Needle Roller Bearings - Ntn-snr.com

Needle Roller Bearings - Ntn-snr.com

Needle Roller Bearings - Ntn-snr.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical Data<br />

NTN<br />

11.3 Calculation Examples<br />

11.3.1 Shrinkage factor and post-installation<br />

clearance of drawn cup needle roller bearing<br />

The re<strong>com</strong>mended fit data for the standard bearings is<br />

as described in Table 1 on page B-33. This paragraph<br />

describes hereunder the calculation methods to be used<br />

when the bearing fit conditions are reviewed in detail.<br />

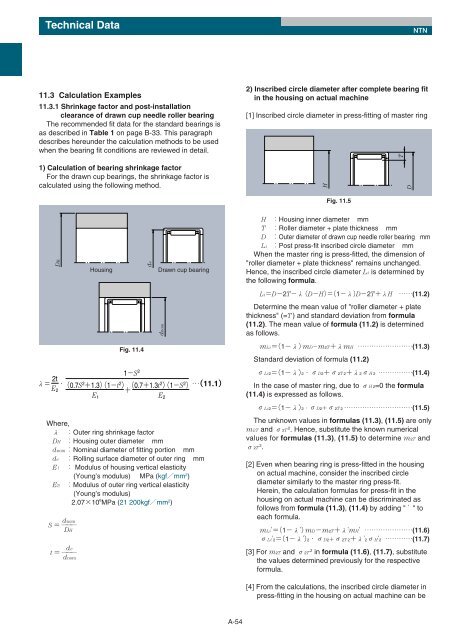

2) Inscribed circle diameter after <strong>com</strong>plete bearing fit<br />

in the housing on actual machine<br />

[1] Inscribed circle diameter in press-fitting of master ring<br />

T<br />

1) Calculation of bearing shrinkage factor<br />

For the drawn cup bearings, the shrinkage factor is<br />

calculated using the following method.<br />

H<br />

Fig. 11.5<br />

D<br />

DH<br />

Housing<br />

de<br />

Drawn cup bearing<br />

1S 2<br />

2t<br />

0.7S 2 1.31t 2 0.71.3t 2 1S 2 11.1<br />

E 2<br />

<br />

E 1 E 2<br />

Where,<br />

Outer ring shrinkage factor<br />

DH Housing outer diameter mm<br />

dnom Nominal diameter of fitting portion mm<br />

de Rolling surface diameter of outer ring mm<br />

E Modulus of housing vertical elasticity<br />

(Young’s modulus) MPa (kgfmm 2 )<br />

E Modulus of outer ring vertical elasticity<br />

(Young’s modulus)<br />

2.0710 6 MPa (21 200kgfmm 2 )<br />

dnom<br />

S <br />

DH<br />

de<br />

t <br />

dnom<br />

Fig. 11.4<br />

dnom<br />

H Housing inner diameter mm<br />

T <strong>Roller</strong> diameter + plate thickness mm<br />

D Outer diameter of drawn cup needle roller bearing mm<br />

Li Post press-fit inscribed circle diameter mm<br />

When the master ring is press-fitted, the dimension of<br />

"roller diameter + plate thickness" remains unchanged.<br />

Hence, the inscribed circle diameter Li is determined by<br />

the following formula.<br />

LiD2TDH1D2TH<br />

(11.2)<br />

Determine the mean value of "roller diameter + plate<br />

thickness" (=T) and standard deviation from formula<br />

(11.2). The mean value of formula (11.2) is determined<br />

as follows.<br />

mLi1mDm2TmH<br />

Standard deviation of formula (11.2)<br />

(11.3)<br />

Li212D22T 22H 2 (11.4)<br />

In the case of master ring, due to H 2=0 the formula<br />

(11.4) is expressed as follows.<br />

Li212D22T 2 (11.5)<br />

The unknown values in formulas (11.3), (11.5) are only<br />

mT and 2T 2 . Hence, substitute the known numerical<br />

values for formulas (11.3), (11.5) to determine m2T and<br />

2T 2 .<br />

[2] Even when bearing ring is press-fitted in the housing<br />

on actual machine, consider the inscribed circle<br />

diameter similarly to the master ring press-fit.<br />

Herein, the calculation formulas for press-fit in the<br />

housing on actual machine can be discriminated as<br />

follows from formula (11.3), (11.4) by adding " " to<br />

each formula.<br />

mLi1mDm2TmH (11.6)<br />

Li212D22T 22H2 (11.7)<br />

[3] For m2T and 2T 2 in formula (11.6), (11.7), substitute<br />

the values determined previously for the respective<br />

formula.<br />

[4] From the calculations, the inscribed circle diameter in<br />

press-fitting in the housing on actual machine can be<br />

A-54