Spies Hecker

Spies Hecker

Spies Hecker

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

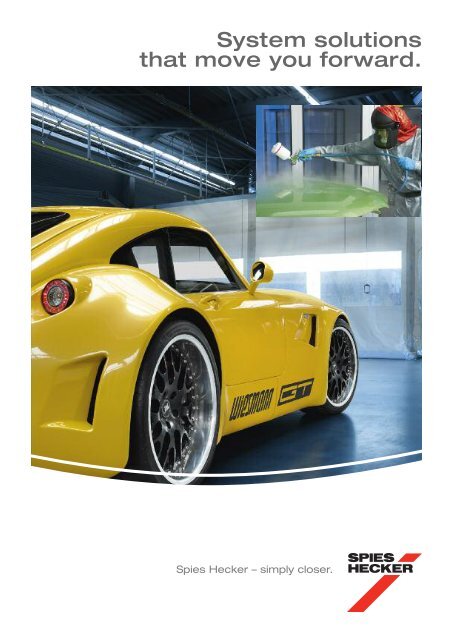

System solutions<br />

that move you forward.<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

Permahyd ® Permafleet ®<br />

Permaflex ®<br />

Permasolid ®<br />

• Simple application<br />

• System-based reliability<br />

• Outstanding color accuracy<br />

• Rapid drying<br />

• High opacity<br />

• Brilliant surface finish

Color.<br />

Technical support.<br />

Training.<br />

With digital color identification, formula<br />

searches at the PC and professional<br />

materials management, bodyshops<br />

organize their processes even more<br />

efficiently.<br />

Well organized workshop processes<br />

are distinguished by reliable results and<br />

efficiency. We support you here and show<br />

you possible ways of improving processes<br />

in your workshop.<br />

Professionals who want to develop<br />

their skills are welcome to come to the<br />

<strong>Spies</strong> <strong>Hecker</strong> Training Center. Find out<br />

the latest about product systems, painting<br />

techniques and efficient work<br />

processes.<br />

Trend towards digital<br />

instruments for color<br />

identification.<br />

• ColorDialog spectro spectrophotometer<br />

• CRplus digital formula database<br />

• Formula search via the Internet<br />

• ColorTint PC system<br />

<strong>Spies</strong> <strong>Hecker</strong> advisers<br />

give you excellent technical<br />

support.<br />

• Technical and coloristic advice<br />

• Introduction of new product systems<br />

geared to workshop needs<br />

• Explanation of new painting techniques<br />

• Analysis and optimization of workshop<br />

processes<br />

Training that moves<br />

you forward.<br />

• Basic painting skills, from substrate<br />

pretreatment through to blending in<br />

• New product systems, efficient painting<br />

techniques<br />

• Painting of plastics, Speed Repair<br />

• Color trends and color management<br />

• Energy-efficient processes<br />

• Occupational safety and health<br />

• Management economics<br />

• Individual training in the workshop

Permahyd ® Hi-TEC 480 – the new<br />

waterborne base coat for greater efficiency.<br />

Permahyd®Hi-TEC 480, the advanced <strong>Spies</strong> <strong>Hecker</strong> waterborne base coat,<br />

is a genuine innovation in refinishing and sets new standards in<br />

terms of simple processing, short process times and greater versatility<br />

in its applications.<br />

Clear Coat<br />

Base Coat<br />

The Permahyd®Hi-TEC system is based on a totally new, patented<br />

hybrid technology. The futuristic mixing colours yield a particularly<br />

uniform effect. Numerous colours are available in a more<br />

highly pigmented form in order to ensure high opacity.<br />

Surfacer<br />

Wash Primer/<br />

Primer<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permahyd ® Hi-TEC 480.<br />

