A Solution to the Inherent List on Nimitz Class Aircraft Carriers

A Solution to the Inherent List on Nimitz Class Aircraft Carriers

A Solution to the Inherent List on Nimitz Class Aircraft Carriers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

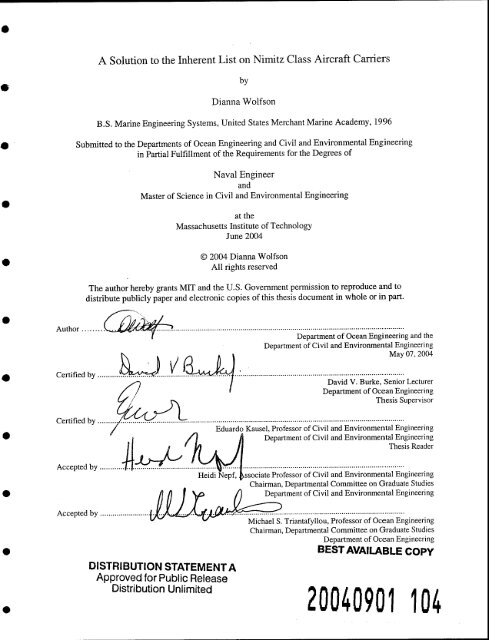

A <str<strong>on</strong>g>Soluti<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Inherent</str<strong>on</strong>g> <str<strong>on</strong>g>List</str<strong>on</strong>g> <strong>on</strong> <strong>Nimitz</strong> <strong>Class</strong> <strong>Aircraft</strong> <strong>Carriers</strong><br />

by<br />

Dianna Wolf s<strong>on</strong><br />

B.S. Marine Engineering Systems, United States Merchant Marine Academy, 1996<br />

Submitted <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> Departments of Ocean Engineering and Civil and Envir<strong>on</strong>mental Engineering<br />

in Partial Fulfillment of <str<strong>on</strong>g>the</str<strong>on</strong>g> Requirements for <str<strong>on</strong>g>the</str<strong>on</strong>g> Degrees of<br />

Naval Engineer<br />

and<br />

Master of Science in Civil and Envir<strong>on</strong>mental Engineering<br />

at <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

Massachusetts Institute of Technology<br />

June 2004<br />

© 2004 Dianna Wolfs<strong>on</strong><br />

All rights reserved<br />

The author hereby grants MIT and <str<strong>on</strong>g>the</str<strong>on</strong>g> U.S. Government permissi<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> reproduce and <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

distribute publicly paper and electr<strong>on</strong>ic copies of this <str<strong>on</strong>g>the</str<strong>on</strong>g>sis document in whole or in part.<br />

Author<br />

Certified by<br />

Certified by<br />

Department of Ocean Engineering and <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

Department of Civil and Envir<strong>on</strong>mental Engineering<br />

May 07, 2004<br />

David V. Burke, Senior Lecturer<br />

Department of Ocean Engineering<br />

Thesis Supervisor<br />

Eduardo Kausel, Professor of Civil and Envir<strong>on</strong>mental Engineering<br />

Department of Civil and Envir<strong>on</strong>mental Engineering<br />

Thesis Reader<br />

Accepted by<br />

Heidi Nepf,<br />

ssociate Professor of Civil and Envir<strong>on</strong>mental Engineering<br />

Chairman, Departmental Committee <strong>on</strong> Graduate Studies<br />

Department of Civil and Envir<strong>on</strong>mental Engineering<br />

Accepted by<br />

DISTRIBUTION STATEMENT A<br />

Approved for Public Release<br />

Distributi<strong>on</strong> Unlimited<br />

Michael S. Triantafyllou, Professor of Ocean Engineering<br />

Chairman, Departmental Committee <strong>on</strong> Graduate Studies<br />

Department of Ocean Engineering<br />

BEST AVAILABLE COPY<br />

20040901 104

PAGE INTENTIONALLY LEFT BLANK

A <str<strong>on</strong>g>Soluti<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>Inherent</str<strong>on</strong>g> <str<strong>on</strong>g>List</str<strong>on</strong>g> <strong>on</strong> <strong>Nimitz</strong> <strong>Class</strong> <strong>Aircraft</strong> <strong>Carriers</strong><br />

by<br />

Dianna Wolfs<strong>on</strong><br />

Abstract<br />

Submitted <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> Departments of Ocean Engineering and<br />

Civil and Envir<strong>on</strong>mental Engineering<br />

<strong>on</strong> May 07, 2004, in partial fulfillment of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

Requirements for <str<strong>on</strong>g>the</str<strong>on</strong>g> degrees of<br />

Naval Engineer<br />

and<br />

Master of Science in Civil and Envir<strong>on</strong>mental Engineering<br />

<strong>Nimitz</strong> class aircraft carriers possess an inherent list <str<strong>on</strong>g>to</str<strong>on</strong>g> starboard that <str<strong>on</strong>g>the</str<strong>on</strong>g>ir list c<strong>on</strong>trol<br />

systems (LCS) are typically unable <str<strong>on</strong>g>to</str<strong>on</strong>g> correct while under Combat Load C<strong>on</strong>diti<strong>on</strong>s. As a result,<br />

it has become necessary <str<strong>on</strong>g>to</str<strong>on</strong>g> use fresh water ballast in a number of inner bot<str<strong>on</strong>g>to</str<strong>on</strong>g>m voids and damage<br />

c<strong>on</strong>trol voids <str<strong>on</strong>g>to</str<strong>on</strong>g> augment <str<strong>on</strong>g>the</str<strong>on</strong>g> LCS. Maintaining liquid ballast in damage c<strong>on</strong>trol voids is<br />

unacceptable, as it reduces <str<strong>on</strong>g>the</str<strong>on</strong>g> design counter flooding capability of <str<strong>on</strong>g>the</str<strong>on</strong>g> ship, and thus reduces<br />

ship survivability. In order <str<strong>on</strong>g>to</str<strong>on</strong>g> res<str<strong>on</strong>g>to</str<strong>on</strong>g>re <str<strong>on</strong>g>the</str<strong>on</strong>g> ships operati<strong>on</strong>al flexibility and achieve <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

necessary/desired list correcti<strong>on</strong>, this study determines <str<strong>on</strong>g>the</str<strong>on</strong>g> effect of adding solid ballast <str<strong>on</strong>g>to</str<strong>on</strong>g> a<br />

series of voids/tanks identified <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> 2""^, 4*, and 8* decks.<br />

Based <strong>on</strong> ballast density, tank locati<strong>on</strong> and capacity, ease of ballast installati<strong>on</strong>, minor<br />

tank structural modificati<strong>on</strong>s, and a decisi<strong>on</strong> making cost analysis, solid ballast was determined<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> be <str<strong>on</strong>g>the</str<strong>on</strong>g> most advantageous for use in correcting <str<strong>on</strong>g>the</str<strong>on</strong>g> inherent list <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong> class aircraft<br />

carriers. Fresh water ballast was also examined as a possible alternative, but not as extensively<br />

due <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> large quantity of water required and its limited ability <str<strong>on</strong>g>to</str<strong>on</strong>g> achieve a list correcti<strong>on</strong>.<br />

<strong>Nimitz</strong> class aircraft carriers currently have an average list of L5 degrees and a KG of 47<br />

feet. Since <str<strong>on</strong>g>the</str<strong>on</strong>g>ir allowable KG cannot exceed 48.5 feet, <str<strong>on</strong>g>the</str<strong>on</strong>g> average service life allowance (SLA)<br />

for KG is approximately 1.5 feet. This study shows that by adding approximately 400 I<str<strong>on</strong>g>to</str<strong>on</strong>g>n of<br />

solid ballast, list can be corrected by 1.5 degrees with <strong>on</strong>ly a 0.1 percent increase in KG. Thus,<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> permanently fix <str<strong>on</strong>g>the</str<strong>on</strong>g> average <strong>Nimitz</strong> class aircraft carrier starboard list, <str<strong>on</strong>g>the</str<strong>on</strong>g>re would be a 0.05<br />

foot increase in KG, which in all cases is within <str<strong>on</strong>g>the</str<strong>on</strong>g> SLA. Additi<strong>on</strong>ally, this study shows that<br />

this L5 degree list correcti<strong>on</strong> can be accomplished at a low cost of approximately $1,200 per<br />

I<str<strong>on</strong>g>to</str<strong>on</strong>g>n. C<strong>on</strong>sidering <str<strong>on</strong>g>the</str<strong>on</strong>g> reducti<strong>on</strong> in operati<strong>on</strong>al c<strong>on</strong>straints and <str<strong>on</strong>g>the</str<strong>on</strong>g> benefits <str<strong>on</strong>g>to</str<strong>on</strong>g> ship survivability,<br />

this is truly an inexpensive propositi<strong>on</strong>.<br />

Thesis Supervisor: David V. Burke<br />

Title: Senior Lecturer<br />

Thesis Reader: Eduardo Kausel<br />

Title: Professor of Civil and Envir<strong>on</strong>mental Engineering

Acknowledgements<br />

I would like <str<strong>on</strong>g>to</str<strong>on</strong>g> thank CDR Kevin Terry who c<strong>on</strong>tacted MIT with a project proposal <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

find an advantageous and cost effective soluti<strong>on</strong> for fixing <str<strong>on</strong>g>the</str<strong>on</strong>g> inherent list <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong> class<br />

aircraft carriers. Without his support, this <str<strong>on</strong>g>the</str<strong>on</strong>g>sis would not have been possible.<br />

