The Granite Industry of Southwestern New Brunswick: A Historical ...

The Granite Industry of Southwestern New Brunswick: A Historical ...

The Granite Industry of Southwestern New Brunswick: A Historical ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Part Two — <strong>The</strong> Hampstead District 79<br />

All the granite quarries are sheet quarries. In Quarry 58 the<br />

sheets are dipping at a low angle to the northwest. <strong>The</strong> sheetings<br />

become progressively thicker the deeper they are in the quarry,<br />

some being 2 feet and more in thickness. <strong>The</strong> main joint set strikes<br />

approximately N60ºE and dips 80ºSE; there are two minor sets<br />

<strong>of</strong> joints, one striking east–west with a dip <strong>of</strong> 80ºN and the other<br />

striking N40ºW with a vertical dip. <strong>The</strong> main joints are 10 to 20 feet<br />

apart. <strong>The</strong> rift is horizontal or nearly so, being generally parallel to the<br />

sheeting, while the grain is vertical with an east–west strike.<br />

In Quarry 56 the sheeting is considerably thicker than in<br />

Quarry 58, running as much as 8 to 10 feet thick in places. <strong>The</strong><br />

sheets dip to the southeast at a low angle, with the rift parallel to<br />

the sheets. <strong>The</strong> main joints strike northwesterly and are vertical,<br />

while the grain is also vertical and at right angles to the strike <strong>of</strong><br />

the main joints.<br />

Analysis<br />

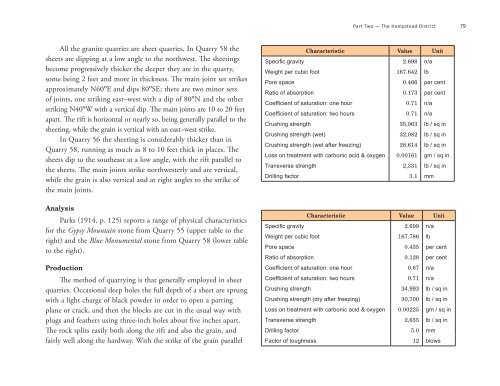

Parks (1914, p. 125) reports a range <strong>of</strong> physical characteristics<br />

for the Gypsy Mountain stone from Quarry 55 (upper table to the<br />

right) and the Blue Monumental stone from Quarry 58 (lower table<br />

to the right).<br />

Production<br />

<strong>The</strong> method <strong>of</strong> quarrying is that generally employed in sheet<br />

quarries. Occasional deep holes the full depth <strong>of</strong> a sheet are sprung<br />

with a light charge <strong>of</strong> black powder in order to open a parting<br />

plane or crack, and then the blocks are cut in the usual way with<br />

plugs and feathers using three-inch holes about five inches apart.<br />

<strong>The</strong> rock splits easily both along the rift and also the grain, and<br />

fairly well along the hardway. With the strike <strong>of</strong> the grain parallel<br />

Characteristic Value Unit<br />

Specific gravity 2.698 n/a<br />

Weight per cubic foot 167.642 lb<br />

Pore space 0.466 per cent<br />

Ratio <strong>of</strong> absorption 0.173 per cent<br />

Coefficient <strong>of</strong> saturation: one hour 0.71 n/a<br />

Coefficient <strong>of</strong> saturation: two hours 0.71 n/a<br />

Crushing strength 35,063 lb / sq in<br />

Crushing strength (wet) 32,082 lb / sq in<br />

Crushing strength (wet after freezing) 28,614 lb / sq in<br />

Loss on treatment with carbonic acid & oxygen 0.00161 gm / sq in<br />

Transverse strength 2,331 lb / sq in<br />

Drilling factor 3.1 mm<br />

Characteristic Value Unit<br />

Specific gravity 2.699 n/a<br />

Weight per cubic foot 167.786 lb<br />

Pore space 0.435 per cent<br />

Ratio <strong>of</strong> absorption 0.128 per cent<br />

Coefficient <strong>of</strong> saturation: one hour 0.67 n/a<br />

Coefficient <strong>of</strong> saturation: two hours 0.71 n/a<br />

Crushing strength 3 4 , 9 9 3 lb / sq in<br />

Crushing strength (dry after freezing) 30,700 lb / sq in<br />

Loss on treatment with carbonic acid & oxygen 0.00225 gm / sq in<br />

Transverse strength 2,655 lb / sq in<br />

Drilling factor 5.0 mm<br />

Factor <strong>of</strong> toughness 12 blows