Effect of Coupling Agents on Mechanical Properties and Morphology ...

Effect of Coupling Agents on Mechanical Properties and Morphology ...

Effect of Coupling Agents on Mechanical Properties and Morphology ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Journal <str<strong>on</strong>g>of</str<strong>on</strong>g> Metals, Materials <strong>and</strong> Minerals, Vol.18 No.2 pp.131-135, 2008<br />

<str<strong>on</strong>g>Effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Coupling</str<strong>on</strong>g> <str<strong>on</strong>g>Agents</str<strong>on</strong>g> <strong>on</strong> <strong>Mechanical</strong> <strong>Properties</strong> <strong>and</strong> <strong>Morphology</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 -filled Recycled High Density Polyethylene<br />

Nilubol PHUEAKBUAKHAO 1* , Walaiporn PRISSANAROON-OUAJAI 1<br />

<strong>and</strong> Narumol KREUA-ONGARJNUKOOL 1<br />

Department <str<strong>on</strong>g>of</str<strong>on</strong>g> Industrial Chemistry, Faculty <str<strong>on</strong>g>of</str<strong>on</strong>g> Applied Science,<br />

King M<strong>on</strong>gkut’s University <str<strong>on</strong>g>of</str<strong>on</strong>g> Technology North Bangkok<br />

Abstract<br />

Received Nov. 24, 2008<br />

Accepted Feb. 11, 2009<br />

This research presents mechanical properties <strong>and</strong> morphology <str<strong>on</strong>g>of</str<strong>on</strong>g> recycled high density polyethylene<br />

(r-HDPE) filled with 10 wt.% CaCO 3 . The influence <str<strong>on</strong>g>of</str<strong>on</strong>g> treatment <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 with various coupling agents,<br />

including stearic acid (SA), aminopropyltriethoxy silane (AMPTES), glycidoxypropyltrimethoxy silane<br />

(GPTMS) <strong>and</strong> maleic anhydride grafted HDPE (MA-g-HDPE), was investigated. This study clearly<br />

dem<strong>on</strong>strated that the additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> coupling agent to CaCO 3 modifies the mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g> the r-<br />

HDPE/CaCO 3 composites. It was also found that each coupling agent gives rise to increases in a particular<br />

mechanical properties due to its characteristics. In the case <str<strong>on</strong>g>of</str<strong>on</strong>g> AMPTES, the best mechanical properties was<br />

observed at 2 wt.% whereas GPTMS <strong>and</strong> MA-g-HDPE showed the best performance at 3 wt.% <strong>and</strong> 4 wt.%,<br />

respectively. SEM micrographs <str<strong>on</strong>g>of</str<strong>on</strong>g> the fractured surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> the composites revealed a str<strong>on</strong>g interfacial<br />

interacti<strong>on</strong> between r-HDPE <strong>and</strong> CaCO 3 , resulting in improvement <str<strong>on</strong>g>of</str<strong>on</strong>g> the fracture toughness.<br />

Key words : <str<strong>on</strong>g>Coupling</str<strong>on</strong>g> <str<strong>on</strong>g>Agents</str<strong>on</strong>g>, Calcium Carb<strong>on</strong>ate, Polyethylene/CaCo 3 Composite<br />

Introducti<strong>on</strong><br />

The<br />

High density polyethylene (HDPE) is <strong>on</strong>e<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the most widely used polymers, having a broad<br />

amount <str<strong>on</strong>g>of</str<strong>on</strong>g> applicati<strong>on</strong>s such as bottles, c<strong>on</strong>tainers<br />

<strong>and</strong> c<strong>on</strong>sumer goods, due to its superior stiffness, yield<br />

strength <strong>and</strong> toughness <strong>and</strong> excellent envir<strong>on</strong>mental<br />

stress cracking resistance. Post-c<strong>on</strong>sumer HDPE is<br />

an interesting source <str<strong>on</strong>g>of</str<strong>on</strong>g> recycled materials <strong>and</strong> has<br />

potential in a number <str<strong>on</strong>g>of</str<strong>on</strong>g> applicati<strong>on</strong>s (Albano, et<br />

al. 2000) however, the mechanical <strong>and</strong> impact<br />

properties <str<strong>on</strong>g>of</str<strong>on</strong>g> the recycled HDPE (r-HDPE)<br />

