GL – Mapping the Future in Offshore Wind - Germanischer Lloyd

GL – Mapping the Future in Offshore Wind - Germanischer Lloyd

GL – Mapping the Future in Offshore Wind - Germanischer Lloyd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

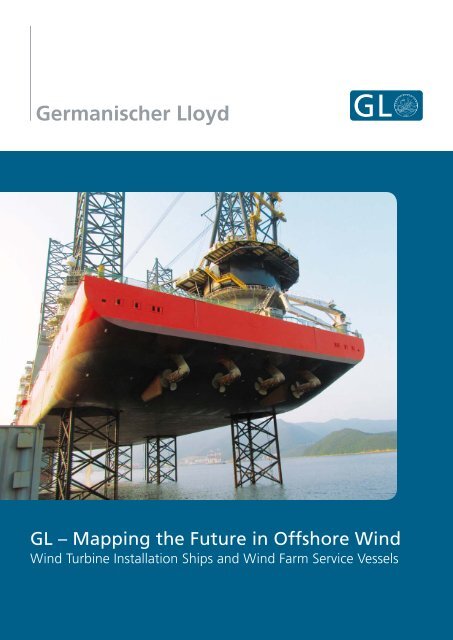

<strong>GL</strong> <strong>–</strong> <strong>Mapp<strong>in</strong>g</strong> <strong>the</strong> <strong>Future</strong> <strong>in</strong> <strong>Offshore</strong> W<strong>in</strong>d<br />

W<strong>in</strong>d Turb<strong>in</strong>e Installation Ships and W<strong>in</strong>d Farm Service Vessels

The power of <strong>in</strong>novation:<br />

offshore w<strong>in</strong>d energy<br />

Dynamic growth<br />

W<strong>in</strong>d energy is one of <strong>the</strong> key renewable energy sources that<br />

will make a significant contribution towards clean and <strong>in</strong>dependent<br />

energy around <strong>the</strong> world. As a reflection of this, <strong>the</strong><br />

w<strong>in</strong>d energy <strong>in</strong>dustry is <strong>in</strong> a period of significant growth and<br />

<strong>in</strong> Europe <strong>the</strong> ma<strong>in</strong> driver is a political one: by 2020 <strong>the</strong> EU<br />

plans to cover 20 % of its primary energy consumption us<strong>in</strong>g<br />

renewable sources. W<strong>in</strong>d energy will play a key role as 10,000<br />

offshore w<strong>in</strong>d turb<strong>in</strong>es are expected to be <strong>in</strong>stalled <strong>in</strong> European<br />

offshore waters.<br />

A wide range of vessels<br />

This development presents ship owners, operators and<br />

yards with considerable opportunities <strong>in</strong> <strong>the</strong> construction<br />

and deployment of suitable vessels. The range of vessels<br />

needed to develop, <strong>in</strong>stall and operate w<strong>in</strong>d farms comprises<br />

multiple crafts such as W<strong>in</strong>d Turb<strong>in</strong>e Installation Ships (WTIS),<br />

crew boats as well as o<strong>the</strong>r types such as survey vessels,<br />

offshore support vessels, cable-lay<strong>in</strong>g vessels and anchor<br />

handl<strong>in</strong>g tugs.<br />

2

The power of <strong>in</strong>novation: offshore w<strong>in</strong>d energy<br />

Increas<strong>in</strong>g demand<br />

Globally, <strong>the</strong> offshore w<strong>in</strong>d market is grow<strong>in</strong>g rapidly. In Europe,<br />

UK development is forecast to rise steadily, while projects <strong>in</strong><br />

Germany and <strong>the</strong> Ne<strong>the</strong>rlands are expected to beg<strong>in</strong> development<br />

on a large scale, and o<strong>the</strong>r European markets are also<br />

becom<strong>in</strong>g <strong>in</strong>creas<strong>in</strong>gly active, as will <strong>the</strong> North American and<br />

Ch<strong>in</strong>ese markets.<br />

At present, approximately 1GW is <strong>in</strong>stalled per year, which is<br />

expected to rise to 5GW. This is equivalent to an <strong>in</strong>crease of:<br />

ÂÂfrom 250 to 1,000 turb<strong>in</strong>es per year<br />

ÂÂfrom 150 to 700 km of export cable<br />

ÂÂfrom 4 to 20 vessels to <strong>in</strong>stall support structures<br />

ÂÂfrom 3 to 14 vessels to <strong>in</strong>stall turb<strong>in</strong>es<br />

ÂÂfrom 1 to 8 vessels to repair turb<strong>in</strong>es<br />

ÂÂfrom 300 to 500 support vessels<br />

Current figures from <strong>the</strong> European W<strong>in</strong>d Energy Association<br />

(EWEA) state that <strong>in</strong> 2010, <strong>the</strong> total <strong>in</strong>stalled offshore capacity<br />

reached 3,000 MW. This meets 0.3 % of EU electricity<br />

demand. For <strong>the</strong> year 2030, 150,000 MW of <strong>in</strong>stalled offshore<br />

capacity are projected, which will meet between 13 and 17 %<br />

of total EU electricity demand.<br />

A complex challenge requires<br />

<strong>in</strong>novative solutions<br />

<strong>Offshore</strong> w<strong>in</strong>d farm<strong>in</strong>g requires a series of highly specialized<br />

vessels adapted to <strong>the</strong> particular challenges faced <strong>in</strong> this sector:<br />

ÂÂlarge units: w<strong>in</strong>d turb<strong>in</strong>e <strong>in</strong>stallation, construction and<br />

cable-lay<strong>in</strong>g vessels<br />

ÂÂsmaller units: ma<strong>in</strong>tenance and supply vessels<br />

ÂÂcrew transport vessels<br />

ÂÂtransportation vessels for all equipment from foundation to<br />

blades equipment<br />

Increas<strong>in</strong>g turb<strong>in</strong>e sizes and weights need to be taken <strong>in</strong>to<br />

consideration, as <strong>the</strong> offshore w<strong>in</strong>d <strong>in</strong>dustry moves <strong>in</strong>to<br />

deeper water and fur<strong>the</strong>r from <strong>the</strong> shore beyond <strong>the</strong> so-called<br />

20:20 envelope (20 m water depth, 20 km from shore). This<br />

requires vessels that have a high tolerance to adverse wea<strong>the</strong>r<br />

conditions <strong>–</strong> speed and resilience to seastate are key factors<br />

for w<strong>in</strong>d farm <strong>in</strong>stallation and service vessels, just as reliability<br />

and flexibility are key factors <strong>in</strong> <strong>the</strong>ir successful operation.<br />

