Issue 9 - faculty.ait.ac.th - Asian Institute of Technology

Issue 9 - faculty.ait.ac.th - Asian Institute of Technology

Issue 9 - faculty.ait.ac.th - Asian Institute of Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

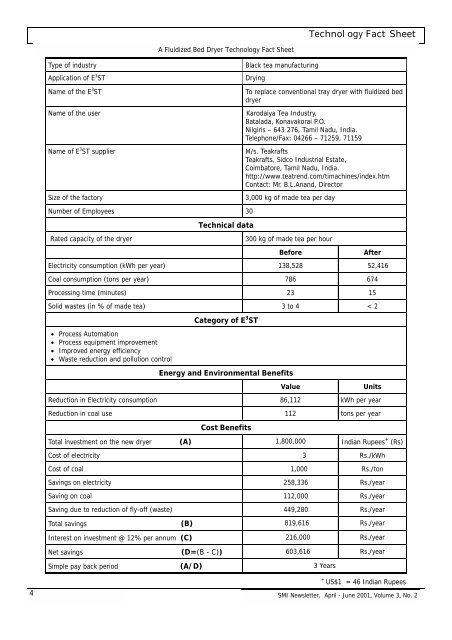

A Fluidized Bed Dryer <strong>Technology</strong> F<strong>ac</strong>t Sheet<br />

Type <strong>of</strong> industry Bl<strong>ac</strong>k tea manuf<strong>ac</strong>turing<br />

Application <strong>of</strong> E 3 ST Drying<br />

<strong>Technology</strong> F<strong>ac</strong>t Sheet<br />

Name <strong>of</strong> <strong>th</strong>e E 3 ST To repl<strong>ac</strong>e conventional tray dryer wi<strong>th</strong> fluidized bed<br />

dryer<br />

Name <strong>of</strong> <strong>th</strong>e user Karodaiya Tea Industry,<br />

Batalada, Konavakorai P.O.<br />

Nilgiris – 643 276, Tamil Nadu, India.<br />

Telephone/Fax: 04266 – 71259, 71159<br />

Name <strong>of</strong> E 3 ST supplier M/s. Teakrafts<br />

Teakrafts, Sidco Industrial Estate,<br />

Coimbatore, Tamil Nadu, India.<br />

http://www.teatrend.com/tim<strong>ac</strong>hines/index.htm<br />

Cont<strong>ac</strong>t: Mr. B.L.Anand, Director<br />

Size <strong>of</strong> <strong>th</strong>e f<strong>ac</strong>tory 3,000 kg <strong>of</strong> made tea per day<br />

Number <strong>of</strong> Employees 30<br />

Technical data<br />

Rated cap<strong>ac</strong>ity <strong>of</strong> <strong>th</strong>e dryer 300 kg <strong>of</strong> made tea per hour<br />

Before After<br />

Electricity consumption (kWh per year) 138,528 52,416<br />

Coal consumption (tons per year) 786 674<br />

Processing time (minutes) 23 15<br />

Solid wastes (in % <strong>of</strong> made tea) 3 to 4 < 2<br />

• Process Automation<br />

• Process equipment improvement<br />

• Improved energy efficiency<br />

• Waste reduction and pollution control<br />

Category <strong>of</strong> E 3 ST<br />

Energy and Environmental Benefits<br />

Value Units<br />

Reduction in Electricity consumption 86,112 kWh per year<br />

Reduction in coal use 112 tons per year<br />

Cost Benefits<br />

Total investment on <strong>th</strong>e new dryer (A) 1,800,000 Indian Rupees + (Rs)<br />

Cost <strong>of</strong> electricity 3 Rs./kWh<br />

Cost <strong>of</strong> coal 1,000 Rs./ton<br />

Savings on electricity 258,336 Rs./year<br />

Saving on coal 112,000 Rs./year<br />

Saving due to reduction <strong>of</strong> fly-<strong>of</strong>f (waste) 449,280 Rs./year<br />

Total savings (B) 819,616 Rs./year<br />

Interest on investment @ 12% per annum (C) 216,000 Rs./year<br />

Net savings (D=(B - C)) 603,616 Rs./year<br />

Simple pay b<strong>ac</strong>k period (A/D) 3 Years<br />

+ US$1 = 46 Indian Rupees<br />

4 SMI Newsletter, April - June 2001, Volume 3, No. 2