significantly decrease compared to the virgin<br />

HDPE. Introducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> particulate inorganic fillers<br />

generally enhances some mechanical properties,<br />

such as Young’s modulus or yield strength, <strong>and</strong><br />

reduces the cost. The most comm<strong>on</strong> filler for<br />

HDPE is CaCO 3 because <str<strong>on</strong>g>of</str<strong>on</strong>g> its stability, high<br />

whiteness <strong>and</strong> low cost. (5) Although CaCO 3 improves<br />

some mechanical properties menti<strong>on</strong>ed above,<br />

other important properties like toughness <strong>and</strong><br />

impact strength are usually degraded. (3, 7) Several<br />

researches have reported that promoti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 -<br />

polymer interacti<strong>on</strong> would improve the tensile <strong>and</strong><br />

impact properties <strong>and</strong> has been achieved by surface<br />

(10, 6, 4)<br />

treatment <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 with coupling agents.<br />

purpose <str<strong>on</strong>g>of</str<strong>on</strong>g> this study was to investigate<br />

the effect <str<strong>on</strong>g>of</str<strong>on</strong>g> adding CaCO 3 , treated with<br />

various coupling agents, including stearic acid<br />

(SA), 3-aminopropyltriethoxysilane (AMPTES),<br />

3-glycidoxy propyltrimethoxy silane (GPTMS) <strong>and</strong><br />

maleic anhydride grafted HDPE (MA-g-HDPE), <strong>on</strong><br />

the mechanical behavior <str<strong>on</strong>g>of</str<strong>on</strong>g> the r-HDPE/CaCO 3<br />

composites. The impact behavior in relati<strong>on</strong> to the<br />

morphology <str<strong>on</strong>g>of</str<strong>on</strong>g> the fractured surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> the r-<br />

HDPE/CaCO 3 composites was also studied.<br />

Materials <strong>and</strong> Experimental Procedures<br />

Materials<br />

r-HDPE (MFI: 7.92 g/10 min; 190 °C <strong>and</strong><br />

2.16 load) was supplied by S.D.C. Plastic Co., Ltd.<br />

Two commercial CaCO 3 grades, untreated <strong>and</strong> SAtreated<br />

forms, with particle size <str<strong>on</strong>g>of</str<strong>on</strong>g> 2 µm were<br />

obtained from Surint Omya Chemicals Co., Ltd.<br />

AMPTES <strong>and</strong> GPTMS, silane coupling agents,<br />

were purchased from Italmar (Thail<strong>and</strong>) Co., Ltd.<br />

MA-g-HDPE was provided by Dup<strong>on</strong>t (Thail<strong>and</strong>)<br />

Co., Ltd. The chemical structure <str<strong>on</strong>g>of</str<strong>on</strong>g> the coupling<br />

agents are given in Table 1.<br />

*Corresp<strong>on</strong>ding author : Nilubol Phueakbuakhao Tel. 02-9132500-24 ext. 4808,<br />

Fax. 02-9132500-24 ext.4816 E-mail : pnilubol @ yahoo.com

132<br />

PHUEAKBUAKHAO, N. et al.<br />

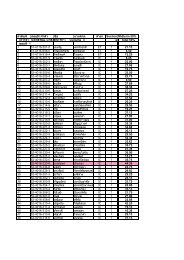

Table 1. Chemical structure <str<strong>on</strong>g>of</str<strong>on</strong>g> the selected coupling agents.<br />

Abbreviati<strong>on</strong> Name Chemical structure<br />

SA<br />

AMPTES<br />

GPTMS<br />

Stearic acid<br />

3-Aminopropyltriethoxy silane<br />

3-Glycidoxypropyltrimethoxy silane<br />

CH 3 -(CH 2 ) 15 -CH 2 -COOH<br />

NH 2 -CH 2 -CH 2 -CH 2 -Si-(O-CH 2 -CH 3 ) 3<br />

CH 2 -CH-CH 2 -O-CH 2 -CH 2 -CH 2 -Si-(O-CH 3 ) 3<br />

O<br />

MA-g-HDPE<br />

Maleic anhydride grafted HDPE<br />

CHCH 2<br />

n<br />

O<br />

O<br />

O<br />

Surface Treatment <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 with Silane <str<strong>on</strong>g>Coupling</str<strong>on</strong>g><br />

<str<strong>on</strong>g>Agents</str<strong>on</strong>g>. (2) Surface treatment <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 was carried<br />

out in the suspensi<strong>on</strong> c<strong>on</strong>taining 30 g CaCO 3 <strong>and</strong><br />

30 ml n-butanol. The desired volume <str<strong>on</strong>g>of</str<strong>on</strong>g> the silane<br />

coupling agent, either AMPTES or GPTMS, to<br />

reach 1, 2, 3, 4 <strong>and</strong> 5 wt.% compositi<strong>on</strong>s which<br />

respect to CaCO 3 was added to the stirred<br />

suspensi<strong>on</strong>. After being stirred for 3 h, the slurry<br />

was left st<strong>and</strong>ing for 3 days. The solvent was<br />

removed by vacuum evaporating <strong>and</strong> dried. The<br />

treated CaCO 3 was put into saturated water vapor<br />

atmosphere for 10<br />

Preparati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> r-HDPE/CaCO 3 Composites<br />

The r-HDPE was blended with 10 wt.%<br />

silane-treated CaCO 3 in a twin screw extruder at<br />

190 °C. The composite pellets were compressi<strong>on</strong>molded<br />

into specimens according to ASTM D256,<br />

ASTMD638 <strong>and</strong> ISO 178.<br />

In the case <str<strong>on</strong>g>of</str<strong>on</strong>g> using MA-g-HDPE as a<br />

coupling agent, the required amount <str<strong>on</strong>g>of</str<strong>on</strong>g> MA-g-<br />

HDPE to reach 1, 2, 3, 4 <strong>and</strong> 5 wt.% compositi<strong>on</strong>s<br />

which respect to CaCO 3 was added to the mixture<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> r-HDPE <strong>and</strong> untreated CaCO 3 before blending<br />

in a twin screw extruder.<br />

Characterizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> r-HDPE/CaCO 3 Composites<br />

The tensile <strong>and</strong> flexural properties were<br />

determined using an Universal Test Machine<br />

(LLOYD Instruments; LR 10 K). The tensile tests<br />

were performed at a crosshead speed <str<strong>on</strong>g>of</str<strong>on</strong>g> 50<br />

mm/min with a fixed gauge length <str<strong>on</strong>g>of</str<strong>on</strong>g> 50 mm. For<br />

the flexural testing, a three point loading system<br />

with a span <str<strong>on</strong>g>of</str<strong>on</strong>g> 64 mm was used <strong>and</strong> the crosshead<br />

speed was set at 50 mm/min. The notched Izod<br />

Impact strength was determined using a pendulum<br />

energy <str<strong>on</strong>g>of</str<strong>on</strong>g> 10.96 J. The analysis <str<strong>on</strong>g>of</str<strong>on</strong>g> the fractured<br />

surface <str<strong>on</strong>g>of</str<strong>on</strong>g> the specimens after the impact test was<br />

carried out a using scanning electr<strong>on</strong> microscope<br />

(JEOL; JSM 5410 LV). Before observati<strong>on</strong>, the<br />

fractured surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> the tested specimens were<br />

vacuum coated with a thin layer <str<strong>on</strong>g>of</str<strong>on</strong>g> gold to make<br />

them electrically c<strong>on</strong>ductive.<br />

Results <strong>and</strong> Discussi<strong>on</strong><br />

Characterizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 Treated with AMPTES<br />

<strong>and</strong> GPTMS<br />

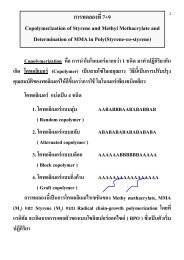

The characteristic spectra <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 before <strong>and</strong><br />

after treatment with AMPTES <strong>and</strong> GPTMS are<br />

presented in Figure 1 <strong>and</strong> Figure 2, respectively.<br />

Table 2 presents the selected peals assignment. As<br />

can be seen in Figure 1, the absorpti<strong>on</strong>s at 2926 cm -<br />

1 <strong>and</strong> 2853 cm -1 attributed to the alkyl chains <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

AMPTES are observed. In additi<strong>on</strong>, there is an<br />

increase in absorbance in these b<strong>and</strong>s with the<br />

increment <str<strong>on</strong>g>of</str<strong>on</strong>g> AMPTES c<strong>on</strong>tent, suggesting more<br />

coupling level. The peaks in the range <str<strong>on</strong>g>of</str<strong>on</strong>g> 1250-950<br />

cm -1 assigned to Si-O-Si stretching vibrati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

polysiloxane structure, indicating the incorporati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the silane coupling agent into CaCO 3 particles. (8)<br />

The similar results are observed for GPTMStreated<br />

CaCO 3 as shown in Figure 2.

