Arc Welding of Specific Steels and Cast Irons

Arc Welding of Specific Steels and Cast Irons

Arc Welding of Specific Steels and Cast Irons

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Arc</strong> <strong>Welding</strong> <strong>of</strong> Heat-Resistant Low-Alloy Steel<br />

In addition to the conventional steels discussed above, Enhanced 2.25Cr-1Mo,<br />

2.25Cr-1Mo-0.25V, <strong>and</strong> 3Cr-1Mo-0.25V-Ti-B steels have been developed. These advanced steels<br />

have higher strength than those <strong>of</strong> the conventional steels, as shown in Table 1.2. The higher<br />

strength is derived from lower tempering temperatures for Enhanced 2.25Cr-1Mo steel <strong>and</strong><br />

small amounts <strong>of</strong> alloying elements for the other two types. The higher strength facilitates the<br />

use <strong>of</strong> higher allowable stresses over a range <strong>of</strong> metal temperatures, as shown in Fig. 1.3, as<br />

compared with conventional 2.25Cr-1Mo steel. These advanced steels, therefore, can be used<br />

in higher temperature services <strong>and</strong> facilitate the use <strong>of</strong> decreased thickness <strong>of</strong> stress<br />

sustaining components. The typical applications are pressure vessels subjected to hydrogen<br />

service at elevated temperatures <strong>and</strong> high pressures in petroleum refineries <strong>and</strong><br />

petrochemical plants.<br />

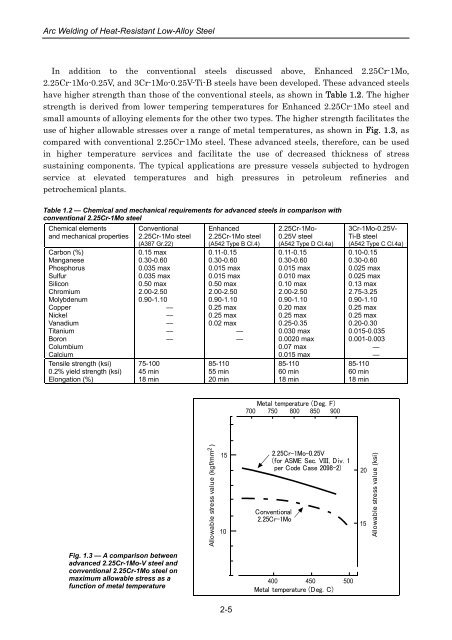

Table 1.2 — Chemical <strong>and</strong> mechanical requirements for advanced steels in comparison with<br />

conventional 2.25Cr-1Mo steel<br />

Chemical elements<br />

<strong>and</strong> mechanical properties<br />

Carbon (%)<br />

Manganese<br />

Phosphorus<br />

Sulfur<br />

Silicon<br />

Chromium<br />

Molybdenum<br />

Copper<br />

Nickel<br />

Vanadium<br />

Titanium<br />

Boron<br />

Columbium<br />

Calcium<br />

Tensile strength (ksi)<br />

0.2% yield strength (ksi)<br />

Elongation (%)<br />

Conventional<br />

2.25Cr-1Mo steel<br />

(A387 Gr.22)<br />

0.15 max<br />

0.30-0.60<br />

0.035 max<br />

0.035 max<br />

0.50 max<br />

2.00-2.50<br />

0.90-1.10<br />

—<br />

—<br />

—<br />

—<br />

—<br />

75-100<br />

45 min<br />

18 min<br />

Enhanced<br />

2.25Cr-1Mo steel<br />

(A542 Type B Cl.4)<br />

0.11-0.15<br />

0.30-0.60<br />

0.015 max<br />

0.015 max<br />

0.50 max<br />

2.00-2.50<br />

0.90-1.10<br />

0.25 max<br />

0.25 max<br />

0.02 max<br />

—<br />

—<br />

85-110<br />

55 min<br />

20 min<br />

2.25Cr-1Mo-<br />

0.25V steel<br />

(A542 Type D Cl.4a)<br />

0.11-0.15<br />

0.30-0.60<br />

0.015 max<br />

0.010 max<br />

0.10 max<br />

2.00-2.50<br />

0.90-1.10<br />

0.20 max<br />

0.25 max<br />

0.25-0.35<br />

0.030 max<br />

0.0020 max<br />

0.07 max<br />

0.015 max<br />

85-110<br />

60 min<br />

18 min<br />

3Cr-1Mo-0.25V-<br />

Ti-B steel<br />

(A542 Type C Cl.4a)<br />

0.10-0.15<br />

0.30-0.60<br />

0.025 max<br />

0.025 max<br />

0.13 max<br />

2.75-3.25<br />

0.90-1.10<br />

0.25 max<br />

0.25 max<br />

0.20-0.30<br />

0.015-0.035<br />

0.001-0.003<br />

—<br />

—<br />

85-110<br />

60 min<br />

18 min<br />

Metal temperature (Deg. F)<br />

700 750 800 850 900<br />

Allowable stress value (kgf/mm 2 )<br />

15<br />

10<br />

2.25Cr-1Mo-0.25V<br />

(for ASME Sec. VIII, Div. 1<br />

per Code Case 2098-2)<br />

Conventional<br />

2.25Cr-1Mo<br />

20<br />

15<br />

Allowable stress value (ksi)<br />

Fig. 1.3 — A comparison between<br />

advanced 2.25Cr-1Mo-V steel <strong>and</strong><br />

conventional 2.25Cr-1Mo steel on<br />

maximum allowable stress as a<br />

function <strong>of</strong> metal temperature<br />

400 450 500<br />

Metal temperature (Deg. C)<br />

2-5