Rahul Dewan - Jacobs University

Rahul Dewan - Jacobs University

Rahul Dewan - Jacobs University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4. µC-SI SOLAR CELLS WITH INTEGRATED LAMELLAR GRATINGS<br />

Incoming<br />

Light<br />

Glass<br />

Glass<br />

Glass<br />

Transparent<br />

Conductive Oxide<br />

ZnO: Al<br />

ZnO: Al<br />

Microcrystalline<br />

Silicon Diode<br />

µc-Si<br />

Profile<br />

Height<br />

µc-Si<br />

Metal<br />

Back Contact<br />

Metal<br />

Back Contact<br />

Metal<br />

Back Contact<br />

Period<br />

(a) (b) (c)<br />

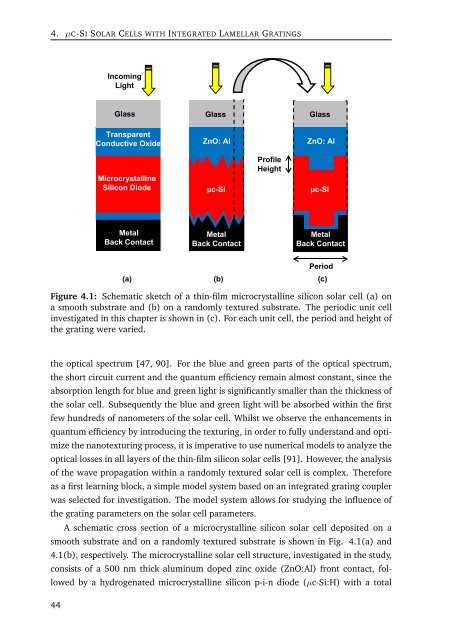

Figure 4.1: Schematic sketch of a thin-film microcrystalline silicon solar cell (a) on<br />

a smooth substrate and (b) on a randomly textured substrate. The periodic unit cell<br />

investigated in this chapter is shown in (c). For each unit cell, the period and height of<br />

the grating were varied.<br />

the optical spectrum [47, 90]. For the blue and green parts of the optical spectrum,<br />

the short circuit current and the quantum efficiency remain almost constant, since the<br />

absorption length for blue and green light is significantly smaller than the thickness of<br />

the solar cell. Subsequently the blue and green light will be absorbed within the first<br />

few hundreds of nanometers of the solar cell. Whilst we observe the enhancements in<br />

quantum efficiency by introducing the texturing, in order to fully understand and optimize<br />

the nanotexturing process, it is imperative to use numerical models to analyze the<br />

optical losses in all layers of the thin-film silicon solar cells [91]. However, the analysis<br />

of the wave propagation within a randomly textured solar cell is complex. Therefore<br />

as a first learning block, a simple model system based on an integrated grating coupler<br />

was selected for investigation. The model system allows for studying the influence of<br />

the grating parameters on the solar cell parameters.<br />

A schematic cross section of a microcrystalline silicon solar cell deposited on a<br />

smooth substrate and on a randomly textured substrate is shown in Fig. 4.1(a) and<br />

4.1(b), respectively. The microcrystalline solar cell structure, investigated in the study,<br />

consists of a 500 nm thick aluminum doped zinc oxide (ZnO:Al) front contact, followed<br />

by a hydrogenated microcrystalline silicon p-i-n diode (µc-Si:H) with a total<br />

44