MASTER BOOK – SECTION 1 Rev. 2007 - EKA Group

MASTER BOOK – SECTION 1 Rev. 2007 - EKA Group

MASTER BOOK – SECTION 1 Rev. 2007 - EKA Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4.1 <strong>–</strong> INSTALLATION<br />

3 - INSTALLATION<br />

The floor installation has to be carried out in accordance with the above mentioned conditions. The slab in the<br />

room should be cleaned with a vacuum cleaner and a layer of anti-dust paint, preferably polyurethanic or<br />

epossidic types (because they do not alter in the time), should be applied. This procedure must be followed<br />

when the subfloor void will be used as an air-supply/return duct.<br />

The installation method depends on type of floor, with or without stringers. Once the layout of the panels has<br />

been decided, the installation can start.<br />

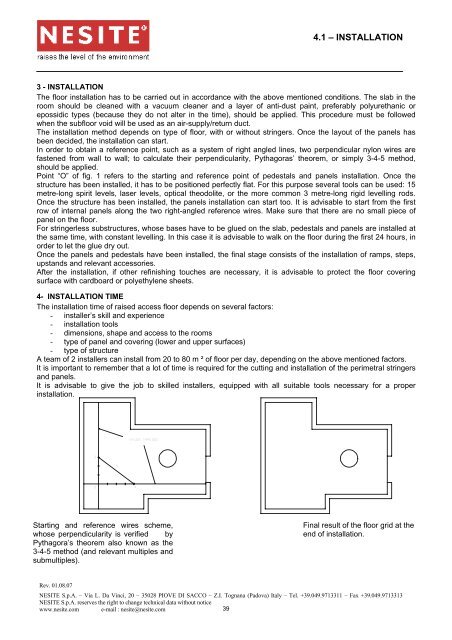

In order to obtain a reference point, such as a system of right angled lines, two perpendicular nylon wires are<br />

fastened from wall to wall; to calculate their perpendicularity, Pythagoras’ theorem, or simply 3-4-5 method,<br />

should be applied.<br />

Point “O” of fig. 1 refers to the starting and reference point of pedestals and panels installation. Once the<br />

structure has been installed, it has to be positioned perfectly flat. For this purpose several tools can be used: 15<br />

metre-long spirit levels, laser levels, optical theodolite, or the more common 3 metre-long rigid levelling rods.<br />

Once the structure has been installed, the panels installation can start too. It is advisable to start from the first<br />

row of internal panels along the two right-angled reference wires. Make sure that there are no small piece of<br />

panel on the floor.<br />

For stringerless substructures, whose bases have to be glued on the slab, pedestals and panels are installed at<br />

the same time, with constant levelling. In this case it is advisable to walk on the floor during the first 24 hours, in<br />

order to let the glue dry out.<br />

Once the panels and pedestals have been installed, the final stage consists of the installation of ramps, steps,<br />

upstands and relevant accessories.<br />

After the installation, if other refinishing touches are necessary, it is advisable to protect the floor covering<br />

surface with cardboard or polyethylene sheets.<br />

4- INSTALLATION TIME<br />

The installation time of raised access floor depends on several factors:<br />

- installer’s skill and experience<br />

- installation tools<br />

- dimensions, shape and access to the rooms<br />

- type of panel and covering (lower and upper surfaces)<br />

- type of structure<br />

A team of 2 installers can install from 20 to 80 m ² of floor per day, depending on the above mentioned factors.<br />

It is important to remember that a lot of time is required for the cutting and installation of the perimetral stringers<br />

and panels.<br />

It is advisable to give the job to skilled installers, equipped with all suitable tools necessary for a proper<br />

installation.<br />

NYLON THREADS<br />

3<br />

5<br />

0<br />

4<br />

Starting and reference wires scheme,<br />

whose perpendicularity is verified by<br />

Pythagora’s theorem also known as the<br />

3-4-5 method (and relevant multiples and<br />

submultiples).<br />

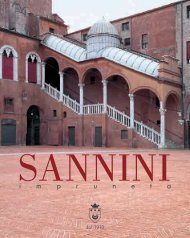

Final result of the floor grid at the<br />

end of installation.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

39