Throughout <str<strong>on</strong>g>the</str<strong>on</strong>g> course of this project, many individuals from various organizati<strong>on</strong>s<br />

provided invaluable operati<strong>on</strong>al and technical assistance. I would like <str<strong>on</strong>g>to</str<strong>on</strong>g> take this opportunity <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

thank every<strong>on</strong>e for <str<strong>on</strong>g>the</str<strong>on</strong>g>ir c<strong>on</strong>tributi<strong>on</strong>s and advice. I would also like <str<strong>on</strong>g>to</str<strong>on</strong>g> thank my husband for his<br />

friendship, love, and encouragement over <str<strong>on</strong>g>the</str<strong>on</strong>g> past three years and always.<br />

NAVSEA<br />

CDR Kevin Terry<br />

CAPT (ret.) Chuck Bush<br />

CAPT T. Moore<br />

CAPT James Murdoch<br />

Dominick Cimino<br />

Roger M. Nutting<br />

Evelisse Marti r<br />

Wei d<strong>on</strong> Gimbel<br />

LCDR Brian Lawerence<br />

LCDR Rick Thiel<br />

Bath Ir<strong>on</strong> Works<br />

John Grostick<br />

Lew Pratt<br />

Allen Pac<br />

Ray Lacour<br />

LCDR Michael Taylor<br />

CVN Ships<br />

LCDR Chariie Strassle (DCA, CVN 69)<br />

CDR Robert Finely (Cheng, CVN 71)<br />

LCDR Peter Pasquale (DCA, CVN 71)<br />

LCDR John Rickards (DCA, CVN 72)<br />

LCDR Scott Noe (DCA, CVN 76)<br />

CDR Glenn Hofert (Cheng, CVN 76)<br />

Massachusetts Institute of Technology<br />

Dr. David V. Burke<br />

CDR (ret.) John Amy<br />

CDR Timothy McCoy<br />

NGC - Newport News Shipbuilding<br />

Jerry Dudley<br />

Hal McCaskill<br />

NSWC Carderock<br />

John M. Rosborough<br />

Carlos R. Corretjer<br />

Charlie Snelling<br />

Bruce Winterstein<br />

Todd Heidenreich<br />

PCCI. Inc.<br />

John A. 'T<strong>on</strong>y" Kupersmith<br />

Jessica R. Coles<br />

Herbert Engineering Corporati<strong>on</strong><br />

Colin Moore<br />

Norfolk Naval Shipvard<br />

Walt Del<strong>on</strong>g<br />

Larry Back<br />

Ballast Technologies. Inc.<br />

Mark Ensio<br />

N.S. NAPPI Associates<br />

Nat Nappi, Sr.<br />

#<br />

Please accept my apologies if I have left some<strong>on</strong>e off this list.

Table of C<strong>on</strong>tents<br />

Abstract 3<br />

Acknowledgements 4<br />

Table of C<strong>on</strong>tents 5<br />

<str<strong>on</strong>g>List</str<strong>on</strong>g> of Figures 6<br />

<str<strong>on</strong>g>List</str<strong>on</strong>g> of Tables 6<br />

<str<strong>on</strong>g>List</str<strong>on</strong>g> of Appendices 6<br />

1.0 Introducti<strong>on</strong> 7<br />

1.0 Introducti<strong>on</strong> 7<br />

1.1 Motivati<strong>on</strong> 7<br />

1.2 Background 7<br />

1.2.1 Past Research 10<br />

1.2.2 Stability 10<br />

1.2.3 Survivability 13<br />

1.2.4 Displacement Limits 14<br />

1.2.5 KG Limits 14<br />

1.3 Present Opti<strong>on</strong>s 15<br />

1.3.1 C<strong>on</strong>tinue <str<strong>on</strong>g>to</str<strong>on</strong>g> operate using inner bot<str<strong>on</strong>g>to</str<strong>on</strong>g>m and DC voids 15<br />

1.3.2 Add a list c<strong>on</strong>trol tank <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> port side 17<br />

1.3.3 Move or exchange compartment spaces 18<br />

1.3.4 C<strong>on</strong>vert a current DC void(s) <str<strong>on</strong>g>to</str<strong>on</strong>g> a JP-5 tank(s) and pump last 18<br />

1.3.5 Future ship alterati<strong>on</strong>s and modificati<strong>on</strong>s 18<br />

1.3.6 Re-examine current <str<strong>on</strong>g>List</str<strong>on</strong>g> C<strong>on</strong>trol System 19<br />

1.3.7 Ballast Additi<strong>on</strong> 21<br />

1.3.7.1 Water Ballast 21<br />

1.3.7.2 Solid Ballast 21<br />

1.4 Opti<strong>on</strong> Selecti<strong>on</strong> 23<br />

2.0 Preliminary Analysis and Results 23<br />

2.1 Tank Selecti<strong>on</strong> 24<br />

2.2 Modeling Analysis Performed 25<br />

2.3 Preliminary Decisi<strong>on</strong>-Making Cost Estimati<strong>on</strong> 31<br />

2.4 Structural Analysis 35<br />

2.4.1 Structural Modificati<strong>on</strong>s 39<br />

2.4.1.1 Modificati<strong>on</strong>s <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> 2"'* Deck 39<br />

2.4.1.2 Modificati<strong>on</strong>s <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> 4"" Deck 41<br />

2.4.1.3 Modificati<strong>on</strong>s <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> 8* Deck 43<br />

3.0 Final Analysis and Results 44<br />

3.1 Final POSSE Results 45<br />

3.2 Final Cost Estimati<strong>on</strong> 46<br />

3.2.1 Ease of Removal 48<br />

3.2.2 Evidence Perma Ballast® is n<strong>on</strong>-corrosive 48<br />

4.0 C<strong>on</strong>clusi<strong>on</strong> 50<br />

5.0 Recommendati<strong>on</strong>s 51<br />

References 53

<str<strong>on</strong>g>List</str<strong>on</strong>g> of Figures<br />

Figure 1: Stresses in rectangular plates under uniform lateral pressure [2] 38<br />

Figure 2: 2"^* Deck Compartment 2-165-8-V 39<br />

Figure 3: 2"'' Deck Compartment 2-165-8-V, transverse secti<strong>on</strong> 41<br />

Figure 4: 4"" Deck Compartment 4-165-4-V 42<br />

Figure 5: S'*" Deck Compartment 8-225-6-V 43<br />

<str<strong>on</strong>g>List</str<strong>on</strong>g> of Tables<br />

Table 1: CVN 68 <strong>Class</strong> Delivery Data and <strong>Class</strong> Predicti<strong>on</strong>s as of 11/17/03 8<br />

Table 2: Deck Locati<strong>on</strong> Cost Comparis<strong>on</strong> 32<br />

Table 3: Required Structural Modificati<strong>on</strong>s for 2-165-8-V 40<br />

Table 4: Required Structural Modificati<strong>on</strong>s for 4-165-4-V 42<br />

Table 5: Required Structural Modificati<strong>on</strong>s for 8-225-6-V 44<br />

Table 6: Final Cost, Weight Additi<strong>on</strong>, and Change in KG Comparis<strong>on</strong> 47<br />

<str<strong>on</strong>g>List</str<strong>on</strong>g> of Appendices<br />

Appendix A: Tank Locati<strong>on</strong> Study 54<br />

Appendix B: Preliminary POSSE Modeling Results 58<br />

Appendix C: Preliminary Cost Estimati<strong>on</strong> Data and Worksheets 62<br />

Appendix D: Preliminary Cost Comparis<strong>on</strong> 86<br />

Appendix E: Complete Structural Analysis 88<br />

Appendix F: Final POSSE Modeling Results 148<br />

Appendix G: Final Cost Estimati<strong>on</strong> Data and Worksheets 150

1.0 Introducti<strong>on</strong><br />

1.1 Motivati<strong>on</strong><br />

<strong>Aircraft</strong> carriers are <str<strong>on</strong>g>the</str<strong>on</strong>g> largest combatant ships in <str<strong>on</strong>g>the</str<strong>on</strong>g> world. They are huge floating<br />

cities, carrying thousands of sailors and aircraft, each vessel with more military power than many<br />

nati<strong>on</strong>s. But with such might comes mighty operati<strong>on</strong>al requirements.<br />

In order <str<strong>on</strong>g>to</str<strong>on</strong>g> launch and recover aircraft <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> flight deck, most ships will report any<br />

change in list in excess of V4 degree <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> Engineering Officer of <str<strong>on</strong>g>the</str<strong>on</strong>g> Watch (EOOW) for<br />

correcti<strong>on</strong>. The <strong>Nimitz</strong> class aircraft carrier was designed <str<strong>on</strong>g>to</str<strong>on</strong>g> maintain a level deck during flight<br />

operati<strong>on</strong>s through <str<strong>on</strong>g>the</str<strong>on</strong>g> utilizati<strong>on</strong> of <str<strong>on</strong>g>the</str<strong>on</strong>g> LCS. The LCS is designed <str<strong>on</strong>g>to</str<strong>on</strong>g> compensate for <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

operati<strong>on</strong>al effects of aircraft movement <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> flight deck and in <str<strong>on</strong>g>the</str<strong>on</strong>g> hangar bays and not<br />

intended <str<strong>on</strong>g>to</str<strong>on</strong>g> compensate for an inherent list. Any inherent list imposes operati<strong>on</strong>al c<strong>on</strong>straints <strong>on</strong><br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> ship, particularly when <str<strong>on</strong>g>the</str<strong>on</strong>g> carrier has embarked a full air-wing and full fuel loading (Combat<br />

