MASTER BOOK – SECTION 1 Rev. 2007 - EKA Group

MASTER BOOK – SECTION 1 Rev. 2007 - EKA Group

MASTER BOOK – SECTION 1 Rev. 2007 - EKA Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

aises the level of the environment<br />

Access Floor<br />

• FEATURES<br />

• COATING<br />

• ACCESSORIES<br />

• INSTALLATION<br />

<strong>MASTER</strong> <strong>BOOK</strong> <strong>–</strong> <strong>SECTION</strong> 1 <strong>Rev</strong>. <strong>2007</strong>

INTRODUCTION<br />

THE SYSTEM<br />

The continuous technological development makes “Nesite Access Floor System” crucial for “Intelligent Building”<br />

and therefore to create “Active Work Areas”, ready to deal with these changes.<br />

Thanks to its characteristics of flexibility, “Access Floor System” grants the designers full “design freedom”,<br />

offering a wide range of panels, covering materials and substructures, all manufactured according to tight<br />

technical standards and providing Official Certificates concerning following important technical aspects, such as:<br />

- fire resistance and fire reaction<br />

- mechanical characteristics (concentrated and distributed loads)<br />

- electrical characteristics (antistatic or conductive)<br />

- acoustical characteristics<br />

- anti-seismic characteristics<br />

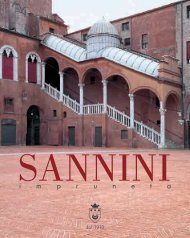

PANELS<br />

Thanks to its experience and know-how, Nesite is able to provide to the market high level performances and<br />

quality panels with core made of chipboard (different possible density), inert material or even matching both.<br />

Being able to deal with the different acoustic and structural needs, already tested to be assembled with<br />

traditional market flooring, from the cheaper such as HPL to the more expensive such as ceramic, wood, marble<br />

and granite via the classic vinyl, linoleum, rubber and carpets.<br />

Nesite products have been developed co-operating with the main covering producers, elected by the R&D<br />

department based on aesthetic and technical consideration.<br />

A set of aluminium or steel top surface panels allows to lay any kind of covering.<br />

Special materials like glass and steel, alone or together combined, are standard products for Nesite.<br />

SUBSTRUCTURES<br />

Nesite Access Floor System is completed by a range of 6 different types of structure, all patented and<br />

manufactured by Nesite itself, starting from MP (Multi Purpose) family with/without stringers according to the<br />

required loading performances, to the SSH system (single central screw), which grants easy and fast installation<br />

in large areas.<br />

ACCESSORIES<br />

Nesite provides a range of accessories, especially designed to complete the “Access Floor System” for the full<br />

satisfaction of the end user: from underfloor partitions to ramps and steps.<br />

Hatches, turrets, grills and perforated metal panels optimise the use of electrical and air-conditioning equipment<br />

installed in the underfloor plenum.<br />

NESITE SERVICE<br />

One of the most important aspects and advantages of “Access Floor System” is the service offered by Nesite to<br />

its customers for the best use of the System itself. From the design to the after sales service, every phase is<br />

thought to grant the customers more than the simple supply of a product.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

1

1 <strong>–</strong> RAISED FLOOR SYSTEM<br />

<strong>MASTER</strong> <strong>BOOK</strong><br />

INDEX<br />

1.1 Fire resistance<br />

1.2 Fire reaction<br />

1.3 Acoustic insulation and comfort<br />

1.4 Mechanical resistance<br />

1.5 Electrical characteristics<br />

1.6 Earthing<br />

1.7 Antiseismic test<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

2

1.1 - FIRE RESISTANCE<br />

The European Technical Committee CNE TC127/WG17 is drawing up a specific norm regarding the fire<br />

resistance of raised access floor. At the moment the valid norm in Italy is the circular of the Interior Ministry N°<br />

91 of 1961 which deals with the fire resistance tests of materials and building structures , or the norm UNI<br />

7678/ISO 834.<br />

After the publication of the above circular, several tests have been carried out at the Centre of Studies of the Fire<br />

Service of Rome and at other laboratories, obtaining the appropriate official certificates.<br />

Subsequently after the circular N° 91, other circulars and decrees have been issued to clarify this argument,<br />

stating that the tests have to take into account the following elements:<br />

- Structural stability (R)<br />

- Integrity=passage of smoke and flame (E)<br />

- Thermal insulation (I)<br />

These three elements must be tested together and at the same time for the certificate to be approved by the<br />

Italian Fire Service.<br />

Nesite possesses all the certificates issued by the Italian Interior Ministry <strong>–</strong> General Management of Civil<br />

Protection and Fire Protection Service attesting the validity of Nesite Raised floor certificates based on the three<br />

above mentioned criteria.<br />

The Nesite Access Floor System can be classified as REI 15, 30, 45, 60, 90, depending on the kind of cores and<br />

coverings.<br />

Test scheme<br />

0<br />

C<br />

Underfloor temperature<br />

1200<br />

C<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

A<br />

B<br />

100<br />

15 30 45<br />

min<br />

An underfloor burning is simulated in a furnace and the temperature increases as per the standardized curve C.<br />

The average surface temperature of the panel is measured, and whenever it exceeds 150°C, the time elapsed in<br />

minutes is noted since the furnace has been switched on. During this measurement both the stability and<br />

integrity must be maintained.<br />

In the above drawing panel “A” has exceeded the temperature limit (150°C) after 15 minutes only, whereas panel<br />

“B” after 47 minutes.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

3

1.1 - FIRE RESISTANCE<br />

FURNACE TESTS PROCEDURE TO BE FOLLOWED FOR THE APPROVAL OF MATERIALS:<br />

1 - TEST IN ACCORDANCE WITH GOVERNMENT CIRCULAR N° 91 September 1961<br />

CLASSES<br />

REI 15, REI 30, REI 45, REI 60, REI 90, REI 120, REI 180<br />

EQUIPMENT USED<br />

Furnace able to heat the specimen and to create the required heat and pressure conditions.<br />

TEMPERATURE CURVE<br />

The firebox and the furnace temperature must increase according to the test curve shown in the following figure.<br />

TEMPERATURE MEASUREMENT<br />

The furnace temperature must be the average obtained from the temperature measured in at least three<br />

positions, 10 centimetres far from the tested specimen. Not less than three thermal sensors must be placed on<br />

the unexposed surface of the specimen.<br />

DIMENSIONS<br />

The tested elements must have the same characteristics like the ones utilized on the regular building.<br />

TEMPERATURE<br />

The average temperature shall not be over 150°C, and the temperature at any point shall not increase by more<br />

than 180°C above the initial temperature, and in any case not over 220°C, whatever was the initial temperature.<br />

OTHER FACTORS DETERMINING THE FIRE RESISTANCE<br />

Passage of smoke and flame; structural stability.<br />

2 - TEST ACCORDING TO UNI 7678 / ISO 834<br />

CLASSES<br />

F 15, F 30, F 45, F 60, F 90, F 120, F 180<br />

EQUIPMENT USED<br />

Furnace able to heat the specimen and to create the required heat and pressure conditions.<br />

