Arc Welding of Specific Steels and Cast Irons

Arc Welding of Specific Steels and Cast Irons

Arc Welding of Specific Steels and Cast Irons

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Arc</strong> <strong>Welding</strong> <strong>of</strong> Heat-Resistant Low-Alloy Steel<br />

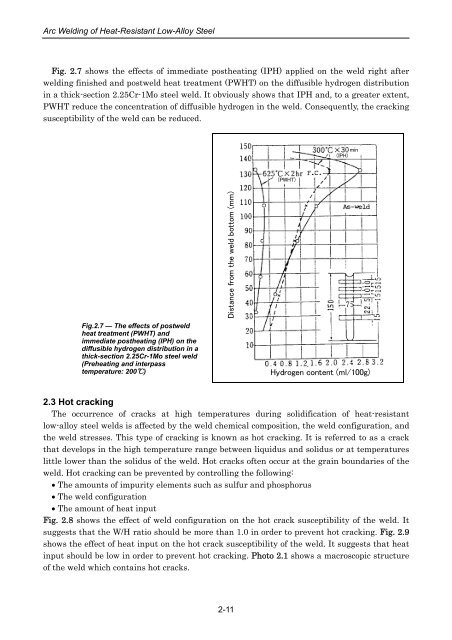

Fig. 2.7 shows the effects <strong>of</strong> immediate postheating (IPH) applied on the weld right after<br />

welding finished <strong>and</strong> postweld heat treatment (PWHT) on the diffusible hydrogen distribution<br />

in a thick-section 2.25Cr-1Mo steel weld. It obviously shows that IPH <strong>and</strong>, to a greater extent,<br />

PWHT reduce the concentration <strong>of</strong> diffusible hydrogen in the weld. Consequently, the cracking<br />

susceptibility <strong>of</strong> the weld can be reduced.<br />

min<br />

(IPH)<br />

(PWHT)<br />

Fig.2.7 — The effects <strong>of</strong> postweld<br />

heat treatment (PWHT) <strong>and</strong><br />

immediate postheating (IPH) on the<br />

diffusible hydrogen distribution in a<br />

thick-section 2.25Cr-1Mo steel weld<br />

(Preheating <strong>and</strong> interpass<br />

temperature: 200℃)<br />

Distance from the weld bottom (mm)<br />

Hydrogen content (ml/100g)<br />

2.3 Hot cracking<br />

The occurrence <strong>of</strong> cracks at high temperatures during solidification <strong>of</strong> heat-resistant<br />

low-alloy steel welds is affected by the weld chemical composition, the weld configuration, <strong>and</strong><br />

the weld stresses. This type <strong>of</strong> cracking is known as hot cracking. It is referred to as a crack<br />

that develops in the high temperature range between liquidus <strong>and</strong> solidus or at temperatures<br />

little lower than the solidus <strong>of</strong> the weld. Hot cracks <strong>of</strong>ten occur at the grain boundaries <strong>of</strong> the<br />

weld. Hot cracking can be prevented by controlling the following:<br />

The amounts <strong>of</strong> impurity elements such as sulfur <strong>and</strong> phosphorus<br />

The weld configuration<br />

The amount <strong>of</strong> heat input<br />

Fig. 2.8 shows the effect <strong>of</strong> weld configuration on the hot crack susceptibility <strong>of</strong> the weld. It<br />

suggests that the W/H ratio should be more than 1.0 in order to prevent hot cracking. Fig. 2.9<br />

shows the effect <strong>of</strong> heat input on the hot crack susceptibility <strong>of</strong> the weld. It suggests that heat<br />

input should be low in order to prevent hot cracking. Photo 2.1 shows a macroscopic structure<br />

<strong>of</strong> the weld which contains hot cracks.<br />

2-11