www . intelligentactuator . de Long Stroke and High-Speed ...

www . intelligentactuator . de Long Stroke and High-Speed ...

www . intelligentactuator . de Long Stroke and High-Speed ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GB<br />

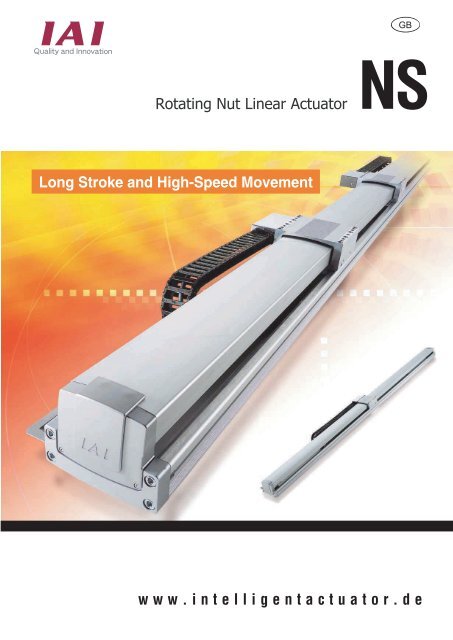

Rotating Nut Linear Actuator<br />

NS<br />

<strong>Long</strong> <strong>Stroke</strong> <strong>and</strong> <strong>High</strong>-<strong>Speed</strong> Movement<br />

w w w . i n t e l l i g e n t a c t u a t o r . d e

Maximum speed 2400 mm/s, maximum<br />

acceleration 1g high-speed performance<br />

A maximum speed of 2400 mm/s is attained through the<br />

use of high-lead precision screws (equivalent to C5). Also,<br />

since there is minimal impact from dangerous rotation<br />

speeds, movement is possible at the maximum 2400<br />

mm/s even at the maximum stroke (3000 mm), so the<br />

cycle time can be greatly reduced.<br />

Maximum speed (m/s)<br />

ISA series<br />

NS series<br />

about 3.5x<br />

high-speed<br />

performance<br />

The intermediate support structure provi<strong>de</strong>s a<br />

long stroke of 3000 mm.<br />

<strong>Stroke</strong> (mm)<br />

The NS series combines nut rotation functions with the<br />

intermediate support structure that has proven itself in<br />

the ISA series to attain a 3000-mm stroke, stunning for a<br />

ball screw machine.<br />

Intermediate<br />

support<br />

Intermediate<br />

support<br />

Multi-sli<strong>de</strong>r support [Equipped with<br />

collision prevention function]<br />

Two sli<strong>de</strong>rs are set on one shaft <strong>and</strong> a multi-sli<strong>de</strong>r is set to operate<br />

them separately. Since this makes it possible for two shafts to<br />

operate in the space of one shaft, it has a great effect in saving<br />

space <strong>and</strong> reducing takt time. The "collision prevention function" to<br />

prevent collisions between the sli<strong>de</strong>rs is st<strong>and</strong>ard equipment.<br />

Length reduced further<br />

Using a built-in nut rotation motor <strong>and</strong> putting the motor<br />

on the outsi<strong>de</strong> of the ball screw eliminates the previous<br />

need for motor installation space <strong>and</strong> links the ball<br />

screw directly to further shorten the length even<br />

compared to the IS series which has already greatly<br />

reduced it.<br />

62 mm shortening<br />

Extension cableveyor option setting<br />

A cableveyor that<br />

exp<strong>and</strong>s the capacity<br />

is available as an<br />

option.<br />

<br />

NS series<br />

IS series<br />

* Compared with 2500mm stroke <strong>and</strong> with<br />

intermediate support<br />

<br />

2

Rotating Nut Linear Actuator that Provi<strong>de</strong>s<br />

<strong>Long</strong> <strong>Stroke</strong> <strong>and</strong> <strong>Speed</strong> Nearly as Fast as Linear<br />

Maximum <strong>Speed</strong> 2400 mm/s, Maximum Acceleration 1G<br />

<strong>High</strong>-<strong>Speed</strong> Performance <strong>and</strong> Multisli<strong>de</strong>r to<br />

Greatly Reduce Cycle Time<br />

Moves the sli<strong>de</strong>r by rotating a nut, not with a ball screw.<br />

The actuator structure is that rather than<br />

moving the nut in the straight line by<br />

rotating a ball screw, the ball screw is fixed<br />

<strong>and</strong> the nut is rotated by a built-in nut rotation<br />

motor built into the sli<strong>de</strong>r, so the sli<strong>de</strong>r moves<br />

in a straight line.<br />

Because the ball screw does not rotate,<br />

the influence of dangerous rotation<br />

speeds is minimal <strong>and</strong> this makes possible<br />

movement at high speed even for long<br />

strokes.<br />

Nut<br />

Ball screw<br />

Motor<br />

Ball screw<br />

ISA series<br />

Built-in nut rotation motor<br />

1<br />

NS series

Mo<strong>de</strong>l<br />

N S 4 0 0 T 2<br />

Series Type Enco<strong>de</strong>r type Motor type Lead <strong>Stroke</strong> Adaptive controller Cable length Options<br />

Absolute<br />

Incremental<br />

Horizontal specifications/<br />

single sli<strong>de</strong>r<br />

Horizontal specifications/<br />

multi-sli<strong>de</strong>r<br />

Horizontal specifications/<br />

single sli<strong>de</strong>r with intermediate<br />

support<br />

Vertical specifications/<br />

single sli<strong>de</strong>r<br />

Vertical specifications/<br />

multi-sli<strong>de</strong>r<br />

No cable<br />

1 m<br />

3 m<br />

5 m<br />

Length specified<br />

Robot cable<br />

Brakes<br />

(only for vertical specifications)<br />

Creep<br />

St<strong>and</strong>ard cableveyor direction 2<br />

St<strong>and</strong>ard cableveyor direction 3<br />

St<strong>and</strong>ard cableveyor direction 4<br />

Extension cableveyor direction 1<br />

Extension cableveyor direction 2<br />

Extension cableveyor direction 3<br />

Extension cableveyor direction 4<br />

Limit switch<br />

Specifications Table<br />

Sli<strong>de</strong>r Appearance Type Enco<strong>de</strong>r type Motor type Lead <strong>Stroke</strong> Rated Maximum Maximum Page<br />

(mm) (mm) thrust (N) transportable speed"<br />

weight (kg) (mm/s)<br />

Horizontal<br />

specifications<br />

Single sli<strong>de</strong>r<br />

LXMS<br />

40<br />

20<br />

500〜1200<br />

170<br />

340.1<br />

40<br />

80<br />

2400<br />

1300<br />

P5<br />

Multi-sli<strong>de</strong>r<br />

LXMM<br />

40<br />

20<br />

250〜2250<br />

170<br />

340.1<br />

40<br />

80<br />

2400<br />

1300<br />

P6<br />

Horizontal<br />

specifications<br />

with intermediate<br />

support<br />

Single sli<strong>de</strong>r<br />

LXMXS<br />

Absolute<br />

Incremental<br />

400<br />

40<br />

20<br />

1300〜3000<br />

170<br />

340.1<br />

40<br />

80<br />

2400<br />

1300<br />

P7<br />

Single sli<strong>de</strong>r<br />

LZMS<br />

500〜1000<br />

P8<br />

Vertical<br />

specifications<br />

20<br />

340.1<br />

16<br />

1000<br />

Multi-sli<strong>de</strong>r<br />

LZMM<br />

250〜950<br />

P9<br />

Table of Transportable Weight By Acceleration Conditions<br />

1. Horizontal installation<br />

Type Motor output Lead Maximum Maximum Transportable weight by acceleration (kg)<br />

