Spies Hecker

Spies Hecker

Spies Hecker

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

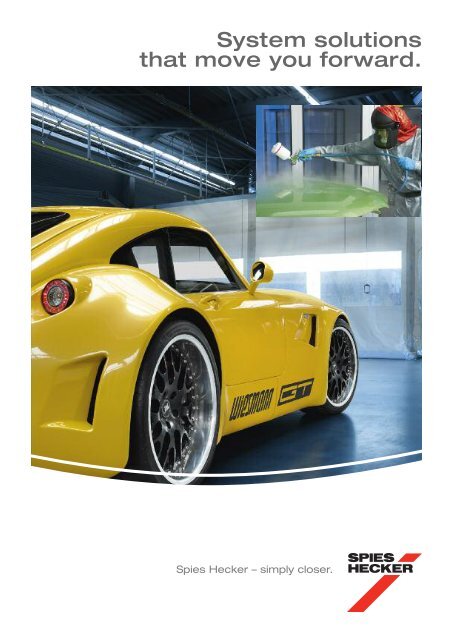

System solutions<br />

that move you forward.<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

Permahyd ® Permafleet ®<br />

Permaflex ®<br />

Permasolid ®<br />

• Simple application<br />

• System-based reliability<br />

• Outstanding color accuracy<br />

• Rapid drying<br />

• High opacity<br />

• Brilliant surface finish

Color.<br />

Technical support.<br />

Training.<br />

With digital color identification, formula<br />

searches at the PC and professional<br />

materials management, bodyshops<br />

organize their processes even more<br />

efficiently.<br />

Well organized workshop processes<br />

are distinguished by reliable results and<br />

efficiency. We support you here and show<br />

you possible ways of improving processes<br />

in your workshop.<br />

Professionals who want to develop<br />

their skills are welcome to come to the<br />

<strong>Spies</strong> <strong>Hecker</strong> Training Center. Find out<br />

the latest about product systems, painting<br />

techniques and efficient work<br />

processes.<br />

Trend towards digital<br />

instruments for color<br />

identification.<br />

• ColorDialog spectro spectrophotometer<br />

• CRplus digital formula database<br />

• Formula search via the Internet<br />

• ColorTint PC system<br />

<strong>Spies</strong> <strong>Hecker</strong> advisers<br />

give you excellent technical<br />

support.<br />

• Technical and coloristic advice<br />

• Introduction of new product systems<br />

geared to workshop needs<br />

• Explanation of new painting techniques<br />

• Analysis and optimization of workshop<br />

processes<br />

Training that moves<br />

you forward.<br />

• Basic painting skills, from substrate<br />

pretreatment through to blending in<br />

• New product systems, efficient painting<br />

techniques<br />

• Painting of plastics, Speed Repair<br />

• Color trends and color management<br />

• Energy-efficient processes<br />

• Occupational safety and health<br />

• Management economics<br />

• Individual training in the workshop

Permahyd ® Hi-TEC 480 – the new<br />

waterborne base coat for greater efficiency.<br />

Permahyd®Hi-TEC 480, the advanced <strong>Spies</strong> <strong>Hecker</strong> waterborne base coat,<br />

is a genuine innovation in refinishing and sets new standards in<br />

terms of simple processing, short process times and greater versatility<br />

in its applications.<br />

Clear Coat<br />

Base Coat<br />

The Permahyd®Hi-TEC system is based on a totally new, patented<br />

hybrid technology. The futuristic mixing colours yield a particularly<br />

uniform effect. Numerous colours are available in a more<br />

highly pigmented form in order to ensure high opacity.<br />

Surfacer<br />

Wash Primer/<br />

Primer<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permahyd ® Hi-TEC 480.<br />

