The New Standard of X-ray Diffractometer: MultiFlex - Rigaku

The New Standard of X-ray Diffractometer: MultiFlex - Rigaku

The New Standard of X-ray Diffractometer: MultiFlex - Rigaku

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>The</strong> <strong>Rigaku</strong> Journal<br />

Vol. 17/ No. 2/ 2000<br />

Product Information<br />

<strong>The</strong> <strong>New</strong> <strong>Standard</strong> <strong>of</strong> X-<strong>ray</strong> Dfffraction<br />

<strong>Rigaku</strong> Automated Powder X-<strong>ray</strong> <strong>Diffractometer</strong><br />

<strong>The</strong> Multiflex is a powerful tool for materials<br />

development and evaluation<br />

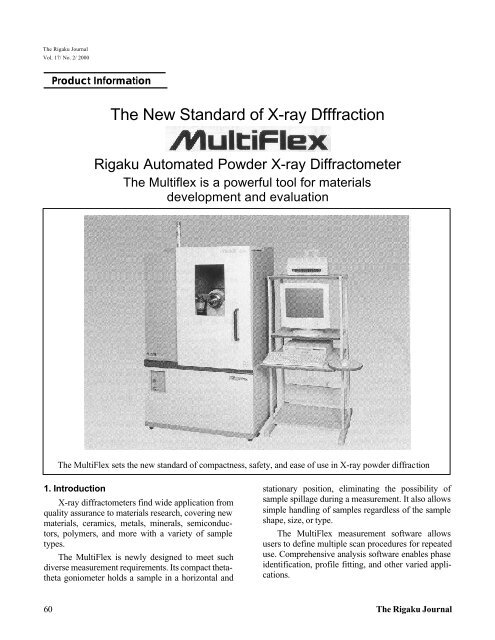

<strong>The</strong> <strong>MultiFlex</strong> sets the new standard <strong>of</strong> compactness, safety, and ease <strong>of</strong> use in X-<strong>ray</strong> powder diffraction<br />

1. Introduction<br />

X-<strong>ray</strong> diffractometers find wide application from<br />

quality assurance to materials research, covering new<br />

materials, ceramics, metals, minerals, semiconductors,<br />

polymers, and more with a variety <strong>of</strong> sample<br />

types.<br />

<strong>The</strong> <strong>MultiFlex</strong> is newly designed to meet such<br />

diverse measurement requirements. Its compact thetatheta<br />

goniometer holds a sample in a horizontal and<br />

stationary position, eliminating the possibility <strong>of</strong><br />

sample spillage during a measurement. It also allows<br />

simple handling <strong>of</strong> samples regardless <strong>of</strong> the sample<br />

shape, size, or type.<br />

<strong>The</strong> <strong>MultiFlex</strong> measurement s<strong>of</strong>tware allows<br />

users to define multiple scan procedures for repeated<br />

use. Comprehensive analysis s<strong>of</strong>tware enables phase<br />

identification, pr<strong>of</strong>ile fitting, and other varied applications.<br />

60 <strong>The</strong> <strong>Rigaku</strong> Journal

2. Features<br />

(1) Sample Stays Horizontal<br />

<strong>The</strong>ta-<strong>The</strong>ta Goniometer<br />

<strong>The</strong> sample is mounted horizontally, which is an<br />

ideal configuration when dealing with large or irregular<br />

samples, loose powders, or a high-temperature<br />

stage.<br />

an optional sample changer, multiple samples can be<br />

loaded and measured with individual procedures to<br />

increase throughput.<br />

(5) A Variety <strong>of</strong> Attachments (Optional)<br />

• Six-Sample Automatic Sample Changer: Enables<br />

up to six samples to be measured in<br />

succession. With its integrated sample spinning<br />

mechanism, this device effectively measures<br />

samples having large grains or preferred<br />

orientation.<br />

(2) Compact, Space-Saving Design<br />

Because lab space is <strong>of</strong>ten at a premium, the<br />

system's footprint is now reduced by 40% compared<br />

with other models <strong>of</strong> <strong>Rigaku</strong> stand-alone X-<strong>ray</strong><br />

diffractometers. Casters are provided for ease <strong>of</strong><br />

moving the system.<br />

(3) Safety Design<br />

Safety interlocks and automatic alignment ensure<br />

safe and convenient operation.<br />

(4) <strong>Rigaku</strong> Measurement S<strong>of</strong>tware (Optional)<br />