TEMPERATURE CURVE<br />

The furnace temperature must vary with time, as per the following formula:<br />

T+To = 345 lg (8t + 1) in which:<br />

T = furnace temperature at time t<br />

To = initial furnace temperature<br />

t = time expressed in minutes<br />

TEMPERATURE MEASUREMENT<br />

The furnace temperature is considered as the average value calculated by the thermocouples installed in the<br />

furnace; 1 every 1,5 m 2 of surface.<br />

DIMENSIONS<br />

The tested elements must have the same characteristics like the ones utilized on the regular building.<br />

TEMPERATURE<br />

The average temperature shall not be over the initial temperature + 140°C, and the temperature at any point<br />

shall not increase by more than 180°C above the initial temperature, and in any case not over 220°C, whatever<br />

was the initial temperature.<br />

OTHER FACTORS DETERMINING THE FIRE RESISTANCE<br />

Passage of smoke and flame; structural stability.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

4

1.1 - FIRE RESISTANCE<br />

COMPARISON BETWEEN TEMPERATURE CURVES<br />

CIRCULAR 91/UNI 7678 <strong>–</strong> ISO 834<br />

1200<br />

1000<br />

800<br />

°C<br />

600<br />

400<br />

200<br />

0<br />

0 30 60 90 120 150 180<br />

min<br />

Circolare 91 UNI 7678 - ISO 834<br />

Time<br />

[min]<br />

Circular 91<br />

[°C]<br />

UNI 7678 <strong>–</strong> ISO 834<br />

[°C]<br />

5 450 556<br />

10 650 659<br />

15 750 718<br />

30 880 821<br />

60 1000 925<br />

90 1025 986<br />

120 1040 1029<br />

180 1100 1090<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

5

1.2 FIRE REACTION<br />

This concept expresses the response of a raised access floor to a tentative ignition (flame penetration) coming<br />

from the environment (the room where the panel is installed). Most of Nesite panels has been tested with this<br />

method and obtained the certification in class “1”; class “0” can be achieved for instance by stones or marbles.<br />

Various Nesite panels have been tested and certified as per Ministerial Decree of 26/06/84, regular supplement<br />

of the Gazzetta Ufficiale of 25/08/84, and listed in the Gazzetta Ufficiale of 29/08/86.<br />

90°<br />

RADIANT PANEL<br />

SAMPLE<br />

WIRES<br />

BURNER<br />

FLAME<br />

TESTING PROCEDURE CSE RF 3/77<br />

COMBUSTION CHAMBER<br />

SAMPLE<br />

FLAME<br />

SUPPORT<br />

TESTING PROCEDURE CSE RF 2/75/A<br />

TEST FOR COVERING MATERIALS<br />

The flame, once the covering material has been set on fire, spreads out and cuts the wires within a cert period of<br />

time. In Italy the CSE/RF norm classifies the materials in classes 0,1,2,3,4 etc.; class 0 (not combustible) is the<br />

less sensitive.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

6

1.3 - ACOUSTIC INSULATION<br />

AND CONFORT<br />

A raised floor when walking on it generates noise, which can vary in intensity according to the following factors:<br />

- mass and rigidity of the panel<br />

- panel covering material<br />

- characteristics of the substructure and related gaskets.<br />

The noise so generated is transferred through the supporting slab, down to the area below (standardized ISO<br />

test method)<br />

Test scheme<br />

a) in this situation the trampling noise can be heard in the<br />

area below. The noise reduction is considerable.<br />

b) while, in this kind of situation, the trampling noise is<br />

heard in the same room. The noise level is slightly<br />

higher than that of a traditional flooring. This difference<br />

will be smaller by an accurate designing and choosing<br />

suitable materials.<br />

BASIC MEASUREMENTS AS COMPARISON PARAMETERS<br />

Test “a” has been standardized. The noise heard in the area below is examinated, comparing the noise levels of<br />

a raised floor with those of a traditional floor positioned in the room above.<br />

The influence of covering is one of the key parameters.<br />

Test “b” has not been standardized. The noise within the room itself is measured.<br />

The noise is influenced up to 80% by the type of covering, the remaining 20% by the weight of the panel.<br />

Therefore it is not possible to compare the two types of flooring, because at the moment a test which exactly<br />

quantifies such noise does not exist.<br />

Thus we may have a situation such as the one described hereunder, in which the arrows size means the noise<br />

level generated.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

7

1.4 MECHANICAL RESISTANCE<br />

This is intended as the capacity of a floor to bear, while deflecting, a certain working load.<br />

SITUATION OF CURRENT NORMS<br />

The CEN/TC 323 “Raised Access Floor” is issuing the European Norm prEn 12825 regarding the raised floor.<br />

Regarding Italy, UNI - Building Commission GL13 - SC4 has elaborated on the base of recommendations of the<br />

Association of Raised Floor Manufacturers the norms UNI 10465, UNI 10466, UNI 10467, UNI10467-1, UNI<br />

10467-2, UNI 10467-3, UNI 10467-4 and UNI 10467-5 regarding the raised floor. During 1995 these norms have<br />

been published and are now available. Regarding this argument the norm UNI 10466 establishes 4 different<br />

load-classes, as follows:<br />

- class 1 : kN2 (~ 200 kg) light load<br />

- class 2 : kN3 (~ 300 kg) medium load<br />

- class 3 : kN4.5 (~ 450 kg) heavy load<br />

- class 4 : special loads, to be defined at project stage, in any case > 4.5 kN (> 450 kg)<br />

ACTUAL STATUS<br />

Today, apart from the classification UNI 10466, the data for mechanical resistance of a raised floor is expressed<br />

according to two parameters:<br />

- concentrated load bearing capacity<br />

- distributed load bearing capacity (not included in the new UNI norms and in the CEN draft norm)<br />

The resistance values are expressed according to the deflection of the floor at the established load values during<br />

use. The reference value is normally 2.5 mm, and is related to the grade of comfort the floor has to give to<br />

walking.<br />

A raised floor (in case of uniformly distributed load) normally gives a higher resistance than the slab; for this<br />

reason this parameter is not contemplated in the norms and in the norm-drafts.<br />

Therefore the resistance to concentrated load is has a bigger importance during the choice and evaluation of the<br />

raised floor system.<br />

Indicatively, for a choice the following concentrated loads can be considered:<br />

- offices ~ 2 kN (about class 1 UNI 10466)<br />

- computer rooms ~ 3 kN (about class 2 UNI 10466)<br />

- control rooms ~4.5-5 kN (about class 3 UNI 10466)<br />

We have to consider the following indications:<br />

- very heavy equipments (strong-boxes, archives, etc.) may be placed in the offices<br />

- some projects require higher mechanical resistance, around 500 kg concentrated loads.<br />

MECHANICAL RESISTANCE TESTS<br />

A given working load is applied on a raised floor module by means of hydraulic equipment; then the total<br />

deflection of the module is measured axially to the load itself. The deflection should be ≤ 2.5 mm.<br />

The weight is usually increased until the panel breaks. The ratio between the breaking load and the working load<br />

expresses the safety factor rate, which according to the new norms and the norm-drafts has to be ≥ 2.<br />