Five advantages that make all the difference!<br />

1. Hi-TEC: Simple and quick processing.<br />

• Addition of just one additive (WT Additive 6050/6051)<br />

• Easy application and very good surface wetting<br />

• High vertical stability and excellent opacity<br />

• Application in a single spray pass without flash-off between coats<br />

• Immediately visible paint results<br />

2. Hi-TEC: Results you can rely on.<br />

• High colour accuracy<br />

• Uniform effect<br />

• Reliable paint results<br />

3. Hi-TEC: Short process times.<br />

• Rapid flash-off<br />

• Rapid through-drying<br />

• Immediate further processing after flash-off<br />

• Very easy multicolour finishing<br />

• Higher film thicknesses without flash-off between coats<br />

4. Hi-TEC: Easy to blend in.<br />

• Simple work process<br />

• Extremely uniform fade-out zone<br />

5. Hi-TEC: Greater flexibility.<br />

• Simple painting of interiors<br />

• Rapid 3-stage and multicolour finishes<br />

• Optimal through-drying of intermediate films<br />

• Excellent chemical and mechanical strength<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

The right surfacer<br />

for every field of application.<br />

The quality of the paintwork as a whole depends essentially on the right<br />

choice of surfacer. <strong>Spies</strong> <strong>Hecker</strong> surfacers provide high processing<br />

security and satisfy the preconditions for high-grade<br />

paintwork. They ensure optimal flow and thus a brilliant surface<br />

finish. <strong>Spies</strong> <strong>Hecker</strong> surfacer products are also geared to<br />

specific applications and special workshop conditions. The wide<br />

range of surfacers permits precise adaptation to the particular<br />

requirements.<br />

Clear Coat<br />

Base Coat<br />

Surfacer<br />

Wash Primer/<br />

Primer<br />

Permasolid ®<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permasolid ®<br />

HS Surfacers.<br />

A match for all applications.<br />

The classics.<br />

Permasolid ® HS Premium Surfacer 5310.<br />

Wet-on-wet<br />

• 2K surfacer with reliable processing characteristics<br />

• Outstanding sanding characteristics and build<br />

• Very long processing time<br />

• Well suited to IR drying<br />

• Ensures outstanding paint flow<br />

Permasolid ® HS Vario Surfacer 8590.<br />

Wet-on-wet<br />

Normal<br />

build<br />

Normal<br />

build<br />

Medium<br />

build<br />

Medium<br />

build<br />

Higher<br />

build<br />

Higher<br />

build<br />

• Versatile 2K surfacer<br />

• Suitable as a non-sanding and sanding surfacer<br />

• Reliable processing<br />

• Good isolating characteristics even on old<br />

thermoplastic paintwork<br />

• Very good paint flow<br />

The specialists.<br />

Permasolid ® HS Transparent Surfacer 5180<br />

new.<br />

Wet-on-wet<br />

• Rapid wet-on-wet application<br />

• Suitable as an adhesion promoter<br />

• Also suitable for isolating polyester substrates<br />

Permasolid ® HS SpectroFlex Surfacer 5400.<br />

Wet-on-wet<br />

Normal<br />

build<br />

Normal<br />

build<br />

Medium<br />

build<br />

Medium<br />

build<br />

Higher<br />

build<br />

Higher<br />

build<br />

• Pigmented 2K HS surfacer system<br />

• Colour variants are produced by mixing<br />

6 ground colours<br />

• Suitable as a non-sanding and sanding surfacer<br />

• Very quick flash-off<br />

• Outstanding build<br />

• Suitable as an interior paint<br />

High productivity.<br />

Permasolid ® HS Express Surfacer 5250.<br />

Wet-on-wet<br />

Normal<br />

build<br />

Medium<br />

build<br />

Higher<br />

build<br />

• 2K surfacer for high productivity<br />

• Good paint flow<br />

• Fast drying, sandable after an hour at 20 °C<br />

• Very good IR drying<br />

Permasolid ® HS Wet-on-Wet Surfacer 5330.<br />

Wet-on-wet<br />

Normal<br />

build<br />

Medium<br />

build<br />

Higher<br />

build<br />

• 2K surfacer, quick and easy to apply<br />

• Rapid flash-off: 15 – 20 min<br />

• Particularly suitable for rapid recoating with<br />

Permahyd®280/285 and Permahyd®Hi-TEC 480<br />

and for new parts<br />

• Good paint flow every time<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Permasolid ® HS Clear Coats<br />

