Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

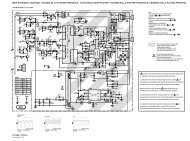

SECTION 4<br />

ADJUSTMENT<br />

4.1 Before adjustment<br />

4.1.1 Precaution<br />

• The adjustments of this unit inclu<strong>de</strong> the mechanism compatibility<br />

and electrical adjustments. During the performance<br />

of this work, be sure to observe the precautions for<br />

each type of adjustment.<br />

• If there is a reference to a signal input method in the signal<br />

column of the adjustment chart, “Ext. S-input” means the<br />

Y/C separated vi<strong>de</strong>o signal and “Ext. input” means the<br />

composite vi<strong>de</strong>o signal input.<br />

• Unless otherwise specified, all measuring points and<br />

adjustment parts are located on the Main board.<br />

4.1.2 Required <strong>test</strong> equipments<br />

• Color (colour) television or monitor<br />

• Oscilloscope: wi<strong>de</strong>-band, dual-trace, triggered <strong>de</strong>layed sweep<br />

• Signal generator: RF / IF sweep / marker<br />

• Signal generator: stairstep, color (colour) bar [NTSC]<br />

• Recording tape<br />

• Digit-key remote controller(provi<strong>de</strong>d)<br />

4.1.3 Required adjustment tools<br />

• : Used --- : Not used<br />

Mechanism<br />

compatibility<br />

adjustment<br />

Electrical<br />

adjustment<br />

Roller driver • ---<br />

Jig RCU --- •<br />

Back tension cassette gauge • ---<br />

Alignment tape(MHP) • ---<br />

Alignment tape(MHP-L) • •<br />

Roller driver<br />

PTU94002<br />

Alignment tape<br />

(SP, stairstep, NTSC)<br />

MHP<br />

Jig RCU<br />

PTU94023B<br />

Alignment tape<br />

(EP, stairstep, NTSC)<br />

MHP-L<br />

Back tension cassette gauge<br />

PUJ48076-2<br />

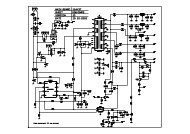

4.1.4 Color (colour) bar signal,Color (colour) bar pattern<br />

1V<br />

Color(colour) bar signal [NTSC]<br />

White(75%)<br />

100 IRE<br />

40 IRE<br />

Horizontal sync<br />

White(100%)<br />

Q<br />

Yellow<br />

Cyan<br />

Green<br />

Magenta<br />

Red<br />

Blue<br />

I<br />

Burst<br />

40 IRE<br />

Color(colour) bar pattern [NTSC]<br />

(75%)<br />

White<br />

Yellow<br />

Cyan<br />

Green<br />

Magenta<br />

Red<br />

White<br />

Q<br />

100%<br />

I Black<br />

Blue<br />

4.1.5 Switch settings<br />

When adjusting this unit, set the VCR mo<strong>de</strong> and switches<br />

as <strong>de</strong>scribed below.<br />

• When using the Jig RCU, it is required to set the VCR to the<br />

Jig RCU mo<strong>de</strong> (the mo<strong>de</strong> in which co<strong>de</strong>s from the Jig RCU can<br />

be received). (See "section 2 SPECIFIC <strong>SERVICE</strong> INSTRUC-<br />

TIONS".)<br />

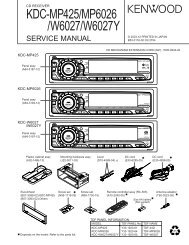

Jig RCU<br />

[Data transmitting method]<br />

Depress the " "( 3 ) button<br />

after the data co<strong>de</strong> is set.<br />

CUSTOM CODE<br />

43: A CODE<br />

DATA CODE<br />

Fig.4-1 Jig RCU [PTU94023B]<br />

• Set the switches as shown below unless otherwise specified<br />

on the relevant adjustment chart. The switches that are not listed<br />

below can be set as <strong>de</strong>sired.<br />

If the VCR is not equipped with the functions <strong>de</strong>tailed below,<br />

setup is not required.<br />

AUTO PICTURE/VIDEO CALIBRATION/<br />

B.E.S.T./D.S.P.C.<br />

PICTURE CONTROL/SMART PICTURE<br />

VIDEO STABILIZER<br />

TBC<br />

Digital 3R<br />

VIDEO NAVIGATION/TAPE MANAGER<br />

BLUE BACK<br />

OFF<br />

INITIAL MODE<br />

NORMAL/NATURAL<br />

OFF<br />

ON<br />

ON<br />

OFF<br />

OFF<br />

4.1.6 Manual tracking mo<strong>de</strong> (Auto tracking ON/OFF) setting<br />

(1) In or<strong>de</strong>r to set to the manual tracking mo<strong>de</strong> during tape<br />

playback, press the “SP/EP(LP)”button on the remote control<br />

unit.<br />

• Each press of the button switches the auto tracking ON<br />

or OFF.<br />

• When the manual tracking mo<strong>de</strong> is set, the tracking is<br />

placed at the center position.<br />

(2) Press “channel +/-” to adjust the tracking manually.<br />

4.1.7 EVR Adjustment<br />

Some of the electrical adjustments require the adjustment performed<br />

by the EVR system. The main unit have EEPROMs for<br />

storing the EVR adjustment data and user setups.<br />

Notes:<br />

• In the EVR adjustment mo<strong>de</strong>, the value is varied with the<br />

channel buttons (+, -). The adjusted data is stored when<br />

the setting mo<strong>de</strong> changes (from PB to STOP, when the<br />

tape speed is changed, etc.). Take care to i<strong>de</strong>ntify the<br />

current mo<strong>de</strong> of each adjustment item when making an<br />

adjustment.<br />

• When changing the address setting in the EVR adjustment<br />

mo<strong>de</strong>, use the Jig RCU or the remote controller<br />

having numeric keypad with which a numeric co<strong>de</strong> can<br />

be directly input.<br />

The remote control co<strong>de</strong> of the Jig RCU corresponds to<br />

each of the digit keys on the remote controller as follows.<br />

1-10 (No.YD006)