Arc Welding of Specific Steels and Cast Irons

Arc Welding of Specific Steels and Cast Irons

Arc Welding of Specific Steels and Cast Irons

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Arc</strong> <strong>Welding</strong> <strong>of</strong> High-Strength Steel<br />

3.1.3 Essential factors for quality control in welding<br />

(a) Redrying <strong>of</strong> covered electrodes<br />

The main sources <strong>of</strong> diffusible hydrogen in a weld metal are the moisture contained in the<br />

covering flux in the as-produced condition, the moisture absorbed by the covering flux during<br />

exposure to the atmosphere, <strong>and</strong> the moisture in the atmosphere. As the amount <strong>of</strong> moisture<br />

increases, the amount <strong>of</strong> diffusible hydrogen in the weld metal increases. Diffusible hydrogen<br />

in a weld metal can cause welding defects such as cracks <strong>and</strong> blowholes. Covered electrodes<br />

should, therefore, be kept dry in storage <strong>and</strong> h<strong>and</strong>ling in order to minimize the moisture<br />

pickup. In particular, low-hydrogen covered electrodes must be redried before use in a<br />

redrying oven to reduce the moisture content <strong>of</strong> the coverings to the as-produced levels for<br />

recovering their inherent usability <strong>and</strong> weldability. The other types <strong>of</strong> covered electrodes<br />

should be redried when they picked up moisture so much that the usability <strong>of</strong> the electrode is<br />

degraded causing much spatter, undercut, <strong>and</strong> blowholes.<br />

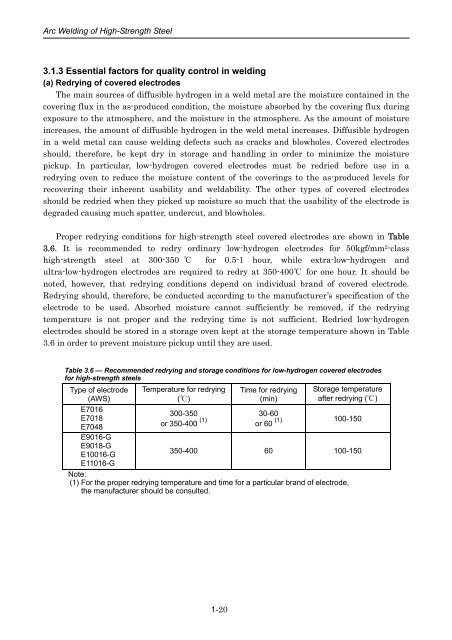

Proper redrying conditions for high-strength steel covered electrodes are shown in Table<br />

3.6. It is recommended to redry ordinary low-hydrogen electrodes for 50kgf/mm 2 -class<br />

high-strength steel at 300-350 ℃ for 0.5-1 hour, while extra-low-hydrogen <strong>and</strong><br />

ultra-low-hydrogen electrodes are required to redry at 350-400℃ for one hour. It should be<br />

noted, however, that redrying conditions depend on individual br<strong>and</strong> <strong>of</strong> covered electrode.<br />

Redrying should, therefore, be conducted according to the manufacturer’s specification <strong>of</strong> the<br />

electrode to be used. Absorbed moisture cannot sufficiently be removed, if the redrying<br />

temperature is not proper <strong>and</strong> the redrying time is not sufficient. Redried low-hydrogen<br />

electrodes should be stored in a storage oven kept at the storage temperature shown in Table<br />

3.6 in order to prevent moisture pickup until they are used.<br />

Table 3.6 — Recommended redrying <strong>and</strong> storage conditions for low-hydrogen covered electrodes<br />

for high-strength steels<br />

Type <strong>of</strong> electrode<br />

(AWS)<br />

E7016<br />

E7018<br />

E7048<br />

E9016-G<br />

E9018-G<br />

E10016-G<br />

E11016-G<br />

Temperature for redrying<br />

(℃)<br />

Time for redrying<br />

(min)<br />

Storage temperature<br />

after redrying (℃)<br />

300-350<br />

30-60<br />

or 350-400 (1) (1) 100-150<br />

or 60<br />

350-400 60 100-150<br />

Note:<br />

(1) For the proper redrying temperature <strong>and</strong> time for a particular br<strong>and</strong> <strong>of</strong> electrode,<br />

the manufacturer should be consulted.<br />

1-20