br />

magnitude of the vapor pressures encountered, <strong>and</strong> by the difference in vapor pressures<br />

between them.<br />

Temperature<br />

Feed temperature or any other representative between feed <strong>and</strong> retentate streams. The feed<br />

liquid provided the heat of vaporization of permeate, <strong>and</strong> in consequence there is a<br />

temperature loss between the feed <strong>and</strong> retentate stream where the membrane act as a heat<br />

exchanger barrier. Furthermore, temperature affects solubility <strong>and</strong> diffusivity of all<br />

permeates, as well as the extent of mutual interaction between them. Favoring the flux <strong>and</strong><br />

having minor effect on selectivity.<br />

2.4.7.5 Type of membranes <strong>and</strong> membrane modules<br />

The choice of the membrane strongly depends on the type of application. It is important<br />

which of the component should be separated <strong>from</strong> the mixture <strong>and</strong> whether this component<br />

is water or an organic liquid.<br />

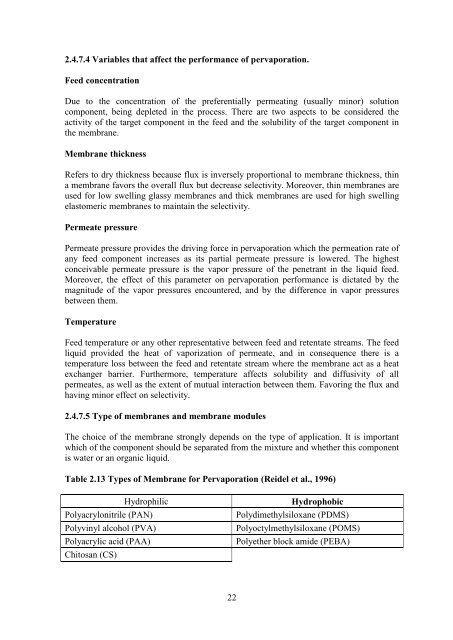

Table 2.13 Types of <strong>Membrane</strong> for Pervaporation (Reidel et al., 1996)<br />

Hydrophilic Hydrophobic<br />

Polyacrylonitrile (PAN) Polydimethylsiloxane (PDMS)<br />

Polyvinyl alcohol (PVA) Polyoctylmethylsiloxane (POMS)<br />

Polyacrylic acid (PAA) Polyether block amide (PEBA)<br />

Chitosan (CS)<br />

22