In short, offshore w<strong>in</strong>d farm<strong>in</strong>g requires highly sophisticated<br />

vessels that operate <strong>in</strong> challeng<strong>in</strong>g surround<strong>in</strong>gs.<br />

approximately 6,900 experts across 80 countries and <strong>in</strong> more<br />

than 200 locations.<br />

Today, we are proud of our lead<strong>in</strong>g position <strong>in</strong> <strong>the</strong> field of w<strong>in</strong>d<br />

turb<strong>in</strong>e <strong>in</strong>stallation vessels and w<strong>in</strong>d farm service vessels. We<br />

explore and implement new solutions for <strong>the</strong> different vessel<br />

types required <strong>in</strong> <strong>the</strong> offshore w<strong>in</strong>d sector. This <strong>in</strong>cludes:<br />

ÂÂnew ideas and <strong>in</strong>novative solutions<br />

ÂÂexpertise from concept to operation<br />

ÂÂimplement<strong>in</strong>g sophisticated eng<strong>in</strong>eer<strong>in</strong>g challenges<br />

ÂÂdevelop<strong>in</strong>g Rules<br />

ÂÂclassification of all vessels needed to develop,<br />

<strong>in</strong>stall and operate offshore w<strong>in</strong>d farms<br />

ÂÂexpert support <strong>in</strong> negotiat<strong>in</strong>g <strong>the</strong> difficult terra<strong>in</strong> of<br />

<strong>in</strong>ternational regulations and compliancy.<br />

Our achievements have led us to:<br />

ÂÂset up a dedicated <strong>Offshore</strong> Service Vessel (OSV)<br />

department<br />

ÂÂdevelop rules for OSVs: hull and mach<strong>in</strong>ery<br />

ÂÂdevelop rules for crew boats<br />

ÂÂpresent OSV-related expertise at panel discussions,<br />

conferences and to ship owners <strong>in</strong> Europe, Ch<strong>in</strong>a,<br />

South Korea, U.A.E. and USA<br />

ÂÂprovide consultancy <strong>in</strong> <strong>the</strong> OSV sector<br />

ÂÂsupport various shipyards with our pool of <strong>in</strong>-depth<br />

knowledge<br />

<strong>GL</strong> acts as advisor to governments, <strong>the</strong> IMO, flag states and<br />

port states. We are ideally placed to provide guidance on<br />

compliancy with all current and upcom<strong>in</strong>g regulations. As a<br />

classification society, we have accompanied <strong>the</strong> design and<br />

construction of a number of w<strong>in</strong>d farm vessels, mak<strong>in</strong>g us<br />

your expert partner for all lifecycle stages of offshore w<strong>in</strong>d<br />

<strong>in</strong>stallation and support vessels.<br />

Jan Schreiber<br />

Ship Type Expert<br />

<strong>Offshore</strong> Service and<br />

Work<strong>in</strong>g Vessels<br />

Phone: +49 40 36149-5235<br />

Jan.Schreiber@gl-group.com<br />

<strong>GL</strong>: your one-stop shop for offshore<br />

w<strong>in</strong>d farm vessels<br />

Founded <strong>in</strong> 1867 as a maritime classification society, <strong>Germanischer</strong><br />

<strong>Lloyd</strong> (<strong>GL</strong>) has expanded to provide a wide range of<br />

classification, certification, software and tra<strong>in</strong><strong>in</strong>g services.<br />

We can po<strong>in</strong>t to 240 years of experience and a network of<br />

"<strong>Offshore</strong> w<strong>in</strong>d farm<strong>in</strong>g requires highly sophisticated<br />

vessels. At <strong>GL</strong> we are proud of <strong>the</strong> range and depth of<br />

expertise we can offer this rapidly expand<strong>in</strong>g market.<br />

From w<strong>in</strong>d turb<strong>in</strong>e <strong>in</strong>stallation and construction vessels,<br />

to ma<strong>in</strong>tenance, supply and crew transport vessels."<br />

3

The <strong>GL</strong> Group <strong>–</strong> global knowledge<br />

and local expertise<br />

Unique solutions from concept to operation<br />

Rules and classification<br />

<strong>Germanischer</strong> <strong>Lloyd</strong> offers rules and guidel<strong>in</strong>es that cover all<br />

aspects of offshore projects: design, development, construction,<br />

security, operation and management. <strong>GL</strong> expertise is currently<br />

supervis<strong>in</strong>g several offshore service vessel newbuild<strong>in</strong>g and<br />

re-build<strong>in</strong>g projects, <strong>in</strong>clud<strong>in</strong>g self-elevat<strong>in</strong>g units for w<strong>in</strong>d<br />

turb<strong>in</strong>e <strong>in</strong>stallation, crew boats, accommodation units, anchor<br />

handlers, cable layers, and various supply and ma<strong>in</strong>tenance<br />

vessels.<br />

Source: HOCHTIEF Solutions<br />

<strong>GL</strong> Rules are constantly be<strong>in</strong>g f<strong>in</strong>e-tuned to reflect advances <strong>in</strong><br />

technology across <strong>the</strong> <strong>in</strong>dustry. The recently issued Rules for<br />

<strong>the</strong> Classification and Construction of <strong>Offshore</strong> Service Vessels<br />

and Underwater Technology <strong>in</strong>clude more than 20 special<br />

notations for <strong>the</strong> wide variety of vessels and tasks undertaken<br />

<strong>in</strong> offshore projects. <strong>GL</strong> Rules <strong>in</strong>clude:<br />

ÂÂ<strong>GL</strong> Rules for <strong>Offshore</strong> Service Vessels <strong>–</strong> Hull Structures<br />

<strong>Germanischer</strong> <strong>Lloyd</strong> Classification<br />

We develop Rules based on state-of-<strong>the</strong>-art eng<strong>in</strong>eer<strong>in</strong>g knowledge<br />

and procedures, as well as provid<strong>in</strong>g guidance for ship<br />

owners, shipyards and <strong>the</strong> maritime supply <strong>in</strong>dustry. We offer<br />

classification services, plan approval and newbuild<strong>in</strong>g supervision,<br />

maritime systems and solutions, and tra<strong>in</strong><strong>in</strong>g.<br />

<strong>GL</strong> Garrad Hassan offers <strong>in</strong>dependent technical and eng<strong>in</strong>eer<strong>in</strong>g<br />

services, products, and tra<strong>in</strong><strong>in</strong>g courses to <strong>the</strong> onshore<br />

and offshore w<strong>in</strong>d, wave, tidal and solar sectors. <strong>GL</strong> Garrad<br />