(W) (mm) speed" acceleration<br />

(mm/s) (G) 0.3G 0.4G 0.5G 0.6G 0.7G 0.8G 0.9G 1.0G<br />

LXMS<br />

LXMM<br />

40<br />

20<br />

2400<br />

1300<br />

1.0<br />

1.0<br />

40<br />

80<br />

30<br />

60<br />

25<br />

48<br />

20<br />

40<br />

17<br />

34<br />

15<br />

30<br />

13<br />

27<br />

10<br />

24<br />

400<br />

LXMXS<br />

40 2400<br />

40 — — — — — — —<br />

0.3<br />

20 1300<br />

80 — — — — — — —<br />

2. Vertical installation<br />

Type Motor output Lead Maximum Maximum Transportable weight by acceleration (kg)<br />

(W) (mm) speed" acceleration<br />

(mm/s) (G) 0.3G 0.4G 0.5G 0.6G 0.7G 0.8G 0.9G 1.0G<br />

3<br />

LZMS<br />

LZMM<br />

400 20 1000 0.8 16 12.3 11.1 10.1 9.2 6 — —

4<br />

Explanation of main unit options<br />

Brakes<br />

Mo<strong>de</strong>l<br />

B<br />

Explanation<br />

This is a structure that holds the sli<strong>de</strong>r so that if the actuator is used vertically <strong>and</strong> the power is switched Off or the servo goes Off, the sli<strong>de</strong>r does not fall <strong>and</strong> damage<br />

installed items. In the NS series vertical specifications (LZMS/LZMM), brakes are st<strong>and</strong>ard equipment. (Brakes are not set for the horizontal specifications.)<br />

Creep sensor<br />

Mo<strong>de</strong>l<br />

C<br />

Explanation<br />

When the return-to-origin operation is carried out with the incremental specifications, in or<strong>de</strong>r to shorten the return-to-origin time, the sli<strong>de</strong>r is moved at high speed<br />

to just before the position <strong>and</strong> when it passes this sensor, the speed is dropped to resume normal return-to-origin operations. Since this sensor is mounted within the<br />

actuator itself, it does not affect the appearance or external dimensions.<br />

St<strong>and</strong>ard cableveyor installation direction change/extension cableveyor installation<br />

Mo<strong>de</strong>l<br />

CT2 / CT3 / CT4 (st<strong>and</strong>ard cableveyor installation direction)<br />

ET1 / ET2 / ET3 / ET4 (exten<strong>de</strong>d cableveyor installation direction)<br />

Explanation<br />

The cableveyor installation direction can be selected from the following four types (including the st<strong>and</strong>ard installation direction).<br />

[Installation direction]<br />

[Cableveyor internal dimensions]<br />

Installation direction 1 (st<strong>and</strong>ard)<br />

St<strong>and</strong>ard cableveyor: No symbol<br />

Exten<strong>de</strong>d cableveyor: Symbol ET1<br />

Installation direction 2 (st<strong>and</strong>ard; different use)<br />

St<strong>and</strong>ard cableveyor: Symbol CT2<br />

Exten<strong>de</strong>d cableveyor: Symbol ET2<br />

<br />

Installation direction 3 (st<strong>and</strong>ard; reverse origin)<br />

St<strong>and</strong>ard cableveyor: Symbol CT3<br />

Exten<strong>de</strong>d cableveyor: Symbol ET3<br />

Installation direction 4 (CT2, origin reversed)<br />

St<strong>and</strong>ard cableveyor: Symbol CT4<br />

Exten<strong>de</strong>d cableveyor: Symbol ET4<br />

<br />

Origin limit switch<br />

Mo<strong>de</strong>l<br />

L<br />

Explanation<br />

Normal NS series return-to-origin operations use the "push contact technique" in which the origin is reached by bringing the sli<strong>de</strong>r in contact with a stopper, inverting,<br />

then <strong>de</strong>tecting the Z phase. L (origin limit switch) is the option for executing the return-to-origin operation without contact by <strong>de</strong>tecting using a proximity sensor, then<br />

inverting. Since origin limit switch is mounted within the actuator itself, it does not affect the appearance or external dimensions.

NS-LXMS<br />

Single-axis robot nut rotation type Main unit width 145mm 400 W horizontal<br />

specifications/single sli<strong>de</strong>r<br />

Mo<strong>de</strong>l item NS LXMS 400 T2<br />

Series<br />

Type<br />

Enco<strong>de</strong>r type<br />

A : Absolute<br />

I : Incremental<br />

Motor type<br />

400:400W<br />

Lead<br />

40:40mm<br />

20:20mm<br />

<strong>Stroke</strong><br />

500:500mm<br />

〜<br />

1200:1200mm<br />

Adaptive<br />

controller<br />

T2:SCON<br />

SSEL<br />

XSEL-P/Q<br />

Cable length<br />

N :None<br />

S :3m<br />

M:5m<br />

X:Length<br />

specified<br />

Options<br />

See option<br />

table<br />

below<br />

Mo<strong>de</strong>l/specs<br />

Mo<strong>de</strong>l<br />

Enco<strong>de</strong>r type<br />

Motor<br />

output<br />

(W)<br />

Lead<br />

(mm)<br />

<strong>Stroke</strong><br />

(mm)<br />

NS-LXMS- 1 -400-40- 2 -T2- 3 - 4<br />

Absolute<br />

40<br />

400<br />

500〜1200<br />

NS-LXMS- 1 -400-20- 2 -T2- 3 - 4<br />

Incremental<br />

20<br />

* For the mo<strong>de</strong>l types above, 1 is the enco<strong>de</strong>r type, 2 the stroke, 3, the cable length, <strong>and</strong> 4 the options.<br />

<strong>Speed</strong><br />

(mm/s)<br />

2400<br />

1300<br />

Acceleration (*1)<br />

Horizontal (G) Vertical (G)<br />

Rated Maximum<br />

Rated<br />

Maximum<br />

0.3 1.0<br />

Horizontal only<br />

0.3 1.0<br />

Transportable weight (*1, *2)<br />

Horizontal (kg) Vertical (kg)<br />

Rated / Maximum<br />

acceleration<br />

40 10<br />

80 24<br />

Rated / Maximum<br />

acceleration<br />

Horizontal only<br />

Rated thrust<br />

(N)<br />

170<br />

340.1<br />

Options<br />

Name<br />

Creep sensor<br />

St<strong>and</strong>ard cableveyor installation<br />

direction change<br />

Exten<strong>de</strong>d cableveyor<br />

Limit switch<br />

Mo<strong>de</strong>l See Page _ Remarks<br />

C<br />

CT2〜CT4<br />

ET1〜ET4<br />

L<br />

→P4<br />

→P4<br />

→P4<br />

→P4<br />

Common specifications<br />

Drive type<br />

Ball screw ø20 mm Equivalent to C5 form rolled<br />

Position repetition precision Absolute specifications ±0.01 mm/Incremental specifications ± 0.02 mm<br />

Backlash<br />

0.02 mm max.<br />

Gui<strong>de</strong><br />

Base one-piece mo<strong>de</strong>l<br />

Permitted load moment Ma: 104.9N・m Mb: 149.9N・m Mc :248.9N・m<br />

Extension load length Ma direction: 750 mm max. Mb, Mc direction: 750 mm max.<br />

Base<br />

Material: Aluminum, white treated alumite<br />

Cable length (*3)<br />

N: No cable S: 3 m M: 5 m X: Length specified<br />

Usage ambient temperature 0-40˚C, 85% RH max. (no con<strong>de</strong>nsation allowed)<br />