Five advantages that make all the difference!<br />

1. Hi-TEC: Simple and quick processing.<br />

• Addition of just one additive (WT Additive 6050/6051)<br />

• Easy application and very good surface wetting<br />

• High vertical stability and excellent opacity<br />

• Application in a single spray pass without flash-off between coats<br />

• Immediately visible paint results<br />

2. Hi-TEC: Results you can rely on.<br />

• High colour accuracy<br />

• Uniform effect<br />

• Reliable paint results<br />

3. Hi-TEC: Short process times.<br />

• Rapid flash-off<br />

• Rapid through-drying<br />

• Immediate further processing after flash-off<br />

• Very easy multicolour finishing<br />

• Higher film thicknesses without flash-off between coats<br />

4. Hi-TEC: Easy to blend in.<br />

• Simple work process<br />

• Extremely uniform fade-out zone<br />

5. Hi-TEC: Greater flexibility.<br />

• Simple painting of interiors<br />

• Rapid 3-stage and multicolour finishes<br />

• Optimal through-drying of intermediate films<br />

• Excellent chemical and mechanical strength<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

The right surfacer<br />

for every field of application.<br />

The quality of the paintwork as a whole depends essentially on the right<br />

choice of surfacer. <strong>Spies</strong> <strong>Hecker</strong> surfacers provide high processing<br />

security and satisfy the preconditions for high-grade<br />

paintwork. They ensure optimal flow and thus a brilliant surface<br />

finish. <strong>Spies</strong> <strong>Hecker</strong> surfacer products are also geared to<br />

specific applications and special workshop conditions. The wide<br />

range of surfacers permits precise adaptation to the particular<br />

requirements.<br />

Clear Coat<br />

Base Coat<br />

Surfacer<br />

Wash Primer/<br />

Primer<br />

Permasolid ®<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permasolid ®<br />

HS Surfacers.<br />

A match for all applications.<br />

The classics.<br />

Permasolid ® HS Premium Surfacer 5310.<br />

Wet-on-wet<br />

• 2K surfacer with reliable processing characteristics<br />

• Outstanding sanding characteristics and build<br />

• Very long processing time<br />

• Well suited to IR drying<br />

• Ensures outstanding paint flow<br />

Permasolid ® HS Vario Surfacer 8590.<br />

Wet-on-wet<br />

Normal<br />

build<br />

Normal<br />

build<br />

Medium<br />

build<br />

Medium<br />

build<br />

Higher<br />

build<br />

Higher<br />

build<br />

• Versatile 2K surfacer<br />

• Suitable as a non-sanding and sanding surfacer<br />

• Reliable processing<br />

• Good isolating characteristics even on old<br />

thermoplastic paintwork<br />

• Very good paint flow<br />

The specialists.<br />

Permasolid ® HS Transparent Surfacer 5180<br />

new.<br />

Wet-on-wet<br />

• Rapid wet-on-wet application<br />

• Suitable as an adhesion promoter<br />

• Also suitable for isolating polyester substrates<br />

Permasolid ® HS SpectroFlex Surfacer 5400.<br />

Wet-on-wet<br />

Normal<br />

build<br />

Normal<br />

build<br />

Medium<br />

build<br />

Medium<br />

build<br />

Higher<br />

build<br />

Higher<br />

build<br />

• Pigmented 2K HS surfacer system<br />

• Colour variants are produced by mixing<br />

6 ground colours<br />

• Suitable as a non-sanding and sanding surfacer<br />

• Very quick flash-off<br />

• Outstanding build<br />

• Suitable as an interior paint<br />

High productivity.<br />

Permasolid ® HS Express Surfacer 5250.<br />

Wet-on-wet<br />

Normal<br />

build<br />

Medium<br />

build<br />

Higher<br />

build<br />

• 2K surfacer for high productivity<br />

• Good paint flow<br />

• Fast drying, sandable after an hour at 20 °C<br />

• Very good IR drying<br />

Permasolid ® HS Wet-on-Wet Surfacer 5330.<br />

Wet-on-wet<br />

Normal<br />

build<br />

Medium<br />

build<br />

Higher<br />

build<br />

• 2K surfacer, quick and easy to apply<br />

• Rapid flash-off: 15 – 20 min<br />

• Particularly suitable for rapid recoating with<br />

Permahyd®280/285 and Permahyd®Hi-TEC 480<br />

and for new parts<br />

• Good paint flow every time<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Permasolid ® HS Clear Coats<br />

