Rolling bearings in electric motors and generators

Rolling bearings in electric motors and generators

Rolling bearings in electric motors and generators

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071<br />

4 Lubrication <strong>and</strong> seal<strong>in</strong>g<br />

Relubrication <strong>in</strong>tervals<br />

For many applications, there is<br />

a practical grease lubrication limit,<br />

when the bear<strong>in</strong>g r<strong>in</strong>g with the highest<br />

temperature exceeds an operat<strong>in</strong>g<br />

temperature of 100 °C. Above this<br />

temperature special greases should<br />

be used. In addition, the temperature<br />

stability of the bear<strong>in</strong>g <strong>and</strong> premature<br />

seal failure should be taken <strong>in</strong>to consideration.<br />

In <strong>electric</strong> mach<strong>in</strong>es, <strong>bear<strong>in</strong>gs</strong><br />

often operate at temperatures<br />

close to 100 °C. Under certa<strong>in</strong> conditions,<br />

SKF LGHP 2 grease is a suitable<br />

selection (➔ diagram 2 , page 60).<br />

For high temperature applications<br />

please consult the SKF application<br />

eng<strong>in</strong>eer<strong>in</strong>g service.<br />

Vertical shaft<br />

For <strong>bear<strong>in</strong>gs</strong> on vertical shafts, the<br />

<strong>in</strong>tervals obta<strong>in</strong>ed from diagram 3 ,<br />

page 65, should be halved. The use<br />

of a good seal or reta<strong>in</strong><strong>in</strong>g shield is a<br />

prerequisite to prevent grease leak<strong>in</strong>g<br />

from the bear<strong>in</strong>g arrangement.<br />

Table<br />

4<br />

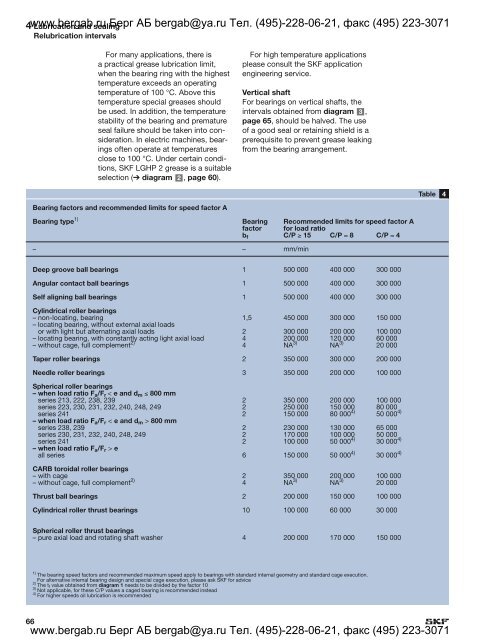

Bear<strong>in</strong>g factors <strong>and</strong> recommended limits for speed factor A<br />

Bear<strong>in</strong>g type 1) Bear<strong>in</strong>g Recommended limits for speed factor A<br />

factor for load ratio<br />

b f C/P ≥ 15 C/P ≈ 8 C/P ≈ 4<br />

– – mm/m<strong>in</strong><br />

Deep groove ball <strong>bear<strong>in</strong>gs</strong> 1 500 000 400 000 300 000<br />

Angular contact ball <strong>bear<strong>in</strong>gs</strong> 1 500 000 400 000 300 000<br />

Self align<strong>in</strong>g ball <strong>bear<strong>in</strong>gs</strong> 1 500 000 400 000 300 000<br />

Cyl<strong>in</strong>drical roller <strong>bear<strong>in</strong>gs</strong><br />

– non-locat<strong>in</strong>g, bear<strong>in</strong>g 1,5 450 000 300 000 150 000<br />

– locat<strong>in</strong>g bear<strong>in</strong>g, without external axial loads<br />

or with light but alternat<strong>in</strong>g axial loads 2 300 000 200 000 100 000<br />

– locat<strong>in</strong>g bear<strong>in</strong>g, with constantly act<strong>in</strong>g light axial load 4 200 000 120 000 60 000<br />

– without cage, full complement 2) 4 NA 3) NA 3) 20 000<br />

Taper roller <strong>bear<strong>in</strong>gs</strong> 2 350 000 300 000 200 000<br />

Needle roller <strong>bear<strong>in</strong>gs</strong> 3 350 000 200 000 100 000<br />

Spherical roller <strong>bear<strong>in</strong>gs</strong><br />

– when load ratio F a /F r < e <strong>and</strong> d m ≤ 800 mm<br />

series 213, 222, 238, 239 2 350 000 200 000 100 000<br />

series 223, 230, 231, 232, 240, 248, 249 2 250 000 150 000 80 000<br />

series 241<br />

– when load ratio F a /F r < e <strong>and</strong> d m > 800 mm<br />

2 150 000 80 000 4) 50 000 4)<br />

series 238, 239 2 230 000 130 000 65 000<br />

series 230, 231, 232, 240, 248, 249 2 170 000 100 000 50 000<br />

series 241<br />

– when load ratio F a /F r > e<br />

2 100 000 50 000 4) 30 000 4)<br />

all series 6 150 000 50 000 4) 30 000 4)<br />

CARB toroidal roller <strong>bear<strong>in</strong>gs</strong><br />

– with cage 2 350 000 200 000 100 000<br />

– without cage, full complement 2) 4 NA 3) NA 3) 20 000<br />

Thrust ball <strong>bear<strong>in</strong>gs</strong> 2 200 000 150 000 100 000<br />

Cyl<strong>in</strong>drical roller thrust <strong>bear<strong>in</strong>gs</strong> 10 100 000 60 000 30 000<br />

Spherical roller thrust <strong>bear<strong>in</strong>gs</strong><br />

– pure axial load <strong>and</strong> rotat<strong>in</strong>g shaft washer 4 200 000 170 000 150 000<br />

1) The bear<strong>in</strong>g speed factors <strong>and</strong> recommended maximum speed apply to <strong>bear<strong>in</strong>gs</strong> with st<strong>and</strong>ard <strong>in</strong>ternal geometry <strong>and</strong> st<strong>and</strong>ard cage execution.<br />

For alternative <strong>in</strong>ternal bear<strong>in</strong>g design <strong>and</strong> special cage execution, please ask SKF for advice<br />

2) The t f value obta<strong>in</strong>ed from diagram 1 needs to be divided by the factor 10<br />

3) Not applicable, for these C/P values a caged bear<strong>in</strong>g is recommended <strong>in</strong>stead<br />

4) For higher speeds oil lubrication is recommended<br />

66<br />

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071