Hydrogen embrittlement in power plant steels - Indian Academy of ...

Hydrogen embrittlement in power plant steels - Indian Academy of ...

Hydrogen embrittlement in power plant steels - Indian Academy of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

440 R K Dayal and N Parvathavarth<strong>in</strong>i<br />

4.2 <strong>Hydrogen</strong> <strong>embrittlement</strong><br />

The energy absorption ability <strong>of</strong> steel is markedly dim<strong>in</strong>ished <strong>in</strong> the presence <strong>of</strong> hydrogen.<br />

The presence <strong>of</strong> hydrogen <strong>in</strong> steel reduces tensile ductility and causes premature failure under<br />

static load that depends on the stress and time. This phenomenon is known as hydrogen<br />

<strong>embrittlement</strong>.<br />

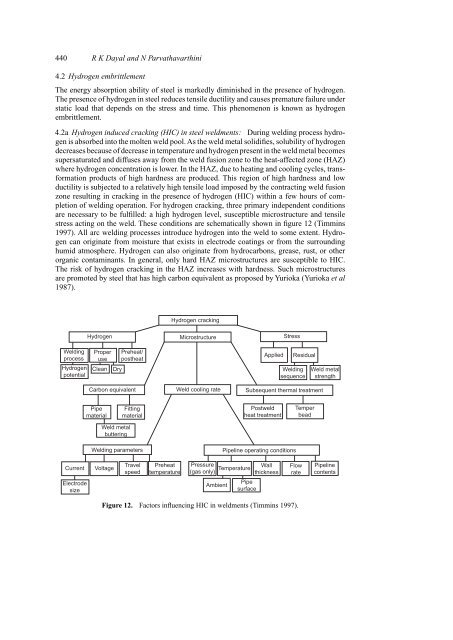

4.2a <strong>Hydrogen</strong> <strong>in</strong>duced crack<strong>in</strong>g (HIC) <strong>in</strong> steel weldments: Dur<strong>in</strong>g weld<strong>in</strong>g process hydrogen<br />

is absorbed <strong>in</strong>to the molten weld pool. As the weld metal solidifies, solubility <strong>of</strong> hydrogen<br />

decreases because <strong>of</strong> decrease <strong>in</strong> temperature and hydrogen present <strong>in</strong> the weld metal becomes<br />

supersaturated and diffuses away from the weld fusion zone to the heat-affected zone (HAZ)<br />

where hydrogen concentration is lower. In the HAZ, due to heat<strong>in</strong>g and cool<strong>in</strong>g cycles, transformation<br />

products <strong>of</strong> high hardness are produced. This region <strong>of</strong> high hardness and low<br />

ductility is subjected to a relatively high tensile load imposed by the contract<strong>in</strong>g weld fusion<br />

zone result<strong>in</strong>g <strong>in</strong> crack<strong>in</strong>g <strong>in</strong> the presence <strong>of</strong> hydrogen (HIC) with<strong>in</strong> a few hours <strong>of</strong> completion<br />

<strong>of</strong> weld<strong>in</strong>g operation. For hydrogen crack<strong>in</strong>g, three primary <strong>in</strong>dependent conditions<br />

are necessary to be fulfilled: a high hydrogen level, susceptible microstructure and tensile<br />

stress act<strong>in</strong>g on the weld. These conditions are schematically shown <strong>in</strong> figure 12 (Timm<strong>in</strong>s<br />

1997). All arc weld<strong>in</strong>g processes <strong>in</strong>troduce hydrogen <strong>in</strong>to the weld to some extent. <strong>Hydrogen</strong><br />

can orig<strong>in</strong>ate from moisture that exists <strong>in</strong> electrode coat<strong>in</strong>gs or from the surround<strong>in</strong>g<br />

humid atmosphere. <strong>Hydrogen</strong> can also orig<strong>in</strong>ate from hydrocarbons, grease, rust, or other<br />

organic contam<strong>in</strong>ants. In general, only hard HAZ microstructures are susceptible to HIC.<br />

The risk <strong>of</strong> hydrogen crack<strong>in</strong>g <strong>in</strong> the HAZ <strong>in</strong>creases with hardness. Such microstructures<br />

are promoted by steel that has high carbon equivalent as proposed by Yurioka (Yurioka et al<br />

1987).<br />

<strong>Hydrogen</strong> crack<strong>in</strong>g<br />

<strong>Hydrogen</strong><br />

Microstructure<br />

Stress<br />

Weld<strong>in</strong>g<br />

process<br />

<strong>Hydrogen</strong><br />

potential<br />

Proper<br />

use<br />

Clean<br />

Dry<br />

Preheat/<br />

postheat<br />

Applied<br />

Residual<br />

Weld<strong>in</strong>g<br />

sequence<br />

Weld metal<br />

strength<br />

Carbon equivalent<br />

Weld cool<strong>in</strong>g rate<br />

Subsequent thermal treatment<br />

Pipe<br />

material<br />

Fitt<strong>in</strong>g<br />

material<br />

Postweld<br />

heat treatment<br />

Temper<br />

bead<br />

Weld metal<br />

butter<strong>in</strong>g<br />

Weld<strong>in</strong>g parameters<br />

Pipel<strong>in</strong>e operat<strong>in</strong>g conditions<br />

Current<br />

Electrode<br />

size<br />

Voltage<br />

Travel<br />

speed<br />

Preheat<br />

temperature<br />

Pressure<br />

(gas only) Temperature<br />

Ambient<br />

Pipe<br />

surface<br />

Wall<br />

thickness<br />

Flow<br />

rate<br />

Pipel<strong>in</strong>e<br />

contents<br />

Figure 12. Factors <strong>in</strong>fluenc<strong>in</strong>g HIC <strong>in</strong> weldments (Timm<strong>in</strong>s 1997).