<str<strong>on</strong>g>Effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Coupling</str<strong>on</strong>g> <str<strong>on</strong>g>Agents</str<strong>on</strong>g> <strong>on</strong><br />

<strong>Mechanical</strong> <strong>Properties</strong> <strong>and</strong> <strong>Morphology</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO<br />

3 -filled Recycled High Density Polyethylene<br />

133<br />

untreated<br />

1 wt.%<br />

2 wt.%<br />

3 wt.%<br />

4 wt.%<br />

5 wt.%<br />

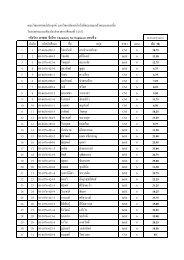

treatment <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 improves the mechanical<br />

properties, including tensile strength, flexurall<br />

strength, impact strength <strong>and</strong> el<strong>on</strong>gati<strong>on</strong> at break,<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the r-HDPE/CaCO 3 composites, compared to<br />

untreatment. By treatment with 1 wt.%<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> different<br />

coupling agents, SA-treated CaCO3 appears to<br />

exhibit the greatest improvement in the<br />

mechanical<br />

properties <str<strong>on</strong>g>of</str<strong>on</strong>g> the r-HDPE/CaCO 3 composites,<br />

particularly impact strength<br />

are shown in Figure 3.<br />

Table 3 <strong>Mechanical</strong> properties <str<strong>on</strong>g>of</str<strong>on</strong>g> r-HDPE/10<br />

wt.% CaCO 3<br />

composi ites. (CaCO 3 treated with 1 wt.% coupling<br />

agents)<br />

Figure 1. Infrared spectra <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 treated with different<br />

c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> AMPTES.<br />

untreated<br />

1 wt.%<br />

2 wt.%<br />

3 wt.%<br />

<str<strong>on</strong>g>Coupling</str<strong>on</strong>g><br />

agent<br />

Tensile<br />

strength<br />

Flexural<br />

strength<br />

Impact<br />

strength<br />

(MPa)<br />

(MPa)<br />

(kJ/m 2 )<br />

Untreated Stearic<br />

acid<br />

AMPTES GPTMS MA-g-<br />

HDPE<br />

14. .01<br />

15. .68<br />

15. .16<br />

14. .98<br />

15. .27<br />

19.87 24.93 23.80 23.73 22.75 10.28<br />

13.23<br />

12.03<br />

11.11<br />

11.96<br />

El<strong>on</strong>gati<strong>on</strong>n<br />

at Break<br />

(%)<br />

18.77<br />

21.65<br />

21.08<br />

19.52<br />

20.19<br />

4 wt.%<br />

5 wt.%<br />

Figure 2. Infrared spectra <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 treated with different<br />

c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> GPTMS.<br />

Table 2. Assignment <str<strong>on</strong>g>of</str<strong>on</strong>g> characteristic b<strong>and</strong>s in the FTIR<br />

spec ctra <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 treated with silane coupling agents<br />

Wavelength<br />

(cm -1 )<br />

Functi<strong>on</strong>al group<br />

2926 - CH 2 Strertching (Asymmetric Vibrati<strong>on</strong>)<br />

- CH<br />

2853<br />

3 <strong>and</strong><br />

- CH 2 -C-H Strertching<br />

(Symmetric Vibrati<strong>on</strong>)<br />

1250-950 Si-O-Si (Polysiloxane) Si-O-Si Strertching<br />

<strong>Mechanical</strong><br />

<strong>Properties</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

r-HDPE/CaCO 3 Composites<br />

<strong>Mechanical</strong> properties <str<strong>on</strong>g>of</str<strong>on</strong>g> r-HDPE/untreated<br />