for any requirement.<br />

An optimal clear coat is distinguished by its ease of application and excellent<br />

paint flow. Along with these key product properties, refinishers<br />

attach great importance to high productivity. This is made<br />

possible by rapid drying and easy polishing. Permasolid®clear<br />

coats satisfy these requirements and also come with a very high<br />

solids content, which reduces the quantity of material used.<br />

Clear Coat<br />

Base Coat<br />

Surfacer<br />

Wash Primer/<br />

Primer<br />

Permasolid ®<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permasolid ®<br />

HS Clear Coats.<br />

A recommendation for every requirement.<br />

Universal applications.<br />

Permasolid ® HS Clear Coat 8035.<br />

Paint flow Application Drying<br />

•••• ••• ••••<br />

• Universally suitable for all types of repair<br />

(e.g. Speed Repair, partial and full resprays)<br />

• Application in a single spray pass<br />

• Good flow<br />

• Rapid drying<br />

• Easy polishing<br />

Permasolid ® HS Clear Coat 8055.<br />

Paint flow Application Drying<br />

•••• ••• ••••<br />

• Flexible application possible, in 1.5 (preferred)<br />

or 2 coats<br />

• Rapid drying<br />

• Varied uses<br />

• Good vertical stability<br />

• Good gloss and flow<br />

• Resistant to surface defects<br />

High productivity.<br />

Permasolid ® HS Optimum Clear Coat 8600.<br />

Paint flow Application Drying<br />

••• ••• •••••<br />

• Simple and economical processing<br />

• Application in a single spray pass<br />

• Rapid drying<br />

• Good IR drying<br />

• Quick and easy polishing<br />

Permasolid ® HS Clear Coat 8650.<br />

Paint flow Application Drying<br />

••• ••• •••••<br />

• Good application even in unfavourable booth<br />

conditions<br />

• Flexible processing possible<br />

• Very rapid drying<br />

• Very good IR drying<br />

• Quick and easy polishing<br />

High gloss.<br />

Permasolid ® HS Clear Coat 8030.<br />

Paint flow Application Drying<br />

••••• •• •<br />

• Simple application; a single spray pass<br />

without flash-off between coats<br />

• Good flow<br />

• Particularly suitable for matt finishes (MA110)<br />

• Brilliant surface finish<br />

User-friendly.<br />

Permasolid ® HS Clear Coat 8034.<br />

Paint flow Application Drying<br />

•••• •••• •••<br />

• Simple application in 2 coats (preferred),<br />

but also possible in 1.5 coats<br />

• Good vertical stability<br />

• Very easy polishing<br />

• Versatile in its applications<br />

• Excellent finish<br />

The specialists.<br />

Permasolid ® HS Diamond Clear Coat 8450.<br />

Permasolid ® UV Starlight Clear Coat 9200.<br />

• = Good •• = Good/Very Good ••• = Very Good<br />

•••• = Very Good/Outstanding ••••• = Outstanding<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Permahyd ® Base Coat 280/285,<br />

the successful waterborne base coat system.<br />

The <strong>Spies</strong> <strong>Hecker</strong> System 280/285 is the tried-and-tested waterborne base<br />

coat system for cost-effective vehicle refinishes, with simple application<br />

conforming to VOC environmental guidelines. This paint<br />

technology is distinguished by simple and reliable application<br />

as well as high efficiency. Its product properties are impressive,<br />

with over 15,000 refinishers appreciating its high opacity, colour<br />

accuracy and simple handling.<br />

Clear Coat<br />

Base Coat<br />

Surfacer<br />

Wash Primer/<br />

Primer<br />

Permahyd ®<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permahyd ® 280/285.<br />