Dimension diagram<br />

CAD drawings can be<br />

downloa<strong>de</strong>d from the homepage<br />

2D<br />

CAD<br />

<br />

<br />

<br />

<br />

<br />

(Reamer pitch)<br />

2-ø 8H7 <strong>de</strong>pth 10<br />

<br />

<br />

<br />

Details D section<br />

Details<br />

Slot <strong>de</strong>pth 10<br />

E section<br />

ø16<br />

ø 9<br />

Base installation<br />

hole section<br />

<br />

Details<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Origin<br />

<br />

<br />

<br />

<br />

8-M8 <strong>de</strong>pth 20<br />

※1 In the return-to-origin,<br />

the sli<strong>de</strong>r moves to the<br />

mechanism end, so watch<br />

out for interference with the<br />

surroundings.<br />

<br />

<br />

<br />

<br />

<br />

<br />

D section<br />

<br />

<br />

<br />

<br />

2-M5 <strong>de</strong>pth 10<br />

<br />

<br />

<br />

<br />

ø8H7 <strong>de</strong>pth 10<br />

SE:<strong>Stroke</strong> end<br />

ME:Mechanism end<br />

<br />

E section<br />

<br />

C-ø9 through hole, ø16 <strong>de</strong>pth spot face<br />

(from opposite si<strong>de</strong>)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

About the number of cables <strong>and</strong> hoses that<br />

can be contained <strong>and</strong> their diameters<br />

1 Make the gap between the cable <strong>and</strong> hose outsi<strong>de</strong> <strong>and</strong> the inner wall <strong>and</strong> the<br />

gap between cables <strong>and</strong> hoses at least 2 mm.<br />

2 Make the cable <strong>and</strong> hose exterior diameter 16.8 or less <strong>and</strong> run cables <strong>and</strong><br />

hoses in parallel, not crossing each other.<br />

3 Be careful. If more cables <strong>and</strong> hoses are put into a cableveyor than the specifications<br />

allow, this imposes excess force on the cables <strong>and</strong> drastically shortens<br />

their service life.<br />

<strong>Stroke</strong> 500 600 700 800 900 1000 1100 1200<br />

L<br />

A<br />

B<br />

C<br />

Weight (kg)<br />

828<br />

1<br />

138<br />

10<br />

18.6<br />

928<br />

1<br />

188<br />

10<br />

20.1<br />

1028<br />

1<br />

238<br />

10<br />

21.6<br />

1128<br />

1<br />

288<br />

10<br />

23.1<br />

1228<br />

2<br />

138<br />

14<br />

24.5<br />

1328<br />

2<br />

188<br />

14<br />

26.0<br />

1428<br />

2<br />

238<br />

14<br />

27.5<br />

1528<br />

2<br />

288<br />

14<br />

29.0<br />

Adaptive controller specifications<br />

5<br />

Adaptive<br />

controller<br />

X-SEL-P/Q<br />

SSEL<br />

SCON<br />

Maximum<br />

number of<br />

axes controlled<br />

6 axes<br />

2 axes<br />

1axis<br />

Connectable<br />

enco<strong>de</strong>r types<br />

Absolute/<br />

incremental<br />

Operation<br />

method<br />

Program<br />

Positioner pulse<br />

string control<br />

Power supply<br />

voltage<br />

Three phase/<br />

single phase<br />

200 VAC<br />

Single phase<br />

100/200 VAC<br />

Notes<br />

Note 1: For <strong>de</strong>tails on the relationship between the acceleration <strong>and</strong> the transportable<br />

weight, see Page 3.<br />

Note 2: The transportable weight is the value when operating at the maximum speed.<br />

Note 3: The maximum cable length is 30 m. When specifying the length, enter in<br />

meters. (Example: X08=8 m)

NS-LXMM<br />

Single-axis robot nut rotation type Main unit width 145mm 400 W<br />

Horizontal specifications/multi-sli<strong>de</strong>r<br />

Mo<strong>de</strong>l item NS LXMM 400 T2<br />

Series<br />

Type<br />

Enco<strong>de</strong>r type<br />

A : Absolute<br />

I : Incremental<br />

Motor type<br />

400:400W<br />

Lead<br />

40:40mm<br />

20:20mm<br />

<strong>Stroke</strong><br />

250:250mm<br />

〜<br />

2250:2250mm<br />

Adaptive<br />

controller<br />

T2:SCON<br />

SSEL<br />

XSEL-P/Q<br />

Cable length<br />

N :None<br />

S :3m<br />

M:5m<br />

X:Length<br />

specified<br />

Options<br />

See option<br />

table<br />

below<br />

Mo<strong>de</strong>l/specs<br />

Mo<strong>de</strong>l<br />

Enco<strong>de</strong>r type<br />

Motor<br />

output<br />

(W)<br />

Lead<br />

(mm)<br />

<strong>Stroke</strong><br />

(mm)<br />

NS-LXMM- 1 -400-40- 2 -T2- 3 - 4<br />

Absolute<br />

40<br />

Incremental 400<br />

250〜2250<br />

NS-LXMM- 1 -400-20- 2 -T2- 3 - 4<br />

20<br />

* For the mo<strong>de</strong>l types above, 1 is the enco<strong>de</strong>r type, 2 the stroke, 3, the cable length, <strong>and</strong> 4 the options.<br />

<strong>Speed</strong><br />

(mm)<br />

2400<br />

1300<br />

Acceleration (*1)<br />

Horizontal (kg) Vertical (kg)<br />

Rated<br />

Maximum<br />

Rated<br />

Maximum<br />

0.3 1.0<br />

Horizontal only<br />

0.3 1.0<br />

Transportable weight (*1, *2)<br />

Horizontal (kg) Vertical (kg)<br />

Rated / Maximum<br />

acceleration<br />

40 10<br />

80 24<br />

Rated / Maximum<br />

acceleration<br />

Horizontal only<br />

Rated thrust<br />

(N)<br />

170<br />

340.1<br />

Options<br />

Name<br />

Creep sensor<br />

Extension cableveyor<br />

Limit switch<br />

Mo<strong>de</strong>l See Page _ Remarks<br />

C<br />

ET1<br />

L<br />

→P4<br />

→P4<br />

→P4<br />

Common specifications<br />

Drive type<br />

Ball screw ø20 mm Equivalent to C5 form rolled<br />

Position repetition precision Absolute specifications ±0.01 mm/Incremental specifications ± 0.02 mm<br />

Backlash<br />

0.02 mm max.<br />

Gui<strong>de</strong><br />

Base one-piece mo<strong>de</strong>l<br />

Permitted load moment Ma:104.9N・m Mb:149.9N・m Mc:248.9N・m<br />

Extension load length Ma direction: 750 mm max. Mb, Mc directions: 750 mm max.<br />

Base<br />

Material: Aluminum, white treated alumite<br />

Cable length (*3)<br />

N: No cable S: 3 m M: 5 m X: Length specified<br />

Usage ambient temperature 0-40˚C, 85% RH max. (no con<strong>de</strong>nsation allowed)<br />

Dimension diagram<br />

CAD drawings can be<br />

downloa<strong>de</strong>d from the homepage<br />

2D<br />

CAD<br />

<br />

<br />

<br />

<br />

(Reamer pitch)<br />

2-ø8 H7 <strong>de</strong>pth 10<br />

<br />

Details<br />

<br />

<br />

<br />

D section<br />

Details<br />

ø 9<br />

Base installation<br />

hole section<br />

Slot <strong>de</strong>pth 10<br />

E section<br />

ø16<br />

<br />

100 (minimum between sli<strong>de</strong>rs) 100 (minimum between sli<strong>de</strong>rs)<br />

