Rolling bearings in electric motors and generators

Rolling bearings in electric motors and generators

Rolling bearings in electric motors and generators

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071<br />

7 SKF solutions<br />

Condition monitor<strong>in</strong>g<br />

Condition monitor<strong>in</strong>g<br />

Vibration Pen plus<br />

The aim of us<strong>in</strong>g a condition monitor<strong>in</strong>g<br />

system is to measure the condition<br />

of “wear” components <strong>and</strong> other functions<br />

that <strong>in</strong>fluence mach<strong>in</strong>e reliability.<br />

The advantage of condition monitor<strong>in</strong>g<br />

us<strong>in</strong>g vibration analysis is that it acts<br />

as an early warn<strong>in</strong>g system. Consequently,<br />

this means that there is sufficient<br />

time for corrective actions <strong>and</strong><br />

bear<strong>in</strong>g replacement can be well<br />

planned (➔ diagram 1 ).<br />

Examples of components <strong>and</strong> systems<br />

that can be monitored are:<br />

• <strong>bear<strong>in</strong>gs</strong><br />

• belt drives<br />

• gearboxes<br />

• <strong>electric</strong> <strong>motors</strong><br />

Some components, such as seals, can<br />

not be monitored, but need manual<br />

<strong>in</strong>spection.<br />

Multi-parameter monitor<strong>in</strong>g<br />

Jo<strong>in</strong>tly developed by SKF Condition<br />

Monitor<strong>in</strong>g <strong>and</strong> the SKF Eng<strong>in</strong>eer<strong>in</strong>g<br />

<strong>and</strong> Research Centre <strong>in</strong> the Netherl<strong>and</strong>s,<br />

multi-parameter monitor<strong>in</strong>g is<br />

the most comprehensive, reliable <strong>and</strong><br />

accurate approach to mach<strong>in</strong>ery<br />

monitor<strong>in</strong>g <strong>and</strong> analysis. Collect<strong>in</strong>g<br />

<strong>and</strong> analys<strong>in</strong>g multiple measurement<br />

parameters greatly <strong>in</strong>creases the capability<br />

to accurately <strong>and</strong> readily identify<br />

bear<strong>in</strong>g damage <strong>and</strong> other mach<strong>in</strong>ery<br />

problems.<br />

By measur<strong>in</strong>g a number of mach<strong>in</strong>ery<br />

related parameters such as acceleration,<br />

velocity <strong>and</strong> displacement <strong>and</strong><br />

process parameters such as speed,<br />

temperature, current, pressure <strong>and</strong><br />

flow, users ga<strong>in</strong> <strong>in</strong>sight <strong>in</strong>to a specific<br />

mach<strong>in</strong>e’s condition. Advanced analysis<br />

techniques such as Acceleration<br />

Envelop<strong>in</strong>g enable analysts to take<br />

the guesswork out of ma<strong>in</strong>tenance<br />

by supply<strong>in</strong>g the required <strong>in</strong>formation<br />

needed <strong>in</strong> order to take the necessary<br />

measures prevent<strong>in</strong>g unscheduled<br />

downtime.<br />

Vibration<br />

Traditional low frequency vibration<br />

monitor<strong>in</strong>g rema<strong>in</strong>s essential <strong>in</strong> identify<strong>in</strong>g<br />

problematic mach<strong>in</strong>ery conditions.<br />

Generally, malfunctions that cause vibration<br />

<strong>and</strong> loss of mach<strong>in</strong>e efficiency<br />

ultimately result <strong>in</strong> damage to the<br />

mach<strong>in</strong>e or its components. While low<br />

frequency vibration analysis can be an<br />

effective <strong>in</strong>dicator of bear<strong>in</strong>g damage,<br />

it may not be the most timely.<br />

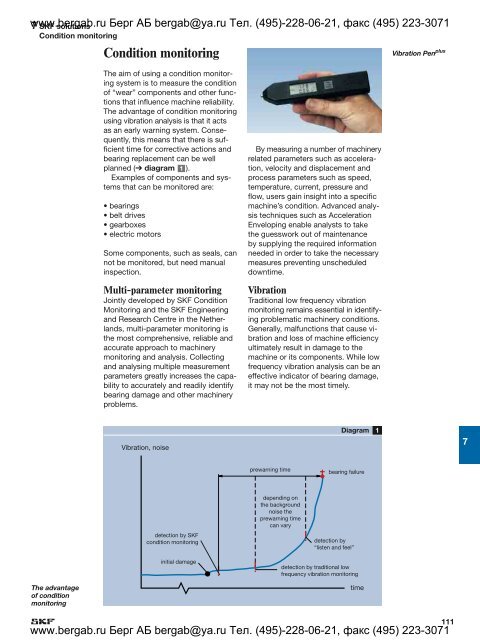

Vibration, noise<br />

Diagram<br />

1<br />

7<br />

prewarn<strong>in</strong>g time<br />

bear<strong>in</strong>g failure<br />

detection by SKF<br />

condition monitor<strong>in</strong>g<br />

depend<strong>in</strong>g on<br />

the background<br />

noise the<br />

prewarn<strong>in</strong>g time<br />

can vary<br />

!<br />

detection by<br />

“listen <strong>and</strong> feel”<br />

<strong>in</strong>itial damage<br />

! !<br />

detection by traditional low<br />

frequency vibration monitor<strong>in</strong>g<br />

The advantage<br />

of condition<br />

monitor<strong>in</strong>g<br />

time<br />

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071<br />

111