Load kg<br />

Deflection mm<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

8

1.5 <strong>–</strong> ELECTRICAL CHARACTERISTICS<br />

This matter is very important for two reasons:<br />

- personal safety<br />

- the good functioning of the data processing equipment and other electro-sensible appliances<br />

On the raised access floor surface, due to trampling friction, electrostatic charges be can generated, which could<br />

be harmful to the people of for the functioning of the data processing equipment. The formation of such charges<br />

is influenced by the air relative humidity, and increases with dry air in the room.<br />

Therefore it is important that such electrostatic charges could dissipate from the top surface of the panels to the<br />

building earth, or directly to the ground. For this reason several solutions can be chosen, depending on the<br />

specific applicative requirements (conductive gluing or earth cables on a few spots for structures with stringers).<br />

To eliminate the above illustrated phenomenon the raised access floor should normally have electrical resistance<br />

values within the range min. 1.5 x 10 and max. 2 x 10 Ω<br />

HOW TO MEASURE ELECTRICAL RESISTANCE<br />

The panels to be tested are climated for 24 hours in a room with a temperature of 20°C and 50% relative<br />

humidity. As per the above figure a voltage of 100 and/or 500 V is supplied between the upper covering and the<br />

lower side of the panel. The electrical resistance is then measured by means of a suitable electrical device.<br />

100 / 500 VOLT<br />

TEXSAS INSTRUMENT<br />

The possible classifications are:<br />

Antistatic Offices, meeting rooms, halls, computer rooms 1 x 10 9 < R ≤ 2 x 10 10 Ω<br />

Static-dissipative clean rooms 1 x 10 7 ≤ R ≤ 1 x 10 9 Ω<br />

Conductive<br />

Laboratories, control rooms, operating rooms,<br />

explosive powder magazines<br />

1.5 x 10 5 < R < 1 x 10 7 Ω<br />

(*) As norm DIN 51953 and 54345 100 Volt; As UNI 10467-5 100 Volt; As NFPA 99 500 Volt.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

9

1.6 - EARTHING<br />

Earthing of the structures, apart from the the problem of the discharge of electrostatic charges, is an important<br />

factor especially when all the wiring run underfloor.<br />

Listed here are some simple but fundamental instructions to be followed for safety reasons:<br />

- when wires run in raceways, boxes and flexible ducts, earthing is not necessary.<br />

- when wires run free in the underfloor void, earthing is required: for structures with stringers a connection every<br />

30 m² approx. is usually enough.<br />

- concerning the stringerless structures, it is recommended to install the wires in tubes, boxes or flexible ducts.<br />

A<br />

BOLT M6x15<br />

+ NUT M6<br />

EARTHING TO<br />

THE BUILDING<br />

EVERY 30 m<br />

2<br />

A<br />

COPPER PLAIT 16 mm<br />

2<br />

WITH RING-LUG<br />

SEZ. A-A<br />

PUT TO EARTHING WITH SSH SUBSTRUCTURE<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

10

1.7 - ANTISEISMIC TEST<br />

The Nesite Access Floor System has recently undergone rigid seismic tests comparable to very strong<br />

earthquake. Nowadays it is present in a large number of computer centres, public and private offices, telephone<br />

exchanges, hospitals and many other working places equipped with high-tech instruments.<br />

The response of the raised floor under specific seismic stress has been proved by means of scientific and<br />

reliable tests.<br />

These tests have been carried out at the ISMES Centre in Bergamo (Institute of experimental models and<br />

structures), one of the most qualified European Laboratories in this field.<br />

The test have been carried out on a access floor sample which has been installed within a room itself and not on<br />

a model, in order to verify the real effects of an earthquake.<br />

The results have clearly proved that the Nesite Access Floor System can bear, without damages, the effects of<br />

the most violent earthquake ever experienced.<br />

TEST RESULTS - reference spectrum according to Newmark<br />

FLOOR TYPE<br />

INTENSITY OF SEISMIC EVENT<br />

[Richter grades]<br />

Panel Structure x z xy<br />

RESULT<br />

PLT (WOT-P) MPS (SST) 8 8 6 no floor alteration<br />

PLT (WOT-P) MPC (SAC) 8 10 5.3 no floor alteration<br />

PG3 (3FO-P) MPS (SST) 8 10 6 no floor alteration<br />

PG3 (3FO-P) MPC (SAC) 8 8 5.3 no floor alteration<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

11

2 <strong>–</strong> RAISED FLOOR SYSTEM<br />

<strong>MASTER</strong> <strong>BOOK</strong><br />

INDEX<br />

2.1 Top Coverings<br />

2.2 Homogeneous vinyl<br />

2.3 Linoleum<br />

2.4 HPL (High pressure laminate)<br />

2.5 Granite agglomerate<br />

2.6 Marble agglomerate<br />

2.7 Needle-punch carpet<br />

2.8 Velour carpet<br />

2.9 Loose lay carpet<br />

2.10 Rubber<br />

2.11 Natural marble<br />

2.12 Natural granite<br />

2.13 Gres of Ceramic<br />

2.14 Natural wood<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

12

2.1 <strong>–</strong> TOP COVERINGS<br />

There are different types of floor coverings available, but not all of them are suitable for raised floor.<br />

This is due to the following reasons:<br />

• the dimensions: since an access floor module is 60 x 60 cm, it is not possible to manufacture with<br />

coverings of smaller dimensions. It is also not advisable to use coverings whose dimensions are not<br />

compatible with the floor module, because of waste excess and/or an unsuccessful final design (for<br />

example studded rubber with module differing from 60 cm).<br />

• not all materials are suitable for being glued to an access floor panel, such as certain floor spongebottomed<br />

carpets; other materials can not even be cut successfully, such as certain bouclè carpet,<br />

because they fray.<br />

ELECTRICAL CHARACTERISTICS<br />

What ever concerning may be, PVC, needle-punch carpet, plastic laminate etc., coverings possess transversal<br />

electric insulation characteristics, (through their thickness), known as electrical resistance. The unit of<br />

measurement is ohm (Ω).<br />

If this value is >1x10 9 ≤2 x 10 10 Ω, we talk about antistatic coverings, if the value is ≥1x10 7 ≤1x10 9 Ω we talk<br />

about static-dissipative coverings, and if the value is >1.5 x 10 5 2 x 10 10 Ω, such as parquet or<br />

some kinds of rubber, but these coverings are not suitable for computer rooms or electronic instrument rooms.<br />

Carpet<br />

Spongy back not<br />

resisting to tear<br />

Panel<br />

On the above drawing, the spongy back does not resist to tear.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

13

2.2 <strong>–</strong> HOMOGENEOUS VINYL<br />

DESCRIPTION<br />

Flexible tile obtained from polyvinyl chloride, filler inerts, plasticizers and dyes, mixed at different production<br />

cycles.<br />

Available both in antistatic, static-dissipative, conductive versions or without any electrical characteristics.<br />