Load C<strong>on</strong>diti<strong>on</strong>). <strong>Nimitz</strong> class carriers have a his<str<strong>on</strong>g>to</str<strong>on</strong>g>ry of inherent starboard list, due primarily <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> ship's c<strong>on</strong>figurati<strong>on</strong>. His<str<strong>on</strong>g>to</str<strong>on</strong>g>ry shows that modificati<strong>on</strong>s <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong> class are have increased<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> inherent starboard list of each carrier. This <str<strong>on</strong>g>the</str<strong>on</strong>g>sis will explore various opti<strong>on</strong>s for finding a<br />

permanent soluti<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong> class list c<strong>on</strong>trol issues, particularly, <str<strong>on</strong>g>the</str<strong>on</strong>g> installati<strong>on</strong> of solid<br />

ballast <str<strong>on</strong>g>to</str<strong>on</strong>g> counter list.<br />

1.2 Background<br />

There are a number of obstacles in finding a permanent soluti<strong>on</strong> for <str<strong>on</strong>g>the</str<strong>on</strong>g> inherent list<br />

associated with most <strong>Nimitz</strong> class carriers, as each carrier has a different inherent list associated<br />

with it. This may sound strange, but every ship is slightly different. The ships are so large and<br />

have such a high procurement cost that <strong>on</strong>ly <strong>on</strong>e is built at a time. It takes an average of five<br />

years <str<strong>on</strong>g>to</str<strong>on</strong>g> build <strong>on</strong>e carrier, and in that time, modernizati<strong>on</strong>s, upgrades, and improvements are

introduced in<str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> design. As such, <str<strong>on</strong>g>the</str<strong>on</strong>g> ships are c<strong>on</strong>stantly changing and evolving, all within<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> same skin designed in <str<strong>on</strong>g>the</str<strong>on</strong>g> late 1960's. A comparative analysis of <str<strong>on</strong>g>the</str<strong>on</strong>g> commissi<strong>on</strong>ed and<br />

predicted current displacement, vertical center of gravity (KG), and list with <str<strong>on</strong>g>the</str<strong>on</strong>g> latest unknown<br />

growth correcti<strong>on</strong>s for <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong> class aircraft carriers are shown in Table 1.<br />

Table 1: CVN 68 <strong>Class</strong> Delivery Data and <strong>Class</strong> Predicti<strong>on</strong>s as of 11/17/03<br />

Delivery<br />

Displacement<br />

(I<str<strong>on</strong>g>to</str<strong>on</strong>g>ns)<br />

Predicted<br />

Current<br />

Displacement<br />

(I<str<strong>on</strong>g>to</str<strong>on</strong>g>ns)<br />

Predicted<br />

Current<br />

KG (ft)<br />

Delivery<br />

<str<strong>on</strong>g>List</str<strong>on</strong>g><br />

(degrees)<br />

Predicted<br />

Current<br />

<str<strong>on</strong>g>List</str<strong>on</strong>g><br />

(degrees)<br />

Delivery<br />

Ship<br />

KG (ft)<br />

68 93,283 100,064 45.73 47.22 l.Ol(S) 0.10 (S)<br />

69 93,832 100,588 45.94 47.1 0.82 (S) 0.25 (S)<br />

70 94,069 100,599 46.29 47.28 1.22 (S) 0.11 (P)<br />

71 96,865 103,700 46.4 47.27 0.27 (S) 0.41 (S)<br />

72 97,497 103,912 46.61 47.2 0.77 (S) 1.81 (S)<br />

73 97,816 104,095 46.54 47.03 0.85 (S) 1.55 (S)<br />

74 97,490 103,419 46.63 47.23 1.63 (S) 2.54 (S)<br />

75 97,944 103,863 46.4 46.93 0.43 (S) 1.61 (S)<br />

76 97,953 101,187 46.66 46.77 0.08 (S) 0.99 (S)<br />

#<br />

<strong>Nimitz</strong> class carrier c<strong>on</strong>tracts require that an Accepted Weight Estimate (AWE) be<br />

negotiated between <str<strong>on</strong>g>the</str<strong>on</strong>g> C<strong>on</strong>trac<str<strong>on</strong>g>to</str<strong>on</strong>g>r and <str<strong>on</strong>g>the</str<strong>on</strong>g> Government. A starboard inherent list was seen<br />

creeping upwards through CVN 73, such that for <str<strong>on</strong>g>the</str<strong>on</strong>g> CVN 74/75 c<strong>on</strong>tract, <str<strong>on</strong>g>the</str<strong>on</strong>g> program office<br />

invoked a list <str<strong>on</strong>g>to</str<strong>on</strong>g>lerance of 0.50 degree (P/S) for <str<strong>on</strong>g>the</str<strong>on</strong>g> combat load c<strong>on</strong>diti<strong>on</strong>. As a result of this<br />

new requirement, and beginning with <str<strong>on</strong>g>the</str<strong>on</strong>g> CVN 74/75 c<strong>on</strong>tract, <str<strong>on</strong>g>the</str<strong>on</strong>g> Navy and <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>trac<str<strong>on</strong>g>to</str<strong>on</strong>g>r<br />

agreed <str<strong>on</strong>g>to</str<strong>on</strong>g> include 850 l<strong>on</strong>g <str<strong>on</strong>g>to</str<strong>on</strong>g>ns of c<strong>on</strong>trac<str<strong>on</strong>g>to</str<strong>on</strong>g>r-c<strong>on</strong>trolled ballast in <str<strong>on</strong>g>the</str<strong>on</strong>g> AWE <str<strong>on</strong>g>to</str<strong>on</strong>g> offset <str<strong>on</strong>g>the</str<strong>on</strong>g> already<br />

projected design inherent starboard list. Before any real ballast was <str<strong>on</strong>g>to</str<strong>on</strong>g> be added <strong>on</strong> CVN 74,<br />

however, <str<strong>on</strong>g>the</str<strong>on</strong>g> program office wanted <str<strong>on</strong>g>to</str<strong>on</strong>g> see if <str<strong>on</strong>g>the</str<strong>on</strong>g>re was indeed a list problem after <str<strong>on</strong>g>the</str<strong>on</strong>g> ship was<br />

delivered and fully loaded. It is at this time that CVN 74 was found <str<strong>on</strong>g>to</str<strong>on</strong>g> a have real inherent<br />

starboard list problem. The identified list problem was resolved by <str<strong>on</strong>g>the</str<strong>on</strong>g> use of fresh water (FW)<br />

ballast. To date, permanent ballast has not been installed <strong>on</strong> any aircraft carrier of <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong>

class. Changes <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> CVN 76 design resulted in a reduced starboard list and c<strong>on</strong>sequently <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

c<strong>on</strong>trac<str<strong>on</strong>g>to</str<strong>on</strong>g>r-c<strong>on</strong>trolled ballast included in <str<strong>on</strong>g>the</str<strong>on</strong>g> AWE was reduced <str<strong>on</strong>g>to</str<strong>on</strong>g> 650 l<strong>on</strong>g <str<strong>on</strong>g>to</str<strong>on</strong>g>ns.<br />

From operati<strong>on</strong>al experience, it would be safe <str<strong>on</strong>g>to</str<strong>on</strong>g> say that <str<strong>on</strong>g>the</str<strong>on</strong>g>re is an inherent starboard<br />

list under full fuel load (or virtually full) with <str<strong>on</strong>g>the</str<strong>on</strong>g> airwing embarked and no flight operati<strong>on</strong>s<br />

being c<strong>on</strong>ducted <strong>on</strong> most <strong>Nimitz</strong> class carriers. When all <str<strong>on</strong>g>the</str<strong>on</strong>g> planes are stacked <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> starboard<br />

side and <str<strong>on</strong>g>the</str<strong>on</strong>g> ship has just been refueled, <str<strong>on</strong>g>the</str<strong>on</strong>g> LCS is unable <str<strong>on</strong>g>to</str<strong>on</strong>g> level <str<strong>on</strong>g>the</str<strong>on</strong>g> deck. This is when it has<br />

become necessary for some carriers <str<strong>on</strong>g>to</str<strong>on</strong>g> use fresh water ballast in a number of inner bot<str<strong>on</strong>g>to</str<strong>on</strong>g>m voids<br />

and damage c<strong>on</strong>trol (DC) voids <str<strong>on</strong>g>to</str<strong>on</strong>g> correct <str<strong>on</strong>g>the</str<strong>on</strong>g> adverse list c<strong>on</strong>diti<strong>on</strong>. But from a ship<br />

survivability standpoint, and as <str<strong>on</strong>g>the</str<strong>on</strong>g>ir name implies, DC voids are not an acceptable list c<strong>on</strong>trol<br />

measure under normal operating c<strong>on</strong>diti<strong>on</strong>s. Maintaining liquid ballast in DC voids reduces <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

design counter flooding capability of <str<strong>on</strong>g>the</str<strong>on</strong>g> ship. N<strong>on</strong>e <str<strong>on</strong>g>the</str<strong>on</strong>g> less, this is how some ships operate in<br />

order <str<strong>on</strong>g>to</str<strong>on</strong>g> keep <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong> class ships at sea.<br />

