MATERIALS AND SYSTEMS

MATERIALS AND SYSTEMS

MATERIALS AND SYSTEMS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ing economy in the building’s structure. However, this benefit is accompanied by several<br />

concerns.<br />

Steel studs can deflect considerably before the bending stress in them exceeds their ultimate<br />

capacity. Brick veneer, on the other hand, deflects by a very small amount before the<br />

mortar joints open. Open mortar joints weaken the wall and also increase the probability of<br />

leakage, corroding the anchors.<br />

Thus, the steel stud backup and brick veneer assembly performs well only if the stud<br />

wall is sufficiently stiff. To obtain the necessary stiffness, the deflection of studs must be<br />

controlled to a fairly small value. In fact, the design of a steel stud backup wall to resist the<br />

lateral loads is governed not by the strength of studs but by their deflection.<br />

The Brick Industry Association (BIA) recommends that the lateral load deflection of<br />

steel studs, when used as backup for brick veneer assembly, should not exceed<br />

stud span<br />

600<br />

where the stud span is the unsupported height of studs. For example, if the height of studs<br />

(e.g., from the top of the floor to the bottom of the spandrel beam in Figure 26.7) is 10 ft,<br />

the deflection of studs under the lateral load must be less than<br />

110 * 122<br />

= 0.2 in.<br />

600<br />

Increasing the stiffness of studs increases the cost of the assembly. Another concern with<br />

steel stud backup is that the veneer is anchored to the backup only through screws that<br />

engage the threads within a light-gauge stud sheet. Over a period of time, condensation can<br />

corrode the screws and the corresponding holes in studs, making the screws come loose.<br />

Condensation is, therefore, an important concern in a steel stud–backed veneer. A more<br />

serious concern is that the anchor installer will miss the studs.<br />

By comparison with steel studs, anchoring of brick veneer to a CMU backup does not<br />

depend on screws; and hence it is more forgiving. Additionally, the anchors in a CMU<br />

backup wall are embedded in the mortar joints, and if they are made of stainless steel, their<br />

corrosion probability is extremely low.<br />

Another advantage of a CMU backup wall is its inherent stiffness. To obtain a steel stud<br />

backup wall of the same stiffness as a CMU backup wall substantially increases the cost of<br />

the stud backup.<br />

NOTE<br />

CHAPTER 26<br />

EXTERIOR WALL CLADDING<br />

Defection of a Steel Stud<br />

Wall Assembly<br />

The design criterion of deflection<br />

not exceeding span<br />

divided by 600, suggested by<br />

BIA, is the minimum requirement.<br />

For critical buildings, a<br />

more stringent deflection criterion,<br />

such as span divided by<br />

720 or span divided by 900, is<br />

recommended by some<br />

experts.<br />

Steel stud manufacturers<br />

generally provide tables for the<br />

selection of their studs to conform<br />

to the deflection criteria.<br />

26.5 AESTHETICS OF BRICK VENEER<br />

It is neither possible nor within the scope of this text to illustrate various techniques used<br />

to add visual interest to brick veneer facades. However, a few examples are provided:<br />

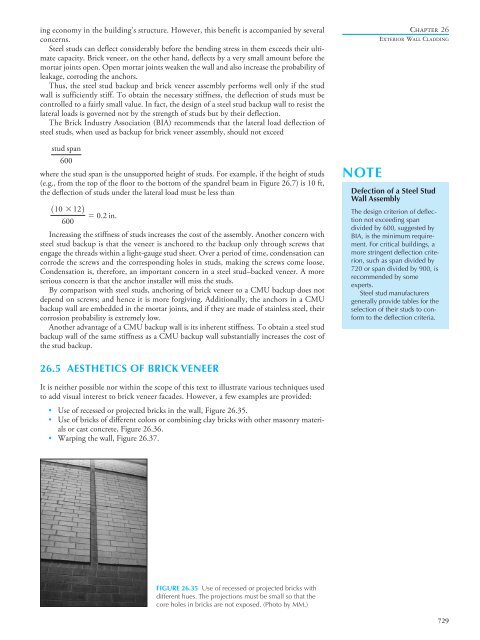

• Use of recessed or projected bricks in the wall, Figure 26.35.<br />

• Use of bricks of different colors or combining clay bricks with other masonry materials<br />

or cast concrete, Figure 26.36.<br />

• Warping the wall, Figure 26.37.<br />

FIGURE 26.35 Use of recessed or projected bricks with<br />

different hues. The projections must be small so that the<br />

core holes in bricks are not exposed. (Photo by MM.)<br />

729