BREAKTHROUGH IN X-RAY DIFFRACTION GENERATORS! - Rigaku

BREAKTHROUGH IN X-RAY DIFFRACTION GENERATORS! - Rigaku

BREAKTHROUGH IN X-RAY DIFFRACTION GENERATORS! - Rigaku

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>BREAKTHROUGH</strong> <strong>IN</strong> X-<strong>RAY</strong> <strong>DIFFRACTION</strong> <strong>GENERATORS</strong>!<br />

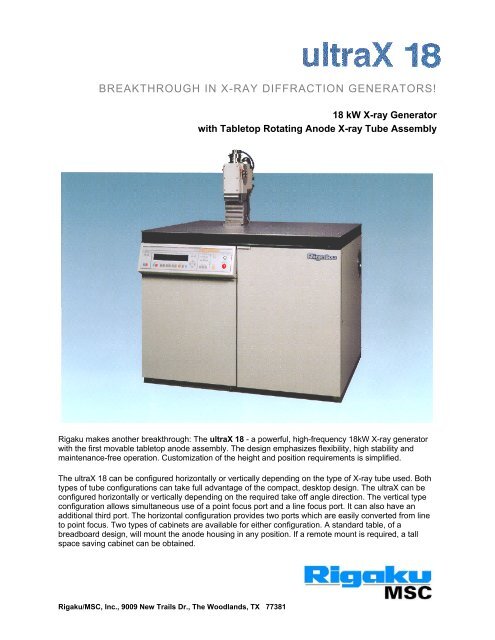

18 kW X-ray Generator<br />

with Tabletop Rotating Anode X-ray Tube Assembly<br />

<strong>Rigaku</strong> makes another breakthrough: The ultraX 18 - a powerful, high-frequency 18kW X-ray generator<br />

with the first movable tabletop anode assembly. The design emphasizes flexibility, high stability and<br />

maintenance-free operation. Customization of the height and position requirements is simplified.<br />

The ultraX 18 can be configured horizontally or vertically depending on the type of X-ray tube used. Both<br />

types of tube configurations can take full advantage of the compact, desktop design. The ultraX can be<br />

configured horizontally or vertically depending on the required take off angle direction. The vertical type<br />

configuration allows simultaneous use of a point focus port and a line focus port. It can also have an<br />

additional third port. The horizontal configuration provides two ports which are easily converted from line<br />

to point focus. Two types of cabinets are available for either configuration. A standard table, of a<br />

breadboard design, will mount the anode housing in any position. If a remote mount is required, a tall<br />

space saving cabinet can be obtained.<br />

<strong>Rigaku</strong>/MSC, Inc., 9009 New Trails Dr., The Woodlands, TX 77381

Features:<br />

A Compact Tabletop Rotating Anode Tube Housing<br />

• The X-ray tube, high-voltage induction unit and main vacuum system are compactly assembled on the<br />

top of the worktable.<br />

• The X-ray tube position is easily adjustable for different optical configurations<br />

• The small-sized high voltage induction unit makes it possible to bring the optical system closer to the<br />

X-ray source.<br />

• The X-ray tube in one compact body permits rapid start-up of the entire system. (Cubic volume of the<br />

tube interior and the total tube height : Approx. 1/2 of the <strong>Rigaku</strong> existing model, respectively)<br />

<strong>Rigaku</strong>/MSC, Inc., 9009 New Trails Dr., The Woodlands, TX 77381

A New Electron Gun<br />

• Electric field simulation was utilized in the design of the electron gun and the X-ray tube interior to<br />

minimize discharge and provide great stability.<br />

• Filament replacement and the installation and removal of the electron gun are straightforward.<br />

A New Direct-Drive Rotating Anode Assembly<br />

• A highly reliable mechanical seal is employed to eliminate potential water leaks.<br />

• The use of a long-life ceramic ball bearing offers low vibration and low noise.<br />

• A new magnetic fluid seal provides high rotation capability, low torque and a long life.<br />

• The smaller overall size and reduce weight make handling easy.<br />

<strong>Rigaku</strong>/MSC, Inc., 9009 New Trails Dr., The Woodlands, TX 77381

Specifications<br />

X-<strong>RAY</strong> GENERATOR<br />

• Maximum Load: 18kW<br />

• Tube Voltage: 20-60kV in 1kV steps<br />

• Tube Current: 10-300mA in 1mA steps [10-450mA (40kV) in 1mA steps (Optional)]<br />

• Stability of High Voltage: +/- 0.01% for a +/-10% variation in the line voltage and +/- 5°C<br />

change in ambient temperature<br />

• Ripple: 1% rms or less (at 60kV, 300mA)<br />

ROTAT<strong>IN</strong>G ANODE ASSEMBLY<br />

• Material: Select one from Cu (standard), Cr, Fe, Co, Ni, Mo, Ag, W, and Au<br />

• Target diameter: 10cm (common to horizontal and vertical types)<br />

• Rotation speed: 6000rpm<br />

• Vacuum sealing for rotary shaft: Low torque type magnetic fluid sealing<br />

• Bearing: Ceramic bearing<br />

• Water sealing: Mechanical seal<br />

X-<strong>RAY</strong> SOURCE SIZE<br />

• Focal spot size on the target: 0.5 x 10mm 2 as standard (Option: 0.3 x 3mm 2 , 0.2 x2mm 2 ,<br />

0.1 x 1mm 2 )<br />

• Effective size at 6° take-off angle: 0.05 x 10mm 2 (line focus), 0.5 x 1mm 2 (point focus)<br />

OPERATION PANEL<br />

• Manual control: Controller from the operation panel<br />

• External control: RS-232C interface is built-in to allow control from the host computer<br />

SAFETY DESIGN<br />

• An LED is used in the warning lamp to prolong life<br />

• Shutter functions are monitored. If failure occurs, the entire system will shut down.<br />

HEAT EXCHANGER (Optional)<br />

• Water cooled type or air cooled type heat exchanger are available<br />

RADIATION ENCLOSURE (Optional)<br />

• Radiation Enclosures: 1200 x 1000 and 1800 x 1000mm (each with fail safe release function)<br />

<strong>Rigaku</strong>/MSC, Inc., 9009 New Trails Dr., The Woodlands, TX 77381

X-<strong>RAY</strong> TAKE OFF DIRECTION<br />

• Horizontal type: 2 directions<br />

• Vertical type: 3 directions<br />

• X-ray take-off angle center: 6°<br />

TUBE HOUS<strong>IN</strong>G DESIGNS<br />

<strong>Rigaku</strong>/MSC, Inc., 9009 New Trails Dr., The Woodlands, TX 77381

ALLOWABLE LOAD FOR TARGET<br />

Target<br />

Material<br />

Maximum<br />

Focus size & Max. Allowable Load (kW)<br />

0.5x10mm 2 0.3x3mm 2 0.2x2mm 2 0.1x1mm 2<br />

Cu, Mo 60 18 5.4 3 1.2<br />

Ag 60 12 5.4 3 1.2<br />

Cr 50 10 4.5 2.5 1.0<br />

Co,Ni,Au 50 10 3.6 2 0.8<br />

Fe 50 9 2.7 1.5 0.6<br />

Installation Requirements<br />

POWER SUPPLY<br />

GROUND<strong>IN</strong>G<br />

3-phase AC 200V, 85A<br />

Resistance should be less than 100 ohms<br />

1 channel, hose I.D.: 15mm dia.<br />

COOL<strong>IN</strong>G WATER<br />

Pressure<br />

Flow rate<br />

3.5kg/cm2 or less (stable pressure)<br />

22 lit/min or more (water temp: