Propeller Design Example

Propeller Design Example

Propeller Design Example

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

prop_design_example.xls<br />

PROPELLER DESIGN USING WAGENINGEN B SERIES<br />

<strong>Design</strong> a propeller for a bulk-carrier with the following details<br />

L BP (m) = 135.34 m<br />

B(m) = 19.3 m<br />

T(m) = 9.16 m<br />

C B = 0.704<br />

V S(service) (knot) = 15 knots<br />

δV = 1<br />

Trial speed range= 2<br />

Sea margin = 1.2<br />

AE/A0 ?<br />

Z 4<br />

SOLUTION STAGE 1<br />

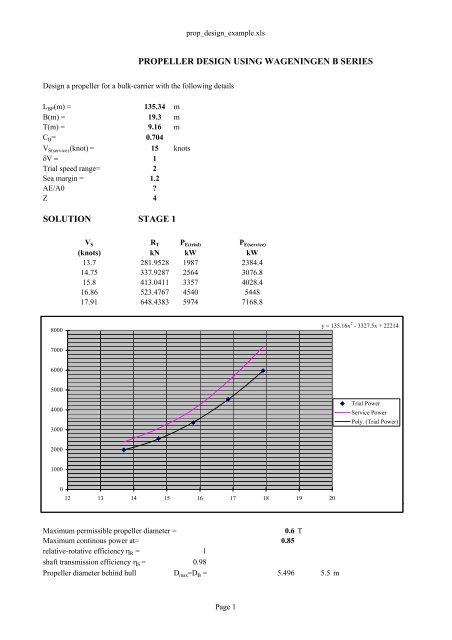

V S R T P E(trial) P E(service)<br />

(knots) kN kW kW<br />

13.7 281.9528 1987 2384.4<br />

14.75 337.9287 2564 3076.8<br />

15.8 413.0411 3357 4028.4<br />

16.86 523.4767 4540 5448<br />

17.91 648.4383 5974 7168.8<br />

8000<br />

y = 135.16x 2 - 3327.5x + 22214<br />

7000<br />

6000<br />

5000<br />

4000<br />

3000<br />

Trial Power<br />

Service Power<br />

Poly. (Trial Power)<br />

2000<br />

1000<br />

0<br />

12 13 14 15 16 17 18 19 20<br />

Maximum permissible propeller diameter =<br />

0.6 T<br />

Maximum continous power at= 0.85<br />

relative-rotative efficiency η R = 1<br />

shaft transmission efficiency η S = 0.98<br />

<strong>Propeller</strong> diameter behind hull D max =D B = 5.496 5.5 m<br />

Page 1

prop_design_example.xls<br />

w = 0.304<br />

t = 0.214<br />

open water diameter D 0 =D B /0.95<br />

5.79 m<br />

A<br />

A<br />

(1.3<br />

( P<br />

+<br />

−<br />

0.3Z<br />

) T<br />

P D<br />

E<br />

=<br />

2<br />

0 0 V<br />

)<br />

+ K<br />

Keller's formula<br />

R T = 434.3604 kN at Vs=16 knots<br />

T=R T/ (1-t)=<br />

552.6214 kN<br />

h=D/2+0.2 (height of shaft centre-line above base)<br />

Atmospheric pressure, P atm = 101300 N/m 2 101300 N/m 2<br />

Vapour pressure of water at 15 °C, P V = 1646 N/m 2 1646 N/m 2<br />

H= T-h 6.212 m<br />

P 0 =P atm +ρgH 163763.2 N/m 2<br />

K= 0.2 for single screw<br />

A E /A 0 0.482127<br />

Wageningen B-4.55 propeller chosen<br />

V S(trial) =<br />

16 knots<br />

P E(trial) = 3574.96 3575 kW<br />

Assume η D = 0.7<br />

P D =P E /η D 5107.143 5107 kW<br />

V A = V S(trial) (1-w)<br />

11.136 knots<br />

B p =1.158(NxP 1/2 D /V 2.5 A )<br />

δ=3.2808(NxD 0 /V A )<br />

To find out rpm, select a range of propeller rpm, e.g. N=80~120 rpm, and calculate B p -δ<br />

and read-off propeller efficiency, ηo at corresponding Bp-δ from the diagram:<br />

