Mid-Mount Platform Manual

Mid-Mount Platform Manual

Mid-Mount Platform Manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

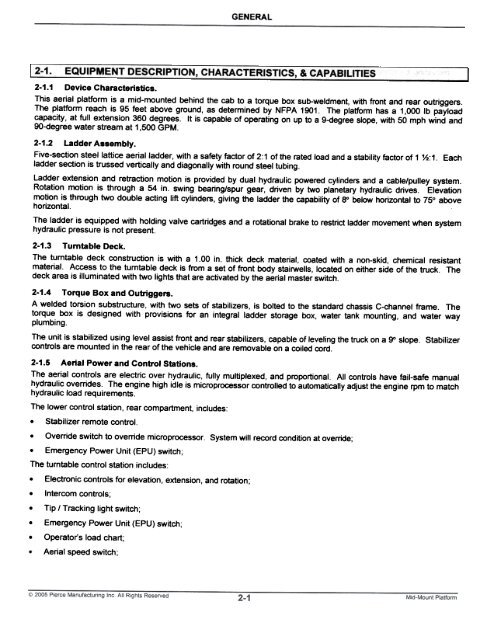

GENERAL<br />

2-1. EQUIPMENT DESCRIPTIQN, CHARACTERI~TICS, & CAPABILITIES<br />

2-1.1 Device Characteristics.<br />

This aerial platform is a mid-mounted behind the cab to a torque box sub-weldment, with front and rear outriggers.<br />

The platform reach is 95 feet above ground, as determined by NFPA 1901. The platform has a 1,000 Ib payload<br />

capacity, at full extension 360 degrees. It is capable of operating on up to a 9-degree slope, with 50 mph wind and<br />

9O-degree water stream at 1,500 GPM.<br />

2-1.2 Ladder Assembly.<br />

Five-section steel lattice aerial ladder, with a safety factor of 2: 1 of the rated load and a stability factor of 1 %: 1. Each<br />

ladder section is trussed vertically and diagonally with round steel tubing.<br />

Ladder extension and retraction motion is provided by dual hydraulic powered cylinders and a cable/pulley system.<br />

Rotation motion is through a 54 in. swing bearing/spur gear, driven by two planetary hydraulic drives. Elevation<br />

motion is through two double acting lift cylinders, giving the ladder the capability of SO below horizontal to 75° above<br />

horizontal.<br />

The ladder is equipped with holding valve cartridges and a rotational brake to restrict ladder movement when system<br />

hydraulic pressure is not present.<br />

2-1.3 Turntable Deck.<br />

The turntable deck construction is with a 1.00 in. thick deck material, coated with a non-skid, chemical resistant<br />

material. Access to the turntable deck is from a set of front body stairwells, located on either side of the truck. The<br />

deck area is illuminated with two lights that are activated by the aerial master switch.<br />

2-1.4 Torque Box and Outriggers.<br />

A welded torsion substructure, with two sets of stabilizers, is bolted to the standard chassis C-channel frame. The<br />

torque box is designed with provisions for an integral ladder storage box, water tank mounting, and water way<br />

plumbing.<br />

The unit is stabilized using level assist front and rear stabilizers, capable of leveling the truck on a go slope. Stabilizer<br />

controls are mounted in the rear of the vehicle and are removable on a coiled cord.<br />

2-1.5 Aerial Power and Control Stations.<br />

The aerial controls are electric over hydraulic, fully multiplexed, and proportional. All controls have fail-safe manual<br />

hydraulic overrides. The engine high idle is microprocessor controlled to automatically adjust the engine rpm to match<br />

hydraulic load requirements.<br />

The lower control station, rear compartment, includes:<br />

. Stabilizer remote control.<br />

. Override switch to override microprocessor. System will record condition at override;<br />

. Emergency Power Unit (EPU) switch;<br />

The turntable control station includes:<br />

. Electronic controls for elevation, extension, and rotation;<br />

. Intercom controls;<br />

. Tip I Tracking light switch;<br />

. Emergency Power Unit (EPU) switch;<br />

.<br />

. Operator's load chart;<br />

Aerial speed switch;