<br />

<br />

<br />

Details<br />

<br />

<br />

Origin<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Origin<br />

<br />

<br />

<br />

8-M8 <strong>de</strong>pth 20<br />

<br />

<br />

In the return-to-origin,<br />

the sli<strong>de</strong>r moves to the<br />

mechanism end, so watch<br />

out for interference with<br />

the surroundings.<br />

<br />

<br />

D section<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

M5 <strong>de</strong>pth 10 M5 <strong>de</strong>pth 10<br />

<br />

<br />

<br />

<br />

<br />

ø8 H7 <strong>de</strong>pth 10<br />

SE: <strong>Stroke</strong> end<br />

ME: Mechanism end<br />

<br />

E section<br />

C-ø9 through hole, ø16 <strong>de</strong>pth<br />

spot face<br />

(from opposite si<strong>de</strong>)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

About the number of cables <strong>and</strong> hoses that<br />

can be contained <strong>and</strong> their diameters<br />

1 Make the gap between the cable <strong>and</strong> hose outsi<strong>de</strong> <strong>and</strong> the inner wall <strong>and</strong> the<br />

gap between cables <strong>and</strong> hoses at least 2 mm.<br />

2 Make the cable <strong>and</strong> hose exterior diameter 16.8 or less <strong>and</strong> run cables <strong>and</strong><br />

hoses in parallel, not crossing each other.<br />

3 Be careful. If more cables <strong>and</strong> hoses are put into a cableveyor than the specifications<br />

allow, this imposes excess force on the cables <strong>and</strong> drastically shortens<br />

their service life.<br />

<strong>Stroke</strong><br />

L<br />

A<br />

B<br />

C<br />

828<br />

1<br />

138<br />

10<br />

Weight (kg) 24.7<br />

250 350 450 550 650 750 850 950 1050 1150 1250 1350 1450 1550 1650 1750 1850 1950 2050 2150 2250<br />

928<br />

1<br />

188<br />

10<br />

26.4<br />

1028<br />

1<br />

238<br />

10<br />

28.2<br />

1128<br />

1<br />

288<br />

10<br />

29.9<br />

1228<br />

2<br />

138<br />

14<br />

31.6<br />

1328<br />

2<br />

188<br />

14<br />

33.4<br />

1428<br />

2<br />

238<br />

14<br />

35.1<br />

1528<br />

2<br />

288<br />

14<br />

36.8<br />

1628<br />

3<br />

138<br />

18<br />

38.6<br />

1728<br />

3<br />

188<br />

18<br />

40.3<br />

1828<br />

3<br />

238<br />

18<br />

42<br />

1928<br />

3<br />

288<br />

18<br />

43.8<br />

2028<br />

4<br />

138<br />

22<br />

45.5<br />

2128<br />

4<br />

188<br />

22<br />

47.2<br />

2228<br />

4<br />

238<br />

22<br />

48.9<br />

2328<br />

4<br />

288<br />

22<br />

50.7<br />

2428<br />

5<br />

138<br />

26<br />

52.4<br />

2528<br />

5<br />

188<br />

26<br />

54.1<br />

2628<br />

5<br />

238<br />

26<br />

55.9<br />

2728<br />

5<br />

288<br />

26<br />

57.6<br />

2828<br />

6<br />

138<br />

30<br />

59.3<br />

Adaptive controller specifications<br />

Adaptive<br />

controller<br />

X-SEL-P/Q<br />

SSEL<br />

SCON<br />

Maximum<br />

number of<br />

axes controlled<br />

6 axes<br />

2 axes<br />

1axis<br />

Connectable<br />

enco<strong>de</strong>r types<br />

Absolute/<br />

incremental<br />

Operation<br />

method<br />

Program<br />

Positioner pulse<br />

string control<br />

Power supply<br />

voltage<br />

Three phase/<br />

single 200 VAC<br />

Single phase<br />

100/200 VAC<br />

Notes<br />

Note 1: For <strong>de</strong>tails on the relationship between the acceleration <strong>and</strong> the transportable<br />

weight, see Page 3.<br />

Note 2: The transportable weight is the value when operating at the maximum speed.<br />

Note 3: The maximum cable length is 30 m. When specifying the length, enter in<br />

meters. (Example: X08=8 m)<br />

6

NS-LXMXS<br />

Single-axis robot nut rotation type Main unit width 145mm 400 W<br />

Horizontal specifications, single sli<strong>de</strong>r with intermediate support<br />

Mo<strong>de</strong>l item NS LXMXS 400 T2<br />

Series<br />

Type<br />

Enco<strong>de</strong>r type<br />

A : Absolute<br />

I : Incremental<br />

Motor type<br />

400:400W<br />

Lead<br />

40:40mm<br />

20:20mm<br />

<strong>Stroke</strong><br />

1300:1300mm<br />

〜<br />

3000:3000mm<br />

Adaptive<br />

controller<br />

T2:SCON<br />

SSEL<br />

XSEL-P/Q<br />

Cable length<br />

N :None<br />

S :3m<br />

M:5m<br />

X:Length<br />

specified<br />

Options<br />

See option<br />

table<br />

below<br />

Mo<strong>de</strong>l/specs<br />

Mo<strong>de</strong>l<br />

Enco<strong>de</strong>r type<br />

Motor<br />

output<br />

(W)<br />

Lead<br />

(mm)<br />

<strong>Stroke</strong><br />

(mm)<br />

NS-LXMXS- 1 -400-40- 2 -T2- 3 - 4<br />

40<br />

Horizontal only 400<br />

1300〜3000<br />

NS-LXMXS- 1 -400-20- 2 -T2- 3 - 4<br />

20<br />

* For the mo<strong>de</strong>l types above, 1 is the enco<strong>de</strong>r type, 2 the stroke, 3, the cable length, <strong>and</strong> 4 the options.<br />

<strong>Speed</strong><br />

(mm)<br />

2400<br />

1300<br />

Acceleration (*1) Transportable weight (*1, *2)<br />

Horizontal (kg) Vertical (kg) Horizontal (kg) Vertical (kg)<br />

Rated<br />

Maximumum<br />

acceleration acceleration<br />

Rated<br />

Maxi-<br />

Rated / Maximum Rated / Maximum<br />

0.3<br />

40<br />

Horizontal only<br />

Horizontal only<br />

0.3<br />

80<br />

Rated thrust<br />

(N)<br />

170<br />

340.1<br />

Options<br />

Name<br />

Creep sensor<br />

St<strong>and</strong>ard cableveyor installation<br />

direction change<br />

Exten<strong>de</strong>d cableveyor<br />

Limit switch<br />

C →P4 Remarks<br />

C<br />

CT2〜CT4<br />

ET1〜ET4<br />

L<br />

→P4<br />

→P4<br />

→P4<br />

→P4<br />

Common specifications<br />

Drive type<br />

Ball screw ø20 mm Equivalent to C5 form rolled<br />

Position repetition precision Absolute specifications ±0.01 mm/Incremental specifications ± 0.02 mm<br />

Backlash<br />

0.02 mm max.<br />

Gui<strong>de</strong><br />

Base one-piece mo<strong>de</strong>l<br />

Permitted load moment Ma:104.9N・m Mb:149.9N・m Mc:248.9N・m<br />

Extension load length Ma direction: 750 mm max. Mb, Mc directions: 750 mm max.<br />

Base<br />

Material: Aluminum, white treated alumite<br />

Cable length (*3)<br />

N: No cable S: 3 m M: 5 m X: Length specified<br />

Usage ambient temperature 0-40˚C, 85% RH max. (no con<strong>de</strong>nsation allowed)<br />