Successful waterborne base coat system.<br />

Quality.<br />

• Water-thinnable base coat<br />

• For solid colour and effect finishes<br />

• Recoatable with any Permasolid®2K Clear Coat<br />

• High colour accuracy<br />

• Over 45,000 colours available<br />

Application.<br />

• Easy to adjust viscosity with Permahyd®Demineralized<br />

Water 6000/6002<br />

• Application in a single spray pass<br />

Economy.<br />

• High yield<br />

• Good coverage thanks to high pigmentation<br />

• No paint waste, as remainders can be subsequently used<br />

(no pot life)<br />

Permahyd ® Base Coat 280/285 is a product of<br />

the GREENTEC line and stands for:<br />

• Low solvent content<br />

• Efficient application<br />

• High opacity<br />

• Reliable results<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Plastic,<br />

easily and reliably painted.<br />

Today, plastics are an established feature of modern vehicle construction and are being increasingly<br />

used. The typical plastic parts on the car are hub caps, bumpers, mirror shells, sills and<br />

trim. When damaged, these have to be repaired. However, plastics are not all the same. An<br />

expert vehicle refinish has to adapt to the various substrates. This is why <strong>Spies</strong> <strong>Hecker</strong> offers<br />

a perfectly balanced product system specifically for the painting of plastics. Meeting all the<br />

challenges of daily requirements. Easy to use with excellent results.<br />

Typical plastic parts on the vehicle,<br />

e.g. hub caps, bumpers, mirror shells,<br />

sills and trim<br />

Possible plastic parts, e.g. bonnets,<br />

mudguards and doors<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

The painting of plastics.<br />

Six products for immaculate finishes on plastic.<br />

Permacron ® 1:1 Elastic Primer Surfacer 3300.<br />

• Reliable adhesion to all conventional plastic parts on cars<br />

• Can be applied wet-on-wet<br />

• Very long processing time and simple handling<br />

• Available in black, light grey and white<br />

• Efficient 2-coat system<br />

• Good top coat flow<br />

Priomat ® Elastic Primer 3304 transparent.<br />

• Universal 1K adhesion promoter for 3-coat systems<br />

• Reliable adhesion to all conventional plastic parts on cars<br />

• Recoatable wet-on-wet with elasticized 2K acrylic surfacers<br />

• Reliable and easy application<br />

• High elasticity<br />

• Also available in a spray can (3410)<br />

Permasolid ® Elastic Additive 9050.<br />

• Universal elasticizer for all Permasolid®2K Acrylic Surfacers,<br />

Top Coats and Clear Coats<br />

• Simple application and good spraying properties<br />

Permasolid ® Matt Component MA 110.<br />

• For the matting of Permasolid®HS Automotive Top Coat 275<br />

and Permasolid®HS Clear Coats<br />

• Different degrees of gloss are possible: matt, satin matt,<br />

satin gloss and glossy<br />

Permasolid ® Component SA 101/SA 102.<br />

• Universal texture component with high elasticity<br />

• Special additive for Permasolid®HS Automotive Top Coat 275<br />

• Simple mixing and good spraying properties<br />

• Optimal texturing, coarse and fine<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Speed Repair –<br />

the perfect solution for minor damage.<br />

Almost 30 % of damage on vehicles is minor damage to the lower part of the body. This is where<br />

bodyshops are expected by a growing number of customers to provide an inexpensive<br />

refinish. For small paint repairs, <strong>Spies</strong> <strong>Hecker</strong> has therefore developed its Speed Repair<br />

process. With this method, the quantity of material used and working time are cut by almost<br />

half compared to a partial respray.<br />

Refinish more efficiently with Speed Repair:<br />

• More effective use of workshop capacity<br />

• Time savings of up to 52 % compared to a partial respray<br />

• Greater customer loyalty thanks to lower costs<br />

• Opportunity for extra business<br />

Less material used.<br />

Material used in grams<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Putty Surfacer Base coat Clear coat<br />

Speed Repair<br />

Partial respray<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Speed Repair.<br />