In February 1999, PEO <strong>Carriers</strong> issued a Message <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> CVN 68 <strong>Class</strong> identifying<br />

several voids (i.e., n<strong>on</strong> DC voids) that could be used for FW ballasting for ships experiencing list<br />

c<strong>on</strong>trol problems. Prior <str<strong>on</strong>g>to</str<strong>on</strong>g> using those voids, however, <str<strong>on</strong>g>the</str<strong>on</strong>g> message requested <str<strong>on</strong>g>the</str<strong>on</strong>g> ships <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

c<strong>on</strong>firm that <str<strong>on</strong>g>the</str<strong>on</strong>g> list c<strong>on</strong>trol difficulties were not <str<strong>on</strong>g>the</str<strong>on</strong>g> result of abnormal LCS operati<strong>on</strong>s or<br />

adverse liquid loading or s<str<strong>on</strong>g>to</str<strong>on</strong>g>res management. <strong>Carriers</strong> experiencing list c<strong>on</strong>trol difficulties were<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> request approval from <str<strong>on</strong>g>the</str<strong>on</strong>g> Type Commander (TYCOM) <str<strong>on</strong>g>to</str<strong>on</strong>g> fill <str<strong>on</strong>g>the</str<strong>on</strong>g> voids listed in <str<strong>on</strong>g>the</str<strong>on</strong>g> message.<br />

The approval would remain in effect for that ship until a permanent soluti<strong>on</strong> was identified and<br />

implemented.<br />

It is obvious that fixing <str<strong>on</strong>g>the</str<strong>on</strong>g> inherent list cannot be solved by leaving aircraft behind or by<br />

limiting <str<strong>on</strong>g>the</str<strong>on</strong>g> load of fuel carried. TYCOM directive states that <str<strong>on</strong>g>the</str<strong>on</strong>g> JP-5 system is required <str<strong>on</strong>g>to</str<strong>on</strong>g>

emain at least 60% full at all times. These ships have a very specific warfighting requirement<br />

that must be achieved, and a reducti<strong>on</strong> in capabilities is unacceptable.<br />

There must be a soluti<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> inherent list problem bey<strong>on</strong>d limiting ships payload or<br />

using <str<strong>on</strong>g>the</str<strong>on</strong>g> DC voids outside of <str<strong>on</strong>g>the</str<strong>on</strong>g>ir designed intent. This report evaluates o<str<strong>on</strong>g>the</str<strong>on</strong>g>r alternatives <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

finding a soluti<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> fix <str<strong>on</strong>g>the</str<strong>on</strong>g> inherent list <strong>on</strong> <strong>Nimitz</strong> class aircraft carriers.<br />

1.2.1 Past Research<br />

A <str<strong>on</strong>g>the</str<strong>on</strong>g>sis was performed in 2001 by Michael Mal<strong>on</strong>e, a graduate of MIT. His <str<strong>on</strong>g>the</str<strong>on</strong>g>sis, titled<br />

"An Alternate Method for <str<strong>on</strong>g>the</str<strong>on</strong>g> Determinati<strong>on</strong> of <strong>Aircraft</strong> Carrier Limiting Displacement for<br />

Strength;" determined that although all <strong>Nimitz</strong> class aircraft carriers are approaching <str<strong>on</strong>g>the</str<strong>on</strong>g>ir<br />

limiting displacement for strength, <str<strong>on</strong>g>the</str<strong>on</strong>g> traditi<strong>on</strong>al methods of such calculati<strong>on</strong>s are c<strong>on</strong>servative.<br />

In fact, <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong> class carriers can accommodate more weight than previously thought.<br />

Because of this <str<strong>on</strong>g>the</str<strong>on</strong>g>sis, <str<strong>on</strong>g>the</str<strong>on</strong>g> U.S. Navy <strong>Aircraft</strong> Carrier Program Office (PMS 312) later directed<br />

N.S. NAPPI Associates <str<strong>on</strong>g>to</str<strong>on</strong>g> c<strong>on</strong>duct a detailed analysis <strong>on</strong> estimating <str<strong>on</strong>g>the</str<strong>on</strong>g> limiting displacement for<br />

strength. Again, it was proven that <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong> class hull is capable of sustaining additi<strong>on</strong>al<br />

weights which would exceed <str<strong>on</strong>g>the</str<strong>on</strong>g> current established limiting displacement for strength.<br />

1.2.2 Stability<br />

The stability status for USN ships is defined in [4] and is supported by [11]. The Chief of<br />

Naval Operati<strong>on</strong>s has directed that <str<strong>on</strong>g>the</str<strong>on</strong>g> Navy's ships will be kept within naval architectural limits<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> ensure that essential survivability features are maintained. For each ship class, <str<strong>on</strong>g>the</str<strong>on</strong>g> Naval Sea<br />

Systems Command's Weights and Stability Divisi<strong>on</strong> is <str<strong>on</strong>g>to</str<strong>on</strong>g> keep track of <str<strong>on</strong>g>the</str<strong>on</strong>g> weight and stability<br />

status, limiting draft and o<str<strong>on</strong>g>the</str<strong>on</strong>g>r limitati<strong>on</strong>s including being an advocate for weight and moment<br />

status and moment compensati<strong>on</strong> necessary <str<strong>on</strong>g>to</str<strong>on</strong>g> adhere <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> established limits. Surface ships are<br />

10

classified in<str<strong>on</strong>g>to</str<strong>on</strong>g> four status c<strong>on</strong>diti<strong>on</strong>s for vertical center of gravity (KG) and limiting drafts. As<br />

specified in [4], <str<strong>on</strong>g>the</str<strong>on</strong>g> definiti<strong>on</strong>s for <str<strong>on</strong>g>the</str<strong>on</strong>g> status listings are:<br />

• STATUS 1 An increase in weight and a rise of <str<strong>on</strong>g>the</str<strong>on</strong>g> ship's center of gravity are<br />

acceptable. Added weight and moment resulting from changes will not require any<br />

compensati<strong>on</strong> unless <str<strong>on</strong>g>the</str<strong>on</strong>g> magnitude of <str<strong>on</strong>g>the</str<strong>on</strong>g> additi<strong>on</strong>s is so large as <str<strong>on</strong>g>to</str<strong>on</strong>g> make <str<strong>on</strong>g>the</str<strong>on</strong>g> ship<br />

approach stability limits.<br />

• STATUS 2<br />

accepted.<br />

Nei<str<strong>on</strong>g>the</str<strong>on</strong>g>r an increase in weight nor a rise of a ship's center of gravity can be<br />

• STATUS 3 An increase in <str<strong>on</strong>g>the</str<strong>on</strong>g> ship's weight is acceptable, but a rise of <str<strong>on</strong>g>the</str<strong>on</strong>g> ship's center<br />

of gravity must be avoided.<br />

• STATUS 4 A rise of <str<strong>on</strong>g>the</str<strong>on</strong>g> ship's center of gravity is acceptable, but increase in weight<br />

must be avoided. Compensati<strong>on</strong> for added weight may be obtained by removal of an<br />

equal or greater weight at any level.<br />

Status 1 is <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>on</strong>ly acceptable ship status. The goal is for ships in <str<strong>on</strong>g>the</str<strong>on</strong>g> fleet <str<strong>on</strong>g>to</str<strong>on</strong>g> remain in<br />

Status 1. In <str<strong>on</strong>g>the</str<strong>on</strong>g> o<str<strong>on</strong>g>the</str<strong>on</strong>g>r three status c<strong>on</strong>diti<strong>on</strong>s, <str<strong>on</strong>g>the</str<strong>on</strong>g> displacement and KG must be closely<br />

m<strong>on</strong>i<str<strong>on</strong>g>to</str<strong>on</strong>g>red <str<strong>on</strong>g>to</str<strong>on</strong>g> ensure <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>diti<strong>on</strong> does not worsen and steps must be taken <str<strong>on</strong>g>to</str<strong>on</strong>g> try <str<strong>on</strong>g>to</str<strong>on</strong>g> bring <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

ship back within acceptable design limits. Typically, when an in-service carrier requires a<br />

modificati<strong>on</strong> that will add weight <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> ship, it is <str<strong>on</strong>g>the</str<strong>on</strong>g> resp<strong>on</strong>sibility of <str<strong>on</strong>g>the</str<strong>on</strong>g> program office and <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

planning yard <str<strong>on</strong>g>to</str<strong>on</strong>g> put <str<strong>on</strong>g>to</str<strong>on</strong>g>ge<str<strong>on</strong>g>the</str<strong>on</strong>g>r a package that includes maintenance and repair items, as well as<br />

modernizati<strong>on</strong> changes. First, a preliminary weight estimate of <str<strong>on</strong>g>the</str<strong>on</strong>g> modernizati<strong>on</strong> changes are<br />

put <str<strong>on</strong>g>to</str<strong>on</strong>g>ge<str<strong>on</strong>g>the</str<strong>on</strong>g>r in <str<strong>on</strong>g>the</str<strong>on</strong>g> package and made ready for installati<strong>on</strong>. Once <str<strong>on</strong>g>the</str<strong>on</strong>g> package is installed, <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

planning yard or shipyard keeps track of <str<strong>on</strong>g>the</str<strong>on</strong>g> weights being installed. At <str<strong>on</strong>g>the</str<strong>on</strong>g> end of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

availability, an actual weight report for <str<strong>on</strong>g>the</str<strong>on</strong>g> installed changes is generated. This report is passed<br />

from <str<strong>on</strong>g>the</str<strong>on</strong>g> shipyard <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> program office where it is incorporated in<str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> stability baseline of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

pertinent ship.<br />

11

For any c<strong>on</strong>figurati<strong>on</strong> changes, such as adding weight <str<strong>on</strong>g>to</str<strong>on</strong>g> a carrier in Stability Status 2, <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

interested party fills out a Justificati<strong>on</strong> Cost Form (JCF) with <str<strong>on</strong>g>the</str<strong>on</strong>g> weight and KG impact as well<br />

as <str<strong>on</strong>g>the</str<strong>on</strong>g> ship's Stability Status. A C<strong>on</strong>figurati<strong>on</strong> C<strong>on</strong>trol Board that includes <str<strong>on</strong>g>the</str<strong>on</strong>g> Program Office,<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> Ship Design Manager, and <str<strong>on</strong>g>the</str<strong>on</strong>g> necessary Technical Authorities <str<strong>on</strong>g>the</str<strong>on</strong>g>n meet <str<strong>on</strong>g>to</str<strong>on</strong>g> approve or<br />

disapprove <str<strong>on</strong>g>the</str<strong>on</strong>g> modificati<strong>on</strong>. If approved, an Engineering Change Proposal (ECP) for newly<br />

commissi<strong>on</strong>ed ships or a Ship Alterati<strong>on</strong> Request (SAR) for in-service ships is <str<strong>on</strong>g>the</str<strong>on</strong>g>n generated.<br />