Dimension diagram<br />

CAD drawings can be<br />

downloa<strong>de</strong>d from the homepage<br />

2D<br />

CAD<br />

<br />

<br />

<br />

<br />

<br />

(Reamer pitch)<br />

2-ø8 H7 <strong>de</strong>pth 10<br />

Details<br />

Slot <strong>de</strong>pth 10<br />

E section<br />

<br />

<br />

<br />

<br />

<br />

Details D section<br />

ø 16<br />

ø 9<br />

Base installation<br />

hole section<br />

<br />

Details<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Origin<br />

8-M8 <strong>de</strong>pth 20<br />

<br />

In the return-to-origin,<br />

<br />

the sli<strong>de</strong>r moves to the<br />

<br />

mechanism end, so watch<br />

out for interference with<br />

the surroundings.<br />

<br />

<br />

<br />

<br />

<br />

<br />

D section<br />

E section<br />

<br />

<br />

<br />

<br />

2-M5 <strong>de</strong>pth 10<br />

<br />

<br />

<br />

<br />

2-ø8 H7 <strong>de</strong>pth 10<br />

SE: <strong>Stroke</strong> end<br />

ME: Mechanism end<br />

<br />

<br />

C-ø9 through hole, ø16 <strong>de</strong>pth spot<br />

face (from opposite si<strong>de</strong>)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

About the number of cables <strong>and</strong> hoses that<br />

can be contained <strong>and</strong> their diameters<br />

1 Make the gap between the cable <strong>and</strong> hose outsi<strong>de</strong> <strong>and</strong> the inner wall <strong>and</strong><br />

the gap between cables <strong>and</strong> hoses at least 2 mm.<br />

2 Make the cable <strong>and</strong> hose exterior diameter 16.8 or less <strong>and</strong> run cables<br />

<strong>and</strong> hoses in parallel, not crossing each other.<br />

3 Be careful. If more cables <strong>and</strong> hoses are put into a cableveyor than the<br />

specifi cations allow, this imposes excess force on the cables <strong>and</strong> drastically<br />

shortens their service life.<br />

<strong>Stroke</strong> 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400 2500 2600 2700 2800 2900 3000<br />

L<br />

A<br />

B<br />

C<br />

Weight (kg)<br />

1728<br />

3<br />

188<br />

18<br />

31.5<br />

1828<br />

3<br />

238<br />

18<br />

32.9<br />

1928<br />

3<br />

288<br />

18<br />

34.4<br />

2028<br />

4<br />

138<br />

22<br />

35.9<br />

2128<br />

4<br />

188<br />

22<br />

37.4<br />

2228<br />

4<br />

238<br />

22<br />

38.9<br />

2328<br />

4<br />

288<br />

22<br />

40.4<br />

2428<br />

5<br />

138<br />

26<br />

41.9<br />

2528<br />

5<br />

188<br />

26<br />

43.4<br />

2628<br />

5<br />

238<br />

26<br />

44.9<br />

2728<br />

5<br />

288<br />

26<br />

46.4<br />

2828<br />

6<br />

138<br />

30<br />

47.9<br />

2928<br />

6<br />

188<br />

30<br />

49.4<br />

3028<br />

6<br />

238<br />

30<br />

50.9<br />

3128<br />

6<br />

288<br />

30<br />

52.3<br />

3228<br />

7<br />

138<br />

34<br />

53.8<br />

3328<br />

7<br />

188<br />

34<br />

55.3<br />

3428<br />

7<br />

238<br />

34<br />

56.8<br />

Adaptive controller specifications<br />

7<br />

Adaptive<br />

controller<br />

X-SEL-P/Q<br />

SSEL<br />

SCON<br />

Maximum<br />

number of<br />

axes controlled<br />

6 axes<br />

2 axes<br />

1 axis<br />

Connectable<br />

enco<strong>de</strong>r types<br />

Absolute/<br />

incremental<br />

Operation<br />

method<br />

Program<br />

Positioner pulse<br />

string control<br />

Power supply<br />

voltage<br />

Three phase/<br />

single phase<br />

200 VAC Notes<br />

Single phase<br />

100/200 VAC<br />

Note 1: The maximum acceleration is 0.3 G.<br />

Note 2: The transportable weight is the value when operating at the maximum speed.<br />

Note 3: The maximum cable length is 30 m. When specifying the length, enter in<br />

meters. (Example: X08=8 m)

NS-LZMS<br />

Single-axis robot nut rotation type Main unit width 145mm 400 W<br />

Vertical specifications, single sli<strong>de</strong>r<br />

Mo<strong>de</strong>l item NS LZMS 400 T2<br />

Series<br />

Type<br />

Enco<strong>de</strong>r type<br />

A : Absolute<br />

I : Incremental<br />

Motor type<br />

400:400W<br />

Lead<br />

40:40mm<br />

<strong>Stroke</strong><br />

500:500mm<br />

〜<br />

1000:1000mm<br />

Adaptive<br />

controller<br />

T2:SCON<br />

SSEL<br />

XSEL-P/Q<br />

Cable length<br />

N :None<br />

S :3m<br />

M:5m<br />

X:Length<br />

specified<br />

Options<br />

See the<br />

option<br />

price table<br />

below.<br />

Mo<strong>de</strong>l/specs<br />

Mo<strong>de</strong>l<br />

NS-LZMS- 1 -400-40- 2 -T2- 3 -B- 4<br />

Enco<strong>de</strong>r type<br />

Absolute<br />

Incremental<br />

Motor<br />

output (W)<br />

400<br />

Lead<br />

(mm)<br />

20<br />

<strong>Stroke</strong> (mm)<br />

Maximum<br />

speed (m/s)<br />

Acceleration (*1)<br />

Horizontal (G) Vertical (G)<br />

Rated<br />

Maximum<br />

Rated<br />

Maximum<br />

Transportable weight (*1, *2)<br />

Horizontal (kg)<br />

Rated / Maximum<br />

acceleration<br />

500〜1000 1000 For vertical only 0.3 0.8 For vertical only<br />

Vertical (G)<br />

Rated / Maximum<br />

acceleration<br />

16 6.0<br />

Rated thrust<br />

(N)<br />

340.1<br />

* For the mo<strong>de</strong>l types above, 1 is the enco<strong>de</strong>r type, 2 the stroke, 3, the cable length, <strong>and</strong> 4 the options.<br />

Options<br />

Name<br />

Brakes<br />

Creep sensor<br />

St<strong>and</strong>ard cableveyor installation<br />

direction change<br />

Exten<strong>de</strong>d cableveyor<br />

Limit switch<br />

Dimension diagram<br />

Mo<strong>de</strong>l See Page _ Remarks<br />

B<br />

C<br />

CT2〜CT4<br />

ET1〜ET4<br />

L<br />

→P4<br />

→P4<br />

→P4<br />

→P4<br />

→P4<br />

St<strong>and</strong>ard equipment<br />

Common specifications<br />

Drive type<br />

Ball screw ø20 mm Equivalent to C5 form rolled<br />

Position repetition precision Absolute specifications ±0.01 mm/Incremental specifications ± 0.02 mm<br />

Backlash<br />

0.02 mm max.<br />

Gui<strong>de</strong><br />

Base one-piece mo<strong>de</strong>l<br />

Permitted load moment Ma:104.9N・m Mb:149.9N・m Mc:248.9N・m<br />

Extension load length Ma direction: 750 mm max. Mb, Mc directions: 750 mm max.<br />