CHARACTERISTICS<br />

Weight Kg/m 2 x mm 1,5<br />

Thickness mm 2 <strong>–</strong> 3<br />

Fire reaction CSE/RF Class 1<br />

FIELDS OF APPLICATION<br />

- Offices, laboratories, computer rooms, technical laboratories, with medium load requirements.<br />

APPLICATION NOTES<br />

- It can be applied on PLN, PLT, PW4, PC5 and PG3 panel core.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

14

2.3 <strong>–</strong> LINOLEUM<br />

DESCRIPTION<br />

Flexible tile made of a mixture of cork and wood with various granulometry, inert charges, organic dyes,<br />

linseed-oil and small quantities of synthetic resins and subsequent glazing. The substance thus obtained is laid<br />

on a jute base and undergoes a forced natural oxidation. Since this is an organic substance, its surface does not<br />

attract electrostatic charges. A static-dissipative version (~ 10 8 Ω) is also available.<br />

CHARACTERISTICS<br />

Weight Kg/m 2 x mm 1.2<br />

Thickness mm 2 <strong>–</strong> 4<br />

Fire reaction CSE/RF Class 1<br />

FIELDS OF APPLICATION<br />

- Offices, banks with low-medium traffic. For medium-high load requirements, it would be advisable to use<br />

bigger thickness.<br />

- Computer rooms in static-dissipative version.<br />

APPLICATION NOTES<br />

- It can be applied on PLN, PLT, PW4, PC5 and PG3 panel core.<br />

- It is cigarette burns resistant.<br />

- It is not advisable to use it in technical rooms because of its difficult maintenance and low resistance to<br />

acids.<br />

- Linoleum matures trough oxidation period and a shade variation (yellowing) is evident (it is more evident with<br />

lighter colours). This is temporary as it reverts back to its true colour once exposed to daylight. This effect is<br />

even faster if there is direct sunlight. To establish the correct colour place sample piece in direct daylight for<br />

a few hours.<br />

The yellowing is not a lack of quality but is simply a natural progression of the raw materials in linoleum.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

15

2.4 <strong>–</strong> HIGH PRESSURE LAMINATE<br />

DESCRIPTION<br />

Rigid sheet made of phenolic resin-soaked Kraft paper and of a specially treated decorative melamine layer. The<br />

paper sheets are then pressed at high temperature and pressure to condensate the resins. The resulting sheet is<br />

then roughed on its bottom side by grinding.<br />

It is available in antistatic or conductive version.<br />

CHARACTERISTICS<br />

Weight Kg/m 2 x mm 1,4<br />

Thickness mm 1,2<br />

Fire reaction CSE/RF Class 1*<br />

* on request<br />

FIELDS OF APPLICATION<br />

- Offices, laboratories, computer rooms, technical laboratories, with medium load requirements.<br />

APPLICATION NOTES<br />

- It can be applied on PLN, PLT, PW4, PC5 and PG3 panel core.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

16

2.5 <strong>–</strong> GRANITE AGGLOMERATE<br />

DESCRIPTION<br />

Flat plates obtained from crushing and controlled granulometry of hard and rocky materials, mixed with polyester<br />

resins, and subsequent thermal polymerization in plates. The material thus obtained is then processed like any<br />

other traditional granite.<br />

CHARACTERISTICS<br />

Weight Kg/m 2 about 14<br />

Thickness mm 6,5<br />

Side dimensions mm 600 x 600<br />

Finishing Type Polished or dressed<br />

Fire reaction CSE/RF Class 1*<br />

Composition % granite 93-95%; polyester resin 5-7%<br />

* on request<br />

FIELDS OF APPLICATION<br />

- Offices with medium load requirements.<br />

APPLICATION NOTES<br />

- It can be applied on PLT, PW4, PC5, PG3 and PC2AV panel core.<br />

- It is not recommended, since the agglomerates mixed with resins are naturally not antistatic and<br />

photosensitive.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

17

2.6 <strong>–</strong> MARBLE AGGLOMERATE<br />

DESCRIPTION<br />

Flat plates obtained from crushing and controlled granulometry of soft stony materials, mixed with polyester<br />

resins, and subsequent vacuum polymerization in blocks or plates. The material thus obtained is then processed<br />

like any other traditional stony materials.<br />

CHARACTERISTICS<br />

Weight Kg/m 2 about 25<br />

Thickness mm 12÷13<br />

Side dimensions mm 600 x 600<br />

Finishing Type Polished or dressed<br />

Fire reaction CSE/RF Class 1*<br />

Composition % marble 93-95%; polyester resin 5-7%<br />

*on request<br />

FIELDS APPLICATION<br />

- Offices with medium load requirements.<br />

APPLICATION NOTES<br />

- It can be applied on PLT, PW4, PC5, PG3 and PC2AV panel core.<br />

- It is not recommended, since the agglomerates mixed with resins are naturally not antistatic and<br />

photosensitive.<br />

.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

18

2.7 <strong>–</strong> NEEDLE PUNCH CARPET<br />

DESCRIPTION<br />

Felt made of synthetic fibres of different diameters, assembled by continuous punching and combined with a<br />

bottom support layer - usually resinate - to increase its peeling resistance. The system requires the use of precoloured<br />

fibres of different colours mixed together to obtain a final result of melange. When the felt contains thin<br />

fibres, for instance stainless steel or carbon, it possesses conductive characteristics.<br />

CHARACTERISTICS<br />

Weight Kg/m 2 1,3<br />

Thickness mm about 6,5<br />

Side dimensions mm 600 x 600<br />

Fire reaction CSE/RF Class 1<br />

FIELDS OF APPLICATION<br />

- Generally for offices, also with high load requirements.<br />

APPLICATION NOTES<br />

- It can be applied on PLN, PLT, PW4, PC5, and PG3 panel core.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

19

2.8 <strong>–</strong> VELOUR CARPET<br />

DESCRIPTION<br />

Carpet obtained from flake weaving of polyamide threads on a synthetic cloth (not woven). The bottom face is<br />

usually glued using latex. Electric conductivity can be obtained by inserting stainless steel fibres in the thread<br />

and contemporarily adding carbon in the lower latex layer.<br />

CHARACTERISTICS<br />

Weight Kg/m 2 1,8<br />

Thickness mm about 6,5<br />

Side dimensions mm 600 x 600<br />

Fire reaction CSE/RF Class 1<br />

FIELDS OF APPLICATION<br />

- Generally for offices, also with high load requirements.<br />

APPLICATION NOTES<br />

- It can be applied on PLN, PLT, PW4, PC5 and PG3 panel core.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

20

2.9 <strong>–</strong> LOOSE LAY CARPET<br />

DESCRIPTION<br />

Square carpet tile obtained by application of needle-punch, velour or tricot carpet with a bottom layer of<br />

reinforced bitumen or multilayer polyvinyl chloride with special characteristics of adaptability.<br />