Hassan has provided more <strong>in</strong>dependent assessments for<br />

operational w<strong>in</strong>d farms than any o<strong>the</strong>r company.<br />

<strong>GL</strong> Noble Denton provides consult<strong>in</strong>g, design, assurance and<br />

project execution services. <strong>GL</strong> Noble Denton comb<strong>in</strong>es excellent<br />

eng<strong>in</strong>eer<strong>in</strong>g and analytical skills with operational experience<br />

to design, build, <strong>in</strong>stall and operate maritime onshore and<br />

offshore assets.<br />

<strong>Future</strong>Ship offers specialised consult<strong>in</strong>g services <strong>in</strong> <strong>the</strong> fields<br />

of maritime strategy, ship design, operations, and compliance.<br />

<strong>Future</strong>Ship’s consult<strong>in</strong>g expertise is complemented by <strong>in</strong>-depth<br />

market <strong>in</strong>telligence, advanced eng<strong>in</strong>eer<strong>in</strong>g solutions and<br />

sophisticated measurement services.<br />

ÂÂNew <strong>GL</strong> Rules for Dynamic Position<strong>in</strong>g System<br />

ÂÂ<strong>GL</strong> Guidel<strong>in</strong>es for Gas as Ship Fuel<br />

ÂÂ2011 <strong>GL</strong> Rules for <strong>Offshore</strong> Service Vessels <strong>–</strong> Mach<strong>in</strong>ery<br />

Installations<br />

ÂÂNew Rules for Load<strong>in</strong>g Gears on seago<strong>in</strong>g ships and<br />

offshore <strong>in</strong>stallations<br />

Ensur<strong>in</strong>g compliance for all vessel types<br />

One of <strong>the</strong> major challenges of all offshore <strong>in</strong>stallation and<br />

service craft is ensur<strong>in</strong>g compliancy for vessels that <strong>in</strong>tegrate<br />

sophisticated concepts and fulfil many different purposes.<br />

<strong>GL</strong> is your guide when apply<strong>in</strong>g <strong>the</strong> regulatory framework<br />

such as SOLAS, MARPOL, Guidel<strong>in</strong>es for <strong>the</strong> Design and<br />

Construction of <strong>Offshore</strong> Supply Vessels 2006 (OSV-Code),<br />

Code of Safety for Special Purpose Ships, 2008 (SPS-Code),<br />

International Code of Safety for High-Speed Craft, 2000<br />

(2000 HSC-Code) and Maritime Labour Convention (MLC).<br />

Our experts are at your side for clarification and negotiations<br />

with flag states to f<strong>in</strong>d <strong>the</strong> most advantageous and practicable<br />

solutions for your projects.<br />

4

The <strong>GL</strong> Group <strong>–</strong> a synergy of global knowledge and local expertise<br />

Class notation: Dynamic Position<strong>in</strong>g<br />

Dynamic Position<strong>in</strong>g (DP) is a great advantage for w<strong>in</strong>d farm<br />

service ships as it is a computer-controlled system that automatically<br />

ma<strong>in</strong>ta<strong>in</strong>s a vessel’s position and head<strong>in</strong>g. Moor<strong>in</strong>gs<br />

and anchor handl<strong>in</strong>g are not needed anymore. Ra<strong>the</strong>r, own<br />

propellers and thrusters are used while sensors for environmental<br />

forces and motion comb<strong>in</strong>ed with a GPS position reference<br />

system control <strong>the</strong> position<strong>in</strong>g of <strong>the</strong> vessel. In <strong>the</strong> offshore<br />

w<strong>in</strong>d sector, typical applications for DP systems are as follows:<br />

ÂÂcable and pipe-lay<strong>in</strong>g vessels<br />

ÂÂdiv<strong>in</strong>g support vessels<br />

ÂÂmaritime research vessels<br />

ÂÂsurvey ships<br />

ÂÂsupply vessels<br />

ÂÂWTIS<br />

Hull optimisation solutions<br />

<strong>Future</strong>Ship is specialised <strong>in</strong> develop<strong>in</strong>g and f<strong>in</strong>e-tun<strong>in</strong>g ship<br />

hull forms. Many hundreds or thousands of candidate designs<br />

are systematically analysed and varied <strong>in</strong> an automated process<br />

based on a unique parametric approach. <strong>Future</strong>Ship can thus<br />

offer expert advice on choos<strong>in</strong>g <strong>the</strong> best hull form as well as<br />

carry<strong>in</strong>g out <strong>the</strong> associated tank test<strong>in</strong>g. This improves fuel<br />

efficiency and ensures that <strong>the</strong> hull of your ship is fit for sitespecific<br />

seakeep<strong>in</strong>g conditions, thus <strong>in</strong>creas<strong>in</strong>g <strong>the</strong> number of<br />

operation days, even <strong>in</strong> stormy wea<strong>the</strong>r.<br />

Noise and vibration challenges<br />

Strong noise and vibration <strong>in</strong> work<strong>in</strong>g and liv<strong>in</strong>g spaces can be<br />

<strong>the</strong> orig<strong>in</strong> of <strong>in</strong>creased crew discomfort and <strong>the</strong>refore lead to<br />

reduced crew performance. Moreover, excessive vibration can<br />

cause damage to structure, mach<strong>in</strong>ery and equipment.<br />

<strong>Future</strong>Ship assists <strong>in</strong> prevent<strong>in</strong>g noise problems dur<strong>in</strong>g all<br />

phases of a ship’s life: from <strong>the</strong> early design stage, through<br />

build<strong>in</strong>g and commission<strong>in</strong>g, to unexpected noises or<br />

vibrations dur<strong>in</strong>g operation.<br />

Construction services<br />

<strong>GL</strong> Noble Denton provides project management and specialist<br />

site personnel on behalf of <strong>the</strong> shipyard. Under <strong>the</strong> guidance<br />

of <strong>GL</strong> Noble Denton, units are delivered to <strong>the</strong> owner’s<br />

satisfaction <strong>in</strong> regard to budget, time and quality standards.<br />

Fur<strong>the</strong>rmore, <strong>GL</strong> Noble Denton verifies <strong>the</strong> tasks undertaken<br />

by that particular craft on site: provid<strong>in</strong>g technical support,<br />

on-location trials, dynamic analyses, lift<strong>in</strong>g calculations and<br />

arrangements for transport and <strong>in</strong>stallation.<br />

Optimisation of <strong>Offshore</strong> Construction<br />

<strong>GL</strong> Garrad Hassan has developed <strong>the</strong> "Optimisation of <strong>Offshore</strong><br />