The <strong>Nimitz</strong> class was assigned <str<strong>on</strong>g>to</str<strong>on</strong>g> Stability Status 2 by <str<strong>on</strong>g>the</str<strong>on</strong>g> Weight C<strong>on</strong>trol and Stability<br />

Divisi<strong>on</strong> of <str<strong>on</strong>g>the</str<strong>on</strong>g> Naval Sea Systems Command. This was d<strong>on</strong>e as a result of <str<strong>on</strong>g>the</str<strong>on</strong>g> stability reanalysis<br />

performed <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong> class carriers. The re-analysis revealed <str<strong>on</strong>g>the</str<strong>on</strong>g> following:<br />

• The originally calculated Allowable KG of 48.50 feet was no l<strong>on</strong>ger applicable for this<br />

class of ships. While 48.50 feet is no l<strong>on</strong>ger <str<strong>on</strong>g>the</str<strong>on</strong>g> allowable KG value, it c<strong>on</strong>tinues <str<strong>on</strong>g>to</str<strong>on</strong>g> be<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> KG compara<str<strong>on</strong>g>to</str<strong>on</strong>g>r for CVN 68 - 77 for c<strong>on</strong>tractual reas<strong>on</strong>s.<br />

• The actual damage capability of this class of carriers is not as originally calculated.<br />

• The damage capability of this class decreases as displacement increases.<br />

• It is important for <str<strong>on</strong>g>the</str<strong>on</strong>g> holding bulkhead <str<strong>on</strong>g>to</str<strong>on</strong>g> remain intact.<br />

• The 40'-l 1" limiting draft is based <strong>on</strong> ship geometry limitati<strong>on</strong>s.<br />

As a result of <str<strong>on</strong>g>the</str<strong>on</strong>g> above study, it was determined by that a stability status of 2 should<br />

c<strong>on</strong>tinue <str<strong>on</strong>g>to</str<strong>on</strong>g> be assigned <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong> class in order <str<strong>on</strong>g>to</str<strong>on</strong>g>:<br />

o C<strong>on</strong>trol <str<strong>on</strong>g>the</str<strong>on</strong>g> displacement growth of <str<strong>on</strong>g>the</str<strong>on</strong>g> class even though some ships are<br />

substantially below <str<strong>on</strong>g>the</str<strong>on</strong>g> displacement associated with <str<strong>on</strong>g>the</str<strong>on</strong>g> limiting draft. This is an<br />

acknowledgement that an increased displacement degrades damage stability<br />

capability.<br />

12

o C<strong>on</strong>trol <str<strong>on</strong>g>the</str<strong>on</strong>g> KG growth of <str<strong>on</strong>g>the</str<strong>on</strong>g> class even though some ships were substantially<br />

below <str<strong>on</strong>g>the</str<strong>on</strong>g> KG compara<str<strong>on</strong>g>to</str<strong>on</strong>g>r of 48.50 feet. This is an acknowledgement that an<br />

increased KG degrades damage stability capability.<br />

1.2.3 Survivability<br />

Survivability is defined in [10] as <str<strong>on</strong>g>the</str<strong>on</strong>g> capacity of a ship <str<strong>on</strong>g>to</str<strong>on</strong>g> absorb damage and maintain<br />

missi<strong>on</strong> integrity. Typically, most decisi<strong>on</strong> making regarding survivability is d<strong>on</strong>e during <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

early trade-off stages of ship design. As a result, it is imperative that naval architectural<br />

parameters be c<strong>on</strong>sidered over <str<strong>on</strong>g>the</str<strong>on</strong>g> lifetime of <str<strong>on</strong>g>the</str<strong>on</strong>g> ship in order <str<strong>on</strong>g>to</str<strong>on</strong>g> successfully withstand<br />

designated threat levels. Every attempt must be made <str<strong>on</strong>g>to</str<strong>on</strong>g> prevent any degradati<strong>on</strong> of a warship's<br />

ability <str<strong>on</strong>g>to</str<strong>on</strong>g> perform its offensive missi<strong>on</strong>, sustain battle damage, and survive. <strong>Aircraft</strong> carriers are<br />

fur<str<strong>on</strong>g>the</str<strong>on</strong>g>r defined in [10] as 'capital ships' in that <str<strong>on</strong>g>the</str<strong>on</strong>g>y are expected <str<strong>on</strong>g>to</str<strong>on</strong>g> survive more than <strong>on</strong>e<br />

weap<strong>on</strong>s hit and return <str<strong>on</strong>g>to</str<strong>on</strong>g> some level of missi<strong>on</strong> capability. All o<str<strong>on</strong>g>the</str<strong>on</strong>g>r ships are <strong>on</strong>ly expected <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

survive design level damage from a single design level weap<strong>on</strong> or a single peacetime hazard.<br />

Survivability, weap<strong>on</strong>s effects and operati<strong>on</strong>al envir<strong>on</strong>ments are categorized in terms of<br />

three levels of severity. Level I represents <str<strong>on</strong>g>the</str<strong>on</strong>g> least severe envir<strong>on</strong>ment anticipated for a class of<br />

ship, while Level El represents <str<strong>on</strong>g>the</str<strong>on</strong>g> most severe envir<strong>on</strong>ment projected for a combatant battle<br />

group and includes <str<strong>on</strong>g>the</str<strong>on</strong>g>ir ability <str<strong>on</strong>g>to</str<strong>on</strong>g> deal with <str<strong>on</strong>g>the</str<strong>on</strong>g> broad degrading effects of damage from antiship<br />

cruise missiles (ASCM). <strong>Aircraft</strong> carriers and battle force surface combatants are both<br />

c<strong>on</strong>sidered Level III. Therefore, it is imperative that <str<strong>on</strong>g>the</str<strong>on</strong>g>se ships be operated and maintained as<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>y were designed. Any digressi<strong>on</strong> from operati<strong>on</strong>al restricti<strong>on</strong>s and guidelines makes all<br />

analyses irrelevant.<br />

13

1.2.4 Displacement Limits<br />

Because <str<strong>on</strong>g>the</str<strong>on</strong>g>se aircraft carriers are so important and because any reducti<strong>on</strong> in freeboard<br />

will inherently reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> effectiveness of <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>to</str<strong>on</strong>g>rpedo side protecti<strong>on</strong> system (TSPS), <str<strong>on</strong>g>the</str<strong>on</strong>g>se ships<br />

are usually displacement critical. The limit is typically expressed in terms of <str<strong>on</strong>g>the</str<strong>on</strong>g> Full Load<br />

C<strong>on</strong>diti<strong>on</strong>. Following is <str<strong>on</strong>g>the</str<strong>on</strong>g> criteria Naval Surface Warfare Center (NSWC) Carderock's Weight<br />

C<strong>on</strong>trol and Stability Divisi<strong>on</strong> uses <str<strong>on</strong>g>to</str<strong>on</strong>g> determine displacement limits for aircraft carriers with a<br />

TSPS:<br />

L2.5 KG Limits<br />

• Strength: The displacement, with an assumed l<strong>on</strong>gitudinal weight distributi<strong>on</strong>, at<br />

which <str<strong>on</strong>g>the</str<strong>on</strong>g> l<strong>on</strong>gitudinal bending moments caused by a standardized wave will<br />

produce <str<strong>on</strong>g>the</str<strong>on</strong>g> maximum allowable stress in <str<strong>on</strong>g>the</str<strong>on</strong>g> ship's hull girder.<br />

• Speed: The displacement for surface warships at which <str<strong>on</strong>g>the</str<strong>on</strong>g> ships machinery,<br />

operating at a specified percent of maximum available power, will drive <str<strong>on</strong>g>the</str<strong>on</strong>g> ship<br />

at <str<strong>on</strong>g>the</str<strong>on</strong>g> original design speed specified by <str<strong>on</strong>g>the</str<strong>on</strong>g> ships characteristics c<strong>on</strong>sidering<br />

power plant, RPM and <str<strong>on</strong>g>to</str<strong>on</strong>g>rque limits.<br />

• TSPS: The maximum draft for a surface warship which prevents <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>to</str<strong>on</strong>g>p of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

