Microwave-Assisted Polymer Synthesis: Recent Developments in a ...

Microwave-Assisted Polymer Synthesis: Recent Developments in a ...

Microwave-Assisted Polymer Synthesis: Recent Developments in a ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Microwave</strong>-<strong>Assisted</strong> <strong>Polymer</strong> <strong>Synthesis</strong>: <strong>Recent</strong> <strong>Developments</strong> <strong>in</strong> ...<br />

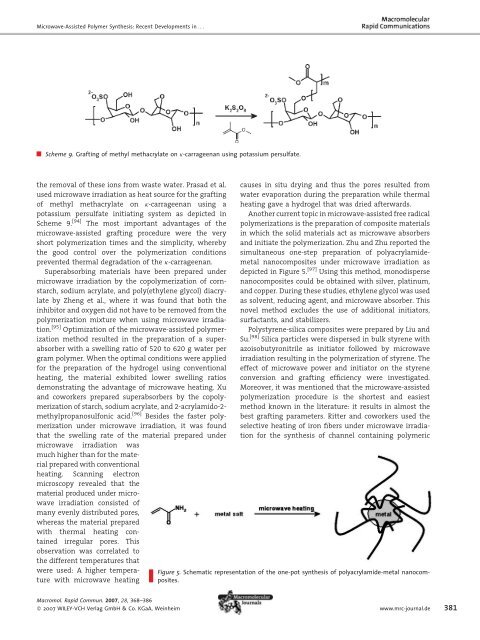

Scheme 9. Graft<strong>in</strong>g of methyl methacrylate on k-carrageenan us<strong>in</strong>g potassium persulfate.<br />

the removal of these ions from waste water. Prasad et al.<br />

used microwave irradiation as heat source for the graft<strong>in</strong>g<br />

of methyl methacrylate on k-carrageenan us<strong>in</strong>g a<br />

potassium persulfate <strong>in</strong>itiat<strong>in</strong>g system as depicted <strong>in</strong><br />

Scheme 9. [94] The most important advantages of the<br />

microwave-assisted graft<strong>in</strong>g procedure were the very<br />

short polymerization times and the simplicity, whereby<br />

the good control over the polymerization conditions<br />

prevented thermal degradation of the k-carrageenan.<br />

Superabsorb<strong>in</strong>g materials have been prepared under<br />

microwave irradiation by the copolymerization of cornstarch,<br />

sodium acrylate, and poly(ethylene glycol) diacrylate<br />

by Zheng et al., where it was found that both the<br />

<strong>in</strong>hibitor and oxygen did not have to be removed from the<br />

polymerization mixture when us<strong>in</strong>g microwave irradiation.<br />

[95] Optimization of the microwave-assisted polymerization<br />

method resulted <strong>in</strong> the preparation of a superabsorber<br />

with a swell<strong>in</strong>g ratio of 520 to 620 g water per<br />

gram polymer. When the optimal conditions were applied<br />

for the preparation of the hydrogel us<strong>in</strong>g conventional<br />

heat<strong>in</strong>g, the material exhibited lower swell<strong>in</strong>g ratios<br />

demonstrat<strong>in</strong>g the advantage of microwave heat<strong>in</strong>g. Xu<br />

and coworkers prepared superabsorbers by the copolymerization<br />

of starch, sodium acrylate, and 2-acrylamido-2-<br />

methylpropanosulfonic acid. [96] Besides the faster polymerization<br />

under microwave irradiation, it was found<br />

that the swell<strong>in</strong>g rate of the material prepared under<br />

microwave irradiation was<br />

much higher than for the material<br />

prepared with conventional<br />

heat<strong>in</strong>g. Scann<strong>in</strong>g electron<br />

microscopy revealed that the<br />

material produced under microwave<br />

irradiation consisted of<br />

many evenly distributed pores,<br />

whereas the material prepared<br />

with thermal heat<strong>in</strong>g conta<strong>in</strong>ed<br />

irregular pores. This<br />

observation was correlated to<br />

the different temperatures that<br />

were used: A higher temperature<br />

with microwave heat<strong>in</strong>g<br />

causes <strong>in</strong> situ dry<strong>in</strong>g and thus the pores resulted from<br />

water evaporation dur<strong>in</strong>g the preparation while thermal<br />

heat<strong>in</strong>g gave a hydrogel that was dried afterwards.<br />

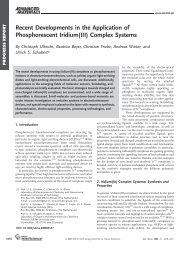

Another current topic <strong>in</strong> microwave-assisted free radical<br />

polymerizations is the preparation of composite materials<br />

<strong>in</strong> which the solid materials act as microwave absorbers<br />

and <strong>in</strong>itiate the polymerization. Zhu and Zhu reported the<br />

simultaneous one-step preparation of polyacrylamidemetal<br />

nanocomposites under microwave irradiation as<br />

depicted <strong>in</strong> Figure 5. [97] Us<strong>in</strong>g this method, monodisperse<br />

nanocomposites could be obta<strong>in</strong>ed with silver, plat<strong>in</strong>um,<br />

and copper. Dur<strong>in</strong>g these studies, ethylene glycol was used<br />

as solvent, reduc<strong>in</strong>g agent, and microwave absorber. This<br />

novel method excludes the use of additional <strong>in</strong>itiators,<br />

surfactants, and stabilizers.<br />

Polystyrene-silica composites were prepared by Liu and<br />

Su. [98] Silica particles were dispersed <strong>in</strong> bulk styrene with<br />

azoisobutyronitrile as <strong>in</strong>itiator followed by microwave<br />

irradiation result<strong>in</strong>g <strong>in</strong> the polymerization of styrene. The<br />

effect of microwave power and <strong>in</strong>itiator on the styrene<br />

conversion and graft<strong>in</strong>g efficiency were <strong>in</strong>vestigated.<br />

Moreover, it was mentioned that the microwave-assisted<br />

polymerization procedure is the shortest and easiest<br />

method known <strong>in</strong> the literature: it results <strong>in</strong> almost the<br />

best graft<strong>in</strong>g parameters. Ritter and coworkers used the<br />

selective heat<strong>in</strong>g of iron fibers under microwave irradiation<br />

for the synthesis of channel conta<strong>in</strong><strong>in</strong>g polymeric<br />

Figure 5. Schematic representation of the one-pot synthesis of polyacrylamide-metal nanocomposites.<br />

Macromol. Rapid Commun. 2007, 28, 368–386<br />

ß 2007 WILEY-VCH Verlag GmbH & Co. KGaA, We<strong>in</strong>heim www.mrc-journal.de 381