Construction" (O2C) model. This provides Monte-Carlo modell<strong>in</strong>g<br />

of <strong>in</strong>stallation and construction activities to evaluate<br />

project schedul<strong>in</strong>g and <strong>in</strong>stallation costs. It allows project<br />

owners and <strong>the</strong>ir contractors to improve cost efficiency by<br />

giv<strong>in</strong>g <strong>the</strong>m an <strong>in</strong>sight <strong>in</strong>to <strong>the</strong> potential temporal and economic<br />

implications of adopt<strong>in</strong>g different strategies.<br />

Optimisation of Operations and Ma<strong>in</strong>tenance<br />

O2M Plus is an upgrade of <strong>the</strong> <strong>GL</strong> Garrad Hassan "Optimisation<br />

of Operations and Ma<strong>in</strong>tenance" (O2M) modell<strong>in</strong>g tool, which<br />

builds on experience ga<strong>in</strong>ed from over 40 projects. It allows<br />

differences between alternative w<strong>in</strong>d turb<strong>in</strong>e access strategies<br />

to be fully explored <strong>in</strong> terms of both costs and plant availability,<br />

and to thus identify optimal strategies.<br />

5

W<strong>in</strong>d Turb<strong>in</strong>e Installation Ships:<br />

<strong>GL</strong>’s expert solutions for WTIS<br />

owners and yards<br />

Implement<strong>in</strong>g <strong>the</strong> ambitious targets of <strong>the</strong> offshore w<strong>in</strong>d<br />

sector requires highly specialised ships capable of anchor<strong>in</strong>g<br />

foundations to <strong>the</strong> sea floor and erect<strong>in</strong>g huge turb<strong>in</strong>e<br />

towers. In Europe, <strong>in</strong> particular, many offshore projects are<br />

planned for deeper waters fur<strong>the</strong>r from <strong>the</strong> shore. This<br />

requires sail<strong>in</strong>g speeds of up to 13 knots and jack<strong>in</strong>g capabilities<br />

for water depths of up to 60 m.<br />

Most of <strong>the</strong> specialised vessels now <strong>in</strong> operation are classed<br />

by <strong>GL</strong>. As world leaders <strong>in</strong> this market we have accumulated<br />

an unrivalled pool of knowledge as well as <strong>in</strong>valuable practical<br />

experience. This enables us to address <strong>the</strong> complexities<br />

posed by <strong>the</strong>se vessels to provide site-specific solutions based<br />

on cutt<strong>in</strong>g-edge technologies. <strong>GL</strong> Group services for WTIS<br />

<strong>in</strong>clude:<br />

ÂÂcomb<strong>in</strong>ed assurance, consult<strong>in</strong>g, eng<strong>in</strong>eer<strong>in</strong>g and<br />

execution support<br />

ÂÂmar<strong>in</strong>e warranty services and dynamic position<strong>in</strong>g<br />

assurance<br />

ÂÂclassification<br />

The importance of pre-design expertise<br />

At <strong>the</strong> pre-design stage, important parameters can be verified<br />

by feasibility studies and classification pre-checks, both carried<br />

out by <strong>GL</strong>. As WTIS <strong>in</strong>volve high levels of complexity, early<br />

<strong>in</strong>vestigations are an effective tool for sav<strong>in</strong>g time and money<br />

at later stages. Relevant issues <strong>in</strong>clude: should <strong>the</strong> ship be self<br />

propelled, with jack<strong>in</strong>g capability; what is <strong>the</strong> desired sail<strong>in</strong>g<br />

speed, size of crane and lift<strong>in</strong>g appliances, number of compartments<br />

and dynamic position<strong>in</strong>g? For vessels with dynamic<br />

position<strong>in</strong>g it is particularly important to def<strong>in</strong>e <strong>the</strong> redundancy<br />

concept at <strong>the</strong> earliest possible stage. Flaws discovered at this<br />

stage result <strong>in</strong> no more than extra paperwork, whereas flaws<br />

disco-vered at later stages, may lead to equipment rework,<br />

delays and commercial losses.<br />

FMEA & <strong>the</strong> redundancy concept<br />

The FMEA is a critical safety element for DP2 and DP3. Cost<br />

efficiency can be optimised at this stage if <strong>the</strong> redundancy<br />

concept and <strong>the</strong> worst-case failure design take <strong>in</strong>to accountoperat<strong>in</strong>g<br />

modes (e.g. <strong>the</strong> work to be carried out, such as pipe<br />

lay<strong>in</strong>g, crane work, supply, transit etc.) and <strong>the</strong> operat<strong>in</strong>g conditions<br />

(e.g. environmental conditions for work, lift<strong>in</strong>g etc.).<br />

This allows for appropriate design modifications before <strong>the</strong>y<br />

become costly and is provided for <strong>in</strong> <strong>the</strong> <strong>GL</strong> Rules "Guidel<strong>in</strong>es<br />

for Vessels with Dynamic Position<strong>in</strong>g Systems" by early approval<br />

of <strong>the</strong> redundancy concept.<br />

Design and construction of<br />

custom-built WTIS<br />

At <strong>the</strong> design stage it is important to determ<strong>in</strong>e <strong>the</strong> most<br />

appropriate design to meet specific requirements. Considerations<br />

<strong>in</strong>clude: expected turb<strong>in</strong>e size, water depth, distance<br />

from shore and <strong>the</strong> time w<strong>in</strong>dow for <strong>in</strong>stallation.<br />

Source: Swire Blue Ocean A/S<br />

PACIFIC ORCA<br />

Type: W<strong>in</strong>d Turb<strong>in</strong>e Installation Ship<br />

Length: 155.614 m<br />

Gross Tonnage: 24,586<br />

Class notations hull<br />

8 100 A5, BMW, <strong>Offshore</strong> Service Vessel,<br />

Self Elevat<strong>in</strong>g Unit, Operation accord<strong>in</strong>g to<br />

Operat<strong>in</strong>g Manual, SPS, WTIS<br />

Class notation mach<strong>in</strong>ery<br />

7 MC AUT DP 2 HELIL EP<br />

Source: RWE Innogy<br />

46

W<strong>in</strong>d Turb<strong>in</strong>e Installation Ships: <strong>GL</strong>’s expert solutions for WTIS owners and yards<br />