for any requirement.<br />

An optimal clear coat is distinguished by its ease of application and excellent<br />

paint flow. Along with these key product properties, refinishers<br />

attach great importance to high productivity. This is made<br />

possible by rapid drying and easy polishing. Permasolid®clear<br />

coats satisfy these requirements and also come with a very high<br />

solids content, which reduces the quantity of material used.<br />

Clear Coat<br />

Base Coat<br />

Surfacer<br />

Wash Primer/<br />

Primer<br />

Permasolid ®<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permasolid ®<br />

HS Clear Coats.<br />

A recommendation for every requirement.<br />

Universal applications.<br />

Permasolid ® HS Clear Coat 8035.<br />

Paint flow Application Drying<br />

•••• ••• ••••<br />

• Universally suitable for all types of repair<br />

(e.g. Speed Repair, partial and full resprays)<br />

• Application in a single spray pass<br />

• Good flow<br />

• Rapid drying<br />

• Easy polishing<br />

Permasolid ® HS Clear Coat 8055.<br />

Paint flow Application Drying<br />

•••• ••• ••••<br />

• Flexible application possible, in 1.5 (preferred)<br />

or 2 coats<br />

• Rapid drying<br />

• Varied uses<br />

• Good vertical stability<br />

• Good gloss and flow<br />

• Resistant to surface defects<br />

High productivity.<br />

Permasolid ® HS Optimum Clear Coat 8600.<br />

Paint flow Application Drying<br />

••• ••• •••••<br />

• Simple and economical processing<br />

• Application in a single spray pass<br />

• Rapid drying<br />

• Good IR drying<br />

• Quick and easy polishing<br />

Permasolid ® HS Clear Coat 8650.<br />

Paint flow Application Drying<br />

••• ••• •••••<br />

• Good application even in unfavourable booth<br />

conditions<br />

• Flexible processing possible<br />

• Very rapid drying<br />

• Very good IR drying<br />

• Quick and easy polishing<br />

High gloss.<br />

Permasolid ® HS Clear Coat 8030.<br />

Paint flow Application Drying<br />

••••• •• •<br />

• Simple application; a single spray pass<br />

without flash-off between coats<br />

• Good flow<br />

• Particularly suitable for matt finishes (MA110)<br />

• Brilliant surface finish<br />

User-friendly.<br />

Permasolid ® HS Clear Coat 8034.<br />

Paint flow Application Drying<br />

•••• •••• •••<br />

• Simple application in 2 coats (preferred),<br />

but also possible in 1.5 coats<br />

• Good vertical stability<br />

• Very easy polishing<br />

• Versatile in its applications<br />

• Excellent finish<br />

The specialists.<br />

Permasolid ® HS Diamond Clear Coat 8450.<br />

Permasolid ® UV Starlight Clear Coat 9200.<br />

• = Good •• = Good/Very Good ••• = Very Good<br />

•••• = Very Good/Outstanding ••••• = Outstanding<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Permahyd ® Base Coat 280/285,<br />

the successful waterborne base coat system.<br />

The <strong>Spies</strong> <strong>Hecker</strong> System 280/285 is the tried-and-tested waterborne base<br />

coat system for cost-effective vehicle refinishes, with simple application<br />

conforming to VOC environmental guidelines. This paint<br />

technology is distinguished by simple and reliable application<br />

as well as high efficiency. Its product properties are impressive,<br />

with over 15,000 refinishers appreciating its high opacity, colour<br />

accuracy and simple handling.<br />

Clear Coat<br />

Base Coat<br />

Surfacer<br />

Wash Primer/<br />

Primer<br />

Permahyd ®<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permahyd ® 280/285.<br />