The strategy for clever operators.<br />

With the Speed Repair method, the repair of minor damage can be limited to the actual area of damage and<br />

is faster than a partial respray as a refinishing method. <strong>Spies</strong> <strong>Hecker</strong> offers one system solution for professional<br />

spot repairs.<br />

Speed Repair is ideal<br />

for these areas.<br />

Speed Repair is not suitable<br />

for these areas.<br />

Standard Speed Repair.<br />

The specially developed and perfectly balanced product system<br />

makes use of conventional technology and yields good paint<br />

results every time.<br />

Specific advantages:<br />

• More effective use of workshop capacity<br />

• Greater customer loyalty thanks to lower costs<br />

• Opportunity for extra business<br />

Wash Primer Base Coat/Clear Coat Top Coat Speed Blender<br />

or<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Speed Repair –<br />

the perfect solution for minor damage.<br />

Almost 30 % of damage on vehicles is minor damage to the lower part of the body. This is where<br />

bodyshops are expected by a growing number of customers to provide an inexpensive<br />

refinish. For small paint repairs, <strong>Spies</strong> <strong>Hecker</strong> has therefore developed its Speed Repair<br />

process. With this method, the quantity of material used and working time are cut by almost<br />

half compared to a partial respray.<br />

Refinish more efficiently with Speed Repair:<br />

• More effective use of workshop capacity<br />

• Time savings of up to 52 % compared to a partial respray<br />

• Greater customer loyalty thanks to lower costs<br />

• Opportunity for extra business<br />

Less material used.<br />

Material used in grams<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Putty Surfacer Base coat Clear coat<br />

Speed Repair<br />

Partial respray<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Speed Repair.<br />

The strategy for clever operators.<br />

With the Speed Repair method, the repair of minor damage can be limited to the actual area of damage and<br />

is faster than a partial respray as a refinishing method. <strong>Spies</strong> <strong>Hecker</strong> offers one system solution for professional<br />

spot repairs.<br />

Speed Repair is ideal for<br />

these areas.<br />

Speed Repair is not suitable<br />

for these areas.<br />

Standard Speed Repair.<br />

The specially developed and perfectly balanced product system<br />

makes use of conventional technology and yields good paint<br />

results every time.<br />

Specific advantages:<br />

• More effective use of workshop capacity<br />

• Greater customer loyalty thanks to lower costs<br />

• Opportunity for extra business<br />

Wash Primer Base Coat/Clear Coat Top Coat Speed Blender<br />

or<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Permafleet ® –<br />

the paint system for trucks and buses.<br />

Whether you paint driver’s cabs, buses or special-purpose vehicles, what counts are quality-oriented<br />

and efficient processes. The Permafleet®product system from <strong>Spies</strong> <strong>Hecker</strong> provides costeffective<br />

solutions for all requirements in the commercial vehicle sector.<br />

Permafleet®– for greater success.<br />

• Balanced system for commercial vehicle painting – for everything from<br />

OEM paintwork to refinishing<br />

• Special paint systems for different fields of application and requirements<br />

• Broad product range<br />

• High colour accuracy and good opacity<br />

• Practical working aids<br />

Permafleet ®<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permafleet ® .<br />

Balanced paint systems for commercial vehicles.<br />

<strong>Spies</strong> <strong>Hecker</strong> supplies special paint systems that can be adapted precisely to the particular application. Whatever<br />

is involved – OEM paintwork, a respray or a refinish – with the Permafleet®paint system for commercial vehicles,<br />