CaCO 3 <strong>and</strong><br />

r-HDPE/treated CaCO 3 compositess are<br />

shown in Table 3. In this case, CaCO 3 was treated<br />

with the fixed 1 wt.% <str<strong>on</strong>g>of</str<strong>on</strong>g> different coupling agents<br />

<strong>and</strong> the amount <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 blended to r-HDPE<br />

matrix weighed <str<strong>on</strong>g>of</str<strong>on</strong>g> 10% %. It can be seen that surface<br />

Figure 3. <str<strong>on</strong>g>Effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 treated with 1% different coupling<br />

agents <strong>on</strong> the impact strength <str<strong>on</strong>g>of</str<strong>on</strong>g> r-HDPE/CaCO 3<br />

composites.<br />

This results may be expounded that a<br />

str<strong>on</strong>g chemical b<strong>on</strong>ding between the polar group<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the stearic acid <strong>and</strong> CaCO 3 to form calcium<br />

stearate enhances the compatibility <str<strong>on</strong>g>of</str<strong>on</strong>g> the polymer<br />

matrix <strong>and</strong> CaCO 3 particles<br />

resulting improvement<br />

the<br />

mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g> composites can be<br />

achieved, by changes hydrophilic <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 to<br />

hydrophobic. In<br />

the case <str<strong>on</strong>g>of</str<strong>on</strong>g> other coupling agents<br />

including AMPTES, GPTMS <strong>and</strong> MA-g-HDPE,<br />

the<br />

interacti<strong>on</strong>n at interface areas between the<br />

polymer matrix <strong>and</strong> CaCO 3 particles can be<br />

achieved by van der waals forces, which are<br />

relatively weak<br />

compared to chemical b<strong>on</strong>ds. Thus,<br />

using a few c<strong>on</strong>centrati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> coupling agent,

134<br />

PHUEAKBUAKHAO, N. et al.<br />

chemical b<strong>on</strong>ding can be improved the interacti<strong>on</strong><br />

at interface areas between the polymer matrix <strong>and</strong><br />

CaCO 3 particles more than physical b<strong>on</strong>ding or van<br />

der waals forces.<br />

Using other coupling agents at c<strong>on</strong>centrati<strong>on</strong>s<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> 2, 3, 4 <strong>and</strong> 5 wt.% to study the possibility <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

increasing the polymer-CaCO 3 interacti<strong>on</strong>. It was<br />

found that the mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g> composite<br />

can be improved, especially impact resistance when<br />

increase the c<strong>on</strong>centrati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> coupling agents.<br />

Table 4 summarizes the mechanical properties<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the r-HDPE filled CaCO 3 treated with the<br />

optimum c<strong>on</strong>centrati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> each coupling agent.<br />

The results show that each coupling agent gives<br />

rise to increase in a particular mechanical properties<br />

due to its characteristics. The r-HDPE/treated-<br />

CaCO 3 composites show the best mechanical<br />

properties when CaCO 3 were treated with SA,<br />

AMPTES, GPTMS <strong>and</strong> MA-g-HDPE at 1, 2, 3 <strong>and</strong><br />

4 wt.%, respectively. This behavior can be<br />

explained based <strong>on</strong> the fact that increasing the<br />

c<strong>on</strong>centrati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> coupling agents can improve the<br />

interacti<strong>on</strong> between the polymer matrix <strong>and</strong> CaCO 3<br />

particle, which are physical forces or van der waals<br />

forces as well as chemical forces but have to use<br />

more c<strong>on</strong>centrati<strong>on</strong>s. This indicates that selecti<strong>on</strong><br />

the type <strong>and</strong> quantity <str<strong>on</strong>g>of</str<strong>on</strong>g> coupling agents for the<br />

composites is important to gets the optimum<br />

property <str<strong>on</strong>g>of</str<strong>on</strong>g> final products.<br />