TSPS from being immersed more than a specified amount.<br />

• Subdivisi<strong>on</strong>: The maximum displacement at which a ship with a TSPS will<br />

satisfac<str<strong>on</strong>g>to</str<strong>on</strong>g>rily resist <str<strong>on</strong>g>the</str<strong>on</strong>g> flooding effects of a specified number of <str<strong>on</strong>g>to</str<strong>on</strong>g>rpedo hits or<br />

similar weap<strong>on</strong>s without submerging <str<strong>on</strong>g>the</str<strong>on</strong>g> margin line at <str<strong>on</strong>g>the</str<strong>on</strong>g> bow or <str<strong>on</strong>g>the</str<strong>on</strong>g> stem.<br />

• Damage Stability: The maximum displacement at which a ship with a TSPS will<br />

satisfac<str<strong>on</strong>g>to</str<strong>on</strong>g>rily resist <str<strong>on</strong>g>the</str<strong>on</strong>g> flooding effects of a specified number of <str<strong>on</strong>g>to</str<strong>on</strong>g>rpedo hits or<br />

similar weap<strong>on</strong>s while providing adequate stability <str<strong>on</strong>g>to</str<strong>on</strong>g> resist high static heel<br />

angles, resist capsizing, and return <str<strong>on</strong>g>to</str<strong>on</strong>g> some level of missi<strong>on</strong> capability.<br />

The KG Limit for a warship is <str<strong>on</strong>g>the</str<strong>on</strong>g> maximum height of <str<strong>on</strong>g>the</str<strong>on</strong>g> vertical center of gravity of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

ship in <str<strong>on</strong>g>the</str<strong>on</strong>g> Full Load c<strong>on</strong>diti<strong>on</strong>. Any Full Load KG below this limit is expected <str<strong>on</strong>g>to</str<strong>on</strong>g> survive <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

hazards of wind, high speed maneuvering or damage, assuming <str<strong>on</strong>g>the</str<strong>on</strong>g> ship follows its liquid<br />

loading instructi<strong>on</strong>s. The Limiting KG is <str<strong>on</strong>g>the</str<strong>on</strong>g> lowest limit of ei<str<strong>on</strong>g>the</str<strong>on</strong>g>r <str<strong>on</strong>g>the</str<strong>on</strong>g> damage stability limit or<br />

14

<str<strong>on</strong>g>the</str<strong>on</strong>g> intact stability limit. Following is <str<strong>on</strong>g>the</str<strong>on</strong>g> DDS-079-1 criteria NSWC Carderock's Weight<br />

C<strong>on</strong>trol and Stability Divisi<strong>on</strong> uses <str<strong>on</strong>g>to</str<strong>on</strong>g> determine stability limits for surface warships with a SPS:<br />

• Intact: 100 Knot Beam Wind - The Full Load KG which will permit <str<strong>on</strong>g>the</str<strong>on</strong>g> ship <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

operate in any normal loading c<strong>on</strong>diti<strong>on</strong> and survive <str<strong>on</strong>g>the</str<strong>on</strong>g> heeling force of a fully<br />

developed hurricane (assumed as a nominal 100 knots). The ship will retain<br />

sufficient stability <str<strong>on</strong>g>to</str<strong>on</strong>g> absorb higher gusts without being knocked over, and <str<strong>on</strong>g>to</str<strong>on</strong>g> absorb<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> dynamic effects of wave acti<strong>on</strong> without being rolled over.<br />

• Damage: The Full Load KG Limit for large surface combatants, such as battleships<br />

and aircraft carriers which have a side protective system, is associated with <str<strong>on</strong>g>the</str<strong>on</strong>g> worst<br />

possible combinati<strong>on</strong> of a specified number of hazards (<str<strong>on</strong>g>to</str<strong>on</strong>g>rpedoes/missiles) which<br />

will:<br />

1) Cause <str<strong>on</strong>g>the</str<strong>on</strong>g> ship <str<strong>on</strong>g>to</str<strong>on</strong>g> heel <str<strong>on</strong>g>to</str<strong>on</strong>g> a large initial angle of 15 - 20 degrees,<br />

2) Cause <str<strong>on</strong>g>the</str<strong>on</strong>g> ship <str<strong>on</strong>g>to</str<strong>on</strong>g> approach a capsize situati<strong>on</strong>, or<br />

3) Exceed <str<strong>on</strong>g>the</str<strong>on</strong>g> counter flooding capability <str<strong>on</strong>g>to</str<strong>on</strong>g> return <str<strong>on</strong>g>to</str<strong>on</strong>g> limited operati<strong>on</strong>. Limited<br />

operati<strong>on</strong> is defined as a heel of less than 5 degrees <str<strong>on</strong>g>to</str<strong>on</strong>g> operate aircraft (should be<br />

3 degrees for current aircraft) or less than 10 degrees <str<strong>on</strong>g>to</str<strong>on</strong>g> operate <str<strong>on</strong>g>the</str<strong>on</strong>g> main turrets.<br />

In any of <str<strong>on</strong>g>the</str<strong>on</strong>g> above damage c<strong>on</strong>diti<strong>on</strong>s <str<strong>on</strong>g>the</str<strong>on</strong>g> ship must still possess sufficient dynamic<br />

stability <str<strong>on</strong>g>to</str<strong>on</strong>g> resist capsizing moments induced by wind and waves.<br />

1.3 Present Opti<strong>on</strong>s<br />

1.3.1 C<strong>on</strong>tinue <str<strong>on</strong>g>to</str<strong>on</strong>g> operate using inner bot<str<strong>on</strong>g>to</str<strong>on</strong>g>m and DC voids<br />

Any departure from proper design and operati<strong>on</strong>al criteria degrades any analysis<br />

performed. For example, most stability analyses performed assumes that DC voids are used<br />

correctly, <str<strong>on</strong>g>the</str<strong>on</strong>g> ship is <strong>on</strong> an even keel, and that <str<strong>on</strong>g>the</str<strong>on</strong>g> limiting displacement is not exceeded. In fact,<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>re is an interrelati<strong>on</strong>ship between increasing displacement and a number of fac<str<strong>on</strong>g>to</str<strong>on</strong>g>rs, <str<strong>on</strong>g>to</str<strong>on</strong>g> include<br />

ship strength, survivability, stability and seakeeping. Increasing <str<strong>on</strong>g>the</str<strong>on</strong>g> weight, or displacement, of<br />

carriers is a serious c<strong>on</strong>cern because any weight increase <strong>on</strong>ly serves <str<strong>on</strong>g>to</str<strong>on</strong>g> reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> service life of<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> ship. It should be noted again that not all carriers use DC voids <str<strong>on</strong>g>to</str<strong>on</strong>g> augment <str<strong>on</strong>g>the</str<strong>on</strong>g> LCS, but it is<br />

also uncertain as <str<strong>on</strong>g>to</str<strong>on</strong>g> how many actually will use <str<strong>on</strong>g>the</str<strong>on</strong>g>m as a last resort.<br />

DC void usage results in a reducti<strong>on</strong> in TSPS defense. The purpose of <str<strong>on</strong>g>the</str<strong>on</strong>g> TSPS <strong>on</strong> any<br />

capital ship is <str<strong>on</strong>g>to</str<strong>on</strong>g> protect <str<strong>on</strong>g>the</str<strong>on</strong>g> vital spaces of <str<strong>on</strong>g>the</str<strong>on</strong>g> ship against flooding and/or de<str<strong>on</strong>g>to</str<strong>on</strong>g>nati<strong>on</strong> of s<str<strong>on</strong>g>to</str<strong>on</strong>g>wed<br />

15

ordnance. Vital spaces include magazine and propulsi<strong>on</strong> system spaces. The TSPS provides <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

desired protecti<strong>on</strong> by being c<strong>on</strong>structed of a series of l<strong>on</strong>gitudinal bulkheads nested transversely.<br />

These l<strong>on</strong>gitudinal spaces are fur<str<strong>on</strong>g>the</str<strong>on</strong>g>r subdivided by transverse fluid-tight bulkheads creating a<br />