Successful waterborne base coat system.<br />

Quality.<br />

• Water-thinnable base coat<br />

• For solid colour and effect finishes<br />

• Recoatable with any Permasolid®2K Clear Coat<br />

• High colour accuracy<br />

• Over 45,000 colours available<br />

Application.<br />

• Easy to adjust viscosity with Permahyd®Demineralized<br />

Water 6000/6002<br />

• Application in a single spray pass<br />

Economy.<br />

• High yield<br />

• Good coverage thanks to high pigmentation<br />

• No paint waste, as remainders can be subsequently used<br />

(no pot life)<br />

Permahyd ® Base Coat 280/285 is a product of<br />

the GREENTEC line and stands for:<br />

• Low solvent content<br />

• Efficient application<br />

• High opacity<br />

• Reliable results<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Plastic,<br />

easily and reliably painted.<br />

Today, plastics are an established feature of modern vehicle construction and are being increasingly<br />

used. The typical plastic parts on the car are hub caps, bumpers, mirror shells, sills and<br />

trim. When damaged, these have to be repaired. However, plastics are not all the same. An<br />

expert vehicle refinish has to adapt to the various substrates. This is why <strong>Spies</strong> <strong>Hecker</strong> offers<br />

a perfectly balanced product system specifically for the painting of plastics. Meeting all the<br />

challenges of daily requirements. Easy to use with excellent results.<br />

Typical plastic parts on the vehicle,<br />

e.g. hub caps, bumpers, mirror shells,<br />

sills and trim<br />

Possible plastic parts, e.g. bonnets,<br />

mudguards and doors<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

The painting of plastics.<br />

Six products for immaculate finishes on plastic.<br />

Permacron ® 1:1 Elastic Primer Surfacer 3300.<br />

• Reliable adhesion to all conventional plastic parts on cars<br />

• Can be applied wet-on-wet<br />

• Very long processing time and simple handling<br />

• Available in black, light grey and white<br />

• Efficient 2-coat system<br />

• Good top coat flow<br />

Priomat ® Elastic Primer 3304 transparent.<br />

• Universal 1K adhesion promoter for 3-coat systems<br />

• Reliable adhesion to all conventional plastic parts on cars<br />

• Recoatable wet-on-wet with elasticized 2K acrylic surfacers<br />

• Reliable and easy application<br />

• High elasticity<br />

• Also available in a spray can (3410)<br />

Permasolid ® Elastic Additive 9050.<br />

• Universal elasticizer for all Permasolid®2K Acrylic Surfacers,<br />

Top Coats and Clear Coats<br />

• Simple application and good spraying properties<br />

Permasolid ® Matt Component MA 110.<br />

• For the matting of Permasolid®HS Automotive Top Coat 275<br />

and Permasolid®HS Clear Coats<br />

• Different degrees of gloss are possible: matt, satin matt,<br />

satin gloss and glossy<br />

Permasolid ® Component SA 101/SA 102.<br />

• Universal texture component with high elasticity<br />

• Special additive for Permasolid®HS Automotive Top Coat 275<br />

• Simple mixing and good spraying properties<br />

• Optimal texturing, coarse and fine<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Speed Repair –<br />

the perfect solution for minor damage.<br />

Almost 30 % of damage on vehicles is minor damage to the lower part of the body. This is where<br />

bodyshops are expected by a growing number of customers to provide an inexpensive<br />

refinish. For small paint repairs, <strong>Spies</strong> <strong>Hecker</strong> has therefore developed its Speed Repair<br />

process. With this method, the quantity of material used and working time are cut by almost<br />

half compared to a partial respray.<br />

Refinish more efficiently with Speed Repair:<br />

• More effective use of workshop capacity<br />

• Time savings of up to 52 % compared to a partial respray<br />

• Greater customer loyalty thanks to lower costs<br />

• Opportunity for extra business<br />

Less material used.<br />

Material used in grams<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Putty Surfacer Base coat Clear coat<br />

Speed Repair<br />

Partial respray<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Speed Repair.<br />

