Product Guide for Design Engineers - Quadrant

Product Guide for Design Engineers - Quadrant

Product Guide for Design Engineers - Quadrant

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

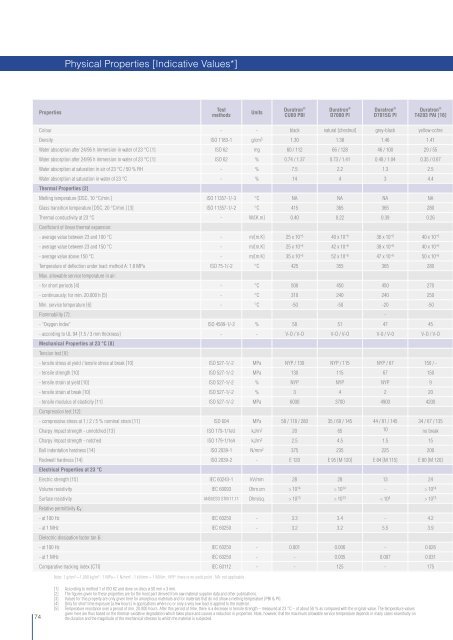

Physical Properties [Indicative Values*]<br />

Properties<br />

Test<br />

methods<br />

Units<br />

Duratron ®<br />

CU60 PBI<br />

Duratron ®<br />

D7000 PI<br />

Duratron ®<br />

D7015G PI<br />

Duratron ®<br />

T4203 PAI [16]<br />

Colour - - black natural [chestnut] grey-black yellow-ochre<br />

Density ISO 1183-1 g/cm 3 1.30 1.38 1.46 1.41<br />

Water absorption after 24/96 h immersion in water of 23 °C [1] ISO 62 mg 60 / 112 66 / 128 46 / 100 29 / 55<br />

Water absorption after 24/96 h immersion in water of 23 °C [1] ISO 62 % 0.74 / 1.37 0.73 / 1.41 0.48 / 1.04 0.35 / 0.67<br />

Water absorption at saturation in air of 23 °C / 50 % RH - % 7.5 2.2 1.3 2.5<br />

Water absorption at saturation in water of 23 °C - % 14 4 3 4.4<br />

Thermal Properties [2]<br />

Melting temperature [DSC, 10 °C/min.] ISO 11357-1/-3 °C NA NA NA NA<br />

Glass transition temperature [DSC, 20 °C/min.] [3] ISO 11357-1/-2 °C 415 365 365 280<br />

Thermal conductivity at 23 °C - W/[K.m] 0.40 0.22 0.39 0.26<br />

Coefficient of linear thermal expansion:<br />

- average value between 23 and 100 °C - m/[m.K] 25 x 10 -6 40 x 10 -6 36 x 10 -6 40 x 10 -6<br />

- average value between 23 and 150 °C - m/[m.K] 25 x 10 -6 42 x 10 -6 38 x 10 -6 40 x 10 -6<br />

- average value above 150 °C - m/[m.K] 35 x 10 -6 52 x 10 -6 47 x 10 -6 50 x 10 -6<br />

Temperature of deflection under load: method A: 1.8 MPa ISO 75-1/-2 °C 425 355 365 280<br />

Max. allowable service temperature in air:<br />

- <strong>for</strong> short periods [4] - °C 500 450 450 270<br />

- continuously: <strong>for</strong> min. 20.000 h [5] - °C 310 240 240 250<br />

Min. service temperature [6] - °C -50 -50 -20 -50<br />

Flammability [7]: -<br />

- “Oxygen Index” ISO 4589-1/-2 % 58 51 47 45<br />

- according to UL 94 [1.5 / 3 mm thickness] - - V-O / V-O V-O / V-O V-0 / V-0 V-O / V-O<br />

Mechanical Properties at 23 °C [8]<br />

Tension test [9]:<br />

- tensile stress at yield / tensile stress at break [10] ISO 527-1/-2 MPa NYP / 130 NYP / 115 NYP / 67 150 / -<br />

- tensile strength [10] ISO 527-1/-2 MPa 130 115 67 150<br />

- tensile strain at yield [10] ISO 527-1/-2 % NYP NYP NYP 9<br />

- tensile strain at break [10] ISO 527-1/-2 % 3 4 2 20<br />

- tensile modulus of elasticity [11] ISO 527-1/-2 MPa 6000 3700 4900 4200<br />

Compression test [12]:<br />

- compressive stress at 1 / 2 / 5 % nominal strain [11] ISO 604 MPa 58 / 118 / 280 35 / 69 / 145 44 / 81 / 145 34 / 67 / 135<br />

Charpy impact strength - unnotched [13] ISO 179-1/1eU kJ/m 2 20 65 10 no break<br />

Charpy impact strength - notched ISO 179-1/1eA kJ/m 2 2.5 4.5 1.5 15<br />

Ball indentation hardness [14] ISO 2039-1 N/mm 2 375 235 225 200<br />

Rockwell hardness [14] ISO 2039-2 - E 120 E 95 [M 120] E 84 [M 115] E 80 [M 120]<br />

Electrical Properties at 23 °C<br />

Electric strength [15] IEC 60243-1 kV/mm 28 28 13 24<br />

Volume resistivity IEC 60093 Ohm.cm > 10 14 > 10 14 - > 10 14<br />

Surface resistivity ANSI/ESD STM 11.11 Ohm/sq. > 10 13 > 10 13 < 10 4 > 10 13<br />

Relative permittivity Ɛr:<br />

- at 100 Hz IEC 60250 - 3.3 3.4 - 4.2<br />

- at 1 MHz IEC 60250 - 3.2 3.2 5.5 3.9<br />

Dielectric dissipation factor tan δ :<br />

- at 100 Hz IEC 60250 - 0.001 0.006 - 0.026<br />

- at 1 MHz IEC 60250 - - 0.005 0.007 0.031<br />

Comparative tracking index [CTI] IEC 60112 - - 125 - 175<br />

Note: 1 g/cm³ = 1,000 kg/m³ ; 1 MPa = 1 N/mm² ; 1 kV/mm = 1 MV/m ; NYP: there is no yield point ; NA: not applicable<br />

74<br />

[1] According to method 1 of ISO 62 and done on discs ø 50 mm x 3 mm.<br />

[2] The fi gures given <strong>for</strong> these properties are <strong>for</strong> the most part derived from raw material supplier data and other publications.<br />

[3] Values <strong>for</strong> this property are only given here <strong>for</strong> amorphous materials and <strong>for</strong> materials that do not show a melting temperature [PBI & PI].<br />

[4] Only <strong>for</strong> short time exposure [a few hours] in applications where no or only a very low load is applied to the material.<br />

[5] Temperature resistance over a period of min. 20.000 hours. After this period of time, there is a decrease in tensile strength – measured at 23 °C – of about 50 % as compared with the original value. The temperature values<br />

given here are thus based on the thermal-oxidative degradation which takes place and causes a reduction in properties. Note, however, that the maximum allowable service temperature depends in many cases essentially on<br />

the duration and the magnitude of the mechanical stresses to which the material is subjected.