'h<strong>on</strong>eycomb' arrangement outboard of <str<strong>on</strong>g>the</str<strong>on</strong>g> vital magazines and machinery spaces. The spaces<br />

thus created between <str<strong>on</strong>g>the</str<strong>on</strong>g> bulkheads are alternately filled with liquids (fuel oil, JP-5, ballast<br />

water, etc.) or are left empty (damage c<strong>on</strong>trol voids). The passive protecti<strong>on</strong> afforded by this<br />

combinati<strong>on</strong> of bulkheads and 'liquid/air layers" serves <str<strong>on</strong>g>to</str<strong>on</strong>g> absorb, deflect and reject <str<strong>on</strong>g>the</str<strong>on</strong>g> explosive<br />

force generated by weap<strong>on</strong>s such as <str<strong>on</strong>g>to</str<strong>on</strong>g>rpedoes or mines. Placing liquid in <str<strong>on</strong>g>the</str<strong>on</strong>g> void layer<br />

combined with an empty liquid layer will be <str<strong>on</strong>g>the</str<strong>on</strong>g> worst-case scenario, while <strong>on</strong>e or <str<strong>on</strong>g>the</str<strong>on</strong>g> o<str<strong>on</strong>g>the</str<strong>on</strong>g>r will<br />

result in less of a reducti<strong>on</strong>.<br />

Similarly, DC voids are supposed <str<strong>on</strong>g>to</str<strong>on</strong>g> be used exactly as <str<strong>on</strong>g>the</str<strong>on</strong>g>ir name implies, <str<strong>on</strong>g>to</str<strong>on</strong>g> combat<br />

flooding with <str<strong>on</strong>g>the</str<strong>on</strong>g> ability <str<strong>on</strong>g>to</str<strong>on</strong>g> adjust for list and trim in order <str<strong>on</strong>g>to</str<strong>on</strong>g> c<strong>on</strong>tinue <str<strong>on</strong>g>to</str<strong>on</strong>g> fulfill missi<strong>on</strong><br />

objectives after sustained damage by being able <str<strong>on</strong>g>to</str<strong>on</strong>g> c<strong>on</strong>tinue <str<strong>on</strong>g>to</str<strong>on</strong>g> launch and recover aircraft. The<br />

specified primary purpose of <str<strong>on</strong>g>the</str<strong>on</strong>g> DC voids is for damage c<strong>on</strong>trol. Sea chests and valves for<br />

flooding underwater side protecti<strong>on</strong> system spaces (DC voids) are required <str<strong>on</strong>g>to</str<strong>on</strong>g> flood within six<br />

minutes <str<strong>on</strong>g>to</str<strong>on</strong>g> fill <str<strong>on</strong>g>the</str<strong>on</strong>g> space <str<strong>on</strong>g>to</str<strong>on</strong>g> within 1 foot of <str<strong>on</strong>g>the</str<strong>on</strong>g> full load waterline per secti<strong>on</strong> 529i of [6]. In fact,<br />

current stability criteria require that <str<strong>on</strong>g>the</str<strong>on</strong>g> ship be able <str<strong>on</strong>g>to</str<strong>on</strong>g> counter flood <str<strong>on</strong>g>to</str<strong>on</strong>g> return <str<strong>on</strong>g>the</str<strong>on</strong>g> flight deck <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

within 5 degrees of upright after damage. When a ship has <str<strong>on</strong>g>to</str<strong>on</strong>g> resort <str<strong>on</strong>g>to</str<strong>on</strong>g> maintaining list by<br />

flooding DC voids, <str<strong>on</strong>g>the</str<strong>on</strong>g> crew becomes encumbered by a task that should be unnecessary. The<br />

Damage C<strong>on</strong>trol Assistant (DCA) and EOOW are drawn away from <str<strong>on</strong>g>the</str<strong>on</strong>g>ir normal tasks and in<str<strong>on</strong>g>to</str<strong>on</strong>g><br />

roles as reacti<strong>on</strong>ary problem-solvers, keeping an eye <strong>on</strong> flight deck aircraft placements, fuel tank<br />

levels, and ship list. This is a poor utilizati<strong>on</strong> of manpower, c<strong>on</strong>sidering <str<strong>on</strong>g>the</str<strong>on</strong>g> primary duties of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

DCA and EOOW, which are <str<strong>on</strong>g>the</str<strong>on</strong>g> coordinati<strong>on</strong> of damage c<strong>on</strong>trol acti<strong>on</strong>s and <str<strong>on</strong>g>the</str<strong>on</strong>g> resp<strong>on</strong>sibility<br />

16

for ships propulsi<strong>on</strong>, respectively. Also, a ship's crew is c<strong>on</strong>tinuously rotating. As a result, <str<strong>on</strong>g>the</str<strong>on</strong>g>re<br />

is a c<strong>on</strong>tinual learning curve that relies <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> passage of operati<strong>on</strong>al knowledge from generati<strong>on</strong><br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> generati<strong>on</strong>. This is not <str<strong>on</strong>g>the</str<strong>on</strong>g> optimal way <str<strong>on</strong>g>to</str<strong>on</strong>g> operate a multi-billi<strong>on</strong> dollar asset, and it is in our<br />

best interest <str<strong>on</strong>g>to</str<strong>on</strong>g> not put <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>on</strong>us of correcting an evoluti<strong>on</strong>ary design fault <strong>on</strong> a crew who will<br />

serve at most a three year <str<strong>on</strong>g>to</str<strong>on</strong>g>ur. Additi<strong>on</strong>ally, de-ballasting DC voids is extremely time intensive.<br />

If a real casualty was <str<strong>on</strong>g>to</str<strong>on</strong>g> occur with <str<strong>on</strong>g>the</str<strong>on</strong>g> wr<strong>on</strong>g or <str<strong>on</strong>g>to</str<strong>on</strong>g>o many DC voids flooded, <str<strong>on</strong>g>the</str<strong>on</strong>g>re may not be<br />

sufficient time <str<strong>on</strong>g>to</str<strong>on</strong>g> correct <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>diti<strong>on</strong>. It is not hard <str<strong>on</strong>g>to</str<strong>on</strong>g> imagine <str<strong>on</strong>g>the</str<strong>on</strong>g> disastrous results possible.<br />

1.3.2 Add a list c<strong>on</strong>trol tank <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> port side<br />

The c<strong>on</strong>trol of permanent lists (static heel angles) by adding an additi<strong>on</strong>al list c<strong>on</strong>trol tank<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g> port side could also be c<strong>on</strong>sidered an opti<strong>on</strong>. The LCS is designed <str<strong>on</strong>g>to</str<strong>on</strong>g> compensate for<br />

variable lists generated by load items that are moved about <str<strong>on</strong>g>the</str<strong>on</strong>g> ship over short periods of time.<br />

Such loads could be liquids, cargo, s<str<strong>on</strong>g>to</str<strong>on</strong>g>res, vehicles or aircraft. The current <strong>Nimitz</strong> class LCS<br />

c<strong>on</strong>sists often list c<strong>on</strong>trol tanks, two centrifugal pumps each rated at 1800 gpm at 30 psi, and <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

associated piping and valves required <str<strong>on</strong>g>to</str<strong>on</strong>g> compensate for lists up <str<strong>on</strong>g>to</str<strong>on</strong>g> 1.5 degrees in 20 minutes.<br />

The system is designed <str<strong>on</strong>g>to</str<strong>on</strong>g> be filled with seawater (SW) or firemain <str<strong>on</strong>g>to</str<strong>on</strong>g> 50% of its <str<strong>on</strong>g>to</str<strong>on</strong>g>tal capacity of<br />

278,533 gall<strong>on</strong>s. This allows tanks <str<strong>on</strong>g>to</str<strong>on</strong>g> be filled <str<strong>on</strong>g>to</str<strong>on</strong>g> 100% <strong>on</strong> <strong>on</strong>e side while <str<strong>on</strong>g>the</str<strong>on</strong>g> o<str<strong>on</strong>g>the</str<strong>on</strong>g>r side is left<br />

empty.<br />

The problems encountered with using SW in tanks may be c<strong>on</strong>mi<strong>on</strong> knowledge <str<strong>on</strong>g>to</str<strong>on</strong>g> most<br />

people; however, potential corrosi<strong>on</strong> from using salt water has encouraged some carriers <str<strong>on</strong>g>to</str<strong>on</strong>g> use<br />

potable water (PW) as a means <str<strong>on</strong>g>to</str<strong>on</strong>g> fill <str<strong>on</strong>g>the</str<strong>on</strong>g>ir list c<strong>on</strong>trol tanks. The LCS is designed with PW as a<br />

back-up <str<strong>on</strong>g>to</str<strong>on</strong>g> using SW or firemain. This is advantageous for corrosi<strong>on</strong> issues, but can be a<br />

problem for PW inven<str<strong>on</strong>g>to</str<strong>on</strong>g>ry. Any leaks in <str<strong>on</strong>g>the</str<strong>on</strong>g> system or maintenance requiring system fill and<br />

17

drain could use a large amount of PW. When underway, potable water c<strong>on</strong>servati<strong>on</strong> is of<br />

primary importance.<br />

1.3.3 Move or exchange compartment spaces<br />

Ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r opti<strong>on</strong> is <str<strong>on</strong>g>to</str<strong>on</strong>g> move or exchange compartment spaces, such as relocating heavy<br />

equipment <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> starboard side <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> port side and vice versa. The reducti<strong>on</strong> of starboard<br />

moment by <str<strong>on</strong>g>the</str<strong>on</strong>g> removal or relocati<strong>on</strong> of items of lightship weight would reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> quantity of<br />

ballast required, but would be very small by comparis<strong>on</strong> <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> amount of permanent ballast<br />

required. In order <str<strong>on</strong>g>to</str<strong>on</strong>g> achieve <str<strong>on</strong>g>the</str<strong>on</strong>g> necessary list correcti<strong>on</strong>s, an enormous amount of weight<br />

would have <str<strong>on</strong>g>to</str<strong>on</strong>g> be relocated. The costs involved with such an undertaking would be extremely<br />

high.<br />

1.3.4 C<strong>on</strong>vert a current DC void(s) <str<strong>on</strong>g>to</str<strong>on</strong>g> a JP-5 tank(s) and pump last<br />

C<strong>on</strong>verting portside DC floodable voids in<str<strong>on</strong>g>to</str<strong>on</strong>g> fuel tanks is also an opti<strong>on</strong>. This opti<strong>on</strong> will<br />

add <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> overall weight of <str<strong>on</strong>g>the</str<strong>on</strong>g> ship and again a reducti<strong>on</strong> in TSPS capability becomes a large<br />

c<strong>on</strong>cern as liquid is being placed in <str<strong>on</strong>g>the</str<strong>on</strong>g> air layer and thus opening a window of vulnerability.<br />