CHARACTERISTICS<br />

Weight Kg/m 2 5<br />

Thickness mm about 8<br />

Side dimensions mm 500 x 500 - 600 x 600<br />

Fire reaction CSE/RF Class 1<br />

FIELDS OF APPLICATION<br />

- Generally for offices.<br />

APPLICATION NOTES<br />

- It can be applied on PLN, PLT, PW4, PC5, and PG3 panel core.<br />

- It is advisable to fix tiles using a stick/detach glue every 2-3 rows of tiles on both longitudinal and orthogonal<br />

directions.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

21

2.10 <strong>–</strong> RUBBER<br />

DESCRIPTION<br />

Flexible tile made of homogeneous mixture of synthetic rubber and stabilizing mineral charges. The mixture is<br />

then glazed and vulcanized in its mould. Also available in antistatic and/or conductive versions. The finishing<br />

surface can have smooth, embossed or studded design.<br />

CHARACTERISTICS<br />

Weight Kg/m 2 1,5<br />

Thickness mm 2 - 4<br />

Fire reaction CSE/RF Class 1<br />

FIELDS OF APPLICATION<br />

- Control rooms, operating rooms, technical rooms, halls with high load requirements.<br />

APPLICATION NOTES<br />

- It can be applied on PLN, PLT, PW4, PC5, and PG3 panel core.<br />

- The surface finishing in relief is not always suitable for raised floor, because of the difference between panel<br />

size and relief size.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

22

2.11 - NATURAL MARBLE<br />

DESCRIPTION<br />

Quarry material with veined decoration or expanded design, usually with a calcareous base. Naturally it does not<br />

store electrostatic charges. This material is relatively resistant to the abrasion.<br />

CHARACTERISTICS<br />

Weight Kg/m 3 2300 -2800<br />

Thickness mm about 17<br />

Measurement mm 600 x 600<br />

Surface finish Type Polished or dressed with chamfer<br />

Fire reaction CSE/RF Class 0<br />

FIELDS OF APPLICATION<br />

- Low-medium load requirements.<br />

APPLICATION NOTES<br />

- It can be applied on PG1AV and PC2AV panel core.<br />

- It is not suitable for high traffic requirements, or in rooms with contact directly to external areas, owing to its<br />

low abrasion resistance.<br />

- The dressed version is recommended, since scratches are less evident.<br />

- It must not be used in rooms equipped with wheelchairs.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

23

2.12 <strong>–</strong> NATURAL GRANITE<br />

DESCRIPTION<br />

Coarse grained quarry material, with repeated thin designs. It does not store electrostatic charges. It is very<br />

resistant to the abrasion.<br />

CHARACTERISTICS<br />

Weight Kg/m 3 2500 <strong>–</strong>2700<br />

Thickness mm about 17<br />

Measurement mm 600 x 600<br />

Surface finish Type Polished or dressed with chamfer<br />

Fire reaction CSE/RF Class 0<br />

FIELDS OF APPLICATION<br />

- Medium-high load requirements.<br />

APPLICATION NOTES<br />

- It can be applied on PG1AV and PC2AV panel core.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

24

2.13 <strong>–</strong> GRES OF CERAMIC<br />

DESCRIPTION<br />

Flat slabs made of clay, quartz, kaolin and feldspar and obtained by sintering the material at over 1200 °C.<br />

The main characteristics are a good resistance to wear, to chemical and atmospherical agents, aging and<br />

bending.<br />

CHARACTERISTICS<br />

Weight Kg/m 2 20 <strong>–</strong> 25<br />

Thickness mm 8 <strong>–</strong> 11<br />

Measurement mm 300 x 300 - 600 x 600<br />

Surface finish type matt or polished<br />

Fire reaction CSE/RF Class 0<br />

FIELDS OF APPLICATION<br />

- Offices, halls, laboratories, and generally rooms with high load requirements.<br />

APPLICATION NOTES<br />

- It can be applied on PLT, PW4, PC5, PG3 and PC2AV panel core.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

25

2.14 <strong>–</strong> NATURAL WOOD<br />

DESCRIPTION<br />

Natural wood strips glued together in strips or other designs, and UV varnished on the surface.<br />

CHARACTERISTICS<br />

Weight Kg/m 2 6 <strong>–</strong> 12<br />

Thickness mm > 3<br />

Surface finish Type varnished<br />

Fire reaction CSE/RF Class 1*<br />

*on request<br />

FIELDS OF APPLICATION<br />

- Directional offices, generally high class offices with low-medium load requirements.<br />

APPLICATION NOTES<br />

- It can be applied on PLT, PW4, PC5 and PG3 panel core.<br />

- It is not suitable for high traffic requirements, or in rooms with contact directly to external areas, owing to its<br />

low abrasion resistance.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

26

3 <strong>–</strong> RAISED FLOOR SYSTEM<br />

<strong>MASTER</strong> <strong>BOOK</strong><br />

INDEX<br />

3.1 Accessories for service connections<br />

3.2 Accessories for air passing<br />

3.3 Connecting ramps<br />

3.4 Connecting steps<br />

3.5 Expansion joint<br />

3.6 Bracing<br />

3.7 Underfloor and fire partitions<br />

3.8 Finishing accessories<br />

3.9 Lifting tools<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

27

3.1 <strong>–</strong> ACCESSORIES FOR<br />

SERVICE CONNECTIONS<br />

PANELS WITH ACCESSORIES<br />

Panels are the same as the standard ones, but they have already incorporated the exits for connections such as<br />

electrical, phone, EDP, etc..<br />

DISTRIBUTION TURRETS<br />

The turrets enable the connection of electrical devices and/or phone in a single point of distribution. They are<br />

positioned in the working areas, usually under the desks.<br />

B<br />

B<br />

B<br />

1 2 3<br />

A<br />

A<br />

A<br />

DESCRIPTION RIF. MATERIAL<br />

Weight A B<br />

[kg] [mm] [mm]<br />

NOTES<br />

Mono 1 (Vertical) 1 plastic ∼ 1 220 150 Ministry certification P.T.<br />

Mono 2 (Horizontal) 2 plastic ∼ 1 180 220 Ministry certification P.T.<br />

Triedra 3 plastic ∼ 1 160 200 Ministry certification P.T.<br />

FLOOR HATCH<br />

The floor hatches do not create any obstruction. The 5 mm thick steel plate of the hatch can withstand<br />

light/medium loads.<br />

B<br />

1 2<br />

A<br />

A<br />

DESCRIPTION RIF. MATERIAL<br />

WEIGHT A B<br />

[kg] [mm] [mm]<br />

NOTES<br />

Hatch 1 steel and plastic ∼ 1.5 195 220 load max 300 Kg<br />

electrical box 2 steel and plastic ∼ 2 300 120 Ministry certification P.T.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

28

3.2 <strong>–</strong> ACCESSORIES FOR AIR<br />

PASSING<br />

PERFORATED PANELS AND GRILLES<br />

These comprise the elements which allow the passage of air from the underfloor plenum to the room, when the<br />

access floor is also used as a supply duct. They can also be used for simply airing the ground floor to avoid<br />

stagnant air.<br />

There are perforated steel panels and aluminium grills, these last one normally have dimensions 150x600 mm.<br />

The grills and the perforated panels with 576 holes are also available with the airflow-regulation as optional.<br />

Perforated steel panels have usually technical coverings and are suitable for clean rooms, since they do not<br />

generate suspended particles, which for example could damage microchip production.<br />