Powerful, flexible s<strong>of</strong>tware handles system<br />

alignment, X-<strong>ray</strong> generator control, routine measurements,<br />

and control <strong>of</strong> the optional high-temperature<br />

attachment. Real-time data display allows you to see<br />

the results as each data point is collected. Predefined<br />

measurement conditions and an intuitive interface<br />

make the system accessible even to beginners. With<br />

• High-Temperature Attachment: Enables programmed<br />

heating and cooling studies from<br />

ambient to ~1500EC under s<strong>of</strong>tware control.<br />

Study the effects <strong>of</strong> thermal processing conditions<br />

on material properties.<br />

• Diffracted-Beam Monochromator: Ensures<br />

high resolution and signal to noise by<br />

removing Kβ, continuous x-<strong>ray</strong>s, and sample<br />

fluorescence from the diffracted beam.<br />

Vol. 17 No. 2 2000 61

3. Specifications<br />

X-<strong>ray</strong> generator<br />

Goniometer<br />

Detector/counting<br />

circuit<br />

Computer<br />

Max. rated output 2 kW 3kW<br />

Rated voltage<br />

2~50 kV<br />

Rated current 2~50 mA 2~60 mA<br />

Control method SCR phase control Inverter control<br />

Stability* Within "0.01% Within "0.005%<br />

Target<br />

Radiation enclousre<br />

Scan mode<br />

Goniometer radius<br />

With interlocking mechanism (2.5:Sv/h or less outside <strong>of</strong> the<br />

enclosure)<br />

Cu<br />

2 s/2 d coupled; 2 s, 2 d independent<br />

185 mm<br />

Measuring angle range 2 s: -4.0 ~ +79E 2 d: -4.0 ~ +79E<br />

Slit<br />

Scan speed<br />

Fixed-speed auto feed<br />

Step feed width<br />

Counting linearity<br />

Scintillation counter<br />

HV/PHA<br />

Operating System<br />

Main memory<br />

Mass storage<br />

CRT<br />

Printer<br />

DS: 1/2E, 1E, 0.05 mm SS: 1/2E, 1, absorber RS: 0.15, 0.3, mm<br />

500E/min<br />

2 s/2 d coupled: 0.002~100E/min (22)<br />

2 s, 2 d independent: 0.001 ~ 50E/min<br />

2 s/2 d coupled: 0.002 ~ 90E/min (22)<br />

2 s, 2 d independent: 0.001 ~ 45E<br />

700,000 cps or more (counting loss correction using a standard<br />

sample provided)<br />

NaI, photomultiplier with preamplifier<br />

0 to 1500 V (with external control)/with baseline and window<br />

external control<br />

Window NT<br />

64 MB<br />

HD 3.5” FD CD-ROM<br />

17” color<br />

Color ink jet printer<br />

* For within "10% input power variations<br />

62 <strong>The</strong> <strong>Rigaku</strong> Journal

4. Installation Requirements<br />

• <strong>The</strong> numeric values <strong>of</strong> performance indicated<br />

in this brochure are based on the test results at<br />

<strong>Rigaku</strong>. <strong>Rigaku</strong> does not warrant that the<br />

identical values can always be obtained<br />

regardless <strong>of</strong> different operational environments.<br />

• Windows NT is a trademark <strong>of</strong> U.S. Micros<strong>of</strong>t<br />

Corporation in the U.S. and other countries.<br />

• Other company names and product names are<br />

trademarks or registered trademarks <strong>of</strong> the<br />

respective companies.<br />

Unit: mm (): 3kW<br />

Power supply<br />

Cooling water<br />

Main body<br />

Computer<br />

Earth ground<br />

30EC or less<br />

2 kW single phase 200V, 30 A<br />

3 kW 3-phase 200V, 20 A<br />

Single=phase 100V, 5A<br />

Grounding resistance: 100 S or<br />

less<br />

4 liters/min or more (1~3<br />

kg/cm 2 ), 1 unit<br />

(Note) <strong>The</strong> power cable, grounding cable and feed water and drain hoses provided with the unit are 5 meters long.<br />

Vol. 17 No. 2 2000 63