1.3.5 Future ship alterati<strong>on</strong>s and modiflcati<strong>on</strong>s<br />

It is also possible that future modificati<strong>on</strong>s <str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <strong>Nimitz</strong> class aircraft carrier will serve <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

provide a port list, <str<strong>on</strong>g>the</str<strong>on</strong>g>reby reducing <str<strong>on</strong>g>the</str<strong>on</strong>g> inherent starboard list. Modificati<strong>on</strong>s such as replacing<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> existing <strong>Nimitz</strong> class starboard island with <str<strong>on</strong>g>the</str<strong>on</strong>g> new modified CVN 76 island could serve <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

reduce <str<strong>on</strong>g>the</str<strong>on</strong>g> starboard list. In fact, CVN 76 has had so many design changes that its starboard<br />

inherent list is less than <strong>on</strong>e degree, currently based <strong>on</strong> preliminary results of its inclining<br />

experiment. <str<strong>on</strong>g>List</str<strong>on</strong>g> for CVN 76 has not been an issue thus far, however, at <str<strong>on</strong>g>the</str<strong>on</strong>g> time feedback was<br />

gained, <str<strong>on</strong>g>the</str<strong>on</strong>g> ship had not been fully loaded out. CVN 76 is slightly different from <str<strong>on</strong>g>the</str<strong>on</strong>g> o<str<strong>on</strong>g>the</str<strong>on</strong>g>r<br />

<strong>Nimitz</strong> class ships. The weap<strong>on</strong>s eleva<str<strong>on</strong>g>to</str<strong>on</strong>g>r is combined in<str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> main structure and <str<strong>on</strong>g>the</str<strong>on</strong>g> aft mast is<br />

18

combined with <str<strong>on</strong>g>the</str<strong>on</strong>g> island which is <strong>on</strong>e level shorter. There is also a more realistic protecti<strong>on</strong><br />

scheme such that a space armor c<strong>on</strong>cept was employed. On <str<strong>on</strong>g>the</str<strong>on</strong>g> older islands, such as CVN 73,<br />

Level III protecti<strong>on</strong> can be seen throughout <str<strong>on</strong>g>the</str<strong>on</strong>g> entire island. This includes 40# (1") plating,<br />

whereas <str<strong>on</strong>g>the</str<strong>on</strong>g> new CVN 76 island has Level II protecti<strong>on</strong> in some areas and is thus lighter.<br />

Ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r opti<strong>on</strong> could be <str<strong>on</strong>g>to</str<strong>on</strong>g> extend <str<strong>on</strong>g>the</str<strong>on</strong>g> port side flight deck <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> old <strong>Nimitz</strong> class, as<br />

was d<strong>on</strong>e <strong>on</strong> CVN 76. This allowed for more operati<strong>on</strong>al flexibility as <str<strong>on</strong>g>the</str<strong>on</strong>g> forward port jet blast<br />

deflec<str<strong>on</strong>g>to</str<strong>on</strong>g>r can now be used <str<strong>on</strong>g>to</str<strong>on</strong>g> its full extent. In any case, it is important <str<strong>on</strong>g>to</str<strong>on</strong>g> note that any number<br />

of ship alterati<strong>on</strong>s could be made when time and m<strong>on</strong>ey become available in <str<strong>on</strong>g>the</str<strong>on</strong>g> future.<br />

1.3.6 Re-examine current <str<strong>on</strong>g>List</str<strong>on</strong>g> C<strong>on</strong>trol System<br />

Fleet feedback was taken in<str<strong>on</strong>g>to</str<strong>on</strong>g> c<strong>on</strong>siderati<strong>on</strong> when performing this study. The design of<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> current LCS reportedly requires extensive manpower for operati<strong>on</strong>s, possesses obsolete<br />

comp<strong>on</strong>ents, and is not integrated with o<str<strong>on</strong>g>the</str<strong>on</strong>g>r shipboard liquid-movement functi<strong>on</strong>s. The<br />

installed LCS c<strong>on</strong>sists of 10 tanks, 2 pumps and 14 associated valves <str<strong>on</strong>g>to</str<strong>on</strong>g> distribute seawater<br />

ballast as required compensating for lists up <str<strong>on</strong>g>to</str<strong>on</strong>g> 1.5 degrees. The manually c<strong>on</strong>trolled system<br />

uses verbal communicati<strong>on</strong>s and associated sailor acti<strong>on</strong>s for operati<strong>on</strong>.<br />

Much of <str<strong>on</strong>g>the</str<strong>on</strong>g> fleet feedback received noted that <str<strong>on</strong>g>the</str<strong>on</strong>g> current LCS provides sufficient<br />

c<strong>on</strong>trol when <str<strong>on</strong>g>the</str<strong>on</strong>g> inherent starboard list has been corrected. The fleet also noted, however, that if<br />

correcti<strong>on</strong> has not been provided, <str<strong>on</strong>g>the</str<strong>on</strong>g> LCS al<strong>on</strong>e does not provide ample list correcti<strong>on</strong> while at<br />

full combat load (average displacement between 98,000 and 100,000 I<str<strong>on</strong>g>to</str<strong>on</strong>g>ns, mean draft<br />

approximately between 38'10" and 39'10", even liquid distributi<strong>on</strong>, and standard spotting of<br />

aircraft for flight operati<strong>on</strong>s). Standard spotting includes F-18s <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> 1 and 4 row, hummers<br />

(fleet jarg<strong>on</strong> for <str<strong>on</strong>g>the</str<strong>on</strong>g> E-2C Hawkeye) in <str<strong>on</strong>g>the</str<strong>on</strong>g> hummer hole, F-14s <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> stem of <str<strong>on</strong>g>the</str<strong>on</strong>g> flight deck.<br />

19

helicopters and C-2 Greyhounds inboard of <str<strong>on</strong>g>the</str<strong>on</strong>g> island, cranes aft of <str<strong>on</strong>g>the</str<strong>on</strong>g> island, and <str<strong>on</strong>g>the</str<strong>on</strong>g> rest of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

aircraft dispersed between <str<strong>on</strong>g>the</str<strong>on</strong>g>m.<br />

The LCS is currently being au<str<strong>on</strong>g>to</str<strong>on</strong>g>mated via <str<strong>on</strong>g>the</str<strong>on</strong>g> Au<str<strong>on</strong>g>to</str<strong>on</strong>g>mated <str<strong>on</strong>g>List</str<strong>on</strong>g> C<strong>on</strong>trol System alterati<strong>on</strong><br />

(ALCS 9145K). The ALCS provides remote c<strong>on</strong>trol and m<strong>on</strong>i<str<strong>on</strong>g>to</str<strong>on</strong>g>ring of <str<strong>on</strong>g>the</str<strong>on</strong>g> aircraft carrier LCS<br />

from Damage C<strong>on</strong>trol Central (DCC) and Shaft Alley via a flat panel display. Four existing loop<br />

valves are upgraded from manual <str<strong>on</strong>g>to</str<strong>on</strong>g> mo<str<strong>on</strong>g>to</str<strong>on</strong>g>r operated and are integrated in<str<strong>on</strong>g>to</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>trol system.<br />

Existing pump c<strong>on</strong>trollers are replaced and c<strong>on</strong>trol of pumps, valves and tank level m<strong>on</strong>i<str<strong>on</strong>g>to</str<strong>on</strong>g>ring<br />

are integrated in<str<strong>on</strong>g>to</str<strong>on</strong>g> a single system with redundant capabilities. The ALCS utilizes commercialoff-<str<strong>on</strong>g>the</str<strong>on</strong>g>-shelf<br />

comp<strong>on</strong>ents and Navy-owned software <str<strong>on</strong>g>to</str<strong>on</strong>g> decrease <str<strong>on</strong>g>the</str<strong>on</strong>g> manpower needed for<br />

operati<strong>on</strong> and maintenance, increase au<str<strong>on</strong>g>to</str<strong>on</strong>g>mati<strong>on</strong>, reduce life cycle costs and significantly<br />

improve system reliability. System line-up and tank management is au<str<strong>on</strong>g>to</str<strong>on</strong>g>mated and managed<br />

such that tanks can be filled faster, utilizing fewer watchstanders and increasing system<br />

efficiency. C<strong>on</strong>trol and m<strong>on</strong>i<str<strong>on</strong>g>to</str<strong>on</strong>g>ring of <str<strong>on</strong>g>the</str<strong>on</strong>g> LCS is performed from two human-machine interface<br />

(HMI) stati<strong>on</strong>s: <strong>on</strong>e in DCC and <strong>on</strong>e in Shaft Alley. The system can also be operated from <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

Central C<strong>on</strong>trol Stati<strong>on</strong>, and operates in both remote and semi-au<str<strong>on</strong>g>to</str<strong>on</strong>g>matic modes.<br />

Very little feedback has been obtained regarding <str<strong>on</strong>g>the</str<strong>on</strong>g> new ALCS and its improvements <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

overall ship operati<strong>on</strong>s. To date, installati<strong>on</strong> has been completed <strong>on</strong> three of <str<strong>on</strong>g>the</str<strong>on</strong>g> ten planned<br />

carriers. Although <str<strong>on</strong>g>the</str<strong>on</strong>g> system provides <str<strong>on</strong>g>the</str<strong>on</strong>g> means <str<strong>on</strong>g>to</str<strong>on</strong>g> au<str<strong>on</strong>g>to</str<strong>on</strong>g>matically operate pumps and valves,<br />