Sustainable Environmental Management - Ricoh

Sustainable Environmental Management - Ricoh

Sustainable Environmental Management - Ricoh

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Top Message About us Our Activities<br />

Data<br />

<strong>Sustainable</strong> <strong>Environmental</strong> <strong>Management</strong><br />

Innovations in manufacturing processes<br />

● Cart production line<br />

An eco-friendly production system that can respond flexibly to<br />

production volume and equipment model changes<br />

In this system, multiple carts are lined up in a row and powered by air cylinders. The carts move<br />

along the production line carrying products. Because huge, high-energy consuming conveyors<br />

are not required, this system has brought large reductions in environmental impact and energy<br />

costs;* moreover, because the layout can be freely changed, the formation can be rearranged on<br />

a case-by-case basis to suit equipment models and production volumes. In-process inventory,<br />

lead time, space, and maintenance are all reduced by 70–80%. In addition, because of the<br />

reduction in space, reductions in air-conditioning and lighting costs are also achieved.<br />

* Air cylinders are used to move the carts, enabling a reduction in electricity consumption of 99% compared with conventional<br />

conveyor line motors.<br />

● On-Demand Toner Filling Machine<br />

Small and portable toner-filling machine<br />

To cope with limited production of a wide range of toner products, <strong>Ricoh</strong> has developed an<br />

“On-Demand Toner Filling Machine” based on conventional machines that is designed to fill a<br />

large amount of toner at high speed. Compared with the conventional toner filler systems, the<br />

new machine takes only 1/40 of the time to switch between product types, requires 1/40 of the<br />

installation space, and uses 1/4 of the electricity. Introducing this toner filling machine into toner<br />

production bases and also into logistics bases and sales companies allows toner cartridges to<br />

be manufactured at and shipped from sites closer to customers in the same manner as at plants.<br />

This has resulted in a reduction in environmental impact from the transportation of cartridges<br />

collected from the market for reuse and a shorter lead time.<br />

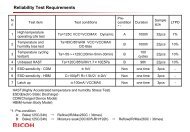

Conventional toner filling<br />

machine<br />

Newly developed “On-Demand Toner<br />

Filling Machine”<br />

● Downsized production lines for a photoconductor<br />

Substantial reduction in air-conditioned clean room space<br />

Production of photoconductors, a component of MFPs and printers, must be conducted in a<br />

clean space containing no dust. Traditional large production lines required large air purifying<br />

and conditioning systems, which inevitably entailed big financial and environmental impacts.<br />

To address this issue, we have developed a new production line system where one or two units<br />

are manufactured at a time and air purifying and conditioning systems are used in that small<br />

area, instead of putting several dozen units on a pallet. The new system requires only about<br />

1/6 of the production line length, 1/16 of the equipment installation space*, 1/92 of the clean,<br />

air-conditioned area, and 1/3 of the capital investment of the conventional lines.<br />

* Ratio of facility area to per-unit production capacity<br />

Small-lot production lines able to meet market demand for multipurpose,<br />

high-quality products<br />

<strong>Ricoh</strong> Group Sustainability Report 2012 66