CORROSION GUIDE 181108_new table content format ... - Reichhold

CORROSION GUIDE 181108_new table content format ... - Reichhold

CORROSION GUIDE 181108_new table content format ... - Reichhold

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

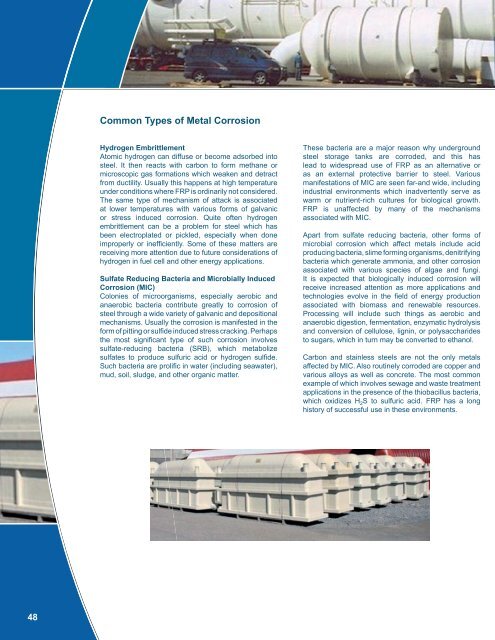

Common Types of Metal Corrosion<br />

Hydrogen Embrittlement<br />

Atomic hydrogen can diffuse or become adsorbed into<br />

steel. It then reacts with carbon to form methane or<br />

microscopic gas <strong>format</strong>ions which weaken and detract<br />

from ductility. Usually this happens at high temperature<br />

under conditions where FRP is ordinarily not considered.<br />

The same type of mechanism of attack is associated<br />

at lower temperatures with various forms of galvanic<br />

or stress induced corrosion. Quite often hydrogen<br />

embrittlement can be a problem for steel which has<br />

been electroplated or pickled, especially when done<br />

improperly or ineffi ciently. Some of these matters are<br />

receiving more attention due to future considerations of<br />

hydrogen in fuel cell and other energy applications.<br />

Sulfate Reducing Bacteria and Microbially Induced<br />

Corrosion (MIC)<br />

Colonies of microorganisms, especially aerobic and<br />

anaerobic bacteria contribute greatly to corrosion of<br />

steel through a wide variety of galvanic and depositional<br />

mechanisms. Usually the corrosion is manifested in the<br />

form of pitting or sulfi de induced stress cracking. Perhaps<br />

the most signifi cant type of such corrosion involves<br />

sulfate-reducing bacteria (SRB), which metabolize<br />

sulfates to produce sulfuric acid or hydrogen sulfi de.<br />

Such bacteria are prolifi c in water (including seawater),<br />

mud, soil, sludge, and other organic matter.<br />

These bacteria are a major reason why underground<br />

steel storage tanks are corroded, and this has<br />

lead to widespread use of FRP as an alternative or<br />

as an external protective barrier to steel. Various<br />

manifestations of MIC are seen far-and wide, including<br />

industrial environments which inadvertently serve as<br />

warm or nutrient-rich cultures for biological growth.<br />

FRP is unaffected by many of the mechanisms<br />

associated with MIC.<br />

Apart from sulfate reducing bacteria, other forms of<br />

microbial corrosion which affect metals include acid<br />

producing bacteria, slime forming organisms, denitrifying<br />

bacteria which generate ammonia, and other corrosion<br />

associated with various species of algae and fungi.<br />

It is expected that biologically induced corrosion will<br />

receive increased attention as more applications and<br />

technologies evolve in the fi eld of energy production<br />

associated with biomass and re<strong>new</strong>able resources.<br />

Processing will include such things as aerobic and<br />

anaerobic digestion, fermentation, enzymatic hydrolysis<br />

and conversion of cellulose, lignin, or polysaccharides<br />

to sugars, which in turn may be converted to ethanol.<br />

Carbon and stainless steels are not the only metals<br />

affected by MIC. Also routinely corroded are copper and<br />

various alloys as well as concrete. The most common<br />

example of which involves sewage and waste treatment<br />

applications in the presence of the thiobacillus bacteria,<br />

which oxidizes H 2 S to sulfuric acid. FRP has a long<br />

history of successful use in these environments.<br />

48