They are usually installed in offices where there is heating/air conditioning, which uses underfloor plenum for airflow.<br />

The grills can be installed with a dust-collector and a sound insulator box.<br />

B<br />

B<br />

C<br />

D<br />

1<br />

2<br />

C<br />

3<br />

m /h<br />

1500<br />

1400<br />

1300<br />

1200<br />

1<br />

2<br />

3<br />

C<br />

1100<br />

1000<br />

4<br />

3<br />

4<br />

900<br />

D<br />

800<br />

700<br />

600<br />

500<br />

400<br />

PERFORATED METAL PANEL WITH 576 HOLES<br />

300<br />

200<br />

100<br />

0<br />

5 10 15 20<br />

25<br />

30 35 40 45 50 Pa<br />

DESCRIPTION RIF. MATERIAL<br />

Walkable grill without<br />

regulation<br />

WEIGHT<br />

[kg]<br />

THICKNESS<br />

[mm]<br />

B<br />

[mm]<br />

C<br />

[mm]<br />

D/∅ HOLES<br />

[mm]<br />

NOTES<br />

1 Al-alloy 2,5 30-52 150 600 - Load max 120 kg<br />

Walkable grill with regulation 2 Al-alloy 3,9 30-52 150 600 80 Load max 120 kg<br />

Metal panel with 576 holes<br />

without regulation<br />

Metal panel with 576 holes with<br />

regulation<br />

3 Steel 7 30 (*) 600 600 10 Load max 300 kg<br />

4 Steel 8 30 (*) 600 600 10 load max 300 kg<br />

(*) to adjust to thicker panels, adjusting pedestals are applied to the four angles of the panels<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

29

Proprieta`riservata - Ri produzione vi etata atermine di lege-<br />

Copyright -Nachdruck verboten-Propriete' reservee<br />

3.3 <strong>–</strong> CONNECTING RAMPS<br />

RAMPS<br />

Ramps are essential features whenever the access floor is higher than the building slab. These up stands are<br />

usually made of wood and covered with studded rubber or any other non-slip covering.<br />

5<br />

<strong>SECTION</strong> A-A<br />

6<br />

PARTICULAR<br />

B<br />

7<br />

8<br />

A<br />

A<br />

B<br />

1<br />

2 3 4<br />

EXTERNAL RAMP<br />

DESCRIPTION RIF. MATERIAL THICKNESS NOTES<br />

[mm]<br />

metal structure of the floor 1 galvanized steel -<br />

steel column for height adjustment 2 galvanized steel Tube 1” regulation ±15 mm<br />

reinforcing frame 3 steel Tube 50x20x2<br />

fixing screw 4 galvanized steel -<br />

angular finishing element 5 aluminium 2 on request<br />

lateral closure 6 black melanine coated chipboard 25 on request<br />

non-slip covering 7 black rubber 5 on request<br />

terminal 8 aluminium -<br />

TYPE 1 TYPE 2<br />

H<br />

H<br />

L<br />

L<br />

W<br />

W<br />

TYPE 3 (EXTERNAL)<br />

TYPE 4 (INTERNAL)<br />

H<br />

L<br />

L<br />

H<br />

W<br />

W<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

30

3.4 <strong>–</strong>CONNECTING STEPS<br />

STEPS<br />

Steps, such as ramps, are necessary whenever the access floor is higher than the building slab. They are<br />

usually made of wood and covered with studded rubber.<br />

3<br />

5<br />

5<br />

4 2<br />

1<br />

EXTERNAL STEP<br />

DESCRIPTION RIF. MATERIAL THICKNESS<br />

NOTES<br />

[mm]<br />

metal structure of the floor 1 galvanized steel -<br />

internal structure of the step 2 listed wood 20<br />

angular element 3 aluminium 2 on request<br />

laterale closure 4 black melanine coated chipboard 25 on request<br />

non-slip covering 5 black rubber 5 on request<br />

TYPE 1 TYPE 2<br />

H<br />

H<br />

L<br />

L<br />

W<br />

W<br />

TYPE 3 (EXTERNAL)<br />

TYPE 4 (INTERNAL)<br />

H<br />

L<br />

L<br />

H<br />

W<br />

W<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

31

3.5 <strong>–</strong> EXPANSION JOINT<br />

JOINT<br />

Joint composed with a supporting aluminium profile and a<br />

neoprene gasket. The raised floor joint is installed in the<br />

same position of the building expansion joint. The profile<br />

is fastened with an angular element to the raised floor<br />

panel and to the head disc of the substructure. The<br />

pedestals have to be fastened to the slab by means of<br />

screw anchors or cross-bracings.<br />

6<br />

2<br />

35<br />

1<br />

3<br />

RIF. DESCRIPTION MATERIAL<br />

1 joint aluminium<br />

2 gasket neoprene<br />

3 angular element aluminium<br />

4 screw anchor Plastic or steel<br />

5 pedestal steel<br />

6 panel various<br />

4<br />

5<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

32

3.6 <strong>–</strong> BRACING<br />

BRACING<br />

The bracing system based on tie rods and struts is required whenever the floor’s horizontal rigidity has to be<br />

increased. Bracing are usually applied when floor ends with vertical wall closure (e.g. curtain walls), without<br />

sufficient horizontal contrast capacity. The tie rods or struts are made of profiled tubes to allow easy fastening to<br />

the slab, on one end, and to the access floor structure, on the other end.<br />

panel<br />

stringer<br />

angular element<br />

fastened to the panel<br />

column<br />

tie rod<br />

glue for<br />

base<br />

screw anchor<br />

Scheme of access floor bracing<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

33

3.7 <strong>–</strong> UNDERFLOOR AND FIRE<br />

PARTITIONS<br />

PARTITIONS<br />

When the conveying of underfloor air, the increasing of acoustic insulation and the fire prevention are<br />

necessaries, some vertical elements are used to subdivide the plenum underfloor. They are known as acoustic<br />

and underfloor partitions, and fire partitions.<br />

Usually they are made of a calcium based inert agglomerate slab, easy to be cut in case of obstacles to be<br />

overcome, inserted in a steel profile guide and sealed with an adhesive gasket or with intumescent mastic. This<br />

material in case of fire becomes spongy and swells up, thus closing up all openings perfectly.<br />

ACOUSTIC AND UNDERFLOOR PARTITIONS<br />

This range includes the vertical elements to be used to convey the air flow underfloor, when this is used as an<br />

inlet/outlet air conditioning duct.<br />

The use of underfloor partitions increase also acoustic comfort of the access floor. The acoustic partitions are<br />

usually installed underneath the partitioning walls installed provided for on the floor, and designed according to<br />

their sound deadening capacity.<br />

FIRE PARTITIONS<br />

Fire prevention is a feature which nowadays must be taken into consideration. Any precautions taken are never<br />

enough. Since the access floor is a linking element inside the building, whenever complete and general fire<br />

protection is required, it is necessary to install fire partitions under the floor. The choice of the fire resistance<br />

level depends on and must be in harmony with the panels installed.<br />

1 2 3<br />

panel<br />

panel<br />

panel<br />

dividing<br />

separator<br />

structure<br />

mpc<br />

dividing<br />

separator<br />

REI 30*<br />

structure<br />

mpc<br />

dividing<br />

separator<br />

REI 60<br />

structure<br />

mpc<br />

DESCRIPTION RIF. DIGIT MATERIAL WIDTH NOTES<br />

[mm]<br />

Underfloor partition 1 BPOA/B Reinforced calcium sulphate 12,5<br />

REI 30* Fire partition 2 BP2A/B Reinforced calcium sulphate 12,5 + 12,5<br />

REI 60 Fire partition 3 BP3A/B Cementicious matrix silicate 20 + 15 CLASS 0<br />

