CASSAVA OPPORTUNTIES IN NIGERIA - FAO.org

CASSAVA OPPORTUNTIES IN NIGERIA - FAO.org

CASSAVA OPPORTUNTIES IN NIGERIA - FAO.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

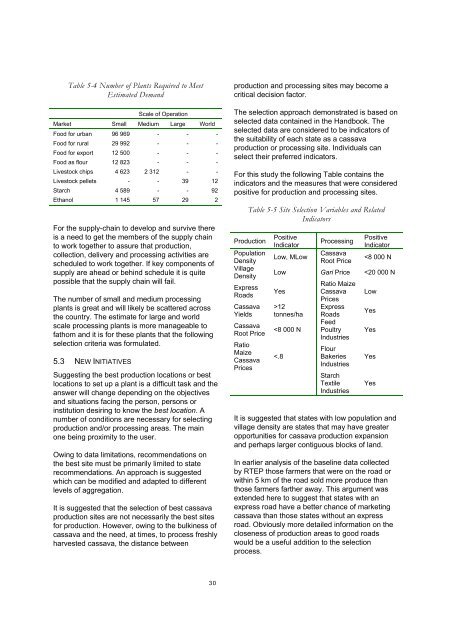

Table 5-4 Number of Plants Required to Meet<br />

Estimated Demand<br />

Scale of Operation<br />

Market Small Medium Large World<br />

Food for urban 96 969 - - -<br />

Food for rural 29 992 - - -<br />

Food for export 12 500 - - -<br />

Food as flour 12 823 - - -<br />

Livestock chips 4 623 2 312 - -<br />

Livestock pellets - - 39 12<br />

Starch 4 589 - - 92<br />

Ethanol 1 145 57 29 2<br />

For the supply-chain to develop and survive there<br />

is a need to get the members of the supply chain<br />

to work together to assure that production,<br />

collection, delivery and processing activities are<br />

scheduled to work together. If key components of<br />

supply are ahead or behind schedule it is quite<br />

possible that the supply chain will fail.<br />

The number of small and medium processing<br />

plants is great and will likely be scattered across<br />

the country. The estimate for large and world<br />

scale processing plants is more manageable to<br />

fathom and it is for these plants that the following<br />

selection criteria was formulated.<br />

5.3 NEW <strong>IN</strong>ITIATIVES<br />

Suggesting the best production locations or best<br />

locations to set up a plant is a difficult task and the<br />

answer will change depending on the objectives<br />

and situations facing the person, persons or<br />

institution desiring to know the best location. A<br />

number of conditions are necessary for selecting<br />

production and/or processing areas. The main<br />

one being proximity to the user.<br />

Owing to data limitations, recommendations on<br />

the best site must be primarily limited to state<br />

recommendations. An approach is suggested<br />

which can be modified and adapted to different<br />

levels of aggregation.<br />

It is suggested that the selection of best cassava<br />

production sites are not necessarily the best sites<br />

for production. However, owing to the bulkiness of<br />

cassava and the need, at times, to process freshly<br />

harvested cassava, the distance between<br />

30<br />

production and processing sites may become a<br />

critical decision factor.<br />

The selection approach demonstrated is based on<br />

selected data contained in the Handbook. The<br />

selected data are considered to be indicators of<br />

the suitability of each state as a cassava<br />

production or processing site. Individuals can<br />

select their preferred indicators.<br />

For this study the following Table contains the<br />

indicators and the measures that were considered<br />

positive for production and processing sites.<br />

Table 5-5 Site Selection Variables and Related<br />

Indicators<br />

Production Positive<br />

Indicator<br />

Processing<br />

Positive<br />

Indicator<br />

Population<br />

Density<br />

Low, MLow<br />

Cassava<br />

Root Price<br />