The strategy for clever operators.<br />

With the Speed Repair method, the repair of minor damage can be limited to the actual area of damage and<br />

is faster than a partial respray as a refinishing method. <strong>Spies</strong> <strong>Hecker</strong> offers one system solution for professional<br />

spot repairs.<br />

Speed Repair is ideal<br />

for these areas.<br />

Speed Repair is not suitable<br />

for these areas.<br />

Standard Speed Repair.<br />

The specially developed and perfectly balanced product system<br />

makes use of conventional technology and yields good paint<br />

results every time.<br />

Specific advantages:<br />

• More effective use of workshop capacity<br />

• Greater customer loyalty thanks to lower costs<br />

• Opportunity for extra business<br />

Wash Primer Base Coat/Clear Coat Top Coat Speed Blender<br />

or<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Speed Repair –<br />

the perfect solution for minor damage.<br />

Almost 30 % of damage on vehicles is minor damage to the lower part of the body. This is where<br />

bodyshops are expected by a growing number of customers to provide an inexpensive<br />

refinish. For small paint repairs, <strong>Spies</strong> <strong>Hecker</strong> has therefore developed its Speed Repair<br />

process. With this method, the quantity of material used and working time are cut by almost<br />

half compared to a partial respray.<br />

Refinish more efficiently with Speed Repair:<br />

• More effective use of workshop capacity<br />

• Time savings of up to 52 % compared to a partial respray<br />

• Greater customer loyalty thanks to lower costs<br />

• Opportunity for extra business<br />

Less material used.<br />

Material used in grams<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Putty Surfacer Base coat Clear coat<br />

Speed Repair<br />

Partial respray<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Speed Repair.<br />

The strategy for clever operators.<br />

With the Speed Repair method, the repair of minor damage can be limited to the actual area of damage and<br />

is faster than a partial respray as a refinishing method. <strong>Spies</strong> <strong>Hecker</strong> offers one system solution for professional<br />

spot repairs.<br />

Speed Repair is ideal for<br />

these areas.<br />

Speed Repair is not suitable<br />

for these areas.<br />

Standard Speed Repair.<br />

The specially developed and perfectly balanced product system<br />

makes use of conventional technology and yields good paint<br />

results every time.<br />

Specific advantages:<br />

• More effective use of workshop capacity<br />

• Greater customer loyalty thanks to lower costs<br />

• Opportunity for extra business<br />

Wash Primer Base Coat/Clear Coat Top Coat Speed Blender<br />

or<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Permafleet ® –<br />

the paint system for trucks and buses.<br />

Whether you paint driver’s cabs, buses or special-purpose vehicles, what counts are quality-oriented<br />

and efficient processes. The Permafleet®product system from <strong>Spies</strong> <strong>Hecker</strong> provides costeffective<br />

solutions for all requirements in the commercial vehicle sector.<br />

Permafleet®– for greater success.<br />

• Balanced system for commercial vehicle painting – for everything from<br />

OEM paintwork to refinishing<br />

• Special paint systems for different fields of application and requirements<br />

• Broad product range<br />

• High colour accuracy and good opacity<br />

• Practical working aids<br />

Permafleet ®<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permafleet ® .<br />

Balanced paint systems for commercial vehicles.<br />

<strong>Spies</strong> <strong>Hecker</strong> supplies special paint systems that can be adapted precisely to the particular application. Whatever<br />

is involved – OEM paintwork, a respray or a refinish – with the Permafleet®paint system for commercial vehicles,<br />

you’ve made the right choice.<br />

Hi-Class systems.<br />

For exceptionally high-quality 3- or 4-<br />

coat paintwork: Wash primer, surfacer<br />

and top coat or clear over base. The<br />

paint is applied to sanding surfacer.<br />

4-Stage System<br />

Clear Coat<br />

Base Coat<br />

Sanding Surfacer<br />

Top systems.<br />

For a cost-effective 3- or 4-coat commercial<br />

vehicle finish: Wash primer,<br />

surfacer and top coat or clear over<br />

base. The system is applied wet-onwet.<br />

Economy systems.<br />

For a cost-effective 2-coat finish.<br />

Primer surfacer and top coat are<br />

applied wet-on-wet.<br />

Wash Primer/<br />

Primer<br />

3-Stage System<br />

Top Coat<br />

Primer Surfacer/<br />

Wet-on-Wet Surfacer<br />

Wash Primer/<br />

Primer<br />

2-Stage System<br />

Top Coat<br />

Primer Surfacer/<br />

Surfacer<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

Permaflex ® – versatile coating solutions<br />

for industrial business.<br />

In the painting of industrial objects, the requirements vary greatly. Different substrates have to<br />