<strong>and</strong> the surface was rather smooth. This shows that<br />

the polymer matrix <strong>and</strong> CaCO 3 particles didn’t<br />

restrain together. On the other h<strong>and</strong>, the rough<br />

surfaces are observed for the r-HDPE/treated<br />

CaCO 3 composites, as presented in Figure 4(b) -<br />

Figure 4(e). This indicates the ductile fracture. The<br />

morphologies <str<strong>on</strong>g>of</str<strong>on</strong>g> the fractured surfaces were<br />

c<strong>on</strong>sistent with the impact strength listed in Table 2<br />

<strong>and</strong> Table 3. High magnified SEM micrographs<br />

(x3500) <str<strong>on</strong>g>of</str<strong>on</strong>g> the r-HDPE/CaCO 3 composites are<br />

illustrated in Figure 5. Phase separati<strong>on</strong> can be<br />

seen when the untreated CaCO 3 was incorporated<br />

in the r-HDPE matrix (Figure 5(a)). This<br />

phenomen<strong>on</strong> is not visible when the treated CaCO 3<br />

was used (Figure 5(b) - Figure 5(e)). The interfacial<br />

interacti<strong>on</strong> between the r-HDPE matrix <strong>and</strong> CaCO 3<br />

particles was str<strong>on</strong>ger, resulted from the<br />

pretreatment <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 particles. This would be<br />

another reas<strong>on</strong> for the improvement in the<br />

mechanical properties, particularly impact strength,<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the r-HDPE/CaCO 3 composites. (9)<br />

(a) untreated<br />

Table 4. <strong>Mechanical</strong> properties <str<strong>on</strong>g>of</str<strong>on</strong>g> r-HDPE/CaCO 3<br />

composites (CaCO 3 treated with optimum<br />

c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> coupling agents)<br />

<str<strong>on</strong>g>Coupling</str<strong>on</strong>g><br />

Agent<br />

Tensile<br />

strength<br />

(MPa)<br />

Flexural<br />

strength<br />

(MPa)<br />

Impact<br />

strength<br />

(kJ/m 2 )<br />

El<strong>on</strong>gati<strong>on</strong><br />

at Break<br />

(%)<br />

Untreated 14.01 19.87 10.28 18.77<br />

1. wt%<br />

Stearic acid<br />

2. wt%<br />

AMPTES<br />

3. wt%<br />

GPTMS<br />

4. wt%<br />

MA-g-HDPE<br />

15.68 24.93 13.23 21.65<br />

16.17 25.54 15.00 22.32<br />

15.87 25.28 14.67 21.95<br />

16.03 25.84 14.89 23.24<br />

(b) 1 wt.% SA<br />

(c) 2 wt.% AMPTES<br />

<strong>Morphology</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> r-HDPE/CaCO 3 Composites<br />

The fractured surfaces <str<strong>on</strong>g>of</str<strong>on</strong>g> the r-HDPE/CaCO 3<br />

composites after the impact test were examined by<br />

SEM. Figure 4(a) shows that the r-HDPE filled<br />

with the untreated CaCO 3 exhibits brittle fracture<br />

(d) 3 wt.% GPTMS<br />

(e) 4 wt.% MA-g-HDPE<br />

Figure 4. SEM micrographs (x500) <str<strong>on</strong>g>of</str<strong>on</strong>g> r-HDPE/CaCO 3<br />

composites when CaCO 3 treated with different<br />

coupling agents

<str<strong>on</strong>g>Effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Coupling</str<strong>on</strong>g> <str<strong>on</strong>g>Agents</str<strong>on</strong>g> <strong>on</strong> <strong>Mechanical</strong> <strong>Properties</strong> <strong>and</strong> <strong>Morphology</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 -filled Recycled High Density Polyethylene<br />

135<br />

Bangkok is also thanks for partial financial<br />

supports for this research.<br />

References<br />

(a) untreated<br />

1. Albano, C., G<strong>on</strong>zález, J., Ichazo, M., Rosales, C.,<br />

Urbina de Navarro C. <strong>and</strong> Parra, C. 2000.<br />

<strong>Mechanical</strong> <strong>and</strong> morphological behavior <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

polyolefin blends in the presence <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3<br />