INNOVATION<br />

Type: W<strong>in</strong>d Turb<strong>in</strong>e Installation Ship<br />

Length: 139.737 m<br />

Gross Tonnage: 21,900<br />

Class notations hull<br />

8 100 A5, NAV-OC DP2 S9P65, Special<br />

Purpose Ship, <strong>Offshore</strong> Service Vessel,<br />

Self Elevat<strong>in</strong>g Unit, Operation accord<strong>in</strong>g<br />

to Operat<strong>in</strong>g Manual, Streng<strong>the</strong>ned for<br />

Heavy Cargo, WTIS<br />

Class notation mach<strong>in</strong>ery<br />

7 MC AUT EP<br />

Source: HGO InfraSea Solutions<br />

<strong>GL</strong> has been <strong>in</strong>volved with three design generations of w<strong>in</strong>d<br />

turb<strong>in</strong>e <strong>in</strong>stallation ships:<br />

Generation I These are comb<strong>in</strong>ed crane and work<strong>in</strong>g barges<br />

with high lift<strong>in</strong>g capacity, high deck load capacity and a large<br />

work<strong>in</strong>g deck. They are used quite often <strong>in</strong> areas close to <strong>the</strong><br />

shore, or if suitable generation II and III vessels are not available<br />

on <strong>the</strong> market.<br />

Generation II These are jack-up barges without propulsion.<br />

They have high lift<strong>in</strong>g capacity, high deck load capacity,<br />

large work<strong>in</strong>g deck capacity, a large accommodation area,<br />

helicopter deck, and <strong>the</strong>y are self elevat<strong>in</strong>g. The jack-up barge<br />

THOR for Hochtief with a 70 x 40 m work<strong>in</strong>g deck and a crane<br />

capacity of 500 t is an example of this vessel type.<br />

Generation III has all <strong>the</strong> features of generation II and also<br />

propulsion with DP2 / DP3 capability. This generation is ma<strong>in</strong>ly<br />

used <strong>in</strong> areas fur<strong>the</strong>r from shore. It significantly reduces <strong>the</strong><br />

time needed for <strong>in</strong>stallation, as <strong>the</strong> time for transferr<strong>in</strong>g<br />

foundations, towers, turb<strong>in</strong>es and blades from transportation<br />

barge to <strong>in</strong>stallation barge can be saved. This also makes<br />

operation much safer. HOCHTIEF’s Innovation or <strong>the</strong> Pacific<br />

Orca belong to this category.<br />

VICTORIA MATHIAS<br />

Type: W<strong>in</strong>d Turb<strong>in</strong>e Installation Ship<br />

Length: 96.023 m<br />

Gross Tonnage: 11,730<br />

THOR<br />

Type: W<strong>in</strong>d Turb<strong>in</strong>e Installation Ship<br />

Length: 67.2 m<br />

Gross Tonnage: 6,769<br />

Class notations hull<br />

8 100 A5, DP2 S9P54, Self Elevat<strong>in</strong>g Unit,<br />

Special Purpose Ship, Operation accord<strong>in</strong>g to<br />

Operat<strong>in</strong>g Manual<br />

Class notation mach<strong>in</strong>ery<br />

7 MC AUT EP<br />

Source: HOCHTIEF Solutions<br />

Class notations hull<br />

8 100 A5, S2D11, Self Elevat<strong>in</strong>g Unit,<br />

Operation accord<strong>in</strong>g to Operat<strong>in</strong>g Manual<br />

Class notation mach<strong>in</strong>ery<br />

7 A-MC AUT<br />

7

Solv<strong>in</strong>g <strong>the</strong> complexity of compliance<br />

A WTIS may be a ship, jack-up, heavy lifter and passenger vessel<br />

all rolled <strong>in</strong>to one. The hybrid nature of such a vessel means<br />

that it must simultaneously fulfil rules and regulations that are<br />

sometimes very contradictory. F<strong>in</strong>d<strong>in</strong>g a way through <strong>the</strong> jungle<br />

of <strong>in</strong>ternational regulations is difficult. The IMO has been<br />

asked to take action to streaml<strong>in</strong>e compliancy issues, and results<br />

are expected <strong>in</strong> <strong>the</strong> near future. <strong>GL</strong> actively participates<br />

<strong>in</strong> all important <strong>in</strong>ternational regulatory committees and is <strong>the</strong>refore<br />

always up to date on regulatory adjustments and changes.<br />

"The Pacific Orca" <strong>–</strong> a <strong>GL</strong> Group success story<br />

With a total length of 161 metres, a breadth of 49 metres<br />

and a depth of 10.4 metres, <strong>the</strong> Pacific Orca is <strong>the</strong> largest<br />

WTIS ever built.<br />

The vessel is capable of carry<strong>in</strong>g and <strong>in</strong>stall<strong>in</strong>g up to twelve<br />

w<strong>in</strong>d turb<strong>in</strong>e units of 3.6 MW dur<strong>in</strong>g one voyage. Fur<strong>the</strong>rmore,<br />

<strong>the</strong> Pacific Orca can <strong>in</strong>stall foundations and erect<br />

turb<strong>in</strong>es <strong>in</strong> water depths of up to 60 metres and with leg<br />

extensions this <strong>in</strong>creases to 75 metres.<br />

Technical considerations and challenges<br />

Leg types and jack<strong>in</strong>g systems<br />

WTIS leg types and jack<strong>in</strong>g systems fall <strong>in</strong>to two categories:<br />

ÂÂcyl<strong>in</strong>drical legs & hydraulic p<strong>in</strong> <strong>in</strong> hole<br />

ÂÂlattice legs & rack and p<strong>in</strong>ion<br />

W<strong>in</strong>d turb<strong>in</strong>e foundation <strong>in</strong>stallation<br />

The monopile has been <strong>the</strong> foundation of choice for <strong>the</strong><br />

offshore w<strong>in</strong>d farm <strong>in</strong>dustry to date. However, this is chang<strong>in</strong>g<br />

as w<strong>in</strong>d turb<strong>in</strong>es move <strong>in</strong>to deeper waters fur<strong>the</strong>r offshore.<br />

Tripod foundations can be <strong>in</strong>stalled to a water depth of up to<br />

50 m and jacket foundations to a depth of up to 70 m. In<br />

5 to 6 years’ time, jacket foundations are expected to lead<br />

<strong>the</strong> way.<br />

This places additional demands on <strong>the</strong> capabilities of w<strong>in</strong>d<br />

turb<strong>in</strong>e <strong>in</strong>stallation ships. <strong>GL</strong> is meet<strong>in</strong>g <strong>the</strong>se demands by<br />

mov<strong>in</strong>g forward <strong>in</strong>to unchartered technical territory and<br />

pioneer<strong>in</strong>g future technologies.<br />

Several bus<strong>in</strong>ess segments of <strong>the</strong> <strong>GL</strong> Group had been <strong>in</strong>volved<br />

