CORROSION GUIDE 181108_new table content format ... - Reichhold

CORROSION GUIDE 181108_new table content format ... - Reichhold

CORROSION GUIDE 181108_new table content format ... - Reichhold

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Resin Descriptions<br />

Chlorendic Polyester Resins<br />

Chlorendic polyester resins are based on the<br />

incorporation of chlorendic anhydride or chlorendic acid<br />

(also called HET acid) into the polymer backbone. Their<br />

most no<strong>table</strong> advantage is superior resistance to mixed<br />

acid and oxidizing environments, which makes them<br />

widely used for bleaching and chromic acid or nitric<br />

acid containing environments, such as in electroplating<br />

applications. The cross linked structure is quite dense,<br />

which results in high heat distortion and good elevated<br />

temperature properties. This is a dense structure that<br />

can display reduced ductility and reduced tensile<br />

elongation. Despite good acid resistance, chlorendic<br />

resins should not be used in alkaline environments.<br />

Due to the halogen <strong>content</strong>, chlorendic resins display<br />

flame retardant and smoke reduction properties.<br />

The DION ® 797 series are chlorendic anhydride based<br />

resins with good corrosion resistance and thermal<br />

properties up to 350° F. DION ® 797 is supplied as a<br />

pre-promoted and thixotropic version. An ASTM E-84<br />

flame spread rating of 30 (Class II) is obtained with the<br />

use of 5% antimony trioxide. Many thermal and corrosion<br />

resistant properties are superior to those of<br />

competitive chlorendic resins.<br />

Atprime ® 2 Bonding & Primer<br />

Atprime ® 2 is a two-component, moisture-activated<br />

primer that provides enhanced bonding of composite<br />

materials to a variety of substrates, such as FRP,<br />

concrete, steel, or thermoplastics. It is especially<br />

well suited for bonding to non-air-inhibited surfaces<br />

associated with contact molding or aged FRP<br />

composites. This ability is achieved due to the <strong>format</strong>ion<br />

of a chemical bond to the FRP surface. Atprime® 2 is<br />

free of methylene chloride and features good storage<br />

stability.<br />

Atprime ® 2 is well-suited for repairs of FRP structures.<br />

Many FRP structures have been known to fail due to<br />

the failure of secondary bonds, which can serve as<br />

the weakest link in an otherwise sound structure.<br />

Thus Atprime ® 2 merits important consideration in<br />

FRP fabrication. The curing mechanism relies on<br />

ambient humidity and does not employ peroxide<br />

chemistry.<br />

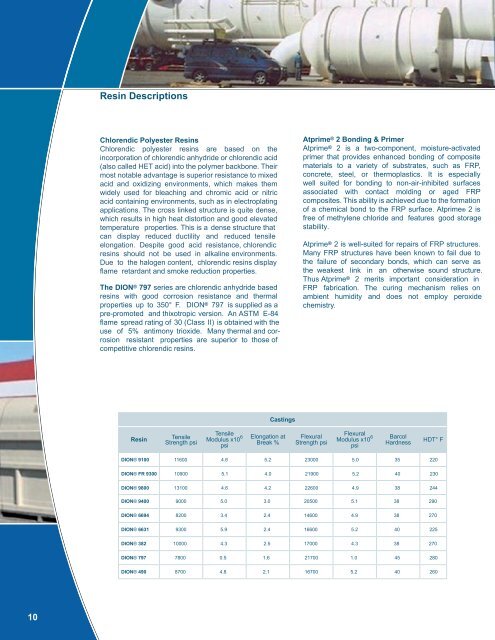

Castings<br />

Resin<br />

Tensile<br />

Strength psi<br />

Tensile<br />

Modulus x10 6<br />

psi<br />

Elongation at<br />

Break %<br />

Flexural<br />

Strength psi<br />

Flexural<br />

Modulus x10 6<br />

psi<br />

Barcol<br />

Hardness<br />

HDT° F<br />

DION® 9100 11600 4.6 5.2 23000 5.0 35 220<br />

DION® FR 9300 10900 5.1 4.0 21900 5.2 40 230<br />

DION® 9800 13100 4.6 4.2 22600 4.9 38 244<br />

DION® 9400 9000 5.0 3.0 20500 5.1 38 290<br />

DION® 6694 8200 3.4 2.4 14600 4.9 38 270<br />

DION® 6631 9300 5.9 2.4 16600 5.2 40 225<br />

DION® 382 10000 4.3 2.5 17000 4.3 38 270<br />

DION® 797 7800 0.5 1.6 21700 1.0 45 280<br />

DION® 490 8700 4.8 2.1 16700 5.2 40 260<br />

10