J. Compos. Struct. 48(1-3) : 49-58.<br />

(b) 1 wt.% SA<br />

(c) 2 wt.% AMPTES<br />

2. Demjén, Z., Pukánszky, B. <strong>and</strong> Nagy, J. 1998.<br />

Evaluatin <str<strong>on</strong>g>of</str<strong>on</strong>g> interfacial interacti<strong>on</strong> in poly<br />

propylene surface treated CaCO 3 composites.<br />

Composites Part A-Applied Seience <strong>and</strong><br />

Manufacturing. 29(3) : 323-329.<br />

3. Gächter, R. <strong>and</strong> Müller, H. 1990. Plastic additives.<br />

Carl Itanser Verlag, Germany.<br />

4. G<strong>on</strong>zález, J., Albano, C., Ichazo, M. <strong>and</strong> Diaz, B.<br />

2002. <str<strong>on</strong>g>Effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> coupling agents <strong>on</strong><br />

mechanical <strong>and</strong> morphological behavior <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the PP/HDPE blend with two different<br />

CaCO 3 . Eur. Polym. J. 38(12) : 2465-2457.<br />

(d) 3 wt.% GPTMS<br />

Figure 5. SEM micrographs (x3500) <str<strong>on</strong>g>of</str<strong>on</strong>g> r-HDPE/CaCO 3<br />

composites when CaCO 3 treated with different<br />

coupling agents<br />

C<strong>on</strong>clusi<strong>on</strong>s<br />

This study obviously dem<strong>on</strong>strated that the<br />

pretreatment <str<strong>on</strong>g>of</str<strong>on</strong>g> CaCO 3 with the coupling agent<br />

improved the mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g> the r-<br />

HDPE/CaCO 3 composites. Due to the particular<br />

characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> the coupling agents, each <strong>on</strong>e<br />

showed rise to increases in a specific mechanical<br />

property. In this study, the r-HDPE/treated-CaCO 3<br />

composites exhibited the best mechanical properties<br />

when CaCO 3 was treated with SA, AMPTES, GPTMS<br />

<strong>and</strong> MA-g-HDPE at 1, 2, 3 <strong>and</strong> 4 wt.%, respectively.<br />

SEM micrographs c<strong>on</strong>firmed a str<strong>on</strong>g interfacial<br />

interacti<strong>on</strong> between r-HDPE matrix <strong>and</strong> CaCO 3 ,<br />

resulting in improvement <str<strong>on</strong>g>of</str<strong>on</strong>g> the fracture toughness.<br />

Acknowledgment<br />

(e) 4 wt.% MA-g-HDPE<br />

The authors gratefully acknowledge Surint<br />

Omya Chemicals (Thail<strong>and</strong>) Co., Ltd. for supplying<br />

CaCO 3 used in this research. The Graduate College,<br />

King M<strong>on</strong>gkut’s University <str<strong>on</strong>g>of</str<strong>on</strong>g> Technology North<br />

5. Maged, O. <strong>and</strong> Ayman, A. 2005. Polymer. 46 :<br />

9476-9488.<br />

6. Mohd Ishak, Z.A., Aminullah, H., Isamail, H.<br />

<strong>and</strong> Rozman, H.D. 1998. J. Appl. Polym.<br />

Sci. 68 : 2189-2203.<br />

7. Surint Omya Chemicals Co., Ltd. 2004. Rev.<br />

Tech.Informat. Plast., Cited in Hohenberger<br />

W. 2000. J. Plast. Eur. 90 : 96-99.<br />

8. Vien, D.L., Colthup, N.B., Fateley, W.G. <strong>and</strong><br />

Grasselli, J.G. 1991. The h<strong>and</strong>book <str<strong>on</strong>g>of</str<strong>on</strong>g> infrared<br />

<strong>and</strong> raman characteristic frequencies <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

organic molecules. New York : Academic<br />

Press, Inc.<br />

9. Yang, K., Yang, Q., Li, G., Sun, Y. <strong>and</strong> Feng, D.<br />

2006. <strong>Morphology</strong> <strong>and</strong> mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

polypropylene/calcium carb<strong>on</strong>ate nanocomposites.<br />

J. Mater. Lett. 60(6) : 805-809.<br />

10. Zhang, Q.X., Yu, Z.Z., Xie, X.L. <strong>and</strong> Mai, Y.W.<br />

2004. Crystallizati<strong>on</strong> <strong>and</strong> impact energy <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

polypropylene/CaCO 3 nanocomposites with<br />

n<strong>on</strong>i<strong>on</strong>ic modifier. Polymer 45(1) : 5985-<br />

5994.