<strong>in</strong> this project:<br />

ÂÂ<strong>GL</strong> Noble Denton undertook eng<strong>in</strong>eer<strong>in</strong>g and design<br />

of legs, spud-cans and jack<strong>in</strong>g system, <strong>in</strong>clud<strong>in</strong>g FMEA,<br />

as well as <strong>in</strong>tegration of <strong>the</strong>se components <strong>in</strong>to <strong>the</strong><br />

ship’s hull. They also provided <strong>the</strong> shipyard consultancy<br />

and site-specific assessment services.<br />

ÂÂ<strong>Future</strong>Ship carried out global strength and fatigue<br />

analyses for <strong>the</strong> ship afloat, and was responsible for<br />

owner consultancy.<br />

ÂÂ<strong>GL</strong> as classification society conducted <strong>the</strong> <strong>in</strong>-place<br />

analysis <strong>in</strong> jacked-up mode, as well as provid<strong>in</strong>g <strong>the</strong><br />

classification services.<br />

On 27 July 2012 Swire Pacific <strong>Offshore</strong> Operations took<br />

delivery of <strong>the</strong> Pacific Orca from Samsung Heavy Industries<br />

<strong>in</strong> Geoje, South Korea.<br />

8

W<strong>in</strong>d Turb<strong>in</strong>e Installation Ships: <strong>GL</strong>’s expert solutions for WTIS owners and yards<br />

Source: Swire Blue Ocean A/S<br />

9

Crew boats <strong>–</strong> ensur<strong>in</strong>g safe<br />

and speedy passage<br />

Transfer of personnel to site and turb<strong>in</strong>es<br />

As offshore w<strong>in</strong>d developments move fur<strong>the</strong>r offshore, <strong>in</strong>to<br />

deeper waters with more extreme wea<strong>the</strong>r conditions, <strong>the</strong><br />

challenge of provid<strong>in</strong>g support dur<strong>in</strong>g construction, operations<br />

and ma<strong>in</strong>tenance is grow<strong>in</strong>g. Personnel access solutions need<br />

to be safe, fast and cost effective.<br />

So far, personnel access to both w<strong>in</strong>d turb<strong>in</strong>es and offshore<br />

substations has been achieved ma<strong>in</strong>ly through <strong>the</strong> use of<br />

relatively small work boats. Speed and resilience to seastate<br />

are <strong>the</strong> key elements when deploy<strong>in</strong>g boats that transfer personnel<br />

to a site. Lack of <strong>the</strong>se elements, particularly tolerance<br />

to adverse wea<strong>the</strong>r, has been a major contributor to reduced<br />

operation availability <strong>in</strong> <strong>the</strong> past. The ideal access solution is<br />

a small, fast and cost-effective vessel capable of transferr<strong>in</strong>g<br />

technicians <strong>in</strong> high seastates.<br />

The current standard is characterised by <strong>the</strong> follow<strong>in</strong>g<br />

benchmark specifications:<br />

ÂÂPassenger<br />

Capacity:<br />

ÂÂLength:<br />

ÂÂBeam:<br />

ÂÂDraft:<br />

ÂÂDesign:<br />

ÂÂSpeed:<br />

ÂÂPropulsion:<br />

ÂÂDeck crane:<br />

12 PAX<br />

~15 - 25 m LOA<br />

~6 m<br />

~1.8 m<br />

Multi-cat<br />

25 knots (max)<br />

Typically 2 x 800 hp<br />

2 tonnes SWL<br />

Far-shore sites: ideas and developments<br />

As proximity to a far-shore site is vital, <strong>in</strong>terest <strong>in</strong> “floatel”<br />

or “mo<strong>the</strong>r ship” based strategies is grow<strong>in</strong>g. These provide<br />

offshore accommodation near <strong>the</strong> site for <strong>the</strong> operation and<br />

ma<strong>in</strong>tenance of projects fur<strong>the</strong>r than 50 km from port.<br />

Under <strong>the</strong>se strategies crews live aboard large, float<strong>in</strong>g vessels<br />

located with<strong>in</strong> <strong>the</strong> vic<strong>in</strong>ity of <strong>the</strong> w<strong>in</strong>d farm, typically adopt<strong>in</strong>g<br />

a 2-week on, 2-week off shift rotor as practised <strong>in</strong> <strong>the</strong> oil and<br />

gas <strong>in</strong>dustry. Access to turb<strong>in</strong>es can be achieved by daughter<br />

craft and / or heave-compensated access systems (such as<br />

Ampelmann or OAS), which can operate <strong>in</strong> high seastates.<br />

Such float<strong>in</strong>g, offshore-based strategies can maximise time<br />

available for plant ma<strong>in</strong>tenance by reduc<strong>in</strong>g transit time to<br />

turb<strong>in</strong>es and enabl<strong>in</strong>g access <strong>in</strong> severe seastates.<br />

Mo<strong>the</strong>r ships <strong>in</strong> particular have <strong>the</strong> ability to deploy multiple<br />

small, agile craft dur<strong>in</strong>g periods of benign wea<strong>the</strong>r conditions,<br />

or transit to <strong>the</strong> turb<strong>in</strong>e <strong>the</strong>mselves and use a specialist access<br />

system dur<strong>in</strong>g periods of more severe conditions.<br />

Pioneer<strong>in</strong>g solutions, deliver<strong>in</strong>g results<br />

The challenge of f<strong>in</strong>d<strong>in</strong>g solutions to <strong>the</strong> difficulty of fast,<br />

safe, reliable and wea<strong>the</strong>r-<strong>in</strong>sensitive transfers of technicians<br />

and components is ongo<strong>in</strong>g.<br />

SWATH vessels<br />

One emerg<strong>in</strong>g solution, currently be<strong>in</strong>g trialled at <strong>the</strong> Bard<br />

<strong>Offshore</strong> W<strong>in</strong>d Project <strong>in</strong> <strong>the</strong> German Bight, is <strong>the</strong> use of a<br />

small water plane area tw<strong>in</strong> hull (SWATH) vessel. In a SWATH<br />

vessel <strong>the</strong> majority of <strong>the</strong> buoyancy is well below <strong>the</strong> waterl<strong>in</strong>e.<br />

This maximises <strong>the</strong> vessel’s stability, ensur<strong>in</strong>g that it is less<br />

affected by wave action, even <strong>in</strong> high seas and at high speeds.<br />