Brakes<br />

Non-excitation operation electromagnetic brakes st<strong>and</strong>ard equipment<br />

Base<br />

Material: Aluminum, white treated alumite<br />

Cable length (*3)<br />

N: No cable S: 3 m M: 5 m X: Length specified<br />

Usage ambient temperature 0-40˚C, 85% RH max. (no con<strong>de</strong>nsation allowed)<br />

CAD drawings can be<br />

downloa<strong>de</strong>d from the homepage<br />

2D<br />

CAD<br />

<br />

<br />

<br />

<br />

<br />

(Reamer pitch)<br />

2-ø8 H7 <strong>de</strong>pth 10<br />

<br />

<br />

Details<br />

Slot <strong>de</strong>pth 10<br />

E section<br />

ø16<br />

<br />

<br />

ø 9<br />

Details D section Base installation Details<br />

hole section<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Origin<br />

<br />

<br />

8-M8 <strong>de</strong>pth 20<br />

<br />

<br />

<br />

In the return-to-origin,<br />

the sli<strong>de</strong>r moves to the<br />

mechanism end, so watch<br />

out for interference with<br />

the surroundings.<br />

<br />

<br />

D section<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

2-M5 <strong>de</strong>pth 10<br />

<br />

<br />

<br />

<br />

ø8H7 <strong>de</strong>pth 10<br />

SE: <strong>Stroke</strong> end<br />

ME: Mechanism end<br />

<br />

E section<br />

<br />

C-ø9 through hole, ø16 <strong>de</strong>pth spot face<br />

(from opposite si<strong>de</strong>)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

About the number of cables <strong>and</strong> hoses that<br />

can be contained <strong>and</strong> their diameters<br />

1 Make the gap between the cable <strong>and</strong> hose outsi<strong>de</strong> <strong>and</strong> the inner wall <strong>and</strong> the<br />

gap between cables <strong>and</strong> hoses at least 2 mm.<br />

2 Make the cable <strong>and</strong> hose exterior diameter 16.8 or less <strong>and</strong> run cables <strong>and</strong><br />

hoses in parallel, not crossing each other.<br />

3 Be careful. If more cables <strong>and</strong> hoses are put into a cableveyor than the specifications<br />

allow, this imposes excess force on the cables <strong>and</strong> drastically shortens<br />

their service life.<br />

<strong>Stroke</strong> 500 600 700 800 900 1000<br />

L<br />

A<br />

B<br />

C<br />

Weight (kg)<br />

878<br />

1<br />

163<br />

10<br />

19.9<br />

978<br />

1<br />

213<br />

10<br />

21.4<br />

1078<br />

1<br />

263<br />

10<br />

22.9<br />

1178<br />

2<br />

113<br />

14<br />

24.4<br />

1278<br />

2<br />

163<br />

14<br />

25.9<br />

1378<br />

2<br />

213<br />

14<br />

27.4<br />

Adaptive controller specifications<br />

Adaptive<br />

controller<br />

X-SEL-P/Q<br />

SSEL<br />

SCON<br />

Maximum<br />

number of axes<br />

controlled<br />

6 axes<br />

2 axes<br />

1 axis<br />

Connectable<br />

enco<strong>de</strong>r types<br />

Absolute/<br />

incremental<br />

Operation<br />

method<br />

Program<br />

Positioner pulse<br />

string control<br />

Power supply<br />

voltage<br />

Three phase/<br />

single phase<br />

200 VAC<br />

Single phase<br />

100/200 VAC<br />

Notes<br />

Note 1: For <strong>de</strong>tails on the relationship between the acceleration <strong>and</strong> the transportable<br />

weight, see Page 3.<br />

Note 2: The transportable weight is the value when operating at the maximum speed.<br />

Note 3: The maximum cable length is 30 m. When specifying the length, enter in<br />

meters. (Example: X08=8 m)<br />

8

NS-LZMM<br />

Single-axis robot nut rotation type main unit width 145 mm 400 W<br />

Vertical specification multi-sli<strong>de</strong>r<br />

Mo<strong>de</strong>l item NS LZMM 400 T2<br />

Series<br />

Type<br />

Enco<strong>de</strong>r type<br />

A : Absolute<br />

I : Incremental<br />

Motor type<br />

400:400W<br />

Lead<br />

20:20mm<br />

<strong>Stroke</strong><br />

250:250mm<br />

〜<br />

950:950mm<br />

Adaptive<br />

controller<br />

T2:SCON<br />

SSEL<br />

XSEL-P/Q<br />

Cable length<br />

N :None<br />

S :3m<br />

M:5m<br />

X:Length<br />

specified<br />

Options<br />

Option<br />

table<br />

below<br />

Reference<br />

Mo<strong>de</strong>l/specs<br />

Mo<strong>de</strong>l<br />

NS-LZMM- 1 -400-20- 2 -T2- 3 -B- 4<br />

Enco<strong>de</strong>r type<br />

Absolute<br />

Incremental<br />

Motor<br />

output<br />

(W)<br />

400<br />

Lead<br />

(mm)<br />

20<br />

<strong>Stroke</strong><br />

(mm)<br />

<strong>Speed</strong><br />

(mm/s)<br />

Acceleration (*1)<br />

Horizontal (G) Vertical (G)<br />

Ratings<br />

Maximum<br />

Ratings<br />

Maximum<br />

Transportable weight (*1, *2)<br />

Horizontal (G)<br />

250〜950 1000 Vertical only 0.3 0.8 Vertical only<br />

Vertical (G)<br />

Ratings / Maximum Ratings / Maximum<br />

acceleration acceleration<br />

16 6.0<br />

Rated<br />

propulsion<br />

340.1<br />

* For the mo<strong>de</strong>l type above, 1 is the enco<strong>de</strong>r type, 2 the stroke, 3, the cable length, <strong>and</strong> 4 the options.<br />

Options<br />

Common specifications<br />

Name<br />

Brakes<br />

Creep sensor<br />

Exten<strong>de</strong>d cable pair<br />

Limit switch<br />

Mo<strong>de</strong>l<br />

B<br />

C<br />

ET1<br />

L<br />

Reference<br />

page<br />

→P4<br />

→P4<br />

→P4<br />

→P4<br />

Remarks<br />

St<strong>and</strong>ard equipment<br />

Drive type<br />

Ball screw ø20 mm Equivalent to C5 form rolled<br />

Positioning repeatability<br />

precision<br />

Absolute specifications ±0.01 mm/Incremental specifications ± 0.02 mm<br />

Backlash<br />

0.02 mm max.<br />

Gui<strong>de</strong><br />

Base one-piece mo<strong>de</strong>l<br />

Permitted load moment Ma:104.9N・m Mb:149.9N・m Mc:248.9N・m<br />

Exten<strong>de</strong>d load length Ma direction: 750 mm max. Mb, Mc direction: 750 mm max.<br />

Brakes<br />

Non-excitation operating electromagnetic brakes st<strong>and</strong>ard<br />

Base<br />

Material: Aluminum, white treated alumite<br />

Cable length (*3) N: No cable S: 3 m M: 5 m X: Length specified<br />

Usage temperature 0-40˚C, 85% RH max. (no con<strong>de</strong>nsation allowed)<br />

Dimensional diagam<br />

CAD drawings can be<br />

downloa<strong>de</strong>d from the home page.<br />

2D<br />

CAD<br />

<br />

<br />

<br />

<br />

<br />

(Reamer pitch)<br />

2-ø8 H7 <strong>de</strong>pth 10<br />

Details<br />

Slot <strong>de</strong>pth 10<br />

E section<br />

ø16<br />

<br />

<br />

<br />

<br />

<br />

<br />

ø 9<br />

Details D section Base installation<br />

hole section <strong>de</strong>tails<br />

100 (minimum between sli<strong>de</strong>rs)<br />

<br />

<br />

<br />

<br />

Origin<br />

<br />

100 (minimum between sli<strong>de</strong>rs)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Origin<br />

