CORROSION GUIDE 181108_new table content format ... - Reichhold

CORROSION GUIDE 181108_new table content format ... - Reichhold

CORROSION GUIDE 181108_new table content format ... - Reichhold

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Laminate Construction<br />

Post-Curing<br />

Post-Curing at elevated temperatures can enhance<br />

the performance of a composite product in most<br />

environments. Post-Curing of composites provides<br />

two benefi ts. The curing reaction is driven to completion<br />

which maximizes the cross-link density of<br />

the resin system, thus eliminating unreacted crosslinking<br />

sites in the resin. This improves both chemical<br />

resistance and physical properties. Thorough and even<br />

Post-Curing for an extended period of time can also<br />

relieve stresses formed in the laminate during cure,<br />

thus reducing the likelihood of warping during normal<br />

thermal cycling/ operation.<br />

In general, one can relate the recommended Post-<br />

Curing temperatures to the chemistry of the matrix resin<br />

used in the construction - this mostly relates to the HDT<br />

of the resin.<br />

It is recommended that the construction is kept for 16-<br />

24 hours at room temperature (>18° C) before Post-<br />

Curing at elevated temperature starts. Increasing and<br />

decreasing temperature should be done stepwise to<br />

avoid possible thermal shock, and consequent possible<br />

built-in stresses.<br />

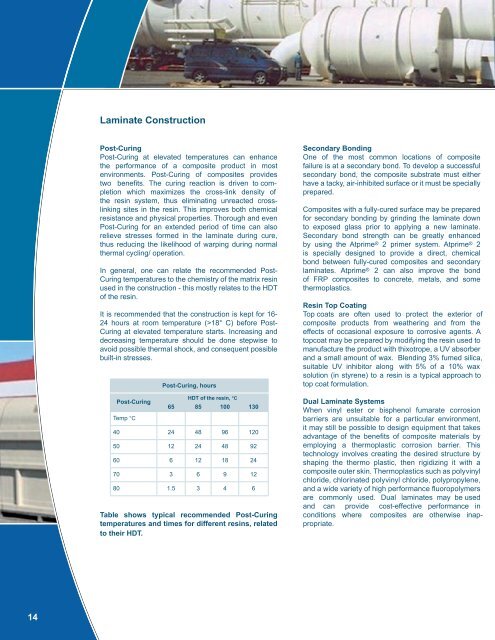

Post-Curing<br />

Temp °C<br />

Post-Curing, hours<br />

HDT of the resin, °C<br />

65 85 100 130<br />

40 24 48 96 120<br />

50 12 24 48 92<br />

60 6 12 18 24<br />

70 3 6 9 12<br />

80 1.5 3 4 6<br />

Table shows typical recommended Post-Curing<br />

temperatures and times for different resins, related<br />

to their HDT.<br />

Secondary Bonding<br />

One of the most common locations of composite<br />

failure is at a secondary bond. To develop a successful<br />

secondary bond, the composite substrate must either<br />

have a tacky, air-inhibited surface or it must be specially<br />

prepared.<br />

Composites with a fully-cured surface may be prepared<br />

for secondary bonding by grinding the laminate down<br />

to exposed glass prior to applying a <strong>new</strong> laminate.<br />

Secondary bond strength can be greatly enhanced<br />

by using the Atprime ® 2 primer system. Atprime ® 2<br />

is specially designed to provide a direct, chemical<br />

bond between fully-cured composites and secondary<br />

laminates. Atprime ® 2 can also improve the bond<br />

of FRP composites to concrete, metals, and some<br />

thermoplastics.<br />

Resin Top Coating<br />

Top coats are often used to protect the exterior of<br />

composite products from weathering and from the<br />

effects of occasional exposure to corrosive agents. A<br />

topcoat may be prepared by modifying the resin used to<br />

manufacture the product with thixotrope, a UV absorber<br />

and a small amount of wax. Blending 3% fumed silica,<br />

sui<strong>table</strong> UV inhibitor along with 5% of a 10% wax<br />

solution (in styrene) to a resin is a typical approach to<br />

top coat formulation.<br />

Dual Laminate Systems<br />

When vinyl ester or bisphenol fumarate corrosion<br />

barriers are unsui<strong>table</strong> for a particular environment,<br />

it may still be possible to design equipment that takes<br />

advantage of the benefi ts of composite materials by<br />

employing a thermoplastic corrosion barrier. This<br />

technology involves creating the desired structure by<br />

shaping the thermo plastic, then rigidizing it with a<br />

composite outer skin. Thermoplastics such as polyvinyl<br />

chloride, chlorinated polyvinyl chloride, polypropylene,<br />

and a wide variety of high performance fl uoropolymers<br />

are commonly used. Dual laminates may be used<br />

and can provide cost-effective performance in<br />

conditions where composites are otherwise inappropriate.<br />

14