Arc Welding of Specific Steels and Cast Irons

Arc Welding of Specific Steels and Cast Irons

Arc Welding of Specific Steels and Cast Irons

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Arc</strong> <strong>Welding</strong> <strong>of</strong> Heat-Resistant Low-Alloy Steel<br />

2. <strong>Welding</strong> metallurgy <strong>and</strong> weldability<br />

Heat-resistant low-alloy steels are weldable but to a lesser degree than ordinary steels<br />

because <strong>of</strong> greater self-hardenability <strong>and</strong> crack susceptibility. The following sections discuss<br />

these problems <strong>and</strong> preventive measures.<br />

2.1 Hardenability <strong>of</strong> welds<br />

Alloying with chromium <strong>and</strong> molybdenum causes such greater hardenability that the steel<br />

can be hardened by cooling in still air from its austenitizing temperature. This hardenability<br />

is <strong>of</strong>ten called “self-hardenability.” The degree <strong>of</strong> self-hardenability <strong>of</strong> Cr-Mo steels can be<br />

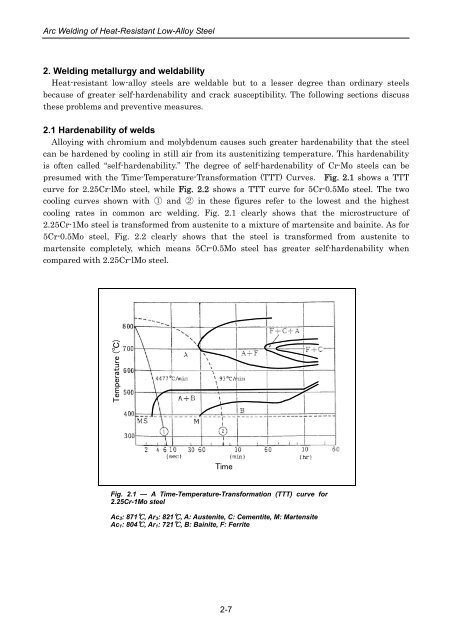

presumed with the Time-Temperature-Transformation (TTT) Curves. Fig. 2.1 shows a TTT<br />

curve for 2.25Cr-lMo steel, while Fig. 2.2 shows a TTT curve for 5Cr-0.5Mo steel. The two<br />

cooling curves shown with 1 <strong>and</strong> 2 in these figures refer to the lowest <strong>and</strong> the highest<br />

cooling rates in common arc welding. Fig. 2.1 clearly shows that the microstructure <strong>of</strong><br />

2.25Cr-1Mo steel is transformed from austenite to a mixture <strong>of</strong> martensite <strong>and</strong> bainite. As for<br />

5Cr-0.5Mo steel, Fig. 2.2 clearly shows that the steel is transformed from austenite to<br />

martensite completely, which means 5Cr-0.5Mo steel has greater self-hardenability when<br />

compared with 2.25Cr-lMo steel.<br />

Temperature (℃)<br />

Time<br />

Fig. 2.1 — A Time-Temperature-Transformation (TTT) curve for<br />

2.25Cr-1Mo steel<br />

Ac 3 : 871℃, Ar 3 : 821℃, A: Austenite, C: Cementite, M: Martensite<br />

Ac 1 : 804℃, Ar 1 : 721℃, B: Bainite, F: Ferrite<br />

2-7