Avoidance of brake squeal by a separation of the brake ... - tuprints

Avoidance of brake squeal by a separation of the brake ... - tuprints

Avoidance of brake squeal by a separation of the brake ... - tuprints

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

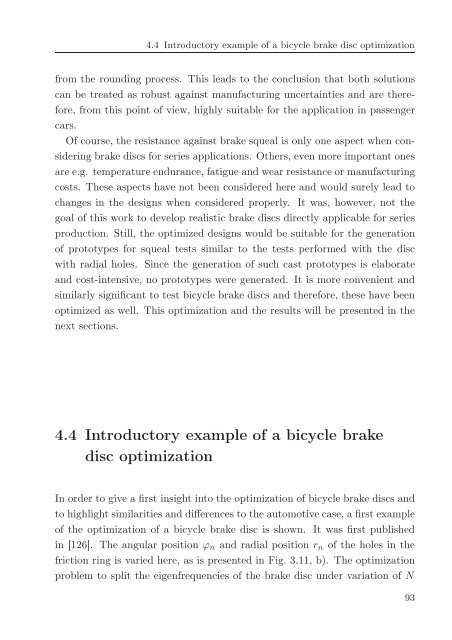

4.4 Introductory example <strong>of</strong> a bicycle <strong>brake</strong> disc optimization<br />

from <strong>the</strong> rounding process. This leads to <strong>the</strong> conclusion that both solutions<br />

can be treated as robust against manufacturing uncertainties and are <strong>the</strong>refore,<br />

from this point <strong>of</strong> view, highly suitable for <strong>the</strong> application in passenger<br />

cars.<br />

Of course, <strong>the</strong> resistance against <strong>brake</strong> <strong>squeal</strong> is only one aspect when considering<br />

<strong>brake</strong> discs for series applications. O<strong>the</strong>rs, even more important ones<br />

are e.g. temperature endurance, fatigue and wear resistance or manufacturing<br />

costs. These aspects have not been considered here and would surely lead to<br />

changes in <strong>the</strong> designs when considered properly. It was, however, not <strong>the</strong><br />

goal <strong>of</strong> this work to develop realistic <strong>brake</strong> discs directly applicable for series<br />

production. Still, <strong>the</strong> optimized designs would be suitable for <strong>the</strong> generation<br />

<strong>of</strong> prototypes for <strong>squeal</strong> tests similar to <strong>the</strong> tests performed with <strong>the</strong> disc<br />

with radial holes. Since <strong>the</strong> generation <strong>of</strong> such cast prototypes is elaborate<br />

and cost-intensive, no prototypes were generated. It is more convenient and<br />

similarly significant to test bicycle <strong>brake</strong> discs and <strong>the</strong>refore, <strong>the</strong>se have been<br />

optimized as well. This optimization and <strong>the</strong> results will be presented in <strong>the</strong><br />

next sections.<br />

4.4 Introductory example <strong>of</strong> a bicycle <strong>brake</strong><br />

disc optimization<br />

In order to give a first insight into <strong>the</strong> optimization <strong>of</strong> bicycle <strong>brake</strong> discs and<br />

to highlight similarities and differences to <strong>the</strong> automotive case, a first example<br />

<strong>of</strong> <strong>the</strong> optimization <strong>of</strong> a bicycle <strong>brake</strong> disc is shown. It was first published<br />

in [126]. The angular position ϕ n and radial position r n <strong>of</strong> <strong>the</strong> holes in <strong>the</strong><br />

friction ring is varied here, as is presented in Fig. 3.11, b). The optimization<br />

problem to split <strong>the</strong> eigenfrequencies <strong>of</strong> <strong>the</strong> <strong>brake</strong> disc under variation <strong>of</strong> N<br />

93