<br />

<br />

8-M8 <strong>de</strong>pth 20<br />

When returning to the<br />

<br />

<br />

origin, the sli<strong>de</strong>r moves<br />

to the mechanical end, so<br />

watch out for interference<br />

around there.<br />

<br />

<br />

D section<br />

<br />

<br />

<br />

<br />

E section<br />

<br />

<br />

<br />

<br />

M5 <strong>de</strong>pth 10 M5 <strong>de</strong>pth 10<br />

<br />

<br />

<br />

<br />

ø8 H7 <strong>de</strong>pth 10<br />

SE: <strong>Stroke</strong> end<br />

ME: Mechanical end<br />

<br />

C –ø9 through hole, ø16 <strong>de</strong>pth<br />

spot face (from opposite si<strong>de</strong>)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

About the number <strong>and</strong> diameters of cables<br />

<strong>and</strong> hoses stored<br />

1 Set the gaps between the outsi<strong>de</strong> of cable <strong>and</strong> hoses <strong>and</strong> the inner walls <strong>and</strong><br />

between cable hoses themselves to 2 mm min.<br />

2 Make cable <strong>and</strong> hose diameters 16.8 max. <strong>and</strong> use them running in parallel to<br />

each other, not crossing over.<br />

3 If more cables <strong>and</strong> hoses are stored than the specifications call for, this will<br />

generate excessive force on them <strong>and</strong> drastically shorten their service life.<br />

<strong>Stroke</strong> 250 350 450 550 650 750 850 950<br />

L<br />

A<br />

B<br />

C<br />

Weight (kg)<br />

928<br />

1<br />

188<br />

10<br />

27.1<br />

1028<br />

1<br />

238<br />

10<br />

28.8<br />

1128<br />

1<br />

288<br />

10<br />

30.5<br />

1228<br />

2<br />

138<br />

14<br />

32.2<br />

1328<br />

2<br />

188<br />

14<br />

34<br />

1428<br />

2<br />

238<br />

14<br />

35.7<br />

1528<br />

2<br />

288<br />

14<br />

37.4<br />

1628<br />

3<br />

138<br />

18<br />

39.2<br />

Adaptive controller specifications<br />

9<br />

Adaptive<br />

controller<br />

X-SEL-P/Q<br />

SSEL<br />

SCON<br />

Maximum<br />

number of axes<br />

controlled<br />

6 axes<br />

2 axes<br />

1axis<br />

Connectable<br />

enco<strong>de</strong>r types<br />

Absolute/<br />

incremental<br />

Operation<br />

dimensions<br />

Program<br />

Positioner pulse<br />

string control<br />

Power supply<br />

voltage<br />

3-phase/1-<br />

phase, 200<br />

VAC<br />

Single phase<br />

AC, 100/200 V<br />

Notes<br />

Note 1: For the relationship between the acceleration <strong>and</strong> the transportable weight,<br />

see Page 3.<br />

Note 2: The transportable weight is for operation at the maximum speed.<br />

Note 3: The maximum cable length is 30 m. Enter the length specification in meters.<br />

(Example: X08=8 m)

Controller specifications<br />

Controller series type<br />

SCON SSEL<br />

XSEL<br />

P (St<strong>and</strong>ard) Type<br />

Q (Global) Type<br />

General specifications Input/output communications Program Control specifications Basic specifications<br />

Appearance<br />

Power supply capacity<br />

Insulation resistance<br />

Withst<strong>and</strong> voltage<br />

Input power supply<br />

Within operating power supply voltage<br />

Maximum connected total axis<br />

output (W)<br />

Maximum number of axes controlled<br />

Position <strong>de</strong>tection technique<br />

Safety circuit configuration<br />

Drive power cut-off<br />

Enable input<br />

<strong>Speed</strong> setting<br />

Acceleration setting<br />

Operation technique<br />

Program language<br />

Program count<br />

Program step count<br />

Multi-task program count<br />

Position count<br />

Data storage <strong>de</strong>vice<br />

Data input <strong>de</strong>vice<br />

(Option)<br />

St<strong>and</strong>ard I/O<br />

Expan<strong>de</strong>d I/O<br />

Serial communications functions<br />

Other I/O<br />

Field network<br />

Protection functions<br />

Usage ambient temperature <strong>and</strong> humidity<br />

Usage ambient atmosphere<br />

External dimensions<br />

Weight<br />

Accessories<br />

844 VA<br />

Single phase 200 VAC<br />

750W (200V power supply<br />

specifications)<br />

1 axis<br />

Positioner operation<br />

Pulse string control<br />

─<br />

─<br />

─<br />

─<br />

512 max.<br />

EEPROM<br />

Teaching box<br />

Mo<strong>de</strong>ls: RCM-T/TD/E/P<br />

Software for PC<br />

Mo<strong>de</strong>l: RCM-101-MW<br />

(for RS232 communications)<br />

RCM-101-USB<br />

(for USB communications)<br />

16 inputs/16 outputs<br />

(NPN/PMP selectable)<br />

Teaching port (RS485)<br />

System I/O<br />

(Emergency stop input,<br />

brake power supply)<br />

DeviceNet、CC-Link、ProfiBus<br />

72 (W)×200.5(H)×121(D)<br />

1.1kg<br />

I/O flat cable (40 lines)<br />

1660 VA max.<br />

(for 400W, 2-axis operation)<br />

500 VDC, 100 MΩ min.<br />

1500 VAC for one minute<br />

400W (100V power supply<br />

specifications) 800W (200V power<br />

supply specifications)<br />

2 axis<br />

Incremental enco<strong>de</strong>r/absolute enco<strong>de</strong>r<br />

Duplex not possible<br />

Duplex not possible<br />

Internal relay cut-off<br />

Internal relay cut-off<br />

B contact input<br />

B contact input<br />

(Internal power feed type)<br />

(internal power feed type)<br />

1 mm/s – upper limit, which <strong>de</strong>pends on the actuator<br />

0.01 G 1 – upper limit, which <strong>de</strong>pends on the actuator<br />

Not possible<br />

Single phase 100 VAC<br />

Single phase 200 VAC<br />

Program operation<br />

Positioner operation<br />

(Switchable)<br />

2000<br />

8<br />

1500<br />

Flash ROM<br />

(Optional SRAM<br />

battery backup)<br />

Teaching box<br />

Mo<strong>de</strong>ls: IA-T-X-J, IA-T-XD-J<br />

Software for PC<br />

Mo<strong>de</strong>l: IA-101-X-MW-J<br />

(for RS232 communications)<br />

IA-101-USB<br />

(for USB communications)<br />

24 inputs/8 outputs<br />

(NPN/PMP selectable)<br />

Teaching port (RS232C)<br />

USB connector<br />

System I/O<br />

(Emergency stop input,<br />

brake power supply)<br />

(Future support planned)<br />

1.4kg<br />

I/O flat cable (34 lines)<br />

Super SEL language<br />

64<br />

Teaching box<br />

Mo<strong>de</strong>ls: IA-T-X, IA-T-XD<br />

Software for PC<br />

Mo<strong>de</strong>l: IA-101-X-MW<br />

(for RS232 communications)<br />

IA-101-X-USB<br />

(for USB communications)<br />

2400W (for three-phase power)<br />

1600W (for single-phase power)<br />

6 axis<br />

Duplexing possible<br />

External safety circuit<br />

B contact input<br />

(External power feed type, duplex)<br />

Program operation only<br />

6000<br />

16<br />

4000<br />

Flash ROM + SRAM battery backup<br />

32 inputs/16 outputs<br />

(NPN/PMP selectable)<br />

192 inputs max./192 outputs max.<br />

Teaching port (RS232C)<br />

2ch RS232C port<br />

Teaching box<br />

Mo<strong>de</strong>l: IA-T-XA<br />

Software for PC<br />

Mo<strong>de</strong>l: IA-101-XA-MW<br />

(for RS232 communications)<br />

Safety category support<br />

with cable)<br />

System I/O<br />

(Emergency stop input, enable input, ready output)<br />

DeviceNet、CC-Link、ProfiBus、Ethrnet<br />

Motor overcurrent, motor driver temperature check, overload check, enco<strong>de</strong>r open line check,<br />

