Product Guide for Design Engineers - Quadrant

Product Guide for Design Engineers - Quadrant

Product Guide for Design Engineers - Quadrant

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

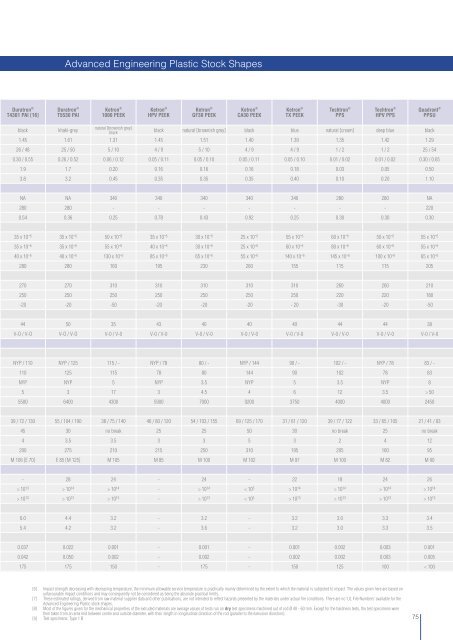

Advanced Engineering Plastic Stock Shapes<br />

Duratron ®<br />

T4301 PAI [16]<br />

Duratron ®<br />

T5530 PAI<br />

Ketron ®<br />

1000 PEEK<br />

Ketron ®<br />

HPV PEEK<br />

Ketron ®<br />

GF30 PEEK<br />

Ketron ®<br />

CA30 PEEK<br />

Ketron ®<br />

TX PEEK<br />

Techtron ®<br />

PPS<br />

Techtron ®<br />

HPV PPS<br />

<strong>Quadrant</strong> ®<br />

PPSU<br />

black<br />

khaki-grey<br />

natural [brownish grey]<br />

black black natural [brownish grey] black blue natural [cream] deep blue black<br />

1.45 1.61 1.31 1.45 1.51 1.40 1.39 1.35 1.42 1.29<br />

26 / 48 25 / 50 5 / 10 4 / 9 5 / 10 4 / 9 4 / 9 1 / 2 1 / 2 25 / 54<br />

0.30 / 0.55 0.26 / 0.52 0.06 / 0.12 0.05 / 0.11 0.05 / 0.10 0.05 / 0.11 0.05 / 0.10 0.01 / 0.02 0.01 / 0.02 0.30 / 0.65<br />

1.9 1.7 0.20 0.16 0.16 0.16 0.18 0.03 0.05 0.50<br />

3.8 3.2 0.45 0.35 0.35 0.35 0.40 0.10 0.20 1.10<br />

NA NA 340 340 340 340 340 280 280 NA<br />

280 280 - - - - - - - 220<br />

0.54 0.36 0.25 0.78 0.43 0.92 0.25 0.30 0.30 0.30<br />

35 x 10 -6 35 x 10 -6 50 x 10 -6 35 x 10 -6 30 x 10 -6 25 x 10 -6 55 x 10 -6 60 x 10 -6 50 x 10 -6 55 x 10 -6<br />

35 x 10 -6 35 x 10 -6 55 x 10 -6 40 x 10 -6 30 x 10 -6 25 x 10 -6 60 x 10 -6 80 x 10 -6 60 x 10 -6 55 x 10 -6<br />

40 x 10 -6 40 x 10 -6 130 x 10 -6 85 x 10 -6 65 x 10 -6 55 x 10 -6 140 x 10 -6 145 x 10 -6 100 x 10 -6 65 x 10 -6<br />

280 280 160 195 230 260 155 115 115 205<br />

270 270 310 310 310 310 310 260 260 210<br />

250 250 250 250 250 250 250 220 220 180<br />

-20 -20 -50 -20 -20 -20 - 20 -30 -20 -50<br />

44 50 35 43 40 40 40 44 44 38<br />

V-O / V-O V-O / V-O V-0 / V-0 V-0 / V-0 V-0 / V-0 V-0 / V-0 V-0 / V-0 V-0 / V-0 V-0 / V-0 V-0 / V-0<br />

NYP / 110 NYP / 125 115 / - NYP / 78 80 / - NYP / 144 90 / - 102 / - NYP / 78 83 / -<br />

110 125 115 78 80 144 90 102 78 83<br />

NYP NYP 5 NYP 3.5 NYP 5 3.5 NYP 8<br />

5 3 17 3 4.5 4 6 12 3.5 > 50<br />

5500 6400 4300 5900 7000 9200 3750 4000 4000 2450<br />

39 / 72 / 130 55 / 104 / 190 38 / 75 / 140 46 / 80 / 120 54 / 103 / 155 69 / 125 / 170 31 / 61 / 120 39 / 77 / 122 33 / 65 / 105 21 / 41 / 83<br />

45 30 no break 25 25 50 30 no break 25 no break<br />

4 3.5 3.5 3 3 5 3 2 4 12<br />

200 275 210 215 250 310 195 205 160 95<br />

M 106 [E 70] E 85 [M 125] M 105 M 85 M 100 M 102 M 97 M 100 M 82 M 90<br />

- 28 24 - 24 - 22 18 24 26<br />

> 10 13 > 10 14 > 10 14 - > 10 14 < 10 5 > 10 14 > 10 14 > 10 14 > 10 14<br />

> 10 13 > 10 13 > 10 13 - > 10 13 < 10 5 > 10 13 > 10 13 > 10 13 > 10 13<br />

6.0 4.4 3.2 - 3.2 - 3.2 3.0 3.3 3.4<br />

5.4 4.2 3.2 - 3.6 - 3.2 3.0 3.3 3.5<br />

0.037 0.022 0.001 - 0.001 - 0.001 0.002 0.003 0.001<br />

0.042 0.050 0.002 - 0.002 - 0.002 0.002 0.003 0.005<br />

175 175 150 - 175 - 150 125 100 < 100<br />

[6] Impact strength decreasing with decreasing temperature, the minimum allowable service temperature is practically mainly determined by the extent to which the material is subjected to impact. The values given here are based on<br />

unfavourable impact conditions and may consequently not be considered as being the absolute practical limits.<br />

[7] These estimated ratings, derived from raw material supplier data and other publications, are not intended to reflect hazards presented by the materials under actual fire conditions. There are no ‘UL File Numbers‘ available <strong>for</strong> the<br />

Advanced Engineering Plastic stock shapes.<br />

[8] Most of the figures given <strong>for</strong> the mechanical properties of the extruded materials are average values of tests run on dry test specimens machined out of rod Ø 40 - 60 mm. Except <strong>for</strong> the hardness tests, the test specimens were<br />

then taken from an area mid between centre and outside diameter, with their length in longitudinal direction of the rod [parallel to the extrusion direction].<br />

[9] Test specimens: Type 1 B<br />

75