*Indicative<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

34

3.8 <strong>–</strong> FINISHING ACCESSORIES<br />

1<br />

SKIRTING<br />

Skirting made of plastic, anodized aluminium or painted<br />

wood.<br />

A<br />

RIF. DESCRIPTION MATERIAL A<br />

[mm]<br />

1 skirting wood 60<br />

1 skirting PVC 70<br />

1 skirting aluminium 70<br />

2 panel various -<br />

3 column steel -<br />

2<br />

3<br />

6<br />

UPSTAND<br />

Made of black melamine coated chipboard, it can feature<br />

the same covering as the floor panel, on request.<br />

2 1<br />

RIF. DESCRIPTION MATERIAL<br />

1 angle bar aluminium<br />

2 panel various<br />

3 upstand element black melamine coated<br />

chipboard<br />

4 screw anchor plastic or steel<br />

5 rectangular element steel<br />

6 screw steel<br />

7 pedestal steel<br />

7<br />

5<br />

3<br />

6<br />

4<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

35

3.9 <strong>–</strong> LIFTING TOOLS<br />

For removing panels in case of maintenance operations, it is recommended the use of suitable lifting tools, which<br />

differ in accordance with the panel covering involved:<br />

- single cup lifting tool for resilient coverings (smooth finish);<br />

- double cup lifting tool for inert and generally heavy panels (e.g. PG3, PG1AV);<br />

- special lifting tool for carpet coverings;<br />

- nail type tool for special coverings.<br />

LIFTING TOOLS<br />

A double-cup lifting tool is recommended for inert (e.g. PG3) and generally heavy panels (PG1AV). The special<br />

lifting tool, for carpet coverings, is suitable for any kind of panel core.<br />

LIFTING NAIL<br />

It is used in case of special finishing panels, for instance bushhammered stones, studded rubbers and worked<br />

metal plates. When designing an access floor with such coverings, it is necessary to include a certain number of<br />

perforated panels and related nails (1 each 3 sqm ca.) to be distributed all around the floor surface.<br />

3<br />

1 2<br />

DESCRIPTION RIF. MATERIAL WEIGHT<br />

NOTES<br />

[kg]<br />

Single cup lifting tool 1 Aluminium-steel-rubber 0,5 Packed in carton box<br />

Double cup lifting tool 2 Aluminium-steel-rubber 1 Packed in carton box<br />

special lifting tool for<br />

carpet<br />

3 Aluminium-rubber 1,25 Packed in carton box<br />

Lifting nail 4 Steel 0,05 Nut, lock nut and washer included<br />

raising pos.<br />

lifting<br />

hook<br />

resting pos.<br />

4<br />

panel<br />

with hole<br />

hook<br />

washer<br />

panel with hole<br />

nut&counter-nut<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

36

4 <strong>–</strong> RAISED FLOOR SYSTEM<br />

<strong>MASTER</strong> <strong>BOOK</strong><br />

INDEX<br />

4.1 Installation<br />

4.2 Guide for the installation of raised floor<br />

4.3 Installation of raised floor with MPS substructure<br />

4.4 Installation of raised floor with MPL/MPM/MPH substructure<br />

4.5 Installation of raised floor with MPC substructure<br />

4.6 Installation of raised floor with SSH substructure<br />

4.7 Complementary products<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

37

4.1 <strong>–</strong> INSTALLATION<br />

1 - SURVEY FOR THE PREPARATION AND ORGANISATION OF THE SITE<br />

First of all the site’s suitability to receive all the materials involved in the installation of the access floor has to be<br />

inspected. The site should have adequate facilities as follows:<br />

- suitable ways to get to the site by truck<br />

- closed weather-protected site for stocking materials<br />

- keeper<br />

- lifting equipment to bring materials to various floors (crane, elevators)<br />

- adequate service access to introduce materials to the various floors (access, doors, windows, ramps, etc.)<br />

- power sockets for apparatus<br />

- adequate electrical lighting<br />

- the rooms where the floor is going to be installed have to be clean and free of materials left from previous<br />

work<br />

- false ceiling and eventual sprinkler system (if any) should be already installed<br />

- external doors and windows should be already installed<br />

- when necessary, sealing of cableways, expansion joints and cracks, should be carried out<br />

- it is very important to verify the quality of the sub-floor finishing, which should be almost smooth. Such a<br />

finishing can be already obtained caring the sub-floor casting.<br />

In order to optimize the fulfilment of the work, the site personnel should give an appropriate support to:<br />

- The installers<br />

- The building Management<br />

- The customer<br />

2 - ALTIMETRICAL SURVEY AND TRACING<br />

After the inspection, when required, the position of the panels has to be traced out. This operation, in agreement<br />

with the client, is very useful as it allows rapid installation and good esthetical results. The floor layout may be<br />

different every time, but some preliminary rules should be followed to obtain better final results.<br />

It is also necessary to calculate the pedestals height, even if they are adjustable up to 50 mm, since the<br />

difference in level in the rooms can be higher than that.<br />

Concerning the height, the range is wider, starting from a minimum height of 10 cm up to about 1 m (and more,<br />

with a dedicated design for the columns).<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

38

4.1 <strong>–</strong> INSTALLATION<br />

3 - INSTALLATION<br />

The floor installation has to be carried out in accordance with the above mentioned conditions. The slab in the<br />

room should be cleaned with a vacuum cleaner and a layer of anti-dust paint, preferably polyurethanic or<br />

epossidic types (because they do not alter in the time), should be applied. This procedure must be followed<br />

when the subfloor void will be used as an air-supply/return duct.<br />

The installation method depends on type of floor, with or without stringers. Once the layout of the panels has<br />

been decided, the installation can start.<br />

In order to obtain a reference point, such as a system of right angled lines, two perpendicular nylon wires are<br />

fastened from wall to wall; to calculate their perpendicularity, Pythagoras’ theorem, or simply 3-4-5 method,<br />

should be applied.<br />

Point “O” of fig. 1 refers to the starting and reference point of pedestals and panels installation. Once the<br />

structure has been installed, it has to be positioned perfectly flat. For this purpose several tools can be used: 15<br />

metre-long spirit levels, laser levels, optical theodolite, or the more common 3 metre-long rigid levelling rods.<br />