be coated and special degrees of gloss and effects are sometimes requested. The<br />

Permaflex®system adapts flexibly to the requirements and achieves this with a<br />

limited product range.<br />

Permaflex®– the system for industrial coatings.<br />

• Wide range of binders for different surface qualities<br />

• Versatile in its applications<br />

• Suitable for different substrates<br />

• Special degrees of gloss and effects are possible<br />

• High colour accuracy<br />

• Based on the Permafleet®(commercial vehicle) mixing system<br />

• Also available ready-mixed<br />

• Only two universal primers necessary<br />

Permaflex ®<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

ems-p.com<br />

Permaflex ® .<br />

The paint system suitable for all industrial requirements.<br />

PUR.<br />

PUR Top Coat 570.<br />

PUR Matt Top Coat 555.<br />

PUR Textured Top Coat 560.<br />

• 2K top coat (polyurethane resin)<br />

• High mechanical and chemical resistance<br />

• For indoor and outdoor applications<br />

• Suitable for primed substrates<br />

• PUR 570: Five degrees of gloss are<br />

possible – high gloss to matt<br />

• PUR 555: For extremely matt surfaces<br />

• PUR 560: For textured surfaces<br />

ACRYLIC PLUS.<br />

Acrylic Plus Top Coat 575.<br />

• Glossy 2K top coat<br />

• Exceptionally lightfast<br />

• Specially designed for painting window frames<br />

• Five degrees of gloss – high gloss to matt<br />

ACRYLIC.<br />

Acrylic Top Coat 550.<br />

• Glossy 2K top coat (polyacrylate-based)<br />

• For 1-coat application/without primer<br />

• Applied straight onto steel, aluminium and zinc<br />

• For indoor and outdoor applications<br />

STONE CHIP PROTECTION.<br />

Stone Chip Protection Top Coat 515.<br />

• 2K top coat (polyacrylate)<br />

• High mechanical strength<br />

• Optimized for application on large items<br />

of equipment<br />

IRON MICA.<br />

ALKYD.<br />

EPOXY.<br />

Iron Mica Top Coat 510.<br />

• 2K top coat (polyacrylate)<br />

• High mechanical and chemical resistance<br />

• Typical gloss and effect<br />

• Outstanding weather-resistance<br />

Synthetic Resin Top Coat 530.<br />

• High-gloss 1K top coat (alkyd resin/<br />

synthetic resin)<br />

• For indoors and outdoors<br />

• Also suitable for rolling and brushing<br />

• Five degrees of gloss – high gloss to matt<br />

Epoxy Top Coat 540.<br />

• 2K epoxy system<br />

• Especially for application indoors<br />

• For objects with extreme surface hardness<br />

and high mechanical and chemical resistance<br />

• Three degrees of gloss – glossy to matt<br />

NITROCELLULOSE.<br />

NC Top Coat 520.<br />

• 1K top coat (nitrocellulose)<br />

• For indoors<br />

• Rapid air drying<br />

• Four degrees of gloss – glossy to matt<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011

ems-p.com<br />

© Copyright by <strong>Spies</strong> <strong>Hecker</strong> GmbH 06/2011<br />

<strong>Spies</strong> <strong>Hecker</strong> GmbH<br />

Horbeller Straße 17<br />

50858 Köln<br />

Tel.: +4922346019 - 3630<br />

Fax: +4922346019 - 3880<br />

www.spieshecker.com