software limit over, system abnormality, battery abnormality, other<br />

0-40˚C, 10-95% (no con<strong>de</strong>nsation allowed)<br />

There must be no corrosive gas <strong>and</strong> dust must not be particularly bad.<br />

100 (W) x 202.6 (H) x 126 (D)<br />

When absolute battery mounted<br />

±10%<br />

4998 VA max.<br />

(for 2400W, 6-axis operation)<br />

500 VDC, 10 MΩ min.<br />

2500 VAC for one minute<br />

1500 VAC for one minute<br />

Three-phase 200 VAC<br />

Single phase 200 VAC<br />

340 (W) x 195 (H) x 125.3 (D)<br />

(For 6-axis absolute specifications)<br />

5.7 kg (for 6-axis absolute specifications)<br />

I/O flat cable (50 lines)<br />

10

NS Series, Flyer No. 0607-E, Version CJ0108-1A<br />

Motor cable (for XSEL-KE/KT/P/Q, SSEL, SCON) *<br />

Mo<strong>de</strong>l CB-X-MA/CB-XEU-MA<br />

(“EU”: Cable option,<br />

see fig. down)<br />

Enter the cable length (L) at . Up to 30 meters is<br />

supported. Example: 080=8 m<br />

(Front diagram)<br />

Controller si<strong>de</strong><br />

Machine si<strong>de</strong> (Front diagram) 0.75sq<br />

Red U 2<br />

White V 3<br />

Wire Color Signal No.<br />

Green PE 1<br />

Black W 4<br />

No. Signal Color Wire<br />

1<br />

2<br />

3<br />

4<br />

U<br />

V<br />

W<br />

PE<br />

Red<br />

White<br />

Black<br />

Green<br />

0.75sq<br />

(press fit)<br />

Enco<strong>de</strong>r cable (for XSEL-P/Q, SSEL, SCON)<br />

Mo<strong>de</strong>l CB-X2-PA/CB-X2EU-PA<br />

(Front diagram)<br />

Controller si<strong>de</strong><br />

Machine si<strong>de</strong><br />

(Front diagram)<br />

Enco<strong>de</strong>r cable (for XSEL-P/Q, SSEL, SCON, specifications with limit switch)<br />

Mo<strong>de</strong>l CB-X2-PLA/CB-X2EU-PLA<br />

Controller si<strong>de</strong><br />

LS<br />

Machine si<strong>de</strong><br />

(Front diagram)<br />

(“EU”: Cable option,<br />

see fig. down)<br />

Enter the cable length (L) at . Up to 30 meters is<br />

supported. Example: 080=8 m<br />

Wire Color Signal No.<br />

White/blue<br />

10<br />

11<br />

12<br />

13<br />

26<br />

25<br />

24<br />

23<br />

9<br />

18<br />

19<br />

1<br />

AWG26 White/yellow<br />

2<br />

(sol<strong>de</strong>red) White/red<br />

3<br />

White/black<br />

4<br />

White/purple<br />

5<br />

White/gray<br />

6<br />

Orange<br />

7<br />

Green<br />

8<br />

Purple<br />

14<br />

Gray<br />

15<br />

Red<br />

16<br />

Black<br />

17<br />

Blue<br />

20<br />

Yellow<br />

21<br />

22<br />

The shield is clamped to the hood.<br />

Drain line <strong>and</strong> shield braid<br />

(The wire colors white/blue show the b<strong>and</strong> color/insulation color.)<br />

(“EU”: Cable option,<br />

see fig. down)<br />

Wire Color Signal No.<br />

White/orange<br />

10<br />

11<br />

12<br />

White/green<br />

13<br />

Brown/blue<br />

26<br />

Brown/yellow<br />

25<br />

Brown/red<br />

24<br />

Brown/black<br />

23<br />

White/blue<br />

9<br />

18<br />

19<br />

1<br />

AWG26 White/yellow<br />

2<br />

(sol<strong>de</strong>red) White/red<br />

3<br />

White/black<br />

4<br />

White/purple<br />

5<br />

White/gray<br />

6<br />

Orange<br />

7<br />

Green<br />

8<br />

Purple<br />

14<br />

Gray<br />

15<br />

Red<br />

16<br />

Black<br />

17<br />

Blue<br />

20<br />

Yellow<br />

21<br />

22<br />

The shield is clamped to the hood.<br />

Drain line <strong>and</strong> shield braid<br />

(The wire colors white/blue show the b<strong>and</strong> color/insulation color.)<br />

No. Signal Color Wire<br />

1<br />

White/blue<br />

2<br />

White/yellow<br />

3<br />

White/red<br />

4<br />

5<br />

White/black<br />

White/purple<br />

AWG26<br />

(press fit)<br />

6<br />

White/gray<br />

7<br />

8<br />

9<br />

Drain<br />

10<br />

Orange<br />

11<br />

Green<br />

12<br />

Purple<br />

13<br />

Gray<br />

14<br />

Red<br />

15<br />

Black<br />

16<br />

17<br />

Blue<br />

18<br />

Yellow<br />

Enter the cable length (L) at . Up to 30 meters is<br />

supported. Example: 080=8 m<br />

No. Signal Color Wire<br />

1 E24V White/orange<br />

2 0V White/green<br />

3 LS Brown/blue AWG26<br />

4 CLEEP Brown/black (press fit)<br />

5 OT Brown/red<br />

6 RSV Brown/black<br />

No. Signal Color Wire<br />

White/blue<br />

White/yellow<br />

White/red<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

White/black<br />

AWG26<br />

White/purple<br />

(press fit)<br />

White/gray<br />

Drain<br />

Orange<br />

Green<br />

Purple<br />

Gray<br />

Red<br />

Black<br />

Blue<br />

Yellow<br />

* Motor Cable suitable for all Controllers:<br />

[XSEL] [SSEL] [SCON]<br />

Option EU (European St<strong>and</strong>ard)<br />

IAI America Inc.<br />

American Headquarters<br />

2 6 9 0 W 2 3 7 th Str., Torrance, CA 90505, USA<br />

Phone: +1-310-891-6015 Fax: +1-310-891-0815<br />

IAI Industrieroboter GmbH<br />

European Headquarters<br />

Ober <strong>de</strong>r Röth 4, D-65824 Schwalbach, Germany<br />

Phone: +49-6196-8895-0 Fax: +49-6196-8895-24<br />

<strong>www</strong>.<strong>intelligentactuator</strong>.<strong>de</strong><br />

IAI CORPORATION<br />

Global <strong>and</strong> Asean Headquarters<br />

645-1 Shimizu Hirose, Shizuoka 424-0102, Japan<br />

Phone: +81-543-64-5105 Fax: +81-543-64-5182