Once the structure has been installed, the panels installation can start too. It is advisable to start from the first<br />

row of internal panels along the two right-angled reference wires. Make sure that there are no small piece of<br />

panel on the floor.<br />

For stringerless substructures, whose bases have to be glued on the slab, pedestals and panels are installed at<br />

the same time, with constant levelling. In this case it is advisable to walk on the floor during the first 24 hours, in<br />

order to let the glue dry out.<br />

Once the panels and pedestals have been installed, the final stage consists of the installation of ramps, steps,<br />

upstands and relevant accessories.<br />

After the installation, if other refinishing touches are necessary, it is advisable to protect the floor covering<br />

surface with cardboard or polyethylene sheets.<br />

4- INSTALLATION TIME<br />

The installation time of raised access floor depends on several factors:<br />

- installer’s skill and experience<br />

- installation tools<br />

- dimensions, shape and access to the rooms<br />

- type of panel and covering (lower and upper surfaces)<br />

- type of structure<br />

A team of 2 installers can install from 20 to 80 m ² of floor per day, depending on the above mentioned factors.<br />

It is important to remember that a lot of time is required for the cutting and installation of the perimetral stringers<br />

and panels.<br />

It is advisable to give the job to skilled installers, equipped with all suitable tools necessary for a proper<br />

installation.<br />

NYLON THREADS<br />

3<br />

5<br />

0<br />

4<br />

Starting and reference wires scheme,<br />

whose perpendicularity is verified by<br />

Pythagora’s theorem also known as the<br />

3-4-5 method (and relevant multiples and<br />

submultiples).<br />

Final result of the floor grid at the<br />

end of installation.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

39

4.1 <strong>–</strong> INSTALLATION<br />

5 - RECOMMENDATIONS<br />

Keep free from obstruction all the access roads to the site where the raised floor will be installed, in order to<br />

permit the unloading of the materials near the access zones or the lifting equipment.<br />

Keep free from obstruction also the horizontal access to the site and to the lifting equipment to the floors, in<br />

order to permit the easy movement of the materials with transpallet. Appropriate passages for the transpallet<br />

have to be indicated where the raised floor will be installed.<br />

It is advisable to define contractually the characteristics and program of use of the lifting equipment for the<br />

vertical transport of materials.<br />

6 - STORAGE ON SITE<br />

The material has to be stored in dry and protected area, with temperature between 5°C and 35°C and relative<br />

humidity between 40% and 75%.<br />

7 - CONDITIONS OF THE ROOMS<br />

The raised floor should be installed in rooms with temperature between 5°C and 35°C and relative humidity<br />

between 40% and 75%. The building works should have been terminated not less than 30 days earlier, damp<br />

works not less than 15 days. External frames have to be already installed, the slab must be clean and flat.<br />

In the installation rooms, the exact finished floor height must to be indicated.<br />

Before starting the installation of the raised floor, all accessory works have to be completed, except from the<br />

mobile partitions which will be installed on the floor,<br />

In order to guarantee the safety and the quality of the installation, nobody (except for the installer can walk on<br />

the raised floor during installation and, if adhesives are being used, also for 24 hours after installation.<br />

8 - CLEANING OF THE SITE<br />

The installation includes the removal of all the wastage material on a pallet next to the installed and cleaned<br />

floor; it excludes the transport to the base level of the building and the transport to the public dump.<br />

After the floor installation and cleaning, it is advisable to protect the covering surface with a suitable material to<br />

avoid impacts, scratches and abrasions during following works. A suitable material is the MDF 2-3 mm thick, or<br />

a similar product.<br />

9 - HANDING OVER OF THE FLOOR<br />

The raised floor is tested and handed over just as soon as the installation is completed, before the application of<br />

the protection material (recommended),and the other accessory works.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

40

4.1 <strong>–</strong> INSTALLATION<br />

10 - FINAL CONTROL<br />

Procedure and acceptance criteria of the site final control.<br />

After the installation the raised floor has to correspond to following parameters:<br />

- allowed deviation of the alignment of the gaps between panels ± 3 mm<br />

- allowed difference of level between adjoining panels measured near the edge (panels without load) ± 1 mm<br />

- allowed difference of level on all the surface of the installed raised floor ± 6 mm<br />

N.B. except from other dispositions of the Customer Site Manager, with reference to connections to other<br />

floors.<br />

- perimetral cuts: maximum gap allowed between cut panel and wall or other element to be cut ≤ 10 mm.<br />

- stability of the panel: the panel has to rest on at least 4 points, (excl. perimetral adjustments) with balancing<br />

allowed, measured alternatively on two opposite corners of the panel without load ± 1 mm.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

41

4.2 <strong>–</strong> GUIDE TO THE<br />

INSTALLATION OF<br />

Preliminary to every installation the following general instructions are valid.<br />

Make sure that the slab is suitable to support the chosen substructure. Generally it can be said that the more<br />

regular the slab, the easier will be the installation and the better the final result.<br />

Make sure that the room where the raised floor will be installed is free of debris and perfectly clean.<br />

Check that all the brickwork and the complementary installation (in particular the external frames) have been<br />

installed some time before the installation is to take place, in order to avoid the formation of moisture.<br />

When required, verify that the slab has been treated with antidust primer.<br />

Check all the materials in order to determine what is missing.<br />

Determine the lowest and the highest point in the room so as to be able to calculate the height of the pedestals.<br />

To reduce the possibility of an error it is advisable to start with an area not exceeding 100-200 m²; nevertheless<br />

the amount may vary according to installer experience.<br />

Also for substructures with stringers sometimes it is necessary to fasten the bases to the slab either with glue or<br />

screw anchor, for example in the following cases:<br />

• height over 60 cm,<br />

• near the joints<br />

• in case of floor without perimetral walls (curtain walls)<br />

• whenever a better stability and stiffness of the raised floor is required.<br />

<strong>Rev</strong>. 01.08.07<br />

NESITE S.p.A. <strong>–</strong> Via L. Da Vinci, 20 <strong>–</strong> 35028 PIOVE DI SACCO <strong>–</strong> Z.I. Tognana (Padova) Italy <strong>–</strong> Tel. +39.049.9713311 <strong>–</strong> Fax +39.049.9713313<br />

NESITE S.p.A. reserves the right to change technical data without notice<br />

www.nesite.com e-mail : nesite@nesite.com<br />

42

4.3 <strong>–</strong> INSTALLATION OF RAISED<br />

FLOOR WITH MPS<br />

1) The adoption of an MPS substructure requires that the slab is laid as flat as possible; the more this<br />

recommendation is followed, the better the final result and stability of the raised floor and the easier the<br />

installation.<br />

2) Start from 2 walls that are as much as possible right-angled; fasten two tight wires, at a distance of not more<br />

than 58 cm from the wall, and at about 2-3 cm above the finished floor. Calculate their perpendicularity by<br />

means of the 3-4-5 method (Pythagoras’ Theorem). Check that there will be no panel crop-ends against the<br />

wall which are shorter than 15 cm.<br />

3) Assemble the MPS pedestals (base + column + gaskets) approximately adapting them to the height<br />

required in the design measurement.<br />

4) Start the installation by laying the first panel on four pedestals, placing it with two sides exactly along the<br />

right-angled wires. Make sure that the mentioned wires do not meet any obstacles and have not been<br />

diverted.<br />