Fjellstrand W<strong>in</strong>dServer Trimarans<br />

The Fjellstrand W<strong>in</strong>dServer is one of a new generation of<br />

offshore service vessels. It <strong>in</strong>cludes a number of <strong>in</strong>novative<br />

features which have been designed to improve access to<br />

offshore <strong>in</strong>stallations <strong>in</strong> rough wea<strong>the</strong>r, optimise fuel efficiency,<br />

ensure <strong>the</strong> safety of <strong>the</strong> personnel on board, and reduce<br />

runn<strong>in</strong>g costs. The vessels will be equipped with four eng<strong>in</strong>es<br />

that power two controllable pitch propellers, giv<strong>in</strong>g improved<br />

operational flexibility while ensur<strong>in</strong>g redundant capacity.<br />

<strong>GL</strong> is very proud to be provid<strong>in</strong>g classification services for<br />

<strong>the</strong> first newbuild<strong>in</strong>gs of this <strong>in</strong>novative design. The order<br />

comprises six new vessels <strong>–</strong> two 30 m vessels and four 25 m <strong>–</strong><br />

built by Fjellstrand for Danish shipp<strong>in</strong>g company World Mar<strong>in</strong>e<br />

<strong>Offshore</strong> A/S. The vessels will have a service speed of 25 knots<br />

and <strong>the</strong> capacity to carry 25 and 12 service personnel, respectively.<br />

They are scheduled to enter service <strong>in</strong> March 2013 and<br />

open a new chapter <strong>in</strong> offshore crew boats.<br />

Source: Fjellstrand AS<br />

10

Crew boats <strong>–</strong> ensur<strong>in</strong>g safe and speedy passage<br />

Natalia Bekker<br />

Type: Work Boat<br />

Length: 26.18 m<br />

Gross Tonnage: 222<br />

Class notations hull<br />

8 100 A5, Work Boat, HSDE OC3 S7D11<br />

Class notation mach<strong>in</strong>ery<br />

7 MC AUT<br />

Crew boats <strong>–</strong> <strong>the</strong> challenge of compliancy<br />

As with many vessels <strong>in</strong> <strong>the</strong> offshore w<strong>in</strong>d sector, crew boats<br />

<strong>in</strong>tegrate new designs and fulfil sophisticated requirements.<br />

This can make <strong>the</strong>m difficult to categorise and class.<br />

To address this challenge, <strong>GL</strong> released <strong>the</strong> first comprehensive<br />

set of classification rules for Crew Boats and <strong>Offshore</strong> W<strong>in</strong>d<br />

Farm Service Craft <strong>in</strong> May 2012. These rules were developed<br />

by br<strong>in</strong>g<strong>in</strong>g toge<strong>the</strong>r all <strong>GL</strong> rules, <strong>in</strong>ternational codes and<br />

recommendations with relevance to <strong>the</strong> classification of crew<br />

boats. They will allow designers to develop customised vessels<br />

that reflect <strong>the</strong> <strong>in</strong>dividual needs of <strong>the</strong>ir clients, with full<br />

confidence that <strong>the</strong>se vessels will meet classification approval.<br />

The <strong>GL</strong> rules were developed <strong>in</strong> consultation with flag states<br />

and will contribute to <strong>the</strong> development of <strong>in</strong>ternational<br />

standards for crew boats.<br />

Additionally, <strong>in</strong> order to establish suitable safety levels for<br />

service craft of more than 12 service personnel, <strong>GL</strong> is actively<br />

contribut<strong>in</strong>g knowledge and expertise to <strong>the</strong> ongo<strong>in</strong>g IMO<br />

debate regard<strong>in</strong>g <strong>the</strong> categorisation of service personnel.<br />

Source: Photo Danny VYVEY<br />

W<strong>in</strong>dcat 28<br />

Type: Work Boat<br />

Length: 18 m<br />

Gross Tonnage: 50<br />

Class notations hull: 100 A5, HSDE III<br />

Class notation mach<strong>in</strong>ery: MC<br />

11

Many tasks, multiple vessels:<br />

support and survey crafts<br />

<strong>GL</strong> provides expertise for all vessel types that are needed for<br />

<strong>the</strong> highly specialised, demand<strong>in</strong>g tasks <strong>in</strong>volved <strong>in</strong> <strong>the</strong> design,<br />

construction and operation of w<strong>in</strong>d farms. Our knowledge<br />

becomes your competitive edge when identify<strong>in</strong>g solutions<br />

that ensure safety, reliability and cost effectiveness.<br />

Multiple craft deployment <strong>in</strong> <strong>the</strong> offshore w<strong>in</strong>d sector may<br />

<strong>in</strong>clude:<br />

Guard vessels<br />

Every site needs a guard vessel. This needs to be a very robust<br />

vessel with good endurance so that it can rema<strong>in</strong> on site dur<strong>in</strong>g<br />

severe wea<strong>the</strong>r conditions. Ma<strong>in</strong> requirements for guard vessels<br />

<strong>in</strong>clude modern radar with AIS / ARPA, all VHF communications<br />

as well as morse flash-lights to communicate with vessels.<br />

Buoy-lay<strong>in</strong>g and retrieval capability is advantageous to monitor<br />

and ma<strong>in</strong>ta<strong>in</strong> buoy positions.<br />

Support vessels<br />

Support vessels cover a broad range of tasks and capabilities.<br />

Dur<strong>in</strong>g foundation <strong>in</strong>stallation of structures such as jackets<br />

and tripods, grout<strong>in</strong>g is usually required. In general, it is more<br />

cost effective to have <strong>the</strong> ma<strong>in</strong> <strong>in</strong>stallation vessel cont<strong>in</strong>ue <strong>in</strong><br />

this role and to deploy a dedicated grout<strong>in</strong>g vessel. A specialist<br />

dive support vessel may also be advantageous as a cont<strong>in</strong>gency<br />

for failure repairs.<br />

Standard support vessels <strong>in</strong> German waters also <strong>in</strong>clude ones<br />

for pil<strong>in</strong>g noise mitigation measures. For this, <strong>the</strong> Bubble<br />

Curta<strong>in</strong> deployment and energis<strong>in</strong>g vessel is fast becom<strong>in</strong>g<br />