assumed<br />

N(rpm) Bp δ ηο<br />

80 15.99796 136.3527 0.62<br />

90 17.9977 153.3968 0.624<br />

100 19.99744 170.4408 0.626<br />

110 21.99719 187.4849 0.622<br />

120 23.99693 204.529 0.605<br />

0.63<br />

0.625<br />

0.62<br />

0.615<br />

0.61<br />

0.605<br />

y = -1E-08x 4 + 4E-06x 3 - 0.0005x 2 + 0.0282x + 0.006<br />

0.6<br />

80 85 90 95 100 105 110 115 120 125<br />

Page 2

prop_design_example.xls<br />

Optimum N<br />

100 RPM<br />

maximum η 0 0.626<br />

η D =η h η R η 0 =(1-t/1-w)η R η 0 0.707<br />

∈=η Dcalculated - η Dpreviuos<br />

Let's assume that η D is converged<br />

Brake power P B =(P E /η D η S )<br />

0.007 if it is > 0.005 go back to "assume η D " and select new value<br />

until it is 0.005<br />

5160 kW<br />

Installed maximum continous power =P B /0.85 6070.696844 6071 kW<br />

Delivered power P D =P B η S<br />

5056.89 kW<br />

Therefore B p = 19.89882<br />

δ = 161.9188<br />

From B p -δ diagram at [19.89,161.92] read-off P b /D B 1<br />

Mean face pitch=<br />

5.50 m<br />

Stage 2 Engine selection<br />

calculated optimum rpm 100<br />

Brake power(85% MCR) 5160 kW<br />

Installed power(100% MCR) 6071 kW<br />

Engine MAN B&W 4S60MC<br />

N rpm Engine Power<br />

L1 105 8160<br />

L2 105 5200<br />

L4 79 3920 100 5160<br />

L3 79 6160 70 5160<br />

79 6160 100 6071<br />

105 8160 70 6071<br />

NoptimumPower<br />

100 5160 85% MCR<br />

100 6071 100%MCR<br />

Power (kWs)<br />

9000<br />

8000<br />

7000<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

0<br />

70 75 80 85 90 95 100 105 110<br />

N (RPM)<br />

Page 3

prop_design_example.xls<br />

STAGE 3 Prediction of performance in service<br />

Prediction of the ship speed and propeller rate of rotation in service with the engine 85% of MCR<br />

w in service= 1.1 w in trial 0.3344<br />

η D (assumed) 0.7<br />

P D =P B η S<br />

5056.89 kW<br />

P E =P D η D<br />

3539.823 kW<br />

From P E (service) vs V S curve at 3539.82 kW obtain V s(service)<br />

V S(service) =<br />

15.3 knots<br />

8000<br />

y = 162.19x 2 - 3993x + 26656<br />

7000<br />

V PE<br />

15.31 3539.873<br />

6000<br />

15.25 3482.062<br />

5000<br />

4000<br />

Trial Power<br />

Service Power<br />

3000<br />

Poly. (Service Power)<br />

2000<br />

1000<br />

0<br />

12 13 14 15 16 17 18 19 20<br />

V A =V S (1-w)<br />

10.18368 knots<br />

B p =<br />

0.248822 xN<br />

δ B =<br />

1.770605 xN<br />

For a range of N's<br />

N B p δ B<br />

80 19.90575 141.6484<br />

90 22.39396 159.3545<br />

100 24.88218 177.0605<br />

110 27.3704 194.7666<br />

120 29.85862 212.4726<br />

read-off η 0 @ intersection of Bp-δ curve with P b /D B<br />

η 0 0.583<br />

η D 0.688<br />

η Dassumed -η Dcalculated<br />

0.012 if this difference is less than 0.005 there is no need for iteration<br />

Let's assume that η D is converged<br />

P E(service) =P D η Dlast<br />

3481.459 kW<br />

Page 4

prop_design_example.xls<br />

V S(service) =<br />

15.25 knots<br />

From B p -δ diagram at above intersection point read-off Bp-δ<br />

B p 24<br />

δ 174<br />

V A<br />

10.1504 knots<br />

N=(δV A /(3.2808D))<br />

N (service)<br />

97.95 rpm<br />

Therefore @ 85% MCR vessel's service speeed, V S =15.25 knots N=97.95 rpm<br />

Page 5

prop_design_example.xls<br />

STAGE 4. Determination of the blade surface area & B.A.R. (Cavitation control)<br />

h=D/2+0.2 (height of shaft centre-line above base)<br />

Atmospheric pressure, P atm = 101300 N/m 2 101300 N/m 2<br />

Vapour pressure of water at 15 °C, P V = 1646 N/m 2 1646 N/m 2<br />

For Trial condition<br />

T =<br />

9.16 m<br />

P D =<br />

5056.89 kW<br />

N =<br />

100 rpm<br />

V A =<br />

11.136 knots<br />

P/D = 1<br />

η 0 0.626<br />

H= T-h 6.212 m<br />

Dynamic pressure q T 224777.6 N/m 2 q T =0.5V 2 R =0.5[V 2 A +(0.7πnD) 2 ]<br />

P 0 -Pv 162117.2 N/m 2<br />

Cavitation number σ R =(P0-Pv)/q T 0.721234<br />

Referring to Burrill's diagram for upper limit @ σ R , the load coefficient, τ c is read-off from fig. 4 as:<br />

τ c 0.225<br />

By definition<br />

T/A p =τ c q T = 50574.96<br />

T=P D η 0 η R /V A 552621.4 N η B =P T /P D =TV A /P D =η 0 η R<br />

A p =T/(τ c q T ) 10.92678 m 2<br />

Developed area from Taylor's relationship<br />

A D =A p /(1.067-0.229xP/D) 13.03911 m 2<br />

Blade Area Ratio<br />

A D ≈ A E<br />

BAR= A E /(πD 2 /4) 0.55<br />

Selected BAR=0.55<br />

Calculated BAR=0.55<br />

Calculated BAR=0.55

prop_design_example.xls<br />

Page 7