Rolling bearings in electric motors and generators

Rolling bearings in electric motors and generators

Rolling bearings in electric motors and generators

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071<br />

1 <strong>Roll<strong>in</strong>g</strong> <strong>bear<strong>in</strong>gs</strong> <strong>in</strong> <strong>electric</strong> mach<strong>in</strong>es<br />

Design requirements<br />

Dimensions<br />

In most cases, power output determ<strong>in</strong>es<br />

shaft size, <strong>and</strong> shaft size determ<strong>in</strong>es<br />

the bore diameter of the <strong>bear<strong>in</strong>gs</strong>.<br />

In recent years, however, the<br />

tendency has been to use <strong>bear<strong>in</strong>gs</strong><br />

with smaller cross sections because<br />

they require less space.<br />

Loads<br />

In order to select the best bear<strong>in</strong>g<br />

for a particular application, all loads<br />

should be considered <strong>and</strong> not just<br />

the weights <strong>in</strong>volved <strong>and</strong> the forces<br />

derived from the power transmitted.<br />

Be sure to <strong>in</strong>clude additional forces<br />

like the magnetic pull result<strong>in</strong>g from<br />

unsymmetrical air gaps, dynamic<br />

forces due to <strong>in</strong>accurate adjustment,<br />

out-of-balance situations, pitch errors<br />

<strong>in</strong> gears, as well as any thrust loads.<br />

Heavy loads are generally carried by<br />

roller <strong>bear<strong>in</strong>gs</strong>, where lighter loads are<br />

carried by ball <strong>bear<strong>in</strong>gs</strong>. Drive forces<br />

are considered only when belts or gears<br />

are utilized. Loads can be radial, axial<br />

or a comb<strong>in</strong>ation of the two. Certa<strong>in</strong><br />

<strong>bear<strong>in</strong>gs</strong>, such as cyl<strong>in</strong>drical roller <strong>bear<strong>in</strong>gs</strong>,<br />

usually carry radial loads only;<br />

where other <strong>bear<strong>in</strong>gs</strong>, such as angular<br />

contact ball <strong>bear<strong>in</strong>gs</strong>, are more suited<br />

for axial loads.<br />

In order to provide satisfactory<br />

operation, ball or roller <strong>bear<strong>in</strong>gs</strong> must<br />

always be subjected to a given m<strong>in</strong>imum<br />

load. Please refer to the relevant<br />

bear<strong>in</strong>g type <strong>in</strong> the table section of the<br />

SKF General Catalogue.<br />

Fig<br />

1<br />

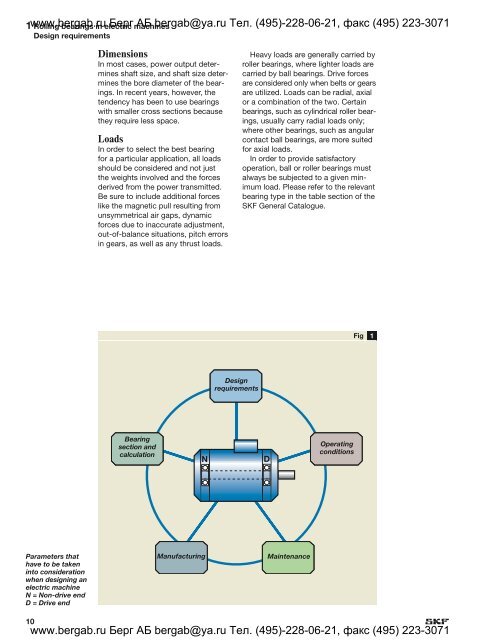

Design<br />

requirements<br />

Bear<strong>in</strong>g<br />

section <strong>and</strong><br />

calculation<br />

Operat<strong>in</strong>g<br />

conditions<br />

Parameters that<br />

have to be taken<br />

<strong>in</strong>to consideration<br />

when design<strong>in</strong>g an<br />

<strong>electric</strong> mach<strong>in</strong>e<br />

N = Non-drive end<br />

D = Drive end<br />

Manufactur<strong>in</strong>g<br />

Ma<strong>in</strong>tenance<br />

10<br />

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071