<strong>the</strong> approved choice.<br />

Fall-pipe vessels<br />

A fall-pipe vessel is capable of deposit<strong>in</strong>g material with great<br />

accuracy <strong>in</strong> deep waters. Such a vessel may be necessary for<br />

lay<strong>in</strong>g scour protection over cable repairs, filter-layer deployment<br />

prior to pil<strong>in</strong>g monopiles, and seabed preparation for<br />

concrete gravity bases.<br />

Side-dump<strong>in</strong>g vessels<br />

Heavy scour protection of foundations is usually a job for sidedump<strong>in</strong>g<br />

vessels. They are able to place rocks of sizes of 60 cm<br />

to 1 m dia. adjacent to monopiles or gravity based structures<br />

(GBSs).<br />

Cable-lay<strong>in</strong>g vessels<br />

(for array and export cables)<br />

Cable lay<strong>in</strong>g vessels of two types are required <strong>–</strong> for array and<br />

export cables. DP2 offshore supply vessels can be retro-fitted<br />

with cable-reels and cable eng<strong>in</strong>es. A frequent requirement<br />

is to tow a jett<strong>in</strong>g sled, <strong>the</strong>refore a knuckle-boom crane or aft<br />

A frame is a valuable addition for launch and recovery.<br />

Survey vessels<br />

Survey vessels come <strong>in</strong> several forms. Environmental survey<br />

vessels run transects across <strong>the</strong> area, often on monthly cycles,<br />

start<strong>in</strong>g months or years before <strong>the</strong> actual <strong>in</strong>stallation phase.<br />

Study<strong>in</strong>g seafloor relief and terra<strong>in</strong> usually <strong>in</strong>volves bathymetric<br />

survey vessels with multi-beam side-scan sonar, sub-bottom<br />

profil<strong>in</strong>g with boomers / p<strong>in</strong>gers and towed hydrophone arrays.<br />

Magnetometer surveys may also need to be carried out to<br />

measure <strong>the</strong> strength and direction of magnetic fields.<br />

Additional vessels<br />

To fulfil <strong>the</strong> large number of tasks needed for <strong>the</strong> <strong>in</strong>stallation,<br />

operation and ma<strong>in</strong>tenance of offshore w<strong>in</strong>d farms, vessels<br />

for <strong>the</strong> deployment of helicopters, a parts store, office space<br />

and o<strong>the</strong>r general facilities may also be required.<br />

Nostag 10<br />

Type: Cable Lay<strong>in</strong>g Barge<br />

Length: 100.50 m<br />

Gross Tonnage: 4,200<br />

Class notations hull<br />

8 100 A5, IW S4D10<br />

Class notation mach<strong>in</strong>ery<br />

7 MC AUT<br />

12

Many tasks, multiple vessels: support and survey crafts<br />

FUGRO EQUATOR<br />

Type: Special Purpose Ship<br />

Length: 59.07 m<br />

Gross Tonnage: 1,929<br />

Class notations hull<br />

8 100 A5, IW, Special Purpose Ship, Survey Vessel<br />

Source: Fugro N.V.<br />

Class notation mach<strong>in</strong>ery<br />

7 MC AUT DP 1<br />

GO Cougar<br />

Type: Supply Vessel<br />

Length: 67.6 m<br />

Gross Tonnage: 2,180<br />

Class notations hull<br />

6 100 A5, DP2 DG<br />

Class notation mach<strong>in</strong>ery<br />

6 MC AUT FF1 CM-PS<br />

Magnus<br />

Type: Anchor Handl<strong>in</strong>g Tug<br />

Length: 54.13 m<br />

Gross Tonnage: 1,767<br />

Class notations hull<br />

7 100 A5 E2, DP2 DG, Tug<br />

Class notation mach<strong>in</strong>ery<br />

7 MC E2 AUT FF1<br />

13

State-of-<strong>the</strong>-Art <strong>Offshore</strong> W<strong>in</strong>d.

<strong>Germanischer</strong> <strong>Lloyd</strong>.<br />

You need a reliable partner at eye-level who you can trust with <strong>the</strong> technological development of your <strong>in</strong>novative W<strong>in</strong>d Turb<strong>in</strong>e<br />

Installation Ship. We provide state-of-<strong>the</strong>-art expertise and lead<strong>in</strong>g offshore classification services: From class notations through to plan<br />

approvals, statutory support, underwater technology, and even to project management <strong>–</strong> <strong>GL</strong> is <strong>the</strong> s<strong>in</strong>gle port of call for all your needs.<br />

www.gl-group.com

Region Americas<br />

1155 Dairy Ashford, Suite 315<br />

Houston, TX 77079<br />

United States of America<br />

Phone: +1 832 320 4641<br />

Fax: +1 832 320 4654<br />

gl-americas@gl-group.com<br />

Region Europe / Middle East / Africa<br />

Brooktorkai 18<br />

20457 Hamburg<br />

Germany<br />

Phone: +49 40 36149-8786<br />

Fax: +49 40 36149-4051<br />

gl-ema@gl-group.com<br />

Region Asia / Pacific<br />

381, Huaihai M. Road<br />

Room 3209-3220, Shanghai Central Plaza<br />

200020 Shanghai, People's Republic of Ch<strong>in</strong>a<br />

Phone: +86 21 6141 6700<br />

Fax: +86 21 6391 5822<br />

gl-asia@gl-group.com<br />

Hamburg<br />

Houston<br />

Shanghai<br />

<strong>Germanischer</strong> <strong>Lloyd</strong> SE<br />

Ship Type Expert:<br />

Jan Schreiber<br />

Phone: +49 40 36149-5235<br />

Jan.Schreiber@gl-group.com<br />

www.gl-group.com<br />

0E005 · 2012-09-01<br />

This brochure was produced with consideration for <strong>the</strong> environment. It is pr<strong>in</strong>ted on paper that is 100% recycled and has an FSC accreditation.<br />

The <strong>GL</strong> Group does not warrant or assume any k<strong>in</strong>d of liability for <strong>the</strong> accuracy, completeness or quality of <strong>the</strong> <strong>in</strong>formation provided. Liability claims aga<strong>in</strong>st any member of <strong>the</strong> <strong>GL</strong> Group<br />

<strong>in</strong> relation to any loss or damage aris<strong>in</strong>g out of or <strong>in</strong> connection with <strong>the</strong> use or non-use of <strong>in</strong>formation provided, <strong>in</strong>clud<strong>in</strong>g <strong>the</strong> use of <strong>in</strong>correct or <strong>in</strong>complete <strong>in</strong>formation, are excluded<br />

to <strong>the</strong> fullest extent permissible by law. All presentations of services and products may be subject to alteration and are non-b<strong>in</strong>d<strong>in</strong>g. Each <strong>GL</strong> Group member expressly reserves <strong>the</strong> right<br />

without notice to change, supplement or delete parts of <strong>the</strong> pages or <strong>the</strong> entire presentation of services and products or to stop <strong>the</strong> publication temporarily or def<strong>in</strong>itively.