you’ve made the right choice.<br />

Hi-Class systems.<br />

For exceptionally high-quality 3- or 4-<br />

coat paintwork: Wash primer, surfacer<br />

and top coat or clear over base. The<br />

paint is applied to sanding surfacer.<br />

4-Stage System<br />

Clear Coat<br />

Base Coat<br />

Sanding Surfacer<br />

Top systems.<br />

For a cost-effective 3- or 4-coat commercial<br />

vehicle finish: Wash primer,<br />

surfacer and top coat or clear over<br />

base. The system is applied wet-onwet.<br />

Economy systems.<br />

For a cost-effective 2-coat finish.<br />

Primer surfacer and top coat are<br />

applied wet-on-wet.<br />

Wash Primer/<br />

Primer<br />

3-Stage System<br />

Top Coat<br />

Primer Surfacer/<br />

Wet-on-Wet Surfacer<br />

Wash Primer/<br />

Primer<br />

2-Stage System<br />

Top Coat<br />

Primer Surfacer/<br />

Surfacer<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Permaflex ® – versatile coating solutions<br />

for industrial business.<br />

In the painting of industrial objects, the requirements vary greatly. Different substrates have to<br />

be coated and special degrees of gloss and effects are sometimes requested. The<br />

Permaflex®system adapts flexibly to the requirements and achieves this with a<br />

limited product range.<br />

Permaflex®– the system for industrial coatings.<br />

• Wide range of binders for different surface qualities<br />

• Versatile in its applications<br />

• Suitable for different substrates<br />

• Special degrees of gloss and effects are possible<br />

• High colour accuracy<br />

• Based on the Permafleet®(commercial vehicle) mixing system<br />

• Also available ready-mixed<br />

• Only two universal primers necessary<br />

Permaflex ®<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permaflex ® .<br />

The paint system suitable for all industrial requirements.<br />

PUR.<br />

PUR Top Coat 570.<br />

PUR Matt Top Coat 555.<br />

PUR Textured Top Coat 560.<br />

• 2K top coat (polyurethane resin)<br />

• High mechanical and chemical resistance<br />

• For indoor and outdoor applications<br />

• Suitable for primed substrates<br />

• PUR 570: Five degrees of gloss are<br />

possible – high gloss to matt<br />

• PUR 555: For extremely matt surfaces<br />

• PUR 560: For textured surfaces<br />

ACRYLIC PLUS.<br />

Acrylic Plus Top Coat 575.<br />

• Glossy 2K top coat<br />

• Exceptionally lightfast<br />

• Specially designed for painting window frames<br />

• Five degrees of gloss – high gloss to matt<br />

ACRYLIC.<br />

Acrylic Top Coat 550.<br />

• Glossy 2K top coat (polyacrylate-based)<br />

• For 1-coat application/without primer<br />

• Applied straight onto steel, aluminium and zinc<br />

• For indoor and outdoor applications<br />

STONE CHIP PROTECTION.<br />

Stone Chip Protection Top Coat 515.<br />

• 2K top coat (polyacrylate)<br />

• High mechanical strength<br />

• Optimized for application on large items<br />

of equipment<br />

IRON MICA.<br />

ALKYD.<br />

EPOXY.<br />

Iron Mica Top Coat 510.<br />

• 2K top coat (polyacrylate)<br />

• High mechanical and chemical resistance<br />

• Typical gloss and effect<br />

• Outstanding weather-resistance<br />

Synthetic Resin Top Coat 530.<br />

• High-gloss 1K top coat (alkyd resin/<br />

synthetic resin)<br />

• For indoors and outdoors<br />

• Also suitable for rolling and brushing<br />

• Five degrees of gloss – high gloss to matt<br />

Epoxy Top Coat 540.<br />

• 2K epoxy system<br />

• Especially for application indoors<br />

• For objects with extreme surface hardness<br />

and high mechanical and chemical resistance<br />

• Three degrees of gloss – glossy to matt<br />

NITROCELLULOSE.<br />

NC Top Coat 520.<br />

• 1K top coat (nitrocellulose)<br />

• For indoors<br />

• Rapid air drying<br />

• Four degrees of gloss – glossy to matt<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

ems-p.com<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011<br />

<strong>Spies</strong> <strong>Hecker</strong> GmbH<br />

Horbeller Straße 17<br />

50858 Köln<br />

Tel.: +4922346019 - 3630<br />

Fax: +4922